Contents

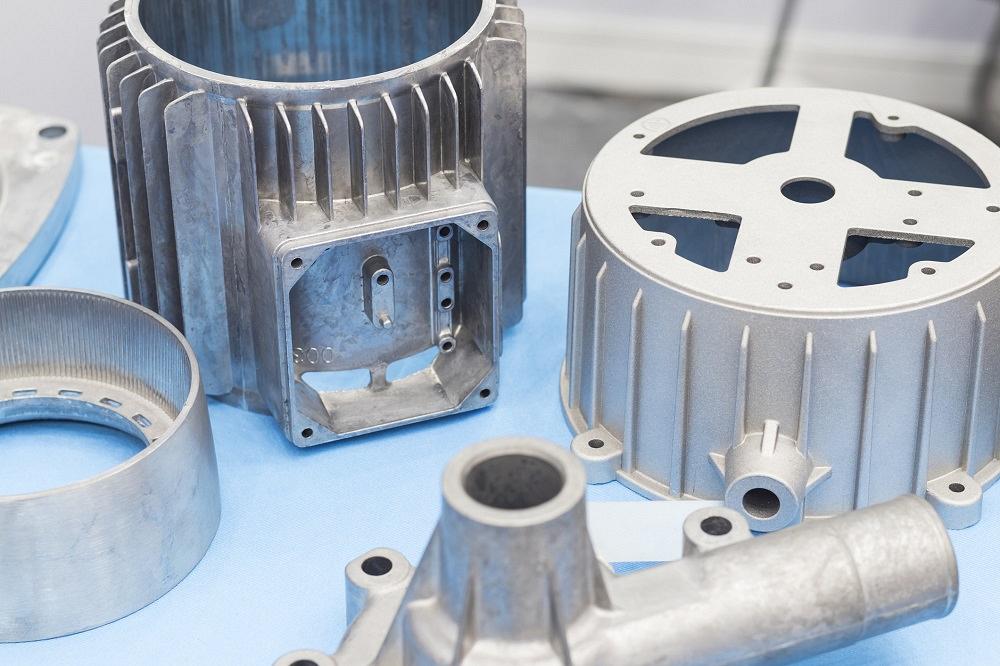

Manufacturing Insight: Cast Aluminum Parts

Precision Integration of Cast Aluminum Components Through Advanced CNC Machining

Cast aluminum parts provide exceptional strength-to-weight ratios and thermal properties essential for demanding applications across aerospace, automotive, and industrial sectors. However, as-cast surfaces often require critical dimensional refinement, feature integration, or tolerance tightening to meet final specifications. At Honyo Prototype, we specialize in transforming near-net-shape aluminum castings into fully functional precision components through our integrated CNC machining services. Our technical expertise spans secondary operations for alloys including A380, A360, 6061, and 7075, where we address inherent casting variables such as porosity, draft angles, and surface finish inconsistencies.

Our CNC machining capabilities deliver tight tolerances down to ±0.0005″ while maintaining geometric integrity through optimized fixturing and process-controlled toolpaths. We execute complex milling, turning, drilling, and tapping operations that add critical interfaces, sealing surfaces, or mounting features directly onto cast substrates—eliminating assembly steps and reducing total part cost. This integrated approach ensures cast components transition seamlessly from prototype validation to low-volume production without redesign.

Accelerate your development timeline with Honyo Prototype’s Online Instant Quote platform. Upload CAD files for cast aluminum parts requiring machining, and receive a detailed technical assessment with manufacturability feedback and lead time within hours—not days. Our system automatically evaluates machining complexity against casting geometry, material constraints, and tolerance requirements to provide accurate, actionable pricing. This digital workflow empowers engineering teams to iterate faster while maintaining strict alignment with production intent.

Partner with Honyo Prototype to convert your aluminum castings into mission-critical components where precision, reliability, and speed determine project success.

Technical Capabilities

Honyo Prototype delivers precision-machined cast aluminum parts utilizing advanced 3, 4, and 5-axis milling along with CNC turning capabilities. These processes are optimized for achieving tight tolerances and complex geometries required in aerospace, automotive, and industrial applications. While cast aluminum is the primary focus, our manufacturing expertise extends to secondary operations on steel, ABS, and nylon components for complete assembly support.

Our 3/4/5-axis milling platforms enable multi-faceted machining in a single setup, reducing cumulative error and improving geometric accuracy. CNC turning ensures high concentricity and surface finish on rotational features. Tight tolerance capabilities are maintained through in-process inspection, thermal compensation, and high-precision tooling systems.

Below is a summary of technical specifications and material compatibility:

| Parameter | Specification / Capability |

|---|---|

| Primary Material | Cast Aluminum Alloys (e.g., A380, A360, ADC12, 6061-T6, 7075-T6) |

| Secondary Materials | Steel (e.g., 4140, 1018, 304/316 Stainless), ABS (for prototypes), Nylon (e.g., PA6, PA66) |

| Machining Processes | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (2-axis and multi-axis turning centers) |

| Typical Tolerance Range | ±0.005 mm (±0.0002″) for critical dimensions; feature-to-feature within ±0.01 mm (±0.0004″) |

| Positional Accuracy | ±0.01 mm (±0.0004″) with probe-assisted setup and alignment |

| Surface Finish (Milled) | Ra 0.8 µm (32 µin) standard; down to Ra 0.4 µm (16 µin) with fine finishing passes |

| Surface Finish (Turned) | Ra 0.4–1.6 µm (16–63 µin), depending on material and feature |

| Max Work Envelope (Milling) | 5-Axis: 1200 x 800 x 600 mm; 3-Axis: up to 2000 x 1000 x 800 mm |

| Max Diameter (Turning) | Up to 500 mm diameter, 1000 mm length |

| Secondary Operations | Deburring, anodizing (Type II & III), passivation, bead blasting, precision cleaning |

| Quality Assurance | CMM inspection, first-article reporting (FAI), GD&T analysis, reverse engineering support |

All cast aluminum parts undergo stress-relief treatment prior to precision machining to minimize distortion. Tight tolerance features such as bores, pocket depths, and mating surfaces are machined using rigid tooling and high-frequency spindle monitoring to ensure repeatability. Multi-axis capabilities allow for undercuts, angled surfaces, and organic contours without secondary fixturing.

For hybrid assemblies, steel inserts, ABS covers, or nylon bushings can be integrated post-machining, with full DFM support provided during quoting.

From CAD to Part: The Process

CAD File Upload and Validation

Clients initiate the process by uploading detailed 3D CAD models via Honyo Prototype’s secure portal. Supported formats include STEP AP203/214, IGES, and native SOLIDWORKS files. Our system automatically validates geometry integrity, checks for unit consistency (millimeters/inches), and confirms compliance with minimum feature size requirements for cast aluminum processes. Invalid submissions trigger immediate feedback for correction, ensuring downstream efficiency.

AI-Powered Quoting Engine

Validated CAD data feeds into our proprietary AI quoting system, which analyzes part geometry, material specifications (e.g., A356, A380 per ASTM B26/B108), and surface finish requirements. The algorithm calculates material volume, estimates machining allowances, and factors in foundry-specific parameters like draft angles and parting line complexity. Quotes—including NRE costs, per-part pricing, and lead times—are generated within 2 business hours, with transparent cost breakdowns for tooling, casting, and secondary operations.

Engineering-Driven DFM Analysis

All quotes undergo mandatory Design for Manufacturing review by Honyo’s casting specialists. Engineers assess critical aluminum casting parameters: minimum wall thickness (≥2.5mm for gravity casting), draft angles (≥1°–3°), fillet radii to prevent hot tears, and strategic placement of gates/risers to minimize porosity. We identify risks like isolated thermal masses or inadequate core support, providing actionable feedback via annotated CAD markups. Clients approve revised designs or discuss trade-offs before tooling fabrication, reducing iteration cycles by 40–60%.

Production Execution and Quality Control

Approved designs move to production, where Honyo coordinates with certified partner foundries for gravity or low-pressure die casting. Raw castings undergo stress relief and heat treatment per AMS 2771 standards. In-process inspections include CMM verification of critical dimensions, X-ray porosity checks (MIL-STD-209G), and chemical composition validation via OES testing. Secondary operations such as CNC machining, anodizing, or powder coating follow ISO 2768-mK tolerances, with full traceability from melt lot to finished part.

Delivery and Documentation

Completed parts ship in custom anti-corrosion packaging with humidity indicators, adhering to specified delivery windows (typically 15–25 days from DFM sign-off). Each shipment includes a comprehensive quality dossier: material certs (ASTM E29), FAI reports, dimensional inspection data, and NDT results. Honyo’s logistics team provides real-time tracking and coordinates customs documentation for global deliveries, ensuring seamless integration into client supply chains.

Start Your Project

Looking for high-quality cast aluminum parts manufactured to precise specifications? Honyo Prototype delivers reliable, cost-effective solutions with fast turnaround times. Our dedicated facility in Shenzhen ensures strict quality control and scalable production capacity to meet your project demands.

Contact Susan Leo today to discuss your casting requirements.

Email: [email protected]

Partner with a trusted manufacturer backed by technical expertise and a commitment to excellence in every component.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.