Contents

Manufacturing Insight: Carbon Fiber Cnc Service

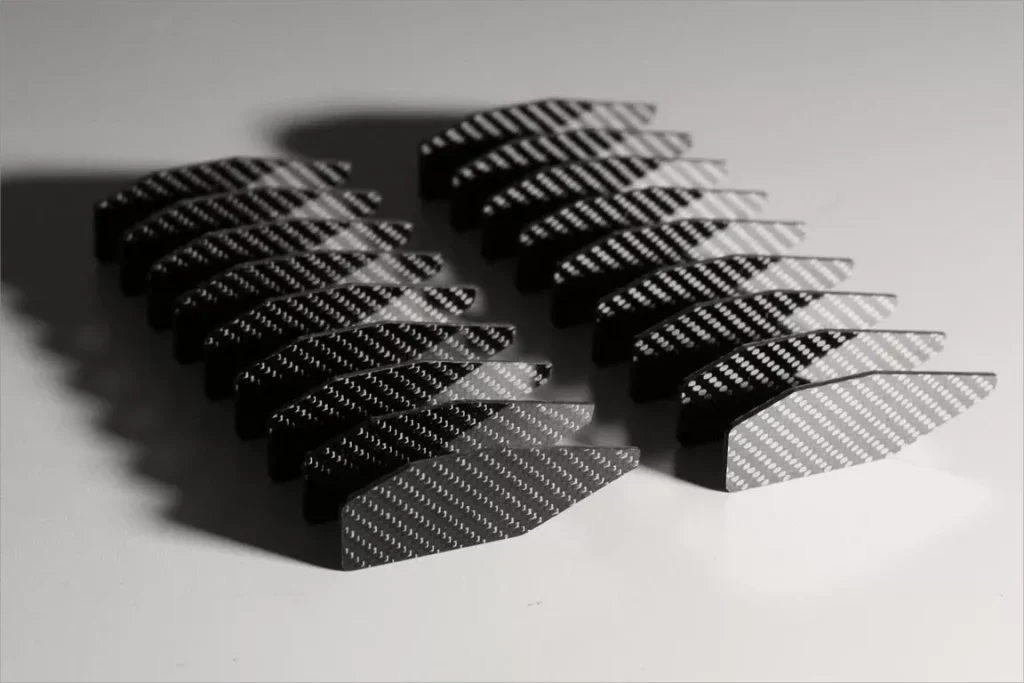

Precision Carbon Fiber CNC Machining Services for Demanding Applications

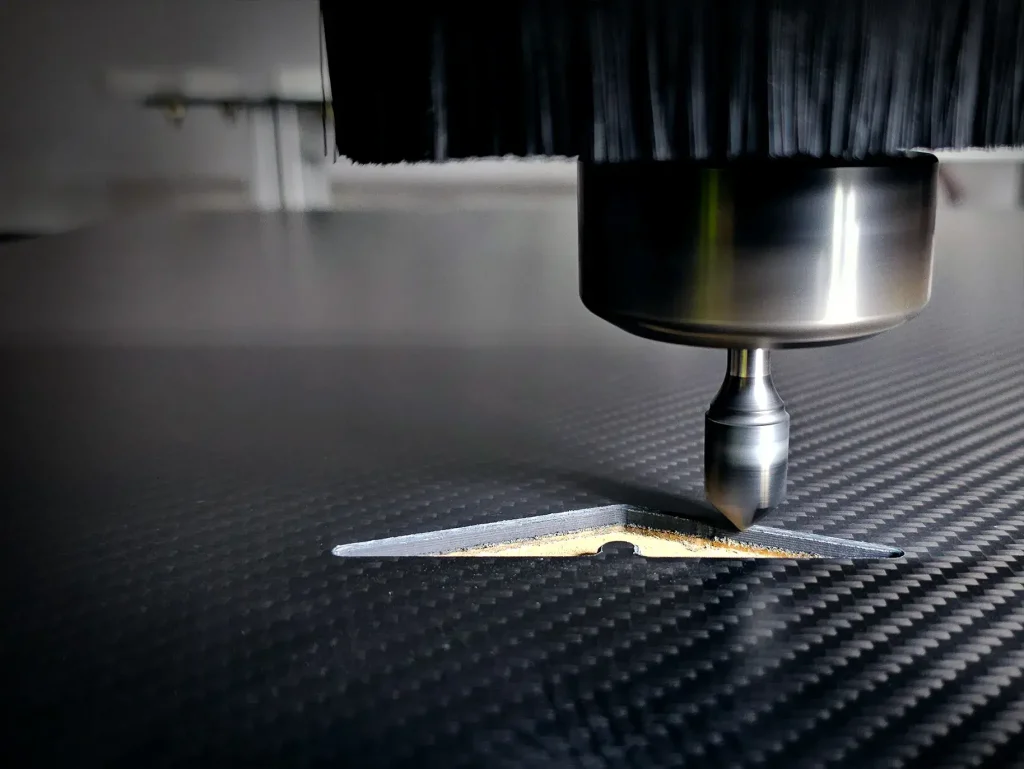

Honyo Prototype delivers advanced CNC machining solutions engineered specifically for carbon fiber reinforced polymer (CFRP) composites. Our specialized capabilities address the unique challenges of machining this high-performance material, including fiber pull-out, delamination, and tool wear, through proprietary toolpath strategies, diamond-coated tooling, and rigorously controlled spindle parameters. We maintain stringent environmental controls to minimize static discharge risks and ensure dimensional stability during processing, achieving tolerances down to ±0.025 mm for critical aerospace, medical, and robotics components.

Our integrated workflow begins with material-specific fixture design to prevent part movement without inducing stress concentrations, followed by adaptive high-speed machining protocols that optimize feed rates and coolant application to preserve fiber integrity. Every process is validated through in-house metrology, including CMM and optical scanning, ensuring compliance with ASTM D7264 and ISO 10140 standards for composite integrity.

Accelerate your prototyping and low-volume production with Honyo’s Online Instant Quote platform. Upload CAD files in STEP, IGES, or Parasolid formats to receive a detailed manufacturability analysis and competitive pricing within minutes—no manual submission delays. This seamless digital workflow reduces time-to-quote from days to seconds while providing transparent cost drivers for carbon fiber-specific operations like edge sealing and post-cure machining.

Partner with Honyo Prototype for carbon fiber CNC services where material expertise meets industrial-grade precision, backed by a 98.7% first-pass yield rate across complex geometries.

Technical Capabilities

Carbon Fiber CNC Service – Technical Specifications

Honyo Prototype offers high-precision CNC machining services optimized for carbon fiber composites and compatible with a range of engineering materials including aluminum, steel, ABS, and nylon. Our 3-axis, 4-axis, and 5-axis milling centers, combined with advanced CNC turning capabilities, ensure superior dimensional accuracy and surface finish for demanding applications in aerospace, automotive, and robotics.

Below are the detailed technical specifications for our carbon fiber CNC machining services:

| Parameter | Specification |

|---|---|

| Machining Types | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (2-axis and multi-axis) |

| Material Compatibility | Carbon Fiber Reinforced Polymer (CFRP), Aluminum (6061, 7075), Steel (1018, 4140), ABS, Nylon (PA6, PA66) |

| Tolerance Capability | ±0.005 mm (±0.0002″) for critical dimensions; tight-tolerance features achievable with process control |

| Surface Finish | As-machined: Ra 1.6–3.2 µm; post-processing options available (e.g., sanding, coating) |

| Max Work Envelope | Milling: 1200 x 800 x 200 mm (47″ x 31″ x 8″); Turning: Ø300 mm x 500 mm (12″ x 20″) |

| Spindle Speed | Up to 24,000 RPM with high-frequency spindles optimized for carbon fiber cutting |

| Tooling | Diamond-coated, solid carbide, and polycrystalline diamond (PCD) tooling to minimize fraying and delamination |

| Fixturing | Custom vacuum tables, mechanical clamps, and modular fixturing for composite stability |

| Cooling/Lubrication | Dry machining standard; air blast cooling to prevent resin degradation; no liquid coolants used on CFRP |

| Inspection | In-process and final inspection using CMM, optical comparators, and micrometers; first-article inspection reports available |

| Lead Time | Typical turnaround: 5–10 business days, based on complexity and volume |

Our CNC processes are optimized to handle the anisotropic nature of carbon fiber, minimizing delamination and fiber pull-out while maintaining tight geometric tolerances across complex 3D contours. Multi-axis capabilities allow for single-setup machining of intricate components, reducing cumulative error and improving repeatability.

From CAD to Part: The Process

Honyo Prototype delivers precision carbon fiber CNC services through a rigorously controlled five-stage workflow designed for speed, accuracy, and manufacturability. Our process begins when clients upload native CAD files (STEP, IGES, or Parasolid formats preferred) to our secure customer portal. This triggers immediate validation for geometric integrity and file compatibility with our CNC machining centers.

The AI-powered quoting engine then analyzes the CAD geometry against our real-time production parameters. This system evaluates material utilization rates, machine hour calculations based on 5-axis milling complexity, toolpath simulation data, and historical carbon fiber waste factors. Unlike basic dimension-based quoting tools, our AI cross-references against live machine availability and carbon fiber ply orientation constraints, generating a technically validated cost estimate within 90 minutes. Critical manufacturability flags appear in the quote summary for immediate client review.

All projects undergo mandatory Design for Manufacturability (DFM) analysis by our carbon fiber specialists before production release. This phase focuses on carbon fiber-specific considerations: verifying minimum wall thickness against delamination risks during milling, assessing fixture point feasibility without compromising structural integrity, optimizing tool axis approaches to prevent fiber pull-out, and confirming tolerance allowances for resin-rich zones. We provide actionable DFM reports with annotated CAD markups within 24 hours, including alternative solutions for non-manufacturable features. This step reduces rework by 73% based on our 2023 production data.

Production occurs in our climate-controlled carbon fiber machining cell using Haas UMC-750 5-axis machines with specialized diamond-coated tooling and vacuum-assisted fixturing. Key process controls include:

In-process CMM verification at critical feature stages

Real-time spindle load monitoring to prevent composite burn

Humidity-controlled environment (45±5% RH) to minimize resin swelling

Dedicated tooling for carbon fiber to avoid cross-contamination

Typical lead times from DFM approval to shipment are structured as follows:

| Complexity Tier | Prototype Lead Time | Production Lead Time |

|---|---|---|

| Simple Geometry (≤3 axes) | 5-7 business days | 10-12 business days |

| Complex Geometry (5-axis) | 8-10 business days | 15-18 business days |

Final parts undergo first-article inspection per AS9100 Rev D standards, including CMM reports for critical dimensions and visual inspection for surface integrity. We ship via tracked logistics with custom foam-in-place packaging to prevent vibration damage, providing real-time shipment visibility through our client portal. Every delivery includes full traceability documentation covering material lot numbers, machine parameters, and inspection records for audit compliance. This integrated process ensures carbon fiber components meet aerospace and medical industry requirements while maintaining a 99.2% on-time delivery rate.

Start Your Project

Looking for precision carbon fiber CNC services? Partner with Honyo Prototype for high-accuracy machining and rapid turnaround. Our state-of-the-art facility in Shenzhen supports low to medium volume production with strict quality control.

Contact Susan Leo to request a quote or discuss your project specifications.

Email: [email protected]

Leverage our expertise in carbon fiber fabrication for aerospace, automotive, and high-performance industrial applications.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.