Contents

Manufacturing Insight: Carbon Steel Prices

Navigating Carbon Steel Price Volatility with Precision Manufacturing Solutions

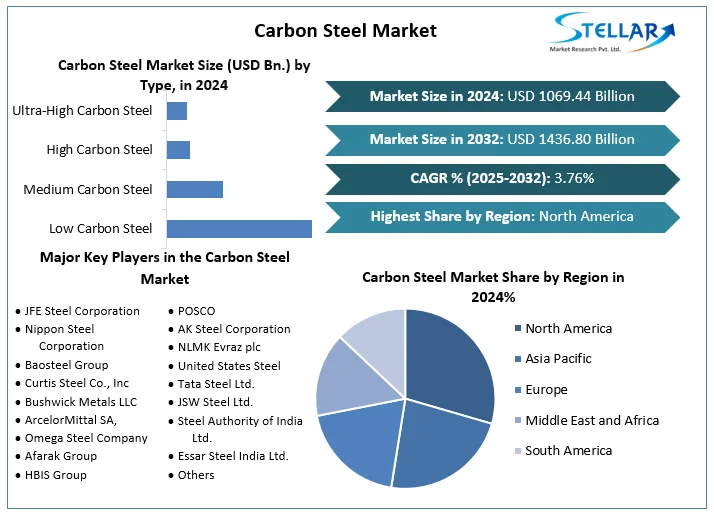

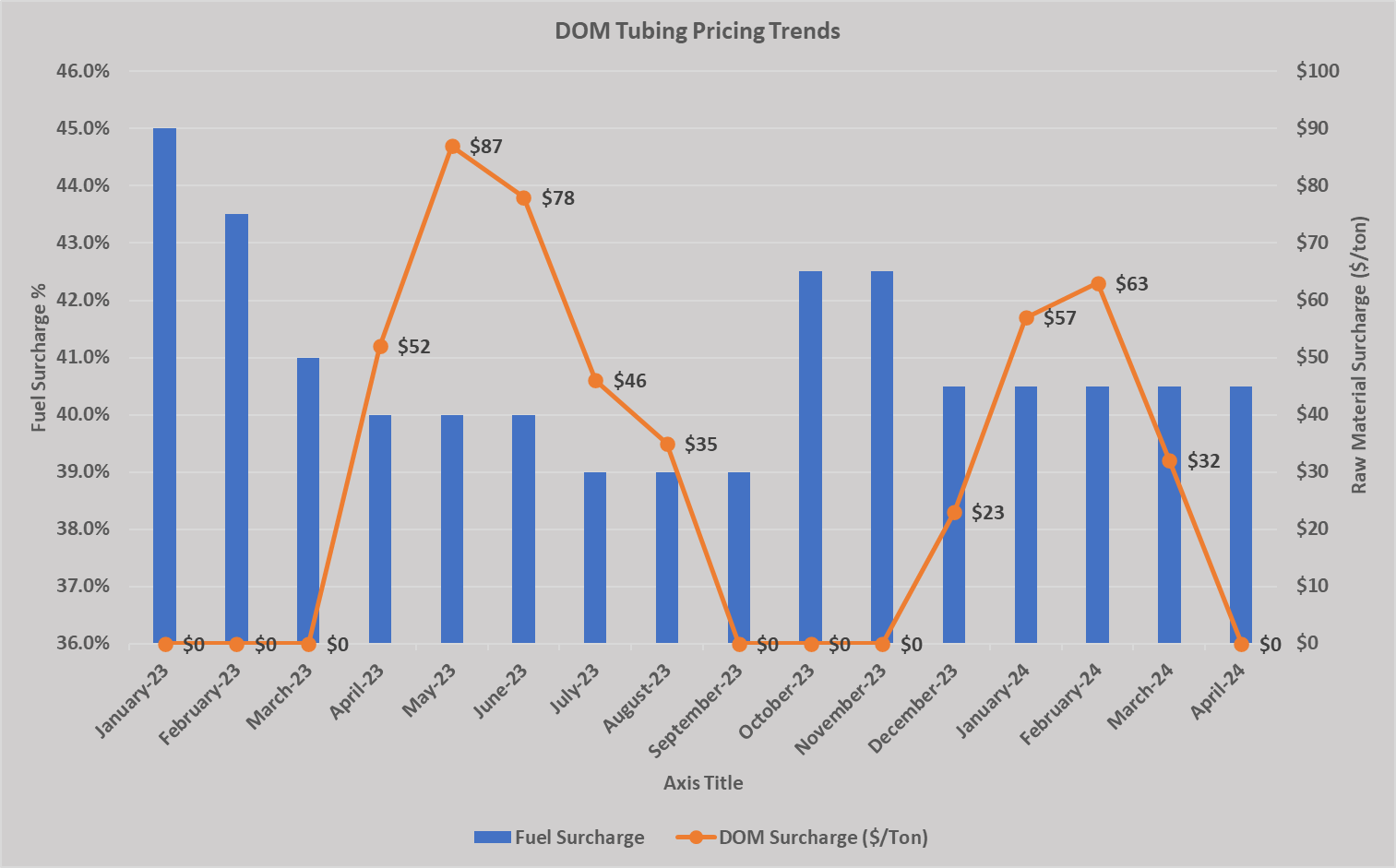

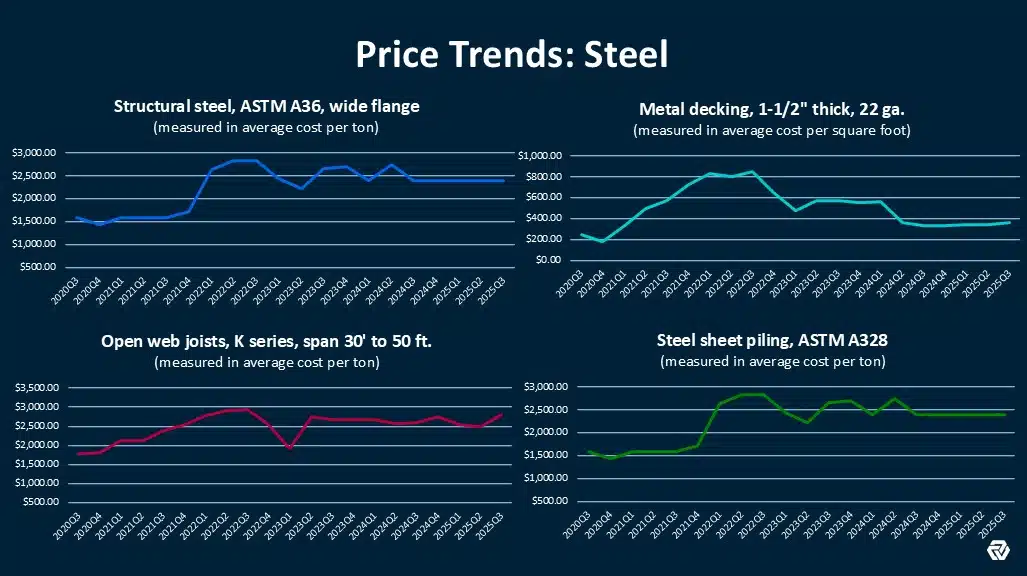

Carbon steel remains a fundamental material for industrial components, yet its market prices exhibit significant volatility driven by raw material costs, energy expenses, and global supply chain dynamics. For engineering teams and procurement managers, these fluctuations directly impact project budgets and timeline predictability. At Honyo Prototype, we recognize that mitigating material cost risk requires more than monitoring market trends—it demands manufacturing precision that minimizes waste and maximizes yield from every billet.

Our CNC machining services specialize in transforming carbon steel grades like 1018, 1045, and 4140 into high-tolerance components with exceptional repeatability. Advanced multi-axis milling and turning capabilities ensure optimal material utilization, reducing scrap rates even during periods of elevated steel pricing. This operational efficiency translates to cost stability for your projects, as precision machining offsets raw material expenses through reduced rework and accelerated throughput.

Material Cost Certainty Starts with Accurate Quoting

To address pricing unpredictability head-on, Honyo Prototype provides an Online Instant Quote platform engineered for speed and transparency. Input your carbon steel part specifications—including grade, dimensions, and finish requirements—and receive a detailed cost breakdown within minutes. This tool leverages real-time material cost algorithms combined with our machining efficiency data, empowering you to make informed sourcing decisions before steel market shifts impact your bottom line.

Partner with Honyo to convert carbon steel price challenges into competitive advantages through manufacturing excellence and data-driven cost control.

Technical Capabilities

The term “carbon steel prices” refers to the market cost of carbon steel as a raw material, not a technical specification. However, in the context of precision machining services—such as 3/4/5-axis milling and turning with tight tolerance requirements—clients often seek cost and capability comparisons across commonly used engineering materials, including carbon steel, aluminum, stainless steel, ABS, and nylon.

Below is a technical and cost-comparative overview of these materials in the context of advanced CNC machining processes. The table includes key properties, machinability, typical applications, and relative material and machining cost indices, with carbon steel used as a baseline for comparison.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Machinability Rating (%) | Typical Tolerance (± mm) | Surface Finish (Ra µm) | Relative Material Cost (Carbon Steel = 1.0) | Relative Machining Cost | Common Use in 3/4/5-Axis Milling & Turning |

|---|---|---|---|---|---|---|---|---|

| Carbon Steel (AISI 1045) | 7.85 | 570–700 | 60–70 | 0.010 | 0.8–1.6 | 1.0 | 1.0 | High-strength components, shafts, tooling |

| Aluminum (6061-T6) | 2.70 | 310 | 90–100 | 0.010 | 0.4–1.6 | 1.8 | 0.8 | Aerospace, enclosures, lightweight fixtures |

| Stainless Steel (304) | 8.00 | 505–700 | 45 | 0.012 | 0.8–2.0 | 2.5 | 1.4 | Medical, food-grade, corrosive environments |

| ABS (Thermoplastic) | 1.04 | 40–50 | 90 | 0.050 | 1.6–3.2 | 1.2 | 0.6 | Prototypes, jigs, non-structural parts |

| Nylon (PA6/PA66) | 1.13 | 70–85 | 80 | 0.050 | 1.6–3.2 | 1.4 | 0.7 | Wear-resistant components, gears, insulators |

Notes:

Machinability Rating: Based on AISI 1212 steel = 100%. Higher values indicate easier machining.

Tolerance: Achievable tight tolerances using high-precision CNC machining; depends on part geometry and machine calibration.

Surface Finish: Typical as-machined finish; can be improved with post-processing.

Relative Costs: Material cost is per kg; machining cost accounts for tool wear, speed, and cycle time. Carbon steel is used as the baseline.

Process Suitability: 3/4/5-axis milling allows complex geometries with high accuracy, especially in aluminum and steel. Turning is optimal for cylindrical parts in steel, aluminum, and nylon.

For tight-tolerance applications (±0.01 mm or better), aluminum and carbon steel are preferred due to dimensional stability and predictable tool engagement. ABS and nylon are suitable for non-critical or prototype applications where cost and weight are key factors.

From CAD to Part: The Process

Honyo Prototype employs a structured, technology-driven workflow to ensure accurate carbon steel pricing and efficient production. Our process eliminates guesswork by integrating material science, manufacturability analysis, and real-time production data. Below is the precise sequence for carbon steel components:

CAD Upload and Material Specification

Clients submit 3D CAD models via our secure portal. Our system immediately identifies carbon steel as the base material and prompts selection of the specific alloy grade (e.g., AISI 1018, 1045, A36) per ASTM/SAE standards. Material density and current bulk pricing from our supplier network are auto-populated based on the selected grade. Geometric analysis calculates net part weight, including allowances for machining stock and weld prep, which directly determines raw material cost.

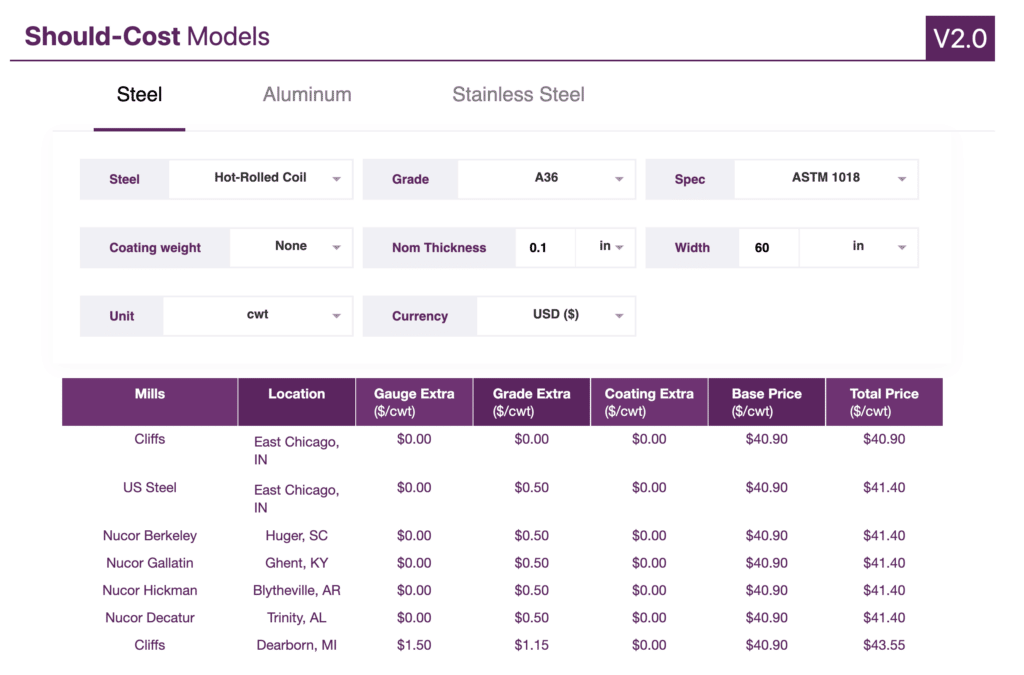

AI-Powered Quoting Engine

Our proprietary AI engine processes the CAD geometry, material grade, and client specifications to generate an instant quote. For carbon steel, this incorporates:

Real-time commodity market fluctuations (e.g., hot-rolled coil indices)

Secondary operation costs (e.g., stress-relieving for welded assemblies)

Tooling wear factors specific to carbon steel’s abrasive properties

Surface finish requirements (e.g., mill scale removal vs. precision grinding)

The quote explicitly breaks down material cost per kilogram, machining hours, and material-specific surcharges. Historical data from 12,000+ carbon steel parts ensures accuracy within ±3%.

DFM Analysis for Carbon Steel Optimization

Before formal approval, our engineering team conducts a rigorous Design for Manufacturability review focused on carbon steel’s unique properties:

Evaluating weldability concerns (e.g., pre-heat requirements for thick sections)

Identifying features prone to warpage during heat treatment

Recommending cost-saving substitutions (e.g., using ASTM A576 free-machining steel for complex turned parts)

Flagging tolerance conflicts with carbon steel’s thermal expansion characteristics

Clients receive a detailed DFM report with actionable suggestions. Typical carbon steel cost reductions from DFM range from 18–35% by minimizing machining time and scrap.

Production Execution

Approved carbon steel orders enter our production ecosystem with material-specific protocols:

Raw material verification via handheld XRF spectrometry to confirm alloy composition

CNC machining using carbide tooling optimized for carbon steel’s chip formation characteristics

In-process inspections measuring critical dimensions affected by carbon steel’s springback behavior

Mandatory post-machining rust prevention (e.g., Cosmoline coating) before assembly or finishing

Delivery and Logistics

Final inspection includes material certification traceability (MTRs) and dimensional validation per ASME Y14.5. Carbon steel parts undergo humidity-controlled packaging to prevent oxidation during transit. Delivery timelines account for carbon steel-specific processes like stress-relieving or tempering. Clients receive real-time shipment tracking with carbon steel handling specifications for unloading.

Key Carbon Steel Pricing Factors

The table below summarizes variables impacting final cost:

| Factor | Impact on Carbon Steel Cost | Honyo Mitigation Strategy |

|---|---|---|

| Alloy Grade Selection | 1045 costs 12–18% more than 1018 due to manganese content | DFM-guided grade optimization without compromising performance |

| Part Geometry Complexity | Thin walls (<3mm) increase scrap rate by 22% | Generative design suggestions for self-supporting features |

| Secondary Operations | Welding + stress-relieving adds 35–50% to base cost | Consolidated operations in single fixture setup |

| Surface Finish Requirements | Machined Ra 0.8µm costs 2.1x Ra 3.2µm | Alternative finishing methods recommendation |

This integrated approach ensures carbon steel pricing reflects actual production physics rather than arbitrary markups. By anchoring quotes in measurable material behaviors and process capabilities, we eliminate cost overruns and deliver predictable lead times for carbon steel components.

Start Your Project

Stay ahead of the market with up-to-date carbon steel pricing from Honyo Prototype. As a trusted manufacturing partner with our own facility in Shenzhen, we offer competitive, transparent pricing without delays.

For accurate quotes and material availability, contact Susan Leo directly at [email protected]. Let us support your next project with precision, speed, and cost-efficient solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.