Guide Contents

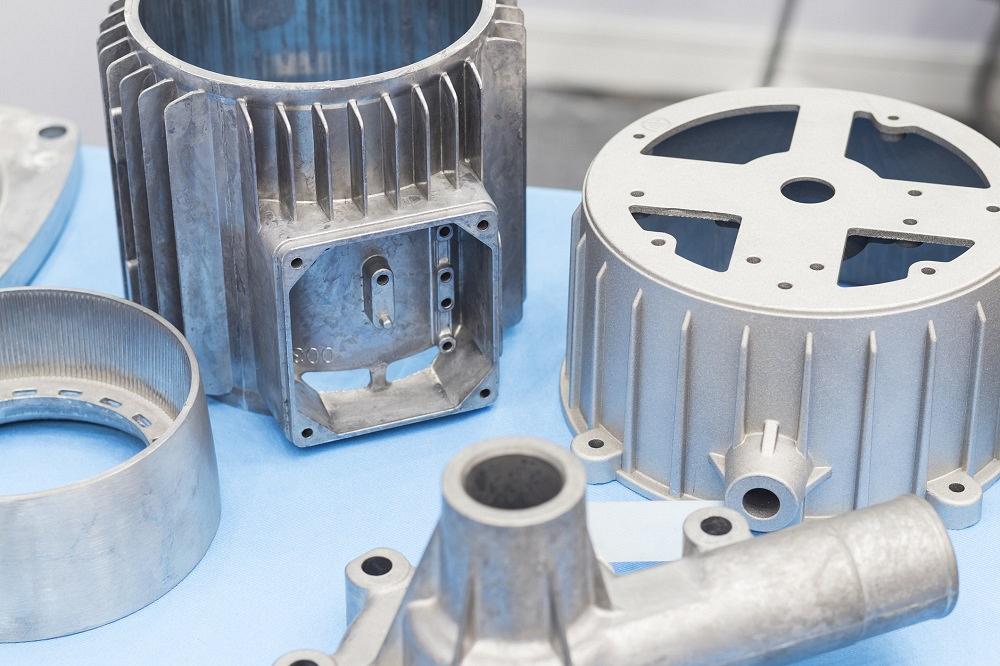

Project Insight: Cast Aluminum Parts

Manufacturing Insight: Cast Aluminum Parts

Why Speed and Precision Define Product Success

Time-to-Market Pressure: Hardware startups face intense competition—delays in prototyping can cost months of market opportunity. Traditional casting processes often require weeks for tooling setup and manual reviews, slowing iteration cycles.

Quality Consistency Challenges: Manual casting processes introduce variability in wall thickness and surface finish, risking part failures that derail production schedules and increase costs.

High Upfront Costs: Die casting tooling can exceed $45,000 for small batches, making early-stage prototyping economically unfeasible for startups with limited capital.

Honyo Prototype: Your Digital Manufacturing Partner

Online Instant Quote: Upload your CAD file and receive real-time pricing, DFM (Design for Manufacturability) feedback, and lead times in seconds—eliminating weeks of back-and-forth quotes and hidden costs.

AI-Powered Precision Engineering: Our platform automatically optimizes designs for castability, analyzing critical factors like draft angles, gating systems, and shrinkage to ensure flawless parts with minimal material waste.

Seamless Prototype-to-Production Workflow: From 3-5 day prototypes to scalable production runs, our integrated digital ecosystem ensures consistent quality and rapid iteration—no retooling delays or communication gaps between stages.

At Honyo Prototype, we turn complex aluminum casting challenges into competitive advantages. With Shenzhen-based digital manufacturing expertise and a one-stop solution from concept to volume production, your innovation stays ahead of the curve.

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities for Cast Aluminum Parts

Precision Cast Aluminum Solutions Tailored for Your Scale

Online Instant Quote – Transparent Pricing in Seconds

Real-time cost estimates with detailed breakdown (material, tooling, labor)

No hidden fees or markups – 20-30% savings vs. traditional suppliers

Interactive DFM (Design for Manufacturability) analysis to optimize design and reduce costs

AI-Powered Digital Manufacturing Ecosystem

Automated process planning and simulation for error-free manufacturing

Integrated CAD/CAM workflow with real-time adjustments and feedback

Predictive analytics to minimize waste and maximize efficiency

Fast Turnaround Guaranteed

Prototypes delivered in 3 days; production in 2–3 weeks

Streamlined workflows and real-time progress tracking

40% faster lead times than traditional manufacturers

ISO-Certified Quality & Scalable Production

Zero MOQ: Produce 1 prototype or 10,000+ parts with consistent quality

Flexible tooling strategies reducing upfront costs by up to 60%

Advanced metrology (CMM, X-ray) and full traceability for every batch

Materials & Surface Finishes

Material Options & Finishes for Cast Aluminum Parts

🌟 Material Selection Guide

Metal Alloys (Casting-Grade)

A356: High strength, heat-treatable, ideal for aerospace and automotive structural components.

A380: Superior fluidity for complex geometries; cost-effective for high-volume die casting.

7075: Maximum tensile strength for heavy-load applications (e.g., robotics, military equipment).

Pro Tip: Our AI-driven material selector analyzes your design specs to recommend the optimal alloy—no guesswork, no over-engineering.

Plastic Options (via Complementary Services)

ABS, Nylon, POM, and more for injection-molded parts.

Note: For aluminum casting projects, focus on our metal alloys; plastics are seamlessly integrated through our full-spectrum manufacturing ecosystem.

🎨 Surface Finishing Solutions

Anodizing: Corrosion resistance + vibrant color options (hard coat for wear-resistant surfaces).

Powder Coating: Eco-friendly, UV-stable finish for outdoor industrial equipment.

Polishing & Buffing: Mirror-smooth finish for premium consumer electronics or luxury products.

Sandblasting: Uniform matte texture for architectural or ruggedized parts.

Painting: Custom RAL/Pantone matching with precision color consistency.

Chemical Film (Alodine): Thin, conductive layer for electrical components.

Why it matters: Our digital finishing platform ensures pixel-perfect color matching and finish quality—no more sample mismatches.

🔍 How to Choose the Right Material

Function & Environment:

High-stress applications? → A356 or 7075 with hard anodizing.

Marine/chemical exposure? → Pair A380 with powder coating for maximum corrosion resistance.

Cost Efficiency:

A380 reduces tooling costs by 20% for high-volume runs—our AI platform optimizes geometry to cut waste.

Instant Quote Tip: Upload your CAD file for real-time cost breakdowns—see how material choices impact pricing instantly.

Lead Time Considerations:

Standard alloys (A380) ship in 5–7 days; custom alloys take 10–15% longer.

Fast Turnaround Guarantee: 72-hour quotes for standard parts; prototyping in 3 days for urgent projects.

✨ Why Honyo Prototype?

One-Stop Solution: From design validation to finished parts—no third-party coordination.

AI-Powered Optimization: Our platform cross-references material properties, manufacturability, and cost to eliminate over-engineering.

Transparent Pricing: Real-time cost simulations with no hidden fees—see exactly how your choices affect your budget.

Try it now: [Upload your CAD file] for an instant quote with material/finish recommendations tailored to your project—zero commitment, zero delay.

From Quote to Part: Our Process

How It Works: From CAD to Part

Honyo’s digital manufacturing ecosystem transforms aluminum casting from a complex, opaque process into a streamlined, transparent journey. Our AI-powered platform eliminates guesswork, delivering real-time pricing, rapid iterations, and industry-leading turnaround times—so you ship faster, spend less, and innovate with confidence.

1. Upload CAD File

Seamless Digital Onboarding: Upload STEP, STL, or native CAD files in seconds—no file size restrictions or manual submissions.

Secure & Scalable: Enterprise-grade encryption ensures your IP is protected, while our cloud infrastructure handles complex geometries effortlessly.

2. Get Instant Quote (AI Engine)

Real-Time Cost Transparency: Our AI analyzes geometry, material, and production parameters to generate a precise quote in <60 seconds—no hidden fees or arbitrary markups.

Dynamic Pricing Insights: See exactly how factors like part complexity, quantity, and surface finish impact costs, with options to adjust variables for optimal savings.

3. DFM Analysis & Optimization

Proactive Design Feedback: AI-driven DFM checks flag casting-specific issues (e.g., draft angles, wall thickness uniformity, gating design) and suggest engineering improvements to reduce material waste and tooling costs.

Collaborative Refinement: Work directly with our engineers via the platform to iterate on designs—no back-and-forth emails or delays.

4. Production & Delivery

End-to-End Digital Workflow: From rapid tooling to casting and finishing, our integrated manufacturing network ensures consistent quality with prototypes delivered in 3–5 days.

Transparent Tracking: Monitor production progress in real time with automated updates and delivery tracking—your part arrives on schedule, every time.

Why Honyo?

As a one-stop solution from prototype to production, we eliminate supply chain friction. Backed by Susan Leo’s vision for transparent, agile manufacturing, our digital ecosystem combines AI precision with on-demand agility—so you turn ideas into market-ready parts faster than ever.

Start Your Project with Honyo

Start Your Project with Honyo – Precision Aluminum Casting, Simplified

Why Choose Honyo for Aluminum Casting?

Online Instant Quote

Get real-time, transparent pricing in seconds. No hidden fees or lengthy wait times – our AI-powered platform delivers accurate cost breakdowns for your specific part.

AI-Powered Optimization

Proprietary algorithms analyze geometry, material, and production variables to optimize tooling, reduce waste, and minimize costs – up to 30% savings vs traditional suppliers.

Fast Turnaround Guaranteed

Prototype to production in record time – typically 50% faster than industry averages, thanks to our automated workflows and integrated digital ecosystem.

Let’s Build Together

As Founder Susan Leo, I’ve built Honyo to empower hardware startups and engineers with seamless, end-to-end manufacturing – from prototype to production, without the usual delays or hidden costs. Let’s bring your vision to life.

📧 [email protected] | 📞 +86 139 2843 8620

📍 Visit our Shenzhen/Dongguan facilities for a hands-on consultation

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.