Contents

Manufacturing Insight: Carbon Fiber Abs Plastic Sheet

Advanced Material Solutions for Precision Manufacturing

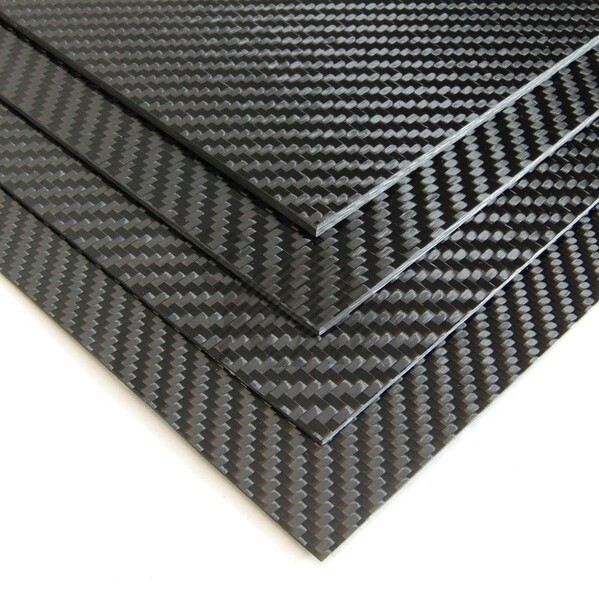

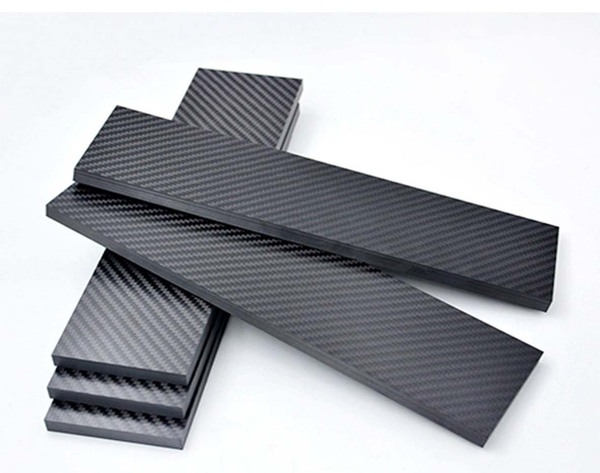

Honyo Prototype delivers engineered material expertise for demanding industrial applications, including high-performance Carbon Fiber Reinforced ABS Plastic Sheets. This composite material combines the structural rigidity and thermal stability of ABS thermoplastic with the exceptional strength-to-weight ratio of carbon fiber reinforcement, making it ideal for lightweight structural components, automotive prototypes, drone frames, and robotics enclosures where dimensional stability under load is critical. Unlike standard ABS, this variant significantly enhances stiffness and creep resistance while maintaining machinability and compatibility with rapid prototyping workflows.

Our Sheet Metal Fabrication services extend this precision to metal-based solutions, providing seamless integration for hybrid assemblies. Whether you require laser cutting, CNC punching, precision bending, or finishing for steel, aluminum, or stainless steel sheets, Honyo ensures tight tolerances (±0.1mm) and rapid turnaround for both prototyping and low-volume production. This capability allows engineers to develop cohesive multi-material systems—pairing carbon fiber ABS enclosures with sheet metal chassis, brackets, or shielding—without supply chain fragmentation.

Accelerate your design validation with Honyo’s Online Instant Quote platform. Upload your CAD files for carbon fiber ABS sheets or sheet metal components to receive a detailed, no-obligation cost assessment within minutes. This tool eliminates traditional RFQ delays, providing transparent pricing based on material selection, geometric complexity, and volume requirements—enabling faster iteration cycles and informed sourcing decisions for time-sensitive projects.

Partner with Honyo Prototype to leverage unified material and fabrication expertise, transforming complex designs into high-integrity functional prototypes and production-ready parts with engineering-grade reliability.

Technical Capabilities

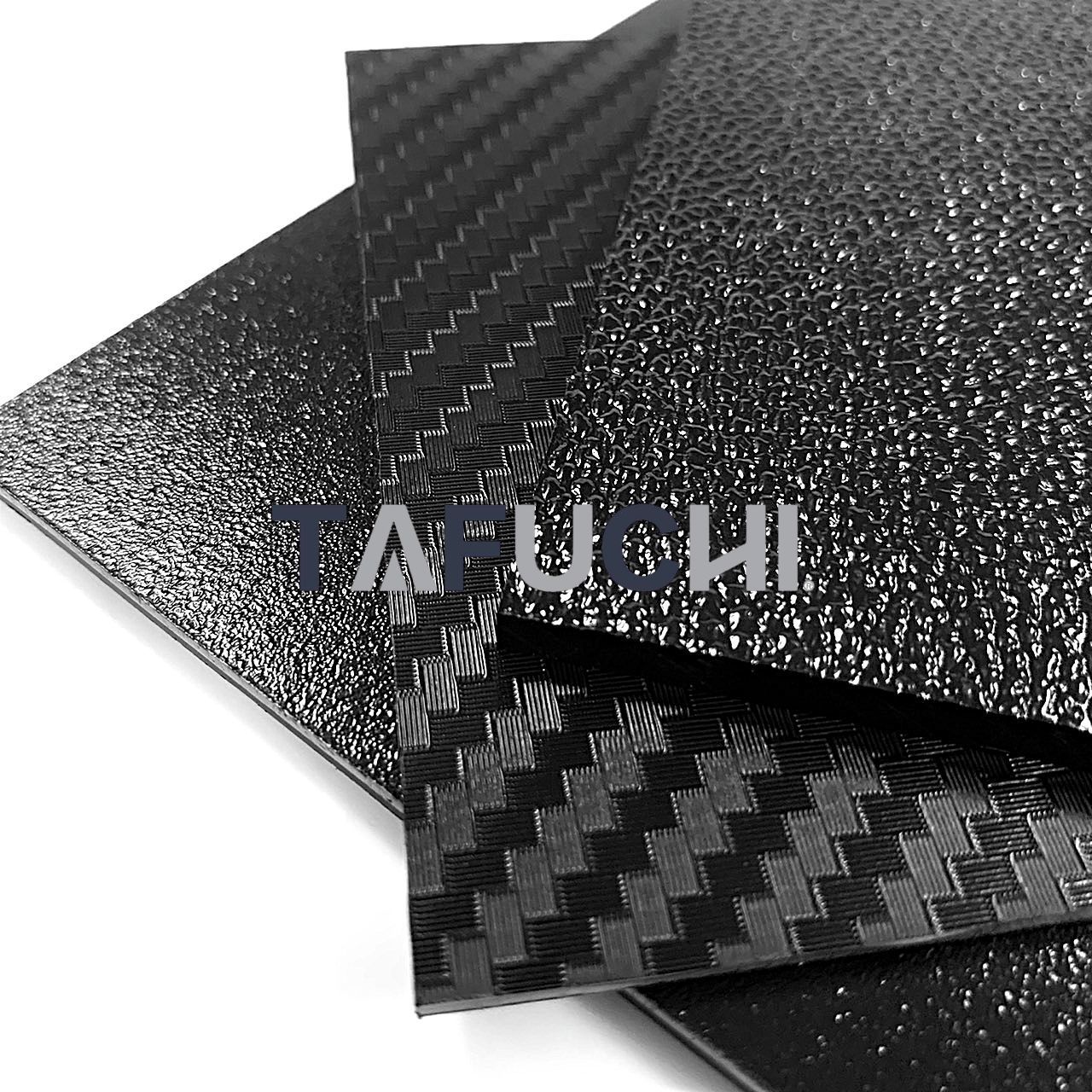

Technical specifications for a carbon fiber-reinforced ABS plastic sheet are critical when evaluating its performance in fabrication processes such as laser cutting, bending, and welding. This composite material combines the structural rigidity of carbon fiber with the thermoplastic toughness of acrylonitrile butadiene styrene (ABS), making it suitable for high-strength, lightweight applications in prototyping and manufacturing.

Below is a comparative table highlighting the technical characteristics of carbon fiber ABS plastic sheet alongside aluminum, steel, and nylon, with a focus on laser cutting, bending, and welding compatibility.

| Material | Laser Cutting Compatibility | Bending Characteristics | Welding Method | Notes on Processing and Material Behavior |

|---|---|---|---|---|

| Carbon Fiber ABS Sheet | Moderate to High | Limited cold bending; heat-formable (80–100°C) | Ultrasonic, vibration, or adhesive bonding only | Risk of delamination or charring during laser cutting due to carbon fiber conductivity; use low-power, high-speed settings. Not suitable for traditional thermal welding. |

| ABS Plastic | High | Excellent thermoforming and bending | Solvent, ultrasonic, or hot-plate welding | Easily laser cut with clean edges; melts predictably under controlled heat. Avoid excessive power to prevent melting or flare-ups. |

| Nylon (PA6/PA66) | Moderate | Good flexibility; heat-formable (70–90°C) | Hot gas, ultrasonic, or laser welding (with additives) | Prone to moisture absorption; pre-drying recommended. Requires precise laser control to avoid melting or warping. |

| Aluminum | Low (reflective, high conductivity) | Good ductility; bendable with tooling | TIG, MIG, or laser welding (with specialized equipment) | Reflects CO2 laser beams; fiber lasers preferred. Requires assist gas (nitrogen/argon) to prevent oxidation. |

| Steel (Mild) | High (with high-power lasers) | Excellent bendability with press brakes | MIG, TIG, spot, or laser welding | Produces dross if parameters not optimized; requires post-cut cleaning. High thermal conductivity affects heat concentration. |

Notes:

Carbon fiber ABS sheets require optimized laser settings (typically CO2 laser at 60–80W, 10–20 mm/s speed) to minimize edge charring and maintain structural integrity.

Mechanical joining or adhesive bonding is strongly recommended over welding for carbon fiber ABS due to material decomposition at high temperatures.

When bending, localized heating using a heat gun or oven (up to glass transition temperature of ABS, ~105°C) enables shaping without fiber breakage.

Among polymers, ABS offers the best balance of machinability and formability, whereas nylon requires more process control.

Metal materials (aluminum, steel) offer superior weldability but require higher energy input and safety measures during laser processing.

For hybrid designs, carbon fiber ABS is often combined with aluminum or steel inserts for enhanced mechanical anchoring, especially in load-bearing applications.

From CAD to Part: The Process

Honyo Prototype delivers precision carbon fiber reinforced ABS composite components through a rigorously controlled digital workflow optimized for complex geometries and material-specific challenges. It is critical to clarify that carbon fiber reinforced ABS is a composite material manufactured as a molded part, not a pre-formed sheet. Standard ABS plastic sheets exist, but integrating continuous or chopped carbon fiber reinforcement requires additive or compression molding processes to achieve structural performance. Our process addresses this distinction explicitly.

CAD File Upload and Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid preferred) via our secure customer portal. Our system performs immediate validation checks for file integrity, unit consistency, and geometric completeness. For carbon fiber ABS composites, we specifically verify wall thickness uniformity (critical for fiber distribution), draft angles, and undercuts that may complicate demolding. Invalid or ambiguous geometries trigger an automated notification requesting clarification before proceeding.

AI-Powered Quoting Engine

Validated CAD data feeds into our proprietary AI quoting system, trained on 15,000+ historical composite manufacturing projects. The engine analyzes over 200 geometric and material parameters including part volume, surface complexity, required fiber orientation, and tolerance zones. Crucially, it cross-references real-time data on carbon fiber ABS material costs (affected by resin type, fiber length, and volume fraction), machine utilization rates, and labor intensity. Quotes include granular cost breakdowns for material, tooling (if required), secondary operations, and QA testing – typically delivered within 2 business hours.

Engineering-Driven DFM Analysis

All quotes undergo mandatory Design for Manufacturability review by our composites engineering team. This phase is non-automated and leverages deep material science expertise. Key carbon fiber ABS specific checks include:

Fiber alignment validation against structural load paths

Risk assessment for print-through or resin starvation in thin sections

Confirmation of minimum radii to prevent fiber breakage during molding

Evaluation of gate locations for optimal fiber distribution

Thermal stress simulation for warpage mitigation

The DFM report provides actionable recommendations with annotated visuals, often reducing material waste by 18-32% through geometry optimization. Client approval of DFM findings is required before tooling fabrication.

Precision Composite Production

Production employs specialized processes distinct from standard thermoplastics:

Material Preparation: Carbon fiber ABS pellets (typically 10-30% fiber content) are dried to <0.02% moisture and pre-compounded with additives

Molding: Utilizing either compression molding for high-fiber-content parts or specialized extrusion-based additive systems for complex geometries with controlled fiber orientation

Curing: Parts undergo staged thermal curing (80°C to 120°C) with precise pressure profiles to minimize voids

Post-Processing: CNC machining of critical interfaces (±0.05mm tolerance), followed by surface finishing to specification

Throughout production, in-process inspections monitor fiber dispersion via ultrasonic testing and dimensional accuracy through CMM spot checks.

Quality-Controlled Delivery

Final inspection includes:

Dimensional verification against CAD per ASME Y14.5

Fiber volume fraction testing via acid digestion (ASTM D3171)

Interlaminar shear strength validation (ASTM D2344)

Visual inspection for surface defects under controlled lighting

All parts ship with a comprehensive Certificate of Conformance detailing material lot numbers, process parameters, and test results. Standard lead time is 10-15 business days from DFM approval, with expedited options available. Key delivery variables include:

| Factor | Standard Impact | Carbon Fiber ABS Specifics |

|---|---|---|

| Part Complexity | Moderate increase | High impact due to fiber alignment requirements |

| Tolerance Class | Increases time 15-25% | Critical for structural interfaces; requires secondary machining |

| Fiber Content | N/A | Higher content (20%+) adds 2-3 days for curing optimization |

| Surface Finish | Minor impact | Requires additional polishing steps to prevent fiber “fuzz” |

This integrated approach ensures carbon fiber ABS components meet aerospace, automotive, and industrial performance requirements while minimizing time-to-part through digital continuity from design to delivery. We maintain ISO 9001:2015 and AS9100D certifications governing all process stages.

Start Your Project

Looking for high-performance carbon fiber ABS plastic sheets for your next project? At Honyo Prototype, we deliver precision-engineered thermoplastic solutions with excellent strength-to-weight ratios, ideal for automotive, aerospace, and consumer electronics applications. Our production facility in Shenzhen ensures fast turnaround and consistent quality control for both prototypes and volume orders.

Contact Susan Leo today at [email protected] to request samples, pricing, or technical specifications. Let’s collaborate to meet your material performance and manufacturing goals.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.