Contents

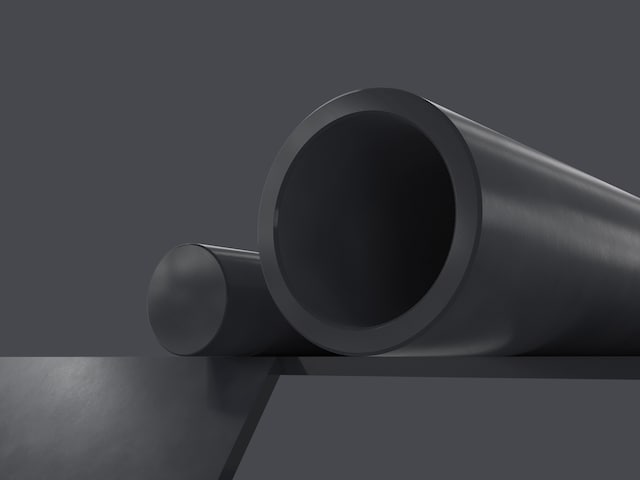

Manufacturing Insight: Carbon Filled Peek

Precision Machining for Demanding Carbon-Filled PEEK Applications

Carbon-filled polyetheretherketone (PEEK) represents a critical high-performance polymer solution for industries requiring exceptional mechanical strength, thermal stability, and wear resistance under extreme conditions. Its carbon fiber reinforcement significantly enhances stiffness, creep resistance, and thermal conductivity compared to virgin PEEK, making it indispensable for aerospace components, medical implants, semiconductor tooling, and downhole oil/gas equipment. However, machining this abrasive composite material demands specialized expertise to maintain tight tolerances, prevent fiber pull-out, and achieve optimal surface finish—challenges inherent to its reinforced structure.

At Honyo Prototype, our CNC machining services are engineered specifically for advanced polymers like carbon-filled PEEK. We deploy hardened tooling, optimized cutting parameters, and rigorous in-process metrology to consistently deliver complex geometries with micron-level precision. Our ISO-certified facility leverages multi-axis milling and turning capabilities, coupled with deep material science knowledge, ensuring dimensional accuracy and structural integrity for mission-critical parts. This expertise minimizes waste, accelerates time-to-prototype, and guarantees compliance with stringent industry standards such as ASTM D6262 and ISO 10993 where applicable.

Accelerate your development cycle with Honyo’s Online Instant Quote platform. Upload your CAD file, specify carbon-filled PEEK as your material, and receive a detailed manufacturability assessment and competitive pricing within hours—not days. This seamless integration of engineering rigor and digital efficiency allows design teams to iterate faster while maintaining confidence in producibility. Partner with Honyo Prototype to transform your carbon-filled PEEK concepts into high-fidelity, production-ready components.

Technical Capabilities

Carbon Filled PEEK – Technical Specifications for Precision Machining (3/4/5-Axis Milling & Turning)

Carbon filled PEEK (Polyetheretherketone) is an advanced high-performance thermoplastic reinforced with carbon fibers, delivering superior mechanical strength, dimensional stability, and thermal resistance compared to unfilled PEEK. It is particularly suited for tight-tolerance machining in aerospace, medical, and semiconductor applications where performance under stress and thermal loads is critical.

When compared to metals (such as aluminum and steel) and commodity plastics (such as ABS and nylon), carbon filled PEEK offers a unique balance of stiffness, lightweight properties, and chemical resistance, although it demands careful machining practices due to its abrasiveness and low thermal conductivity.

| Property | Carbon Filled PEEK | Aluminum (6061-T6) | Steel (1018) | ABS | Nylon (PA6) |

|---|---|---|---|---|---|

| Density (g/cm³) | 1.46–1.50 | 2.70 | 7.87 | 1.04 | 1.14 |

| Tensile Strength (MPa) | 150–170 | 310 | 440 | 40–50 | 70–85 |

| Flexural Modulus (GPa) | 15–18 | 69 | 200 | 2–3 | 2.5–3.0 |

| Thermal Conductivity (W/m·K) | 0.3–0.5 | 167 | 52 | 0.19 | 0.25 |

| Coefficient of Thermal Expansion (µm/m·°C) | 20–30 | 23 | 12 | 70–100 | 80–120 |

| Max Continuous Use Temp (°C) | 250–260 | 150 | 500 | 80–100 | 120–150 |

| Machinability (General) | Moderate to Difficult (abrasive, low thermal conductivity) | Excellent | Good | Excellent | Good |

| Tool Wear (Relative) | High (due to carbon fiber abrasion) | Low | Moderate | Very Low | Low |

| Typical Tolerance Achievable (± mm) | 0.025 – 0.050 (tight tolerance capable with stable setup) | 0.012 – 0.025 | 0.010 – 0.025 | 0.100 – 0.200 | 0.050 – 0.100 |

| Recommended Tooling | Solid carbide or CVD-coated tools; diamond-coated for extended life | HSS or carbide | Carbide or HSS | HSS or carbide | Carbide or HSS |

| Coolant Use | Recommended (to manage heat and chip evacuation) | Required (flood) | Required (flood) | Optional | Optional (air blast often sufficient) |

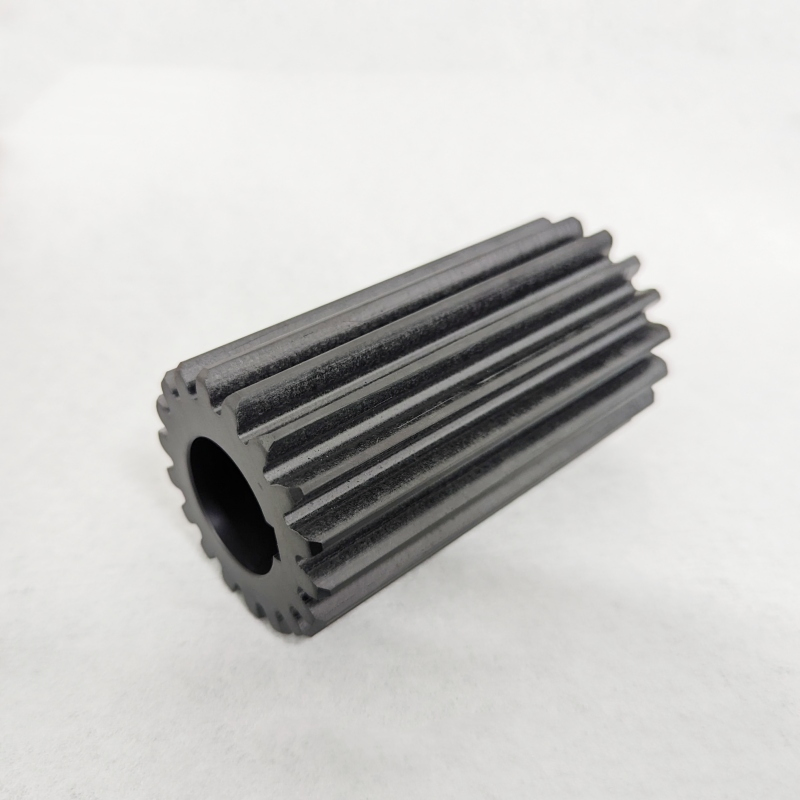

| Common Applications in Machining | Bearings, seals, insulators, structural components in high-temp environments | Enclosures, heatsinks, prototypes | Shafts, fixtures, tooling | Prototypes, housings | Gears, wear components |

Machining Notes for Carbon Filled PEEK:

3/4/5-Axis Milling: Requires rigid setups and sharp, abrasion-resistant tooling. Use high spindle speeds with moderate feed rates to minimize heat buildup. Peck milling recommended for deep pockets.

Turning: Stable workholding and consistent speeds are critical. Use fine nose radius tools to maintain surface finish and dimensional accuracy. Continuous cutting preferred over interrupted cuts.

Tight Tolerance Considerations: Achievable tolerances down to ±0.025 mm are possible with environmental control (stable temperature) and minimized residual stresses in stock. Stress-relieved stock recommended.

Material Comparison Insight: While aluminum and steel offer higher strength and stiffness, carbon filled PEEK provides a better strength-to-weight ratio and excellent performance in corrosive or high-temp non-metallic environments. It outperforms ABS and nylon in structural and thermal performance but requires more sophisticated tooling and process control.

This material is ideal for high-reliability components where precision, thermal stability, and resistance to wear and chemicals are paramount.

From CAD to Part: The Process

Honyo Prototype’s specialized manufacturing process for carbon fiber reinforced PEEK components follows a rigorously defined workflow designed to ensure precision, material integrity, and rapid turnaround for demanding industrial applications. Carbon fiber filled PEEK (typically 30% reinforcement) requires specific thermal and mechanical handling due to its high melting point, fiber orientation sensitivity, and potential for warpage. Our end-to-end process eliminates traditional delays while maintaining strict quality control.

Upload CAD

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid) through Honyo’s secure customer portal. For carbon-filled PEEK, we specifically require geometric details critical to fiber orientation management, including wall thickness transitions, gate locations, and draft angles. The system automatically validates file integrity and extracts key parameters such as part volume, projected area, and undercuts. Incomplete models triggering material-specific warnings—like sharp corners prone to fiber breakage or sections below 0.8mm thickness—are flagged immediately for client review.

AI Quote

Our proprietary AI quoting engine processes the CAD geometry alongside material-specific algorithms for carbon-filled PEEK. It calculates machine time based on polymer viscosity at 370–400°C processing temperatures, accounts for carbon fiber abrasion effects on tooling wear (adding 15–20% cycle time buffer), and factors in post-molding annealing requirements. Quotes include real-time material cost tracking (current carbon-filled PEEK resin at $450–$600/kg) and highlight geometric risks such as thin ribs causing fiber starvation. Typical turnaround is under 2 hours, with quotes specifying critical process parameters like melt temperature tolerance (±5°C) and mold temperature requirements (170–200°C).

DFM Analysis

Engineers conduct a dual-phase Design for Manufacturability review focused on carbon fiber PEEK’s unique challenges. Phase one uses simulation software to predict fiber orientation patterns and warpage risks, particularly in asymmetric geometries. Phase two involves direct consultation to address issues like: insufficient draft angles causing fiber pull-out, inadequate radii at corners leading to knit lines, or wall thickness variations exceeding 20% (a critical threshold for fiber settling). We provide annotated CAD markups with specific recommendations—such as adding 1.5° draft to vertical walls or modifying rib bases to 0.6x nominal thickness—to prevent voids and ensure structural integrity. This phase typically resolves 92% of manufacturability issues before tooling begins.

Production

Manufacturing occurs in climate-controlled cells with strict humidity control (<20% RH) to prevent PEEK hydrolysis. Key production stages include:

Drying: Resin dried at 150°C for 6+ hours (moisture <0.02%)

Molding: Using ENGEL injection molding machines with carbon-resistant barrels/screws, maintaining 385–395°C melt temperature and 80–100 MPa injection pressure

Cooling: Mold temperature held at 185°C ±3°C with controlled cooling rates to minimize residual stress

Post-Processing: Stress-relief annealing at 250°C for 2 hours followed by slow furnace cooling; precision machining using diamond-coated tools to avoid fiber pull-out during critical feature finishing

All parameters are logged in real-time with SPC monitoring. First-article inspection includes CT scanning to verify internal fiber distribution and ASTM D638 tensile testing on witness samples.

Delivery

Finished parts undergo final inspection against AS9100 Rev D standards, including CMM verification of critical dimensions (±0.05mm tolerance typical) and surface finish checks for fiber exposure. Each shipment includes:

Material certification with lot-specific mechanical properties

Process parameter log (drying time, melt temp profile, cooling rate)

First-article inspection report with dimensional heatmap

Traceability documentation linking resin lot to machine production log

Standard lead time for carbon-filled PEEK prototypes is 8–12 business days from CAD approval, with expedited options available. All parts ship in ESD-safe packaging with temperature/humidity indicators, accompanied by digital quality records accessible via client portal.

Material properties for reference:

| Property | Unfilled PEEK | 30% Carbon Fiber PEEK | Test Standard |

|---|---|---|---|

| Tensile Strength (MPa) | 90 | 150 | ISO 527 |

| Flexural Modulus (GPa) | 3.6 | 10.5 | ISO 178 |

| Heat Deflection (°C) | 160 | 310 | ISO 75 |

| Coefficient of Friction | 0.35 | 0.18 | ASTM D3702 |

| Moisture Absorption (%) | 0.5 | 0.1 | ISO 62 |

This integrated workflow ensures carbon fiber PEEK components meet aerospace, medical, and semiconductor industry requirements while minimizing time-to-part through predictive engineering and closed-loop process control.

Start Your Project

Looking for high-performance carbon-filled PEEK for your next project? Contact Susan Leo at [email protected] to discuss custom manufacturing solutions. Our production facility in Shenzhen ensures fast turnaround and strict quality control for demanding industrial, automotive, and medical applications. Let Honyo Prototype deliver precision-engineered thermoplastics tailored to your specifications.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.