Introduction: Navigating the Global Market for carbon fiber drill bits

In today’s competitive landscape, sourcing high-quality carbon fiber drill bits is crucial for businesses aiming to enhance their manufacturing processes and product quality. However, navigating the global market presents challenges, particularly in ensuring that the selected tools meet the specific demands of drilling carbon fiber, a material known for its strength and complexity. This comprehensive guide aims to equip international B2B buyers—particularly those from Africa, South America, the Middle East, and Europe, including key markets like Saudi Arabia and Brazil—with the insights needed to make informed purchasing decisions.

Throughout this guide, we will explore various types of carbon fiber drill bits, their specific applications, and the importance of selecting the right tools for optimal performance. Additionally, we will delve into effective supplier vetting strategies, cost considerations, and best practices for maintaining drill bit integrity. By addressing these critical aspects, this guide empowers businesses to not only enhance operational efficiency but also reduce costs associated with tool wear and material wastage. Understanding the intricacies of carbon fiber drilling will ensure that you can confidently source the best tools, ultimately leading to improved production outcomes and a competitive edge in the marketplace.

Understanding carbon fiber drill bits Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| High-Speed Steel (HSS) | Economical, sharp but dulls quickly; suitable for low volume | General drilling tasks in composite materials | Pros: Low cost; widely available. Cons: Short lifespan; may lead to poor hole quality. |

| Carbide-Tipped Bits | Durable, coated with carbide; better longevity than HSS | Medium to high volume drilling operations | Pros: Longer-lasting; better performance. Cons: Higher cost; requires careful handling. |

| Solid Carbide Bits | Extremely durable, designed for high RPM; brittle | Precision drilling in high-end applications | Pros: Excellent hole quality; can drill many holes. Cons: Fragile; costly; requires a drill press. |

| Diamond Coated Bits | Specialized for carbon fiber; excellent for clean cuts | High-precision applications in aerospace | Pros: Superior cutting performance; minimizes fraying. Cons: Very expensive; limited availability. |

| Forstner Bits | Flat-bottomed, designed for clean holes; limited to specific sizes | Furniture and cabinetry applications | Pros: Produces clean holes; good for specific applications. Cons: Not ideal for all carbon fiber types; limited shank size. |

What Are the Characteristics of High-Speed Steel (HSS) Drill Bits for Carbon Fiber?

High-speed steel (HSS) drill bits are often the first choice for businesses looking to drill carbon fiber due to their affordability. These bits are sharp when new but tend to dull quickly, especially when used on tougher materials like carbon fiber. They are best suited for low-volume tasks where cost is a critical factor. However, frequent replacements may be necessary, which can ultimately lead to higher operational costs.

How Do Carbide-Tipped Bits Enhance Drilling Efficiency?

Carbide-tipped drill bits offer a substantial upgrade over HSS bits, providing better durability and longevity. These bits are ideal for medium to high-volume drilling operations, making them suitable for manufacturers and workshops that require consistent performance. While they come at a higher price point, their ability to withstand wear and tear makes them a more cost-effective solution in the long run, especially for businesses engaged in frequent drilling tasks.

Why Choose Solid Carbide Bits for Precision Drilling?

Solid carbide drill bits are the premium option for drilling carbon fiber, particularly in applications requiring high precision. These bits can handle high RPMs and are designed to create clean holes with minimal fraying. However, they are brittle and should only be used with a drill press to avoid breakage. For businesses in sectors such as aerospace or advanced manufacturing, investing in solid carbide bits can lead to significant improvements in product quality and efficiency.

What Are the Benefits of Using Diamond Coated Bits?

Diamond-coated drill bits are specifically engineered for drilling carbon fiber and are celebrated for their exceptional cutting capabilities. They produce clean holes and minimize the risk of splintering, making them ideal for high-precision applications in industries such as aerospace and automotive. While the initial investment is considerable, the long-term benefits in terms of reduced waste and enhanced product quality justify the cost for many businesses.

When Should You Use Forstner Bits in Carbon Fiber Applications?

Forstner bits are designed to create flat-bottomed holes and are often used in woodworking applications. While they can be effective for drilling carbon fiber in specific scenarios, such as cabinetry or furniture making, they are not universally applicable. Their limited shank size and the potential for rough edges make them less desirable for high-performance carbon fiber applications. Businesses should assess their specific needs before choosing this type of bit.

Key Industrial Applications of carbon fiber drill bits

| Industry/Sector | Specific Application of carbon fiber drill bits | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Drilling holes in carbon fiber composite parts for aircraft | Enhanced structural integrity and weight reduction | Certifications for aerospace-grade materials, supplier reliability, and precision engineering capabilities |

| Automotive | Creating lightweight components in high-performance vehicles | Improved fuel efficiency and vehicle performance | Availability of specialized drill bits for various carbon fiber thicknesses, cost-effectiveness, and durability |

| Marine | Fabricating carbon fiber hulls and components for boats | Increased speed and reduced drag in water | Resistance to corrosion, high precision in hole placement, and compatibility with marine-grade materials |

| Sports Equipment | Manufacturing carbon fiber gear such as bicycles and tennis rackets | Enhanced performance and reduced overall weight | Customization options for specific designs, sourcing from reputable manufacturers, and quality control measures |

| Construction & Infrastructure | Installing carbon fiber reinforcements in structural applications | Increased strength and longevity of structures | Compliance with local building regulations, sourcing from certified suppliers, and availability of technical support |

How Are Carbon Fiber Drill Bits Used in Aerospace Applications?

In the aerospace industry, carbon fiber drill bits are essential for creating precise holes in composite materials used in aircraft structures. These bits ensure that the integrity of the composite is maintained, preventing delamination and structural weaknesses. Buyers in this sector must prioritize suppliers who offer aerospace-grade materials and can guarantee precision engineering to meet stringent safety standards. Additionally, understanding the specific certifications required for aerospace applications is crucial for international buyers, particularly in regions like the Middle East and Europe.

What Role Do Carbon Fiber Drill Bits Play in Automotive Manufacturing?

In automotive manufacturing, carbon fiber drill bits are utilized to create lightweight components that contribute to high-performance vehicles. The ability to drill clean, accurate holes is vital for assembling parts that enhance fuel efficiency and overall vehicle performance. Buyers should consider the durability and cost-effectiveness of drill bits, as well as their suitability for varying carbon fiber thicknesses. Sourcing from manufacturers with a proven track record in automotive applications, especially in markets like Brazil and South Africa, can significantly impact production efficiency.

How Are Carbon Fiber Drill Bits Beneficial in Marine Applications?

Marine manufacturers employ carbon fiber drill bits to fabricate components such as hulls and structural elements in boats. The lightweight nature of carbon fiber, combined with precision drilling, allows for increased speed and reduced drag, critical factors in marine design. Buyers must ensure that the drill bits are resistant to corrosion and capable of providing high precision in hole placement. Understanding the specific requirements for marine-grade materials and sourcing from reputable suppliers will help businesses in this sector optimize their production processes.

In What Ways Do Carbon Fiber Drill Bits Enhance Sports Equipment Manufacturing?

In the sports equipment sector, carbon fiber drill bits are crucial for producing lightweight, high-performance gear such as bicycles and tennis rackets. The use of these drill bits allows manufacturers to create designs that improve performance while reducing overall weight. Buyers should focus on customization options to meet specific design requirements and ensure that they source from manufacturers with stringent quality control measures. This is particularly important for international buyers looking to maintain competitive advantages in diverse markets.

Why Are Carbon Fiber Drill Bits Important in Construction and Infrastructure?

In construction and infrastructure, carbon fiber drill bits are used to install reinforcements in structural applications, enhancing the strength and longevity of buildings and bridges. The precision of these bits is critical for ensuring that the reinforcements are securely placed, which contributes to overall structural integrity. Buyers should be aware of local building regulations and ensure compliance when sourcing these tools. Additionally, selecting suppliers who provide technical support can help streamline the integration of carbon fiber solutions in construction projects.

3 Common User Pain Points for ‘carbon fiber drill bits’ & Their Solutions

Scenario 1: Struggling with Bit Durability and Lifespan

The Problem: One of the most significant challenges for B2B buyers of carbon fiber drill bits is the rapid wear and tear of standard drill bits. Many companies find that traditional high-speed steel (HSS) bits dull quickly when drilling carbon fiber, leading to increased operational costs due to frequent replacements and the risk of poor-quality holes. This not only affects production efficiency but also compromises the integrity of the components being manufactured, which can lead to costly reworks and delays.

The Solution: To mitigate this issue, businesses should invest in carbide-tipped or solid carbide drill bits specifically designed for carbon fiber applications. These types of bits are engineered to withstand the abrasive nature of carbon fiber, providing a longer lifespan and cleaner cuts. When sourcing these bits, it is essential to consider suppliers that offer high-quality, specialized tools, such as McMaster-Carr or industrial tool distributors. Additionally, implementing proper drilling techniques—such as maintaining high RPMs (between 3,000-5,000) and a low feed rate—can significantly enhance the performance of these bits, reducing wear and increasing the number of holes drilled per bit.

Scenario 2: Managing Health and Safety Risks During Drilling

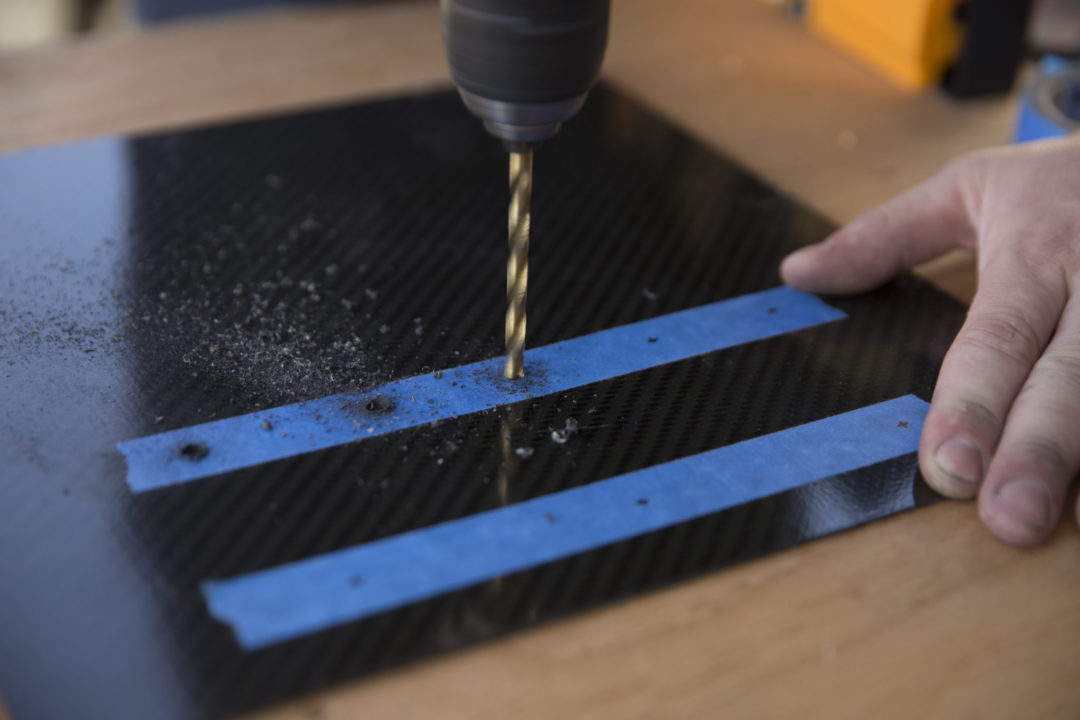

The Problem: Drilling carbon fiber generates fine dust particles that pose health risks, including respiratory issues and skin irritation. For companies in manufacturing and construction, ensuring worker safety while maintaining productivity is a critical concern. Inadequate safety measures can lead to employee health problems and potential legal liabilities, creating a challenging environment for management to navigate.

The Solution: Businesses must prioritize the health and safety of their workforce by implementing comprehensive safety protocols. This includes providing personal protective equipment (PPE) such as dust masks or respirators, gloves, and protective clothing. Furthermore, investing in effective dust extraction systems, such as downdraft tables or shop vacuums, can significantly reduce airborne particles. Training employees on the importance of safety measures and best practices for drilling carbon fiber will foster a culture of safety and enhance overall operational efficiency.

Scenario 3: Achieving Precision in Drilling for Complex Designs

The Problem: Many B2B buyers face difficulties in achieving precise and clean holes when drilling intricate designs in carbon fiber materials. In sectors like aerospace and automotive, where precision is paramount, using the wrong drill bits or techniques can lead to fraying, delamination, or misaligned holes, jeopardizing the quality and performance of the final product.

The Solution: To ensure precision in drilling, companies should adopt specific techniques and tools tailored for carbon fiber. Using masking tape on the drilling surface can help prevent fraying by providing a stabilizing layer for the drill bit. Additionally, employing specialized brad-point or forstner bits that are designed for clean cuts will minimize splintering and ensure accuracy. Furthermore, integrating CNC drilling machines can provide automated precision and consistency, allowing for complex designs to be executed flawlessly. Regular training and quality checks should also be conducted to ensure that all personnel are skilled in these techniques, ultimately leading to higher quality outputs and reduced waste.

Strategic Material Selection Guide for carbon fiber drill bits

When selecting materials for carbon fiber drill bits, it is crucial to consider the properties and performance characteristics that will best suit the specific applications and environments in which these tools will be used. Here, we analyze four common materials used in the manufacturing of carbon fiber drill bits, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

What are the Key Properties of High-Speed Steel (HSS) Drill Bits?

High-Speed Steel (HSS) is a prevalent material for drill bits due to its excellent hardness and ability to withstand high temperatures without losing its temper. HSS bits typically maintain their cutting edge at temperatures up to 600°C, making them suitable for drilling carbon fiber, albeit with limitations. They are also relatively resistant to corrosion, which is beneficial in humid or variable climates.

Pros: HSS drill bits are affordable and widely available, making them a popular choice for general use. They are easy to manufacture and can be sharpened multiple times, extending their lifespan.

Cons: The primary limitation of HSS bits is their tendency to dull quickly when drilling harder materials like carbon fiber. They may only last for a limited number of holes before requiring replacement, which can increase overall costs for high-volume applications.

How Do Carbide-Tipped Drill Bits Enhance Performance?

Carbide-tipped drill bits feature a steel body with tips made from carbide, a material known for its hardness and wear resistance. These bits can maintain sharpness longer than HSS bits, making them ideal for drilling carbon fiber composites, especially in applications requiring precision.

Pros: Carbide-tipped bits offer a significant improvement in durability and performance over HSS bits. They can handle higher speeds and feed rates, which is advantageous when drilling carbon fiber.

Cons: While more durable, carbide-tipped bits are more expensive than HSS options. Additionally, they can be brittle, making them prone to chipping if not used correctly, particularly in handheld applications.

What Makes Solid Carbide Drill Bits the Best Option?

Solid carbide drill bits are designed for high-performance applications, particularly when drilling into tough materials like carbon fiber. They are made entirely from carbide, providing exceptional hardness and the ability to withstand high RPMs without losing their cutting edge.

Pros: These bits can achieve clean, precise holes with minimal fraying or splintering, making them suitable for high-quality applications. They also have a longer lifespan compared to HSS and carbide-tipped bits, often lasting for hundreds of holes.

Cons: The main drawback is their high cost and fragility. Solid carbide bits require a rigid setup, such as a drill press, to prevent breakage during use. This can limit their usability in some environments.

What Role Do Diamond-Coated Drill Bits Play in Carbon Fiber Applications?

Diamond-coated drill bits are equipped with a layer of industrial diamond on their cutting edges, providing superior hardness and wear resistance. These bits excel in creating clean holes in carbon fiber and other composites.

Pros: The diamond coating allows for exceptional cutting performance, reducing the risk of delamination and ensuring clean holes. They are ideal for high-precision applications and can operate at high speeds.

Cons: The cost of diamond-coated bits is significantly higher than other types, which may deter some buyers. Additionally, they can be less effective on softer materials, making them specialized tools rather than general-purpose options.

Summary Table of Material Properties

| Material | Typical Use Case for carbon fiber drill bits | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High-Speed Steel (HSS) | General drilling applications | Affordable and widely available | Dulls quickly in hard materials | Low |

| Carbide-Tipped | Precision drilling in composites | Longer lifespan than HSS | Brittle and more expensive | Medium |

| Solid Carbide | High-performance drilling | Exceptional durability and precision | High cost and requires rigid setup | High |

| Diamond-Coated | High-precision applications | Superior cutting performance | Very high cost and specialized use | High |

This strategic material selection guide provides B2B buyers with actionable insights into the various materials available for carbon fiber drill bits, helping them make informed decisions based on their specific needs and operational contexts. Understanding the properties, pros, and cons of each material will enable buyers to select the most suitable drill bits for their applications, ensuring efficiency and quality in their operations.

In-depth Look: Manufacturing Processes and Quality Assurance for carbon fiber drill bits

What Are the Key Stages in the Manufacturing Process of Carbon Fiber Drill Bits?

The manufacturing of carbon fiber drill bits involves several critical stages, ensuring that the end product meets the specific demands of various industries. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of high-quality raw materials, primarily tungsten carbide or diamond, for the cutting tips. These materials are chosen for their hardness and durability, essential for drilling through tough composites like carbon fiber. The materials are then processed into fine powders through milling, which ensures a consistent grain size for optimal performance.

-

Forming: The prepared powders are mixed with a binder to create a composite material that can be shaped. This mixture is then subjected to a process called pressing, where it is compacted into the desired drill bit shape using hydraulic presses. The pressed bits are then subjected to a sintering process, where they are heated in a controlled environment to form a solid, dense structure. This stage is crucial, as it determines the hardness and toughness of the drill bits.

-

Assembly: In some cases, drill bits may require additional components, such as shanks or specialized coatings. These parts are assembled using precision techniques to ensure alignment and durability. The assembly process may also include the integration of cooling channels or other features designed to enhance performance during drilling.

-

Finishing: The final stage involves surface treatments, such as coating the bits with titanium or diamond, to enhance their wear resistance and reduce friction. This stage often includes precision grinding to achieve the required tolerances and sharpness. Rigorous cleaning processes ensure that no contaminants affect the performance of the drill bits.

How Is Quality Assurance Implemented in the Production of Carbon Fiber Drill Bits?

Quality assurance (QA) in the manufacturing of carbon fiber drill bits is paramount for ensuring that products meet international standards and customer expectations. The QA process typically adheres to recognized international standards, such as ISO 9001, which provides a framework for maintaining high-quality production processes.

-

International and Industry-Specific Standards: Manufacturers often comply with various standards, including CE marking for European markets and API specifications for oil and gas applications. These certifications not only enhance product credibility but also ensure that the manufacturing processes align with safety and performance benchmarks.

-

Quality Control Checkpoints: The QA process includes several checkpoints to monitor quality throughout the production stages:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards. This includes checks on material composition, purity, and physical properties.

– In-Process Quality Control (IPQC): During manufacturing, various parameters such as temperature, pressure, and dimensional tolerances are monitored. This ensures that any deviations are detected and corrected promptly.

– Final Quality Control (FQC): Once the drill bits are completed, they undergo a series of tests to verify their performance characteristics, including hardness, sharpness, and durability. -

Common Testing Methods for Carbon Fiber Drill Bits: Various testing methods are employed to assess the quality of carbon fiber drill bits:

– Performance Testing: Drill bits are tested for their cutting efficiency and wear resistance through standardized drilling tests on carbon fiber and other composite materials.

– Dimensional Inspection: Precision measurement tools are used to ensure that the drill bits meet specified dimensions and tolerances.

– Visual Inspection: A thorough visual inspection helps identify any surface defects or inconsistencies that could affect performance.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is essential to ensure reliable product performance.

-

Conducting Audits: Buyers can request audits of the supplier’s manufacturing facilities. These audits can reveal insights into the production processes, quality assurance practices, and adherence to international standards. A transparent audit process demonstrates the supplier’s commitment to quality.

-

Reviewing Quality Assurance Reports: Suppliers should provide comprehensive quality assurance documentation, including reports from IQC, IPQC, and FQC stages. These reports should detail testing methods, results, and any corrective actions taken in response to quality issues.

-

Utilizing Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These inspections can be particularly useful for ensuring compliance with international standards and identifying potential risks in the supply chain.

-

Understanding Certification Nuances: Buyers should be aware of the specific certifications relevant to their markets. For instance, CE marking is crucial for products sold in Europe, while API certifications may be necessary for oil and gas applications. Understanding these nuances helps buyers assess the credibility and reliability of their suppliers.

What Challenges Do International Buyers Face in Quality Assurance?

International buyers often encounter unique challenges when it comes to quality assurance in the procurement of carbon fiber drill bits. These challenges can include:

-

Regulatory Differences: Different regions may have varying regulations regarding product safety and quality standards. Buyers must navigate these complexities to ensure compliance with local laws and market requirements.

-

Communication Barriers: Language differences and cultural misunderstandings can hinder effective communication between buyers and suppliers, potentially leading to misinterpretations of quality expectations.

-

Logistical Issues: Shipping and logistics can impact the timely delivery of quality-assured products. Buyers must consider the supply chain dynamics and potential delays that can affect their operations.

-

Supplier Reliability: Establishing long-term relationships with reliable suppliers is crucial. Buyers should conduct thorough due diligence to assess the supplier’s reputation, financial stability, and commitment to quality.

By understanding the manufacturing processes and quality assurance practices associated with carbon fiber drill bits, B2B buyers can make informed decisions that align with their operational needs and enhance their overall procurement strategies.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘carbon fiber drill bits’

In the competitive landscape of B2B procurement, sourcing high-quality carbon fiber drill bits requires a systematic approach. This checklist serves as a comprehensive guide for international buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, to ensure they acquire the right tools for their specific applications.

Step 1: Define Your Technical Specifications

Understanding the specific requirements of your project is crucial. Identify the type of carbon fiber material you will be drilling, the hole size, and the volume of holes required. This will help narrow down the appropriate drill bit types, such as solid carbide, carbide-tipped, or high-speed steel (HSS), and ensure compatibility with your existing equipment.

Step 2: Research Drill Bit Types and Their Applications

Not all drill bits are created equal. Familiarize yourself with the various types of drill bits suitable for carbon fiber, including:

– Solid carbide bits: Best for high precision but require a rigid setup.

– Carbide-tipped bits: Offer durability and are suitable for moderate use.

– HSS bits: Cost-effective but may dull quickly with frequent use.

Understanding these distinctions will guide you in selecting the most effective tools for your needs.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, thoroughly vet potential suppliers. Look for:

– Company profiles: Review their experience in supplying carbon fiber drill bits.

– Certifications: Verify industry certifications that ensure quality standards.

– References: Request case studies or testimonials from buyers in similar industries.

This diligence helps ensure you partner with reliable suppliers who can meet your quality and service expectations.

Step 4: Request Samples for Testing

Before making a bulk purchase, request samples to test in your operational environment. This step is essential to assess the performance of the drill bits, including their cutting efficiency and durability on your specific carbon fiber material. Conduct tests under various conditions to ensure the bits meet your quality standards.

Step 5: Inquire About Technical Support and After-Sales Service

A supplier that offers robust technical support can be invaluable. Inquire about:

– Training: Do they provide guidance on optimal use and maintenance?

– Customer service: What support is available post-purchase for troubleshooting?

Having access to technical resources can enhance your operational efficiency and reduce downtime.

Step 6: Review Pricing and Payment Terms

Pricing structures can vary significantly between suppliers. Ensure you:

– Compare costs: Look at the total cost of ownership, including shipping and handling.

– Understand payment terms: Clarify terms like deposits, discounts for bulk purchases, and payment timelines.

This will help you make an informed financial decision that aligns with your budget.

Step 7: Establish a Long-Term Relationship

Building a strong relationship with your supplier can lead to better pricing, priority service, and access to new products. Discuss potential for volume discounts or loyalty programs. Establishing a partnership can provide ongoing support as your needs evolve.

By following this checklist, B2B buyers can effectively navigate the procurement process for carbon fiber drill bits, ensuring they select the right tools for their applications while fostering valuable supplier relationships.

Comprehensive Cost and Pricing Analysis for carbon fiber drill bits Sourcing

What Are the Key Cost Components in Carbon Fiber Drill Bit Production?

The cost structure for carbon fiber drill bits is influenced by several key components, which can vary significantly based on supplier capabilities and manufacturing processes.

-

Materials: High-quality raw materials such as carbide and diamond are crucial for producing durable drill bits. The cost of these materials can fluctuate based on market demand and availability. For instance, solid carbide bits generally offer superior longevity but come at a higher price compared to high-speed steel (HSS) options.

-

Labor: Skilled labor is essential in the manufacturing process, especially when producing specialized drill bits. Labor costs can vary by region, impacting the overall pricing structure. Countries with higher labor costs may produce drill bits at a premium, while those with lower labor costs can offer more competitive pricing.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and equipment maintenance. Advanced manufacturing technologies, such as CNC machines, can increase overhead costs but also enhance precision and efficiency.

-

Tooling: The initial investment in tooling can be substantial, particularly for custom or high-specification drill bits. Tooling costs are typically amortized over production runs, meaning larger orders can lead to lower per-unit costs.

-

Quality Control (QC): Ensuring the drill bits meet stringent quality standards requires investment in QC processes. This can add to the cost but is essential to prevent defects and ensure customer satisfaction.

-

Logistics: Transportation costs can significantly impact pricing, especially for international buyers. Factors such as shipping methods, distances, and tariffs must be considered.

-

Margin: Suppliers will include their profit margin in the final price, which can vary based on competition, brand reputation, and market positioning.

How Do Price Influencers Affect Carbon Fiber Drill Bit Costs?

Several factors can influence the pricing of carbon fiber drill bits, making it essential for buyers to understand these dynamics.

-

Volume/MOQ: Minimum Order Quantities (MOQs) can affect pricing significantly. Higher volume orders typically lead to better pricing due to economies of scale.

-

Specifications and Customization: Custom drill bits tailored to specific applications can command a higher price. Buyers should assess whether standard options meet their needs to avoid unnecessary costs.

-

Material Quality and Certifications: Drill bits that meet industry certifications or are made from premium materials will generally be priced higher. Buyers should weigh the benefits of quality against their budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a history of quality may charge more but could save costs in the long run through fewer defects.

-

Incoterms: Understanding Incoterms is vital for international transactions, as they define the responsibilities of buyers and sellers in terms of shipping costs and risks. Choosing the right Incoterms can significantly affect the total cost.

What Buyer Tips Can Enhance Cost-Efficiency for Carbon Fiber Drill Bits?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency in sourcing carbon fiber drill bits.

-

Negotiation: Engaging in price negotiations can yield favorable terms. Buyers should be prepared to discuss volume discounts and payment terms to optimize their costs.

-

Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the TCO, which includes maintenance, replacement frequency, and performance. Investing in higher-quality bits may result in lower overall costs due to reduced downtime and fewer replacements.

-

Leverage Local Suppliers: Sourcing from local suppliers can reduce shipping costs and lead times, making it a viable option for many buyers.

-

Market Research: Conduct thorough market research to compare prices and quality across different suppliers. Understanding the market landscape can empower buyers to make informed decisions.

-

Stay Informed on Trends: Keeping abreast of industry trends and technological advancements can help buyers identify innovative products that may offer better performance or cost savings.

Disclaimer on Indicative Prices

It is important to note that prices for carbon fiber drill bits can vary widely based on the factors discussed above. This analysis provides indicative pricing insights, but buyers should request specific quotes from suppliers to obtain accurate pricing tailored to their needs.

Alternatives Analysis: Comparing carbon fiber drill bits With Other Solutions

Introduction: Understanding Alternatives in Drilling Solutions

When it comes to drilling carbon fiber, the choice of tools can significantly impact the outcome of your project. While carbon fiber drill bits are specifically designed for this task, there are several alternative solutions available that may also meet the needs of various applications. This analysis will compare carbon fiber drill bits with alternative drilling methods, helping international B2B buyers make informed decisions based on performance, cost, and other essential factors.

Comparison Table

| Comparison Aspect | Carbon Fiber Drill Bits | Cobalt Drill Bits | Diamond-Coated Drill Bits |

|---|---|---|---|

| Performance | Excellent; minimizes fraying and delamination | Good; can dull quickly but effective for limited use | Superior; ideal for high precision and durability |

| Cost | Moderate to high | Low to moderate | High; typically more expensive |

| Ease of Implementation | Requires specific setup and technique | Easy to use with standard drills | Requires specialized equipment; best with drill presses |

| Maintenance | Low; durable with proper use | Moderate; frequent replacements needed | Low; long-lasting if used correctly |

| Best Use Case | Large volume production or high precision work | General drilling in metal applications | High-end applications requiring precision, such as aerospace |

Detailed Breakdown of Alternatives

Cobalt Drill Bits

Cobalt drill bits are made from a steel alloy that includes cobalt, providing increased heat resistance and durability. While they can be an effective solution for drilling carbon fiber, they tend to dull more quickly than specialized carbon fiber bits. They are suitable for general use in metal but may struggle with the unique properties of carbon fiber, leading to fraying. Their lower cost makes them an attractive option for companies with limited budgets, but frequent replacements can offset initial savings.

Diamond-Coated Drill Bits

Diamond-coated drill bits offer superior performance when drilling through hard materials, including carbon fiber. They provide an exceptional cut quality and durability, making them ideal for precision work. However, they require a rigid setup, such as a drill press, to avoid breaking, which can limit their ease of use. Additionally, their higher price point may be a barrier for some businesses, especially those in emerging markets. Nonetheless, for high-end applications, the investment in diamond-coated bits can yield long-term savings through reduced wear and tear.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate drilling solution for carbon fiber depends on various factors, including project requirements, budget constraints, and operational capabilities. While carbon fiber drill bits are specifically engineered for the task, alternatives like cobalt and diamond-coated bits may provide viable options depending on the context of use. B2B buyers should assess their specific needs—such as volume, precision, and cost efficiency—when making their choice. By understanding the strengths and weaknesses of each alternative, businesses can ensure they invest in the right tools to optimize their operations and deliver high-quality results.

Essential Technical Properties and Trade Terminology for carbon fiber drill bits

What are the Key Technical Properties of Carbon Fiber Drill Bits?

When sourcing carbon fiber drill bits, understanding their technical specifications is crucial for ensuring optimal performance and longevity. Below are some essential properties that B2B buyers should consider:

-

Material Composition

Carbon fiber drill bits are typically made from high-speed steel (HSS), carbide, or diamond. HSS bits are suitable for occasional use but may dull quickly. Carbide bits offer better durability and resistance to wear, making them ideal for frequent drilling. Solid carbide or diamond-tipped bits provide superior cutting performance but require precise handling due to their brittleness. -

Cutting Edge Geometry

The design of the cutting edge affects the efficiency and quality of the hole produced. For instance, brad-point bits have a pointed tip that allows for precise drilling, minimizing fraying and splintering. Understanding the geometry helps in selecting the right bit for specific applications, which is essential for maintaining production quality. -

Tolerance

Tolerance indicates the allowable variation in size from the specified dimension of the drill bit. Tight tolerances are critical in applications where precision is key, such as aerospace or automotive industries. Ensuring the bits meet the required tolerances can significantly reduce the risk of errors and enhance product integrity. -

Shank Size

The shank size of the drill bit is crucial for compatibility with drilling equipment. Common shank sizes are 1/4 inch and 1/2 inch, and choosing the correct size ensures a secure fit in the drill chuck. This factor is particularly important for maintaining drill stability and preventing bit slippage during operation. -

RPM Rating

Each type of drill bit has an optimal revolutions per minute (RPM) range for effective drilling. For carbon fiber, high RPMs (3,000-5,000) are recommended to prevent material delamination. Understanding the RPM ratings helps buyers choose the appropriate equipment to maximize efficiency and minimize tool wear. -

Coating Type

Some drill bits come with specialized coatings, such as titanium or cobalt, which enhance their lifespan and cutting capabilities. Coatings reduce friction and heat buildup during drilling, which is especially beneficial for high-performance applications. Selecting bits with the right coating can lead to significant cost savings over time.

What are Common Trade Terms Related to Carbon Fiber Drill Bits?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some key terms to know:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for sourcing high-quality drill bits that meet specific industry standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory management, especially for businesses looking to maintain a steady supply of drill bits without overstocking. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific products. This term is crucial for B2B transactions, as it initiates the procurement process and helps buyers compare costs and terms from different suppliers. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Familiarity with these terms helps businesses navigate cross-border transactions more effectively and avoid unexpected costs. -

Lead Time

Lead time refers to the period between placing an order and receiving the product. Understanding lead times is critical for supply chain management and ensuring that projects remain on schedule. -

Warranty Period

The warranty period is the duration during which a supplier guarantees the performance and quality of the drill bits. Knowing the warranty terms can provide peace of mind and protect against defects, making it an important consideration for B2B buyers.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing carbon fiber drill bits, enhancing their operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the carbon fiber drill bits Sector

Market Overview & Key Trends in Carbon Fiber Drill Bits

The carbon fiber drill bits market is experiencing significant growth driven by the increasing demand for lightweight and high-strength materials across various industries, including aerospace, automotive, and construction. The ongoing shift towards advanced manufacturing technologies, such as automation and precision drilling, is also shaping the landscape. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are seeking suppliers that can provide specialized drill bits designed for carbon fiber applications.

Emerging trends include the development of high-performance carbide and diamond-coated drill bits that offer enhanced durability and efficiency. These innovations not only reduce the frequency of tool replacement but also ensure cleaner cuts, minimizing material waste. Additionally, buyers are increasingly leveraging e-commerce platforms and digital marketplaces to source drill bits, facilitating access to a wider range of suppliers and competitive pricing. The integration of Artificial Intelligence (AI) in inventory management and supply chain logistics is further optimizing procurement processes, allowing companies to anticipate demand and streamline operations.

As environmental concerns grow, B2B buyers are prioritizing suppliers who demonstrate commitment to sustainability and ethical sourcing practices. This shift is prompting manufacturers to invest in greener technologies and materials, which can significantly influence purchasing decisions.

How Does Sustainability Impact the Sourcing of Carbon Fiber Drill Bits?

Sustainability is becoming a pivotal factor in the sourcing of carbon fiber drill bits. The environmental impact of manufacturing processes, including carbon emissions and resource consumption, is under scrutiny. B2B buyers are increasingly aware of the importance of ethical supply chains and are favoring suppliers that prioritize eco-friendly practices. This includes the use of sustainable materials and the implementation of waste reduction strategies in production.

Moreover, certifications such as ISO 14001 (Environmental Management) and the Global Reporting Initiative (GRI) are becoming essential for manufacturers looking to validate their sustainability claims. Buyers are encouraged to seek suppliers who possess these certifications, as they signify a commitment to reducing environmental footprints.

The demand for “green” materials is also rising. Manufacturers that utilize recycled carbon fiber or bio-based resins in their products can appeal to eco-conscious buyers. Additionally, innovations in production methods that minimize energy consumption and emissions are gaining traction, reflecting a broader industry trend towards sustainability.

Brief Evolution/History of Carbon Fiber Drill Bits

The history of carbon fiber drill bits can be traced back to the advancements in composite materials during the mid-20th century. Initially, drilling into carbon fiber was a challenge due to its unique properties, which required specialized tools and techniques. The introduction of carbide and diamond-coated drill bits in the 1980s marked a significant evolution, enabling cleaner and more efficient drilling processes.

Over the years, the industry has seen continuous innovation, driven by the growing applications of carbon fiber in high-performance sectors. Today, the market is characterized by a focus on high precision and durability, with advancements in bit design and material technology. As industries continue to embrace carbon fiber for its lightweight and strength characteristics, the development of specialized drill bits has become crucial for achieving optimal results in manufacturing and assembly processes.

Frequently Asked Questions (FAQs) for B2B Buyers of carbon fiber drill bits

-

How do I solve issues with drill bits dulling quickly when drilling carbon fiber?

To minimize the dulling of drill bits while drilling carbon fiber, consider using carbide or diamond-coated bits. These materials are specifically designed to withstand the unique challenges posed by carbon fiber, offering greater durability than standard high-speed steel (HSS) bits. Additionally, ensure that you are using a high RPM (3000-5000) and a slow feed rate to reduce friction, which can lead to overheating and premature dulling. Using a backing material can also help in achieving cleaner cuts and prolonging the life of your drill bits. -

What is the best drill bit type for drilling carbon fiber?

The best drill bits for carbon fiber are solid carbide or diamond bits, as they provide a clean cut and are durable enough for extensive use. Solid carbide bits excel in high-speed applications and maintain sharpness over numerous uses, while diamond bits can handle the toughest materials but require careful handling due to their brittleness. For less intensive tasks, carbide-tipped bits offer a balance between cost and performance, making them suitable for frequent drilling without frequent replacements. -

How can I ensure the quality of carbon fiber drill bits from suppliers?

When sourcing carbon fiber drill bits, it is essential to conduct thorough supplier vetting. Look for suppliers with a proven track record in manufacturing high-quality tools, and request samples to assess performance. Certifications such as ISO 9001 can indicate adherence to quality management standards. Additionally, inquire about their quality assurance processes, including material sourcing, production techniques, and final inspections, to ensure that the bits meet your specifications. -

What are common minimum order quantities (MOQs) for carbon fiber drill bits?

Minimum order quantities for carbon fiber drill bits can vary widely depending on the supplier and the type of bit. Generally, MOQs may range from 50 to 500 units for standard bits, while specialized or customized bits may have higher MOQs. It’s advisable to discuss your specific needs with potential suppliers to negotiate MOQs that align with your business requirements, especially if you are entering a new market or trying a new product line. -

What payment terms should I expect when sourcing carbon fiber drill bits internationally?

Payment terms for international purchases of carbon fiber drill bits can vary, but common practices include a partial upfront payment (often 30-50%) followed by the balance upon shipment or delivery. Some suppliers may offer letters of credit or payment through escrow services to ensure security for both parties. It is crucial to clarify payment terms upfront and consider factors such as currency fluctuations and transaction fees that might affect the overall cost. -

How do logistics and shipping impact the sourcing of carbon fiber drill bits?

Logistics and shipping are critical components when sourcing carbon fiber drill bits internationally. Factors such as shipping method, delivery time, and customs regulations can significantly influence the total cost and efficiency of your supply chain. Ensure you work with suppliers who have reliable logistics partners and understand the regulations in your country. Additionally, consider the shipping terms (e.g., FOB, CIF) to manage responsibilities and costs effectively. -

What customization options are available for carbon fiber drill bits?

Many suppliers offer customization options for carbon fiber drill bits, including specific sizes, coatings, and tip designs tailored to your application needs. Customization can enhance performance in specific drilling tasks, such as reducing splintering or improving precision. When discussing customization, provide detailed specifications and requirements to ensure that the supplier can meet your expectations and deliver bits that align with your operational needs. -

What safety measures should be taken when drilling carbon fiber?

Drilling carbon fiber can generate harmful dust, so implementing safety measures is essential. Always wear appropriate personal protective equipment (PPE), such as gloves, dust masks, and safety goggles, to protect against irritation and inhalation of dust particles. Ensure good ventilation in your workspace, and consider using a downdraft table or vacuum system to minimize dust accumulation. Proper handling and disposal of carbon fiber waste are also crucial for maintaining a safe working environment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Carbon Fiber Drill Bits Manufacturers & Suppliers List

1. McMaster – Carbon Fiber Drill Bits

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Carbon Fiber Drill Bits, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Knife Network – Carbide Drill Bits

Domain: knifenetwork.com

Registered: 2003 (22 years)

Introduction: Carbide drill bits for drilling carbon fiber; MA Ford Hi Roc straight flute bits averaging about $16 each; smaller bits at #55 and 1.5mm; cobalt bits used previously, lasting about 12 holes with the first 4-5 being good; carbide bits expected to last longer but at 3-4X the cost of cobalt; articles suggest an acute cutting angle to shear fibers, while straight flute is not recommended.

3. 121c Aileron – Carbon Fiber Deck

Domain: forum.esk8.news

Registered: 2017 (8 years)

Introduction: 121c Aileron – Deck made of carbon fiber; concerns about drilling through it; recommended drill bits: cobalt or carbide; HSS drill bits are usable but should be discarded after a few holes; drilling tips include using a backing material, pilot holes, high speed and low pressure, and ensuring ventilation due to harmful carbon fiber dust; safety precautions include wearing a respirator and gloves.

4. Accurate Shooter – Forstner Bit Recommendations

Domain: forum.accurateshooter.com

Registered: 2005 (20 years)

Introduction: 3/4 inch forstner bit recommended for drilling carbon fiber stock; shank size limited to 1/2 inch due to small drill press; forstner bits suggested for clean cuts; alternative suggestions include annular cutter, hole saw, and spade bit; importance of testing on scrap material emphasized; use of tape on surface to prevent chipping recommended.

5. Amana Tool – Solid Carbide Router Bits

Domain: amanatool.com

Registered: 1996 (29 years)

Introduction: Solid Carbide Carbon Graphite and Carbon Fiber Panel Cutting Router Bits – Designed for cutting composite, fiberglass, and phenolic materials. Industrial quality CNC router bits from Amana Tool.

6. Talk Composites – Carbon Fibre Cutting Solutions

Domain: talkcomposites.com

Registered: 2009 (16 years)

Introduction: Carbon fibre sheets can be cut and drilled using various tools. Recommended cutting tools include abrasive tools like Perma-Grit tools, slitting discs in grinders, and fine-toothed blades. Standard drill bits work well, with best results achieved at high speeds and low pressure. CNC machining methods such as CNC routing and water-jet cutting are common, with water-jet cutting being faster but chal…

7. Cloudy Nights – Precision Drilling Solutions

Domain: cloudynights.com

Registered: 2000 (25 years)

Introduction: 1. Diamond grinding wheel set – recommended for drilling carbon fiber foam sandwich. 2. Dremel tool – suggested for precision drilling. 3. Titanium nitride coated drill bits – recommended for larger holes (over 3/32). 4. Diamond Coated Brad Point drills – suggested for drilling carbon fiber. 5. Carbide drills – recommended for small diameters, to be used on a machine. 6. Plywood – advised to place…

Strategic Sourcing Conclusion and Outlook for carbon fiber drill bits

In the evolving landscape of industrial applications, the demand for high-quality carbon fiber drill bits is set to rise, driven by their unparalleled performance and durability. Buyers must prioritize strategic sourcing to ensure they procure the most effective tools tailored for specific needs. Understanding the distinctions between high-speed steel, carbide-tipped, and solid carbide options is crucial for optimizing drilling operations while minimizing costs and downtime.

Investing in quality drill bits not only enhances productivity but also reduces the frequency of replacements, ultimately leading to significant cost savings. Moreover, adopting best practices such as using appropriate PPE and maintaining optimal drilling conditions can greatly improve safety and output quality.

As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe explore sourcing options, it is essential to engage with reputable suppliers who understand local market dynamics and can provide expert guidance on the right tools for diverse applications. By leveraging strategic sourcing, businesses can position themselves for success in an increasingly competitive market. Embrace this opportunity to enhance your operational capabilities and drive growth through informed purchasing decisions.