Contents

Manufacturing Insight: Carbon Steel Vs Iron

Material Selection Precision: Carbon Steel Versus Cast Iron in High-Performance Machining

Understanding the fundamental differences between carbon steel and iron is critical for achieving optimal component performance, durability, and cost-efficiency in precision manufacturing. While “iron” commonly refers to cast iron alloys containing 2–4% carbon alongside silicon and manganese, carbon steel is a precisely engineered ferrous alloy with controlled carbon content (typically 0.05–2.0%) and minimal impurities. This distinction directly impacts machinability, tensile strength, weldability, and thermal stability. Cast iron excels in damping capacity and compressive strength for static applications like machine bases, whereas carbon steel delivers superior tensile strength, ductility, and fatigue resistance essential for dynamic, high-stress components such as shafts, gears, and structural brackets. Selecting the wrong material can lead to premature failure, increased scrap rates, and extended production timelines—risks Honyo Prototype mitigates through expert material guidance and process optimization.

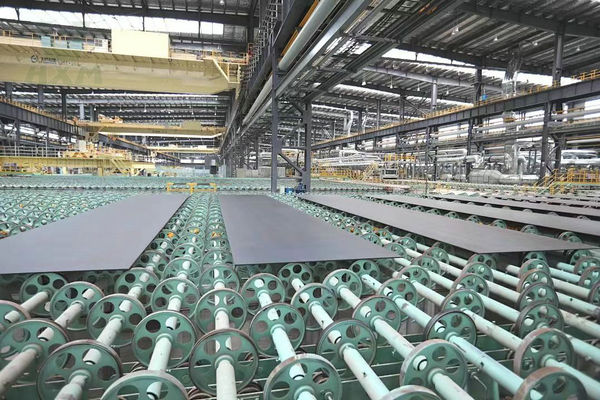

At Honyo Prototype, our CNC machining services leverage advanced multi-axis milling, turning, and grinding capabilities to transform both carbon steel and cast iron into mission-critical parts with micron-level tolerances (±0.005 mm) and exceptional surface finishes (Ra 0.8 µm). We specialize in processing diverse carbon steel grades—including 1045, 4140, and 8620—as well as gray and ductile iron variants, applying tailored cutting parameters, tooling strategies, and coolant systems to address each material’s unique thermal and abrasive characteristics. Our ISO 9001-certified facility ensures rigorous in-process inspection, heat treatment coordination, and first-article validation, guaranteeing that every component meets stringent aerospace, automotive, and industrial OEM specifications.

| Material Property | Carbon Steel (e.g., 1045) | Cast Iron (e.g., G2500) |

|---|---|---|

| Typical Carbon Content | 0.43–0.50% | 2.5–3.5% |

| Tensile Strength | 565–630 MPa | 200–300 MPa |

| Machinability | Moderate to Good | Excellent (free-machining grades) |

| Key Applications | Shafts, bolts, gears | Engine blocks, housings |

Partner with Honyo Prototype to convert material science insight into manufacturing excellence. Our engineering team collaborates with clients from initial design review through final production, ensuring material selection aligns with functional requirements and cost targets. Accelerate your prototyping or low-volume production with our Online Instant Quote platform—upload CAD files in minutes to receive detailed pricing, lead time estimates, and actionable manufacturability feedback, all backed by 25+ years of precision machining expertise. Transform engineering intent into reality with confidence.

Technical Capabilities

When comparing carbon steel and iron in the context of precision CNC machining processes such as 3-axis, 4-axis, and 5-axis milling and turning, several technical factors influence material selection—especially when tight tolerances (±0.001″ or tighter) are required. Below is a comparative analysis focused on machinability, dimensional stability, tool wear, and suitability across common engineering materials including aluminum, steel (specifically carbon steel), cast iron, ABS, and nylon.

| Parameter | Carbon Steel (e.g., 1018, 1045) | Cast Iron (e.g., Gray Iron 30) | Aluminum (e.g., 6061-T6) | ABS (Thermoplastic) | Nylon (Polyamide) |

|---|---|---|---|---|---|

| Typical Use in Milling | High strength components, shafts, fixtures | Engine blocks, housings, bases | Enclosures, aerospace parts | Prototypes, jigs, non-structural | Wear strips, gears, insulators |

| Machinability (Relative) | Moderate (free-machining grades like 12L14 better) | Good (self-breaking chips, dampens vibration) | Excellent (high MRR, low cutting force) | Very Good (soft, easy to cut) | Good (tough, can gum up tools) |

| Tool Wear (CNC Milling) | Moderate to High (abrasive, work-hardens slightly) | High (abrasive graphite flakes) | Low (minimal tool wear) | Very Low | Moderate (adhesive tendencies) |

| Turning Suitability | Excellent with proper tooling (carbide) | Good (short chips, stable) | Excellent (smooth finishes) | Good (requires sharp tools) | Fair (flexible, requires support) |

| Tight Tolerance Capability | ±0.0005″ to ±0.001″ achievable with thermal control | ±0.001″ typical (good stability) | ±0.0005″ possible (low inertia) | ±0.002″ (thermal sensitivity) | ±0.002″ (hygroscopic, dimensional drift) |

| Thermal Stability | Moderate (requires coolant for precision) | High (excellent damping and stability) | Low (expands with heat) | Poor (high thermal expansion) | Poor (absorbs moisture, swells) |

| Surface Finish (Milling) | 32–64 μin achievable (with finishing passes) | 63–125 μin typical (but vibration-damped) | 16–32 μin (excellent finish) | 64–125 μin | 32–64 μin (depends on tool sharpness) |

| Recommended Tooling | Carbide end mills, CVD-coated inserts | Ceramic or CBN for high speed, carbide for general | Carbide, polycrystalline diamond (PCD) | Carbide, sharp HSS | Carbide, polished flutes |

| 5-Axis Milling Suitability | Good (rigid setups, cooling critical) | Fair (heavy parts, fixturing challenge) | Excellent (lightweight, fast cuts) | Fair (soft, may deform) | Limited (flexibility limits precision) |

Notes:

Carbon Steel offers superior tensile strength and hardness compared to iron and is widely used in high-precision mechanical components. However, it requires more robust tooling and process control to maintain tight tolerances due to work hardening and heat generation.

Cast Iron provides excellent vibration damping, making it favorable for machine tool bases and fixtures. Its brittleness allows for efficient chip breaking but increases edge chipping risk in complex 5-axis contours.

Aluminum is optimal for high-speed 3/5-axis milling due to low density and high thermal conductivity. It achieves the tightest tolerances with minimal tool wear.

ABS and Nylon, while machinable, are less suitable for sustained tight-tolerance production due to thermal and moisture sensitivity. Used primarily in prototyping or low-stress applications.

For high-precision, multi-axis CNC operations requiring tight tolerances, aluminum and free-machining carbon steel (e.g., 12L14) are preferred over cast iron and plastics. Cast iron remains relevant for large, stable structures, while plastics like ABS and nylon are limited to non-critical, low-volume prototyping.

From CAD to Part: The Process

Honyo Prototype executes a rigorously defined workflow for carbon steel and cast iron components, ensuring material-specific considerations are addressed at every phase. Material selection remains the client’s responsibility during CAD specification; our process validates feasibility and optimizes manufacturability based on the provided material choice. Below is our stage-by-stage methodology with critical material-specific actions.

Upload CAD

Clients submit fully dimensioned CAD models specifying the exact material grade (e.g., AISI 1045 carbon steel or ASTM A48 Class 30 gray iron). Our system immediately checks for material callout completeness. Missing or ambiguous material specifications trigger an automated hold requiring client clarification before progression. Carbon steel designs are validated against common grades (1018, 1045, 4140), while cast iron submissions undergo scrutiny for minimum wall thickness compliance (typically ≥3mm for gray iron to prevent casting defects).

AI Quote Generation

Our AI engine analyzes CAD geometry alongside the declared material to generate instant cost and lead time estimates. Key material-driven factors include:

| Parameter | Carbon Steel Impact | Cast Iron Impact |

|---|---|---|

| Machining Time | Moderate (easier cutting than stainless) | High (abrasive graphite requires slower speeds) |

| Tool Wear | Low to moderate | Severe (graphite accelerates tool degradation) |

| Secondary Operations | Minimal (common for heat treat) | High (mandatory stress relief annealing) |

| Scrap Rate | 2-5% (predictable machining) | 8-15% (casting porosity risks) |

The AI flags material-specific cost drivers—such as cast iron’s 20-30% higher machining surcharge due to tooling costs—and presents alternatives only if the CAD specifies non-standard grades. No material substitution occurs without explicit client approval.

DFM Analysis

Our engineering team conducts material-centric manufacturability review:

For carbon steel, we verify heat treatment compatibility (e.g., ensuring 4140 sections ≤75mm thick for full hardening) and suggest radius adjustments to prevent stress cracking during quenching. Cast iron DFM focuses on draft angles (≥3° for sand casting), avoidance of thin ribs (<6mm), and strategic placement of machining allowances to compensate for casting distortion. Critical geometric features like bearing bores undergo tolerance recalculation—applying ±0.05mm for steel versus ±0.1mm for cast iron due to inherent variability. All findings are documented in a formal DFM report with annotated CAD markups.

Production Execution

Material-specific protocols govern manufacturing:

Carbon steel parts proceed through CNC machining with optimized toolpaths (e.g., 180m/min cutting speed for 1045), followed by client-specified heat treatment (annealing/QT) in certified furnaces with traceable temperature logs. Cast iron components undergo mandatory vibratory stress relief before machining, utilize carbide tooling with 40% reduced feed rates, and implement HEPA-filtered dust extraction during milling to mitigate graphite particulate hazards. All operations adhere to ISO 9001:2015 with material certificates (e.g., Mill Test Reports for steel, ASTM A48 for iron) maintained in the digital production dossier.

Delivery Assurance

Final inspection includes material-verified quality checks: Carbon steel parts undergo hardness testing at three locations per piece (documented in Rockwell C scale), while cast iron receives ultrasonic porosity screening per ASTM E587. Dimensional reports correlate critical features to material-specific thermal stability allowances. Parts ship with full material traceability documentation, including lot numbers and test certifications. Carbon steel deliveries typically achieve 12-15 business day lead times versus 18-22 days for cast iron due to extended casting/post-cast processing requirements.

This structured approach ensures carbon steel and cast iron components meet identical quality standards while accounting for fundamental material property differences. We maintain strict separation between client material decisions and our execution protocol—providing expertise without overriding design intent. All process deviations undergo client engineering sign-off prior to implementation.

Start Your Project

Learn the key differences between carbon steel and iron in precision manufacturing applications. Understanding material properties is critical for achieving optimal strength, durability, and cost-efficiency in your prototypes and production parts.

For expert guidance on material selection tailored to your project needs, contact Susan Leo at [email protected]. With our advanced manufacturing facility located in Shenzhen, Honyo Prototype delivers high-precision components with fast turnaround and strict quality control.

Let us help you make the right material choice for your next project. Reach out today to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.