Contents

Manufacturing Insight: Carbon Steel Material

Carbon Steel Material Capabilities for Precision CNC Machining at Honyo Prototype

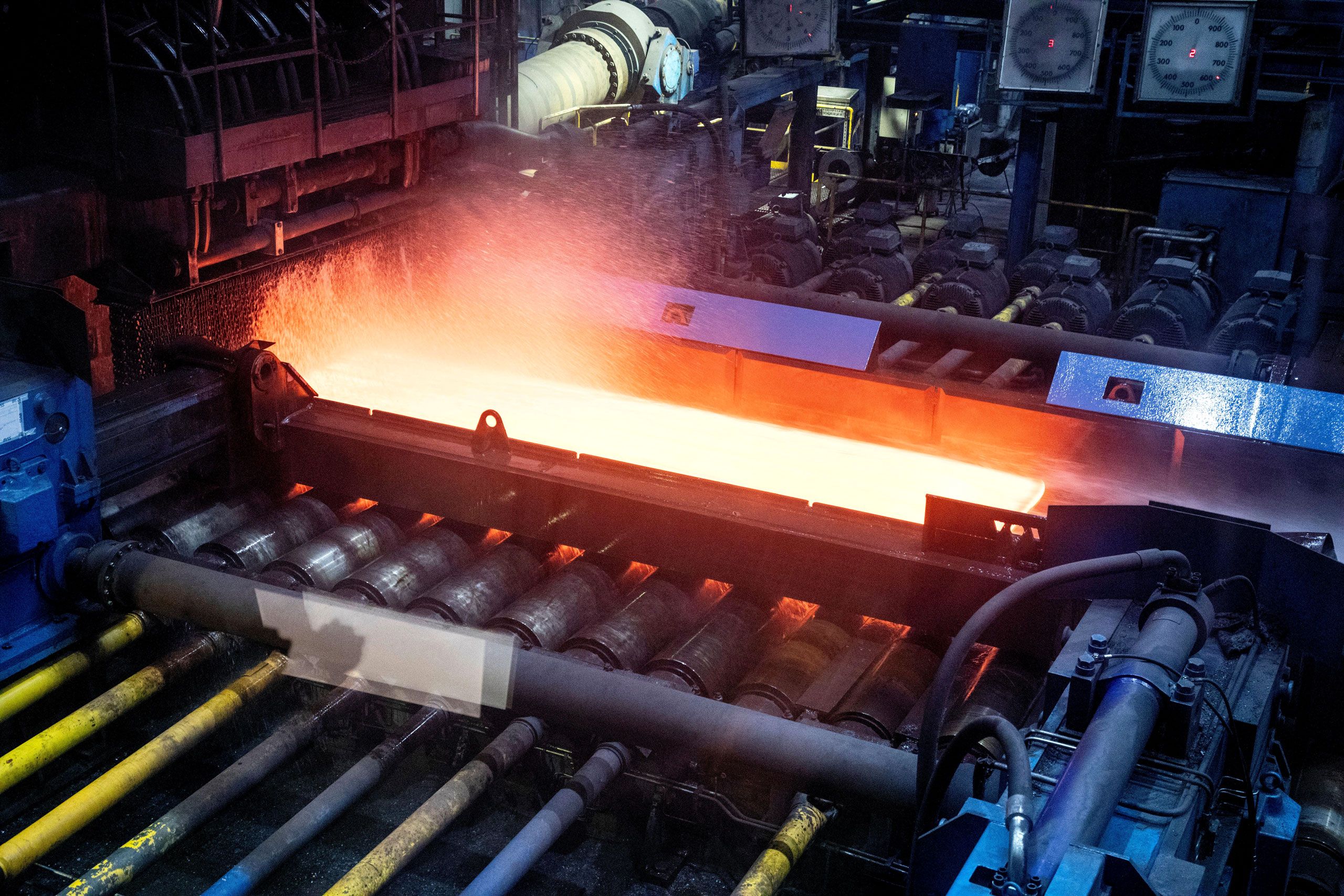

Carbon steel remains a cornerstone material in industrial manufacturing due to its exceptional balance of strength, weldability, and cost-effectiveness. At Honyo Prototype, we leverage our advanced CNC machining infrastructure to transform carbon steel grades—including 1018, 1045, and A36—into mission-critical components with micron-level precision. Our expertise spans complex geometries, tight-tolerance features, and high-volume production runs, ensuring consistent mechanical properties and surface integrity for applications ranging from automotive assemblies to heavy machinery subsystems.

Optimized CNC Processes for Carbon Steel

Our facility utilizes state-of-the-art 3-, 4-, and 5-axis machining centers equipped with specialized tooling and coolant systems calibrated for carbon steel’s unique thermal and abrasive characteristics. This minimizes work-hardening risks, eliminates micro-fractures, and maintains dimensional stability across batches. All parts undergo rigorous in-process CMM validation against ASME Y14.5 standards, guaranteeing compliance with ISO 2768-mK tolerances or customer-specific requirements.

Accelerate Your Project Timeline

Eliminate traditional quoting delays with Honyo’s Online Instant Quote platform. Upload your carbon steel part CAD file (STEP, IGES, or native formats), specify material grade and finish requirements, and receive a comprehensive manufacturability analysis with pricing and lead time within minutes—not days. This seamless integration between engineering validation and production planning reduces time-to-prototype by up to 70% while ensuring design feasibility from the outset.

Partner with Honyo Prototype to convert carbon steel’s inherent durability into components that meet the highest benchmarks for performance and reliability. Our end-to-end CNC machining services, backed by real-time quoting transparency, deliver engineering-grade solutions without compromising speed or precision.

Technical Capabilities

Carbon Steel Material Technical Specifications for Precision Machining Applications

Carbon steel is a widely used engineering material known for its strength, durability, and machinability in high-precision manufacturing environments. In applications involving 3-axis, 4-axis, and 5-axis milling as well as CNC turning, carbon steel offers excellent dimensional stability and surface finish characteristics—especially when tight tolerances (±0.0005″ or tighter) are required. Below is a comparison of carbon steel with other commonly machined materials such as aluminum, steel alloys, ABS, and nylon, focusing on key technical properties relevant to complex machining processes.

| Material | Tensile Strength (MPa) | Hardness (HRC) | Machinability Rating (%) | Thermal Conductivity (W/m·K) | Typical Tolerance (± in) | Surface Finish (Ra, µm) | Best Suited For |

|---|---|---|---|---|---|---|---|

| Carbon Steel (e.g., 1045) | 570–700 | 20–25 | 60–70 | 52 | 0.0005–0.001 | 0.8–1.6 | High-strength components, shafts, tooling, tight-tolerance fixtures |

| Stainless Steel (e.g., 304) | 515–620 | 25–30 | 45–55 | 16 | 0.0005–0.001 | 0.8–2.0 | Corrosion-resistant parts, medical devices, aerospace fittings |

| Aluminum (e.g., 6061-T6) | 310 | 15 | 90–100 | 180 | 0.0005–0.001 | 0.4–1.2 | Lightweight structural parts, prototypes, aerospace enclosures |

| ABS (Thermoplastic) | 40–50 | <10 | 80 | 0.25 | 0.001–0.005 | 1.6–3.2 | Prototypes, jigs, low-wear components, non-structural parts |

| Nylon (Polyamide) | 70–80 | 8–12 | 70 | 0.25 | 0.001–0.005 | 1.6–3.2 | Insulating parts, gears, low-friction components |

Notes on Machining Performance:

Carbon steel, particularly grades like 1045 and 1018, provides a balanced combination of hardness and machinability, making it ideal for tight-tolerance milling and turning operations. It maintains dimensional accuracy under cutting forces typical in 4-axis and 5-axis CNC machining, where complex geometries and multi-sided features are common. Coolant use and proper tool selection (carbide or coated inserts) are recommended to minimize tool wear and prevent thermal deformation.

Aluminum offers superior machinability and thermal conductivity, enabling faster feed rates and excellent surface finishes, but lacks the strength and wear resistance of carbon steel in load-bearing applications. ABS and nylon are suitable for non-metallic prototypes or low-stress components but exhibit higher thermal expansion and lower dimensional stability, limiting their use in high-precision, tight-tolerance production.

For critical applications requiring repeatability and long-term durability under mechanical stress, carbon steel remains a preferred choice in both prototyping and end-use part manufacturing.

From CAD to Part: The Process

Honyo Prototype Carbon Steel Manufacturing Process Overview

Honyo Prototype delivers precision carbon steel components through a rigorously controlled digital workflow designed for speed, quality, and engineering collaboration. This process is optimized for carbon steel’s unique properties—including machinability, weldability, and susceptibility to corrosion—ensuring manufacturability and performance alignment with client specifications. Below is the end-to-end sequence for carbon steel parts.

CAD Upload and Initial Processing

Clients submit 3D CAD files (STEP, IGES, or native formats) via Honyo’s secure portal. Our system immediately validates file integrity, identifies geometric complexity, and extracts critical parameters such as material grade (e.g., AISI 1018, 1045, A36), required tolerances, and surface finish specifications. For carbon steel, we confirm compatibility with standard grades in our inventory and flag non-standard alloys for early consultation.

AI-Powered Quoting with Engineering Validation

Our AI engine generates a preliminary quote within 2 hours by analyzing part geometry, material utilization, and process requirements. For carbon steel, the AI factors in grade-specific variables: machining time (e.g., 1045’s higher hardness vs. 1018), welding complexity, and post-processing needs like powder coating or galvanization. Crucially, a Senior Manufacturing Engineer reviews all AI outputs to adjust for real-world constraints—such as avoiding thin-wall sections prone to warpage during carbon steel welding—and provides a validated quote with actionable lead time estimates.

Engineering-Driven DFM Analysis

DFM (Design for Manufacturability) is conducted by our in-house engineering team within 24 hours of quote acceptance. For carbon steel components, this phase focuses on:

Eliminating features that cause tool deflection or chatter in milling/turning (e.g., optimizing wall thicknesses above 1.5mm for rigidity)

Resolving weld joint designs that risk cracking in carbon steel (e.g., recommending chamfer angles per AWS D1.1)

Proposing cost-saving alternatives like simplifying bend sequences in sheet steel fabrication

Confirming heat treatment feasibility (e.g., normalizing or stress-relieving thick sections)

Clients receive a detailed DFM report with annotated CAD markups and collaborative recommendations before production release.

Precision Carbon Steel Production

Approved designs enter production with strict adherence to carbon steel protocols:

Machining: Performed on CNC mills/turns with carbide tooling optimized for carbon steel (e.g., reduced feed rates for 1045 vs. 1018). Tolerances held to ±0.05mm standard.

Fabrication: Laser cutting, bending, and MIG/TIG welding executed per ASME Section IX. All welds inspected via visual and dye penetrant testing.

Finishing: Deburring, shot blasting, and client-specified coatings (e.g., zinc plating for corrosion resistance) applied. Material traceability (mill certs) maintained throughout.

Real-time production tracking is accessible via client portal, with critical hold points for first-article inspection.

Quality-Controlled Delivery

All carbon steel parts undergo final validation against AS9102 or client-specific FAIR requirements. This includes:

Dimensional verification via CMM for critical features

Material hardness testing (e.g., Rockwell B for low-carbon grades)

Surface roughness validation per ISO 1302

Packaging employs VCI paper and desiccants to prevent oxidation during transit. Shipments include full documentation: COC, mill test reports, and inspection records. Standard lead time from DFM approval is 7–12 business days, with expedited options available.

This integrated process ensures carbon steel components meet mechanical performance requirements while minimizing rework risks—translating design intent into reliable, production-ready hardware. Honyo’s engineering oversight at each phase mitigates common carbon steel pitfalls, from thermal distortion to weld defects, delivering parts that perform in demanding applications.

Start Your Project

Looking for high-quality carbon steel material for your next project? Honyo Prototype offers precision manufacturing with reliable material sourcing, backed by our in-house production facility in Shenzhen.

Contact Susan Leo today at [email protected] to discuss your carbon steel requirements and receive expert support tailored to your prototyping or production needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.