Contents

Manufacturing Insight: Carbon Steel Prices Per Pound

Material Cost Management in Precision Manufacturing

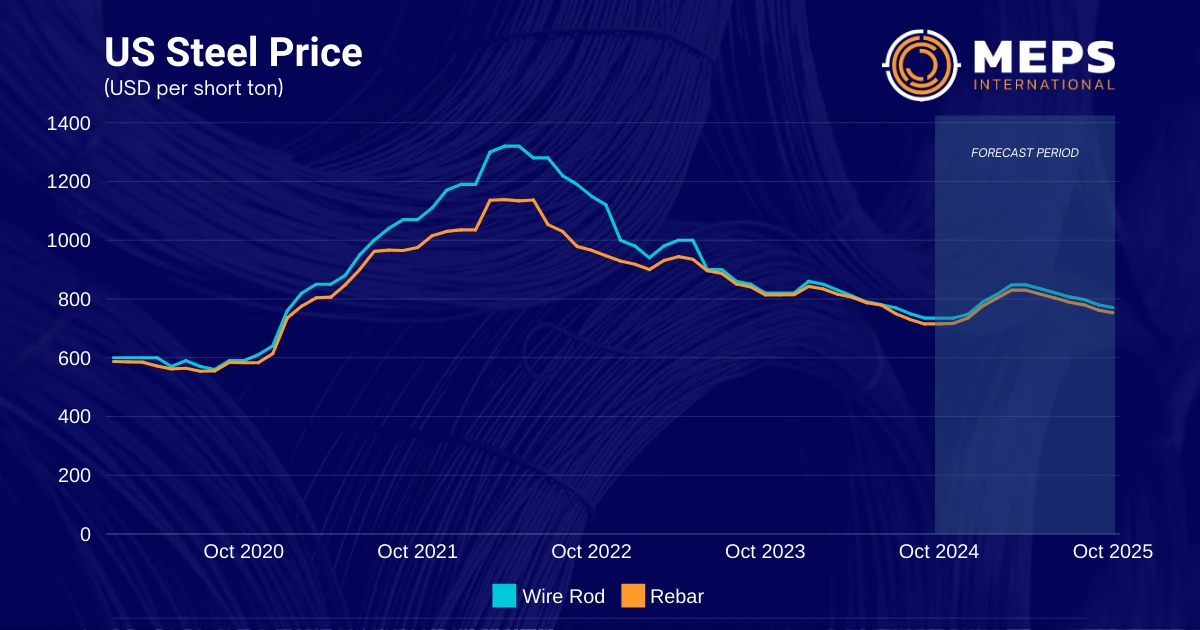

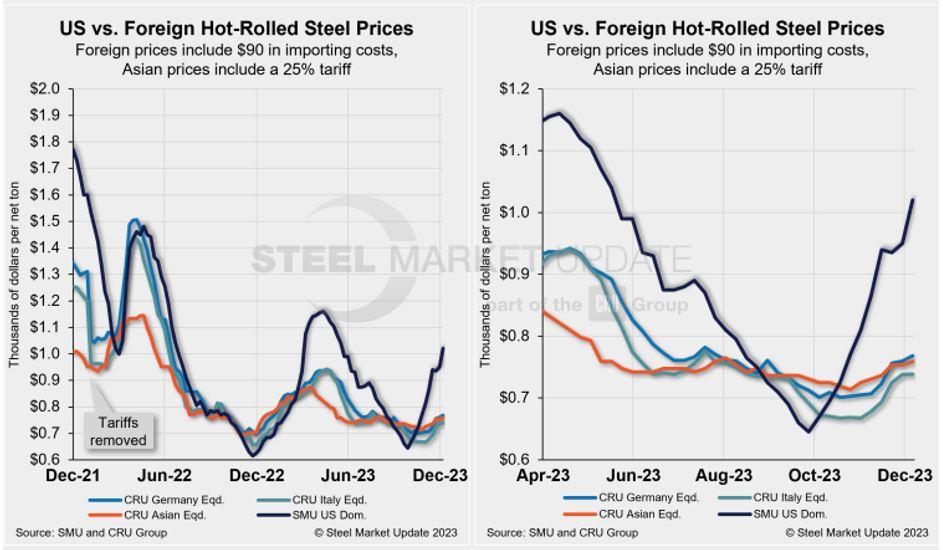

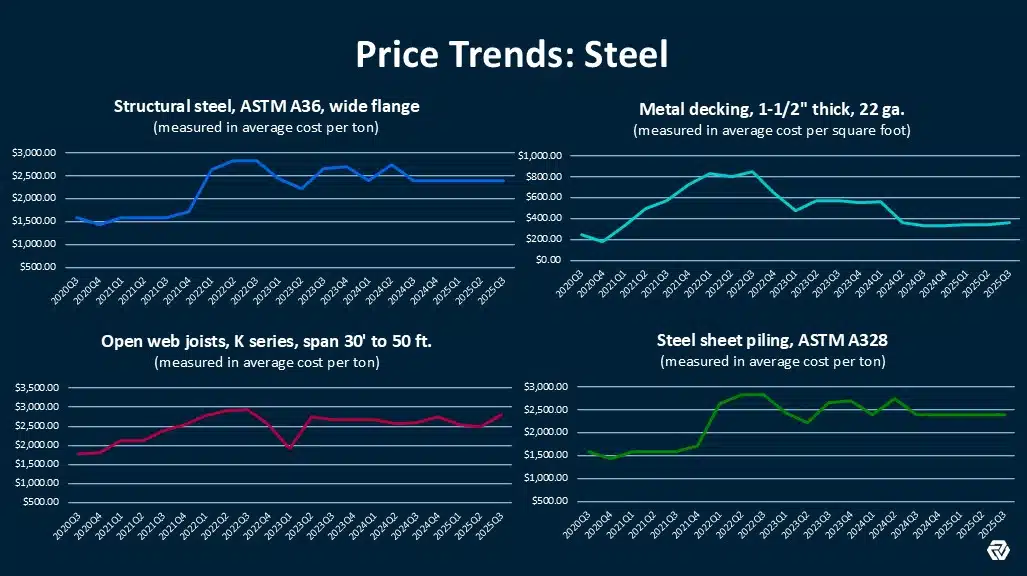

Carbon steel pricing remains highly volatile due to global supply chain dynamics, scrap metal markets, and energy costs, with per-pound rates fluctuating daily across grades like 1018, 1045, and 4140. For engineering teams developing prototypes or low-volume production parts, these uncertainties directly impact budget accuracy and project timelines. At Honyo Prototype, our CNC machining services mitigate this risk through precision-first manufacturing that minimizes material waste and rework. By leveraging advanced 3-5 axis milling and turning capabilities with tolerances held to ±0.0005″, we ensure optimal material utilization—reducing effective cost per functional component even amid raw material volatility.

Our engineering-driven approach includes design-for-manufacturability analysis to identify opportunities for weight reduction and scrap minimization without compromising structural integrity. This focus on efficiency translates directly to predictable unit costs, regardless of spot market swings. To accelerate your procurement process, Honyo provides an Online Instant Quote platform where you can upload CAD files and receive detailed cost breakdowns—including real-time material surcharge adjustments—within minutes. This transparency allows for informed decisions during the critical design phase, turning material cost variables into controlled project parameters.

For immediate project validation, access our quoting engine at honyoprototype.com/quote.

Technical Capabilities

Honyo Prototype provides high-precision CNC machining services with capabilities in 3, 4, and 5-axis milling as well as CNC turning, supporting tight tolerance requirements down to ±0.0002″. While carbon steel pricing is material-specific and market-driven, the cost per pound influences the overall part fabrication cost, especially in high-precision applications. Below is a comparative technical and material overview relevant to machining processes and common materials used, including carbon steel pricing benchmarks.

| Material | Typical Price Range (USD per lb) | Machinability Rating | Common Use in 3/4/5-Axis Milling | Suitability for CNC Turning | Typical Tolerance Capability (± in) | Notes |

|---|---|---|---|---|---|---|

| Carbon Steel (1018, 1045) | $0.50 – $0.80 | Good (60–65% relative to 1212 steel) | Moderate – used for durable components, jigs, and fixtures | Excellent – high strength and dimensional stability | 0.0005″ – 0.001″ | Prone to rust; often plated or coated; higher density increases machining time and tool wear |

| Aluminum (6061, 7075) | $1.20 – $1.80 | Excellent (benchmark for machinability) | High – ideal for complex geometries and lightweight parts | Excellent – fast cutting speeds, low tool wear | 0.0002″ – 0.0005″ | Preferred for tight tolerance and high-speed milling; lower cost per performance in aerospace and prototyping |

| Steel (Stainless 304, 17-4 PH) | $1.50 – $3.00 | Fair to Moderate (varies by grade) | Moderate to High – used in medical, aerospace, and industrial | Good – requires rigid setups and proper tooling | 0.0005″ – 0.001″ | Higher cost and tool wear; excellent corrosion resistance and strength |

| ABS (Thermoplastic) | $1.00 – $1.60 | Very Good – soft but can melt or deform | High – excellent for prototypes and non-structural parts | Good – needs sharp tools and cooling control | 0.001″ – 0.005″ | Lower density; not for high-temp or load-bearing applications |

| Nylon (PA6, PA66) | $2.00 – $3.50 | Moderate – gummy, requires sharp tools | Moderate – good for wear-resistant components | Good – low friction but prone to swelling | 0.001″ – 0.002″ | High strength for plastic; absorbs moisture; used in gears and bushings |

Process Notes

3, 4, and 5-axis milling enables complex part geometry with minimal setups, critical for tight tolerance components. Carbon steel is often chosen for strength and wear resistance, though its higher density and hardness increase machining time and tooling costs compared to aluminum or plastics. Turning operations on carbon steel require carbide tooling and proper coolant management to maintain surface finish and dimensional accuracy.

At Honyo Prototype, material selection is optimized based on functional requirements, cost targets, and precision needs. While carbon steel offers favorable strength-to-cost ratio, aluminum remains the preferred choice for high-accuracy, lightweight applications in prototyping and production.

From CAD to Part: The Process

Honyo Prototype maintains a transparent and data-driven approach to carbon steel component costing, though it is critical to clarify that raw material pricing is not determined by our internal process steps. Carbon steel prices per pound are primarily governed by global market indices (e.g., Platts HRC, Argus FOB Pittsburgh), supplier contracts, and commodity futures. Our workflow integrates these external variables into a structured quotation and production system as follows:

Upload CAD

Upon receiving a customer’s CAD file, our system extracts geometric data including part volume, surface area, and complexity metrics. This input feeds directly into material consumption calculations, where we apply current carbon steel market rates sourced from real-time supplier feeds and industry benchmarks. Material weight is computed using ASTM A36 density (0.284 lb/in³), adjusted for the specific grade requested (e.g., 1018, 1045).

AI Quote Generation

Our proprietary AI engine synthesizes three core cost layers:

1. Raw material cost: Live carbon steel pricing (e.g., $0.80–$1.20/lb for hot-rolled A36, subject to LME-linked volatility) multiplied by net part weight plus processing allowances.

2. Processing cost: Laser/plasma cutting, forming, and secondary operations based on machine time and labor rates.

3. Operational overhead: Quality control, handling, and facility costs.

The AI cross-references historical production data and current market surcharges (e.g., scrap metal differentials) to generate a validated quote within 2 business hours.

DFM Analysis

During Design for Manufacturability review, our engineers identify opportunities to optimize material utilization. For carbon steel parts, this includes:

Nesting efficiency improvements to minimize sheet waste (typical yield: 75–92% for laser cutting)

Substitution recommendations for cost-effective grades (e.g., A572 Gr50 vs. A36 for structural parts)

Tolerance relaxation to reduce machining time

DFM adjustments directly impact the final material cost per part by reducing scrap rates and processing time. A typical DFM revision lowers material costs by 12–18% through yield optimization.

Production Execution

Material procurement leverages pre-negotiated supplier agreements with tier-1 mills (e.g., Nucor, Cleveland-Cliffs). Carbon steel sheets/coils are ordered against live market rates, with pricing locked at purchase order confirmation. Production tracking monitors actual material consumption against quoted weight, with variances reported if >5%.

Delivery

Final invoicing reflects exact material usage from production logs, adjusted for:

Actual steel grade density variations

Verified scrap recovery credits

Freight and handling surcharges

Customers receive a cost breakdown showing material cost per pound against industry benchmarks.

The relationship between market steel prices and final part cost is demonstrated below:

| Cost Component | Typical Contribution to Total Part Cost | Variability Driver |

|---|---|---|

| Raw Carbon Steel | 35–50% | LME indices, mill surcharges |

| Processing Labor | 25–35% | Part complexity, tolerances |

| Scrap Recovery Credit | -5% to -12% | Yield efficiency, scrap market |

| Overhead & Margin | 20–25% | Order volume, logistics |

This structured methodology ensures carbon steel pricing transparency while acknowledging that base material costs originate externally. Honyo’s value lies in accurately translating volatile market rates into predictable, optimized part costs through engineering rigor and supply chain integration. We provide real-time steel price visibility in quotes but cannot dictate commodity market dynamics.

Start Your Project

For the latest carbon steel prices per pound, contact Susan Leo directly at [email protected]. As a trusted manufacturing partner based in Shenzhen, Honyo Prototype delivers competitive material pricing and precise fabrication services for prototyping and low-volume production. Reach out to Susan for a detailed quote tailored to your project specifications.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.