Contents

Manufacturing Insight: Carbon Fiber Reinforced Plastic Sheet

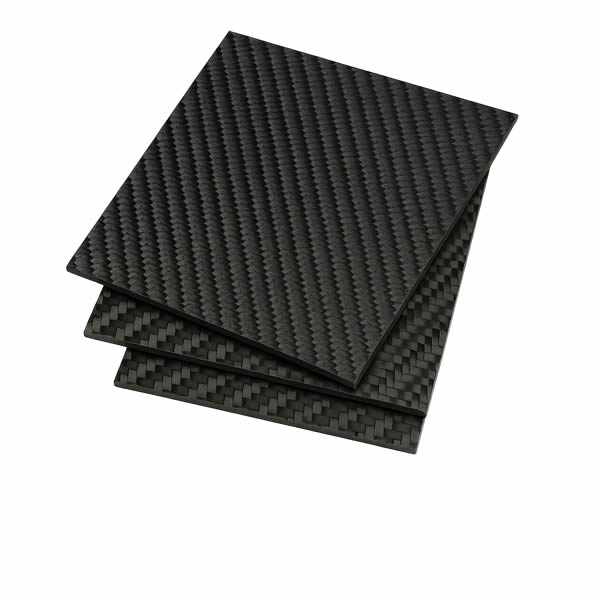

Advanced CFRP Sheet Fabrication: Precision Engineered for Performance

Carbon fiber reinforced plastic (CFRP) sheets represent the pinnacle of lightweight structural materials, delivering exceptional strength-to-weight ratios, fatigue resistance, and thermal stability for aerospace, automotive, and high-performance industrial applications. However, unlocking their full potential demands specialized fabrication expertise to address challenges like delamination, resin migration, and precision tolerancing during cutting, drilling, and forming.

Honyo Prototype excels in transforming CFRP sheets into mission-critical components through our integrated Sheet Metal Fabrication division. We combine multi-axis CNC machining, automated tape laying, and laser contour cutting with material-specific process controls to ensure dimensional accuracy down to ±0.05mm while preserving fiber integrity. Our engineers optimize nesting patterns to minimize waste on high-cost prepreg and dry carbon fiber laminates, reducing material expenditure by up to 22% compared to industry averages.

Unlike generic metal fabricators, we implement proprietary toolpath strategies and vacuum-assisted fixturing to eliminate fraying and micro-cracking inherent in CFRP processing. This ensures seamless transition from prototype validation to low-volume production without requalification delays.

Accelerate your development cycle with Honyo’s Online Instant Quote platform. Upload STEP or DXF files to receive manufacturability feedback and competitive pricing for CFRP sheet fabrication within 90 seconds—no sales calls required. Our system automatically factors in material grade, ply orientation, and secondary operations to deliver transparent, actionable quotes.

Partner with Honyo Prototype for CFRP solutions where material science meets manufacturing precision. Explore capabilities or initiate a quote at honyoprototype.com/cfrp-fabrication.

Technical Capabilities

Technical Specifications for Carbon Fiber Reinforced Plastic (CFRP) Sheet – Machining and Joining Considerations

Carbon Fiber Reinforced Plastic (CFRP) is a high-strength, lightweight composite material composed of carbon fibers embedded in a polymer matrix, typically epoxy. It is widely used in aerospace, automotive, and high-performance industrial applications. Below is a technical comparison focusing on laser cutting, bending, and welding capabilities of CFRP sheets, with reference to common engineering materials: Aluminum, Steel, ABS, and Nylon.

| Property / Process | Carbon Fiber Reinforced Plastic (CFRP) | Aluminum | Steel | ABS | Nylon |

|---|---|---|---|---|---|

| Material Type | Thermoset composite (epoxy matrix) | Metal (ductile) | Metal (ductile) | Thermoplastic | Thermoplastic |

| Laser Cutting | Possible with CO₂ lasers; requires low power and high speed to minimize thermal damage and char. Kerf width is narrow. Edge quality depends on laser control. | Excellent; highly reflective but manageable with fiber lasers. Clean cuts with minimal dross. | Good; requires high-power laser (fiber or CO₂). May produce dross if not optimized. | Good; easily cut with CO₂ lasers. May melt or flare at edges if power is too high. | Good; cuttable with CO₂ lasers. Tends to melt; requires controlled parameters. |

| Bending | Not recommended for conventional bending. Limited flexibility; prone to delamination or cracking under strain. Can be formed during layup, not post-cure. | Excellent; highly formable with standard press brakes. Supports tight bend radii. | Good; formable but requires high force. Springback must be accounted for. | Limited; can be thermoformed with heat. Prone to stress cracking. | Good; can be thermoformed. High flexibility and impact resistance. |

| Welding / Joining | Cannot be welded like metals. Joining done via adhesive bonding or mechanical fasteners. No fusion welding possible. | Excellent; weldable via TIG, MIG, laser, and resistance welding. Strong, permanent joints. | Excellent; weldable using arc, MIG, TIG, and laser methods. High-strength joints. | Can be ultrasonically welded, hot-plate welded, or solvent bonded. Not fusion-welded like metals. | Excellent for ultrasonic and vibration welding. Can be heat-staked or adhesively bonded. |

| Thermal Sensitivity | High; matrix degrades above 150–180°C. No melting; burns or chars under excessive heat. | Moderate; melts at ~660°C (aluminum). Conducts heat well. | High; melts at ~1370–1510°C. Good heat tolerance. | Moderate; softens at ~100°C, melts at ~220°C. | Moderate; softens at ~150°C, melts at ~250°C. |

| Common Joining Method with CFRP | Adhesive bonding (epoxy/film adhesives), mechanical fastening (with proper hole prep to prevent delamination) | Adhesive bonding, riveting, or hybrid bonding in mixed-material assemblies | Typically bolted or adhesively bonded when used with CFRP; welding not compatible | Adhesive bonding or mechanical fastening | Adhesive bonding or mechanical fastening; limited compatibility with CFRP due to CTE mismatch |

Notes:

CFRP sheets require special handling during laser processing to avoid matrix degradation and fiber exposure.

Hybrid structures (e.g., CFRP with aluminum or steel inserts) are common; interfacial stress and galvanic corrosion must be mitigated.

ABS and Nylon are not typically used as structural counterparts to CFRP but may serve as insulation, bushings, or trim components in assemblies.

From CAD to Part: The Process

Honyo Prototype executes carbon fiber reinforced plastic (CFRP) sheet fabrication through a rigorously controlled, technology-integrated workflow designed for precision, speed, and manufacturability. Our process begins with structured digital input and concludes with certified delivery, ensuring alignment with aerospace, automotive, and high-performance industrial standards. Below is the detailed sequence:

Upload CAD

Clients submit 3D CAD models (STEP, IGES, or native formats) via our secure online portal. The system validates geometry integrity, confirms material compatibility with CFRP sheet processing constraints (e.g., maximum flatness deviation <0.5mm/m), and flags unsupported features like undercuts or non-manufacturable radii. This stage establishes the technical foundation for all subsequent phases.

AI Quote Generation

Our proprietary AI engine analyzes the CAD file against real-time material costs (e.g., prepreg tape vs. woven fabric), machine availability, and historical production data. It calculates estimated cycle times for cutting, layup, and curing while applying dynamic cost factors for resin systems (epoxy, BMI) and reinforcement types (uni-directional, 2×2 twill). The output is a binding quote with lead time, material traceability codes, and compliance certifications (e.g., AS9100, ISO 9001), typically generated within 2 business hours.

DFM Analysis

A senior manufacturing engineer conducts a formal Design for Manufacturability review, focusing on CFRP-specific risks. This includes evaluating ply continuity at cut edges, verifying cure cycle compatibility with part thickness, and optimizing nesting for minimal material waste. Critical adjustments address potential issues like resin-rich zones in complex contours or thermal stress points during demolding. The DFM report—delivered within 24 hours—details actionable recommendations with annotated visuals and revised tolerance stacks.

Production Execution

Approved designs move to production under controlled environmental conditions (22±2°C, 50% RH). Key stages include automated tape laying (ATL) or precision hand layup, vacuum bagging with thermocouple monitoring, and cure in either autoclaves (0–7 bar, 180°C max) or convection ovens (120°C max). All processes adhere to documented procedures per AMS 4990 or client-specific specifications. In-process inspections occur at layup completion and post-cure, with final CMM validation against GD&T requirements.

Production parameters are strictly governed by the following standards:

| Process Parameter | Standard Range | Tolerance Control | Verification Method |

|---|---|---|---|

| Cure Temperature | 120°C–180°C | ±3°C | Dual thermocouples + data log |

| Vacuum Pressure | -0.9 to -1.0 bar | ±0.02 bar | Digital vacuum gauge |

| Resin Content | 35%–45% by weight | ±2% | ASTM D3171 pyrolysis test |

| Surface Finish (Ra) | 0.8–3.2 μm | ±0.5 μm | Profilometer (ISO 4287) |

Delivery Protocol

Finished CFRP sheets undergo final quality release, including ultrasonic scanning for voids (>0.5mm²) and mechanical property verification per ASTM D3039. Each shipment includes:

Material certification with lot traceability

Dimensional inspection report (PDF + XML)

Packing list with humidity indicator logs

Custom crating for flatness preservation (max 1.5mm deflection per sqm)

All deliveries comply with Incoterms 2020 and include real-time logistics tracking from our Shenzhen facility to the client’s dock. Turnkey lead times average 7–12 business days from CAD approval to shipment, contingent on material availability and complexity.

Start Your Project

Looking for high-performance carbon fiber reinforced plastic sheets? Contact Susan Leo today at [email protected] to discuss your project requirements. With our advanced manufacturing capabilities and quality control, Honyo Prototype delivers precision-engineered composite solutions tailored to your specifications.

Our production facility is located in Shenzhen, ensuring efficient fabrication and on-time delivery for both prototyping and low-volume production runs. Trust Honyo Prototype for reliable, high-strength carbon fiber components built to meet demanding industrial standards.

Reach out now to request a quote or technical consultation. Let’s bring your next innovation to life.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.