Contents

Manufacturing Insight: Car Sheet Metal Fabrication

Precision Sheet Metal Fabrication for Automotive Innovation

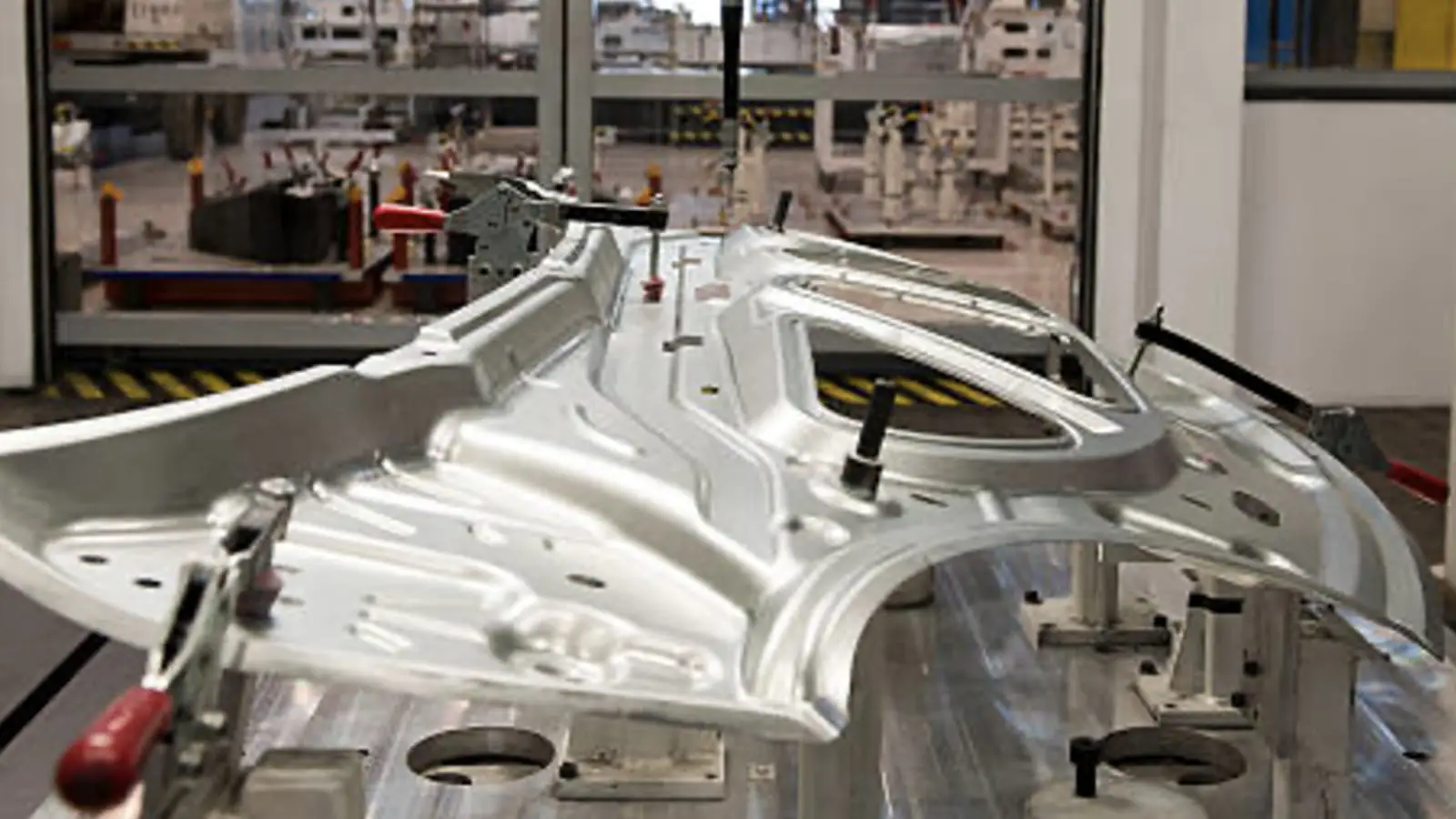

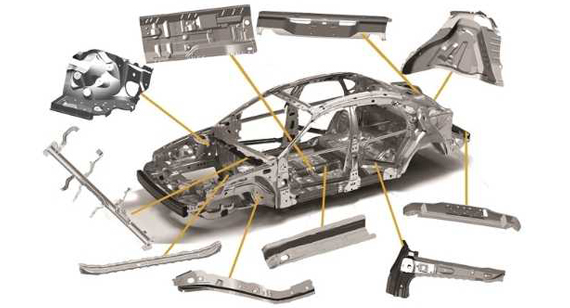

At Honyo Prototype, we engineer high-integrity sheet metal solutions specifically for automotive applications, where dimensional accuracy, material performance, and rapid iteration define success. Our dedicated sheet metal fabrication capabilities support car manufacturers and Tier suppliers from concept validation through low-volume production, addressing the stringent demands of chassis components, body panels, brackets, and structural sub-assemblies. Leveraging advanced laser cutting, CNC bending, precision welding, and finishing processes, we consistently achieve tolerances down to ±0.05mm while adhering to automotive-grade material specifications such as CR4, CR3, and aluminum alloys.

Our end-to-end workflow integrates design for manufacturability (DFM) analysis with in-house prototyping and assembly, ensuring parts meet crashworthiness, NVH, and corrosion resistance requirements critical to vehicle safety and longevity. Every project benefits from our ISO 9001-certified quality management system, with real-time process monitoring and first-article inspections documented to IATF 16949 standards.

Accelerate your development timeline with Honyo’s Online Instant Quote platform. Upload CAD files in STEP, IGES, or DXF format to receive a comprehensive cost and lead time estimate in under 60 seconds—validated by our engineering team for technical feasibility. This seamless interface eliminates procurement delays while providing transparent insights into material utilization, secondary operations, and scalability options.

Partner with Honyo Prototype to transform automotive sheet metal concepts into validated, production-ready components without compromising speed or precision. Initiate your next project with confidence through our digital quoting system at honyoprototype.com/quote.

Technical Capabilities

Technical specifications for car sheet metal fabrication involve a series of precision manufacturing processes including laser cutting, bending, and welding. These processes are critical in producing structural and aesthetic components for automotive applications. While laser cutting and bending are primarily applicable to metallic materials such as aluminum and steel, welding is used extensively for joining metal parts. Non-metallic materials like ABS and nylon are generally not suitable for laser cutting and bending in the same context as sheet metals, but may be processed using alternative methods such as CNC routing or thermal forming.

Below is a detailed comparison of technical specifications based on material and process:

| Process | Material | Thickness Range | Tolerance (Typical) | Equipment Used | Notes |

|---|---|---|---|---|---|

| Laser Cutting | Aluminum | 0.5 mm – 10 mm | ±0.1 mm | Fiber laser cutting machine | High precision; reflective material requires optimized parameters |

| Steel (Mild/CRS/HR) | 0.5 mm – 15 mm | ±0.1 mm | CO₂ or fiber laser cutter | Excellent edge quality; nitrogen or oxygen assist used depending on finish | |

| ABS | 1 mm – 6 mm | ±0.2 mm | CO₂ laser cutter | Not a sheet metal; limited to non-structural trim/enclosure parts | |

| Nylon | 1 mm – 6 mm | ±0.2 mm | CO₂ laser cutter | Poor laser cut quality due to melting; not recommended for precision parts | |

| Bending | Aluminum | 0.8 mm – 8 mm | ±0.2° angular, ±0.1 mm linear | CNC press brake with V-dies | Requires careful tooling to avoid cracking; common for brackets and housings |

| Steel | 0.8 mm – 12 mm | ±0.2° angular, ±0.1 mm linear | CNC press brake | High repeatability; springback compensation applied | |

| ABS | Not applicable | — | — | Not suitable for press brake bending; may crack or deform | |

| Nylon | Not applicable | — | — | Too flexible and low modulus; not used in sheet metal bending | |

| Welding | Aluminum | 1 mm – 8 mm | ±0.5 mm gap tolerance | TIG or MIG (with pulsed spray) | Requires shielding gas (argon); pre-cleaning essential to avoid porosity |

| Steel | 0.8 mm – 10 mm | ±0.5 mm gap tolerance | MIG, TIG, or spot welding | Spot welding common in automotive assembly; MIG for prototypes | |

| ABS | Not applicable | — | Ultrasonic or hot plate welding | Used only for plastic enclosures; not part of sheet metal fabrication | |

| Nylon | Not applicable | — | Vibration or hot gas welding | Limited use in automotive interiors; not compatible with metal joining |

Notes:

Aluminum and steel are the primary materials used in car sheet metal fabrication.

ABS and nylon are polymer materials and are not considered sheet metals; they are typically used for non-structural components and processed using different techniques.

Laser cutting of metals requires high-power fiber lasers for optimal edge quality and speed.

Bending operations require proper bend allowance calculations and tooling setup to maintain dimensional accuracy.

Welding procedures must comply with automotive quality standards such as ISO 3834 and AWS D1.1 for structural integrity.

From CAD to Part: The Process

Honyo Prototype Car Sheet Metal Fabrication Process Overview

Honyo Prototype executes car sheet metal fabrication through a rigorously defined workflow designed for precision, efficiency, and automotive-grade compliance. This integrated process ensures rapid turnaround while maintaining stringent quality standards for prototyping and low-volume production.

Upload CAD

Clients initiate the process by uploading native CAD files (preferred formats: STEP, IGES, Parasolid) via our secure customer portal. Our system validates file integrity, checks for unit consistency (millimeters standard), and confirms geometric completeness. Proprietary CAD data remains encrypted per ISO 27001 protocols; native files (e.g., SolidWorks, NX) are converted to neutral formats to protect intellectual property while enabling downstream processing. Geometry validation ensures no missing surfaces or non-manifold edges that could disrupt fabrication.

AI-Powered Preliminary Quoting

Uploaded geometry is analyzed by our proprietary AI engine, which cross-references real-time material cost databases, machine availability, and historical production data. The system generates a preliminary quote within 2 business hours, including estimated material consumption (accounting for nesting efficiency), base processing time, and surface finish options. This AI estimate undergoes mandatory validation by a senior manufacturing engineer to adjust for complex features (e.g., tight-tolerance bends, multi-stage forming) before client submission.

Engineering-Driven DFM Analysis

All quoted projects enter a mandatory Design for Manufacturability (DFM) review conducted by automotive-specialized engineers. This phase identifies and resolves fabrication risks specific to automotive applications:

| Key DFM Check Category | Automotive-Specific Focus Areas |

|---|---|

| Bend Geometry | Minimum flange widths for robotic welding, springback compensation for high-strength steels (e.g., DP600), k-factor validation |

| Hole & Cutout Placement | Clearance for assembly fixtures, tolerance stack-up for bolt patterns per ISO 2768-mK |

| Material Utilization | Nesting optimization for coated/aluminum sheets, scrap reduction strategies for expensive alloys |

| Secondary Operations | Deburring requirements per OEM specifications, weld nut insertion feasibility |

Engineers collaborate with clients via marked-up 3D PDFs to resolve critical issues (e.g., adjusting bend radii to avoid tool interference) before tooling begins. Typical DFM resolution time: 1–3 business days.

Precision Production Execution

Approved designs move to production in our climate-controlled facility. Automotive sheet metal (typically 0.8–3.0mm cold-rolled steel, aluminum 5052/6061, or DP steels) undergoes:

Laser/punch cutting with ±0.1mm positional accuracy using Bystronic systems, followed by robotic bending on AMADA press brakes with real-time angle monitoring. Critical assemblies (e.g., door frames, chassis brackets) receive in-process CMM verification at setup and per AS9100-defined intervals. All welds comply with AWS D1.1/D1.3 standards, with MIG/TIG procedures qualified per client requirements. Material traceability is maintained via barcode tracking from coil lot to finished part.

Certified Delivery & Logistics

Final inspection includes first-article reporting (FAI) per AS9102B, with full dimensional reports against CAD nominal values. Parts ship in ESD-safe, kitted packaging with protective coatings as specified (e.g., zinc plating per ASTM B633, powder coating). Delivery includes all documentation: material certs (mill test reports), process routings, and non-conformance records if applicable. Standard lead time from DFM sign-off is 7–12 business days for prototypes; JIT delivery options available for volume projects.

This closed-loop process minimizes rework through proactive DFM and leverages automation for consistent output—critical for automotive clients requiring zero-defect validation in prototype phases. All stages adhere to IATF 16949-compliant quality management systems.

Start Your Project

Looking for precision car sheet metal fabrication? Partner with Honyo Prototype for high-quality, custom sheet metal solutions tailored to automotive applications. Our manufacturing facility in Shenzhen offers advanced fabrication capabilities including laser cutting, CNC bending, welding, and assembly—all under strict quality control.

Contact Susan Leo today at [email protected] to discuss your project requirements and get a fast, competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.