Introduction: Navigating the Global Market for car part table

In the dynamic landscape of global commerce, sourcing unique and functional car part tables presents a distinctive challenge for international B2B buyers. Whether you’re looking for a conversation-starting centerpiece or practical storage solutions, understanding the nuances of the car part table market is essential. This comprehensive guide delves into various types of car part tables, their applications in both commercial and residential settings, and the critical aspects of supplier vetting to ensure quality and reliability.

Buyers from regions such as Africa, South America, the Middle East, and Europe—particularly Germany and Brazil—will find actionable insights on navigating costs, negotiating effectively, and identifying reputable suppliers. With increasing demand for automotive-themed furniture that blends aesthetics with functionality, making informed purchasing decisions is vital for standing out in competitive markets.

By the end of this guide, you will be equipped to select the best car part tables that align with your business needs, enhancing your offerings and appealing to a diverse clientele. From understanding market trends to evaluating supplier credentials, this resource empowers you to make confident, strategic investments that drive success in your business endeavors.

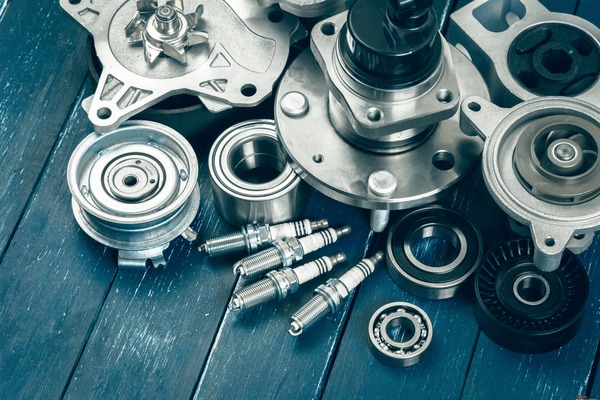

Understanding car part table Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Engine Block Coffee Table | Made from real engine blocks, often featuring intricate designs | Man caves, automotive-themed businesses | Pros: Unique aesthetic; durable material. Cons: High price point; weight may require special handling. |

| Classic Car Replicas | Furniture designed to resemble classic car models | Showrooms, automotive museums, private collectors | Pros: Eye-catching; nostalgic appeal. Cons: Limited functionality; higher maintenance. |

| Custom Automotive Furniture | Tailored designs to meet specific customer needs | Corporate offices, promotional events | Pros: Personalized branding; unique offerings. Cons: Longer lead times; potentially higher costs. |

| Functional Game Tables | Tables designed for gaming, often with automotive themes | Entertainment venues, man caves | Pros: Engaging for clients; multifunctional use. Cons: May not appeal to all demographics; niche market. |

| Upcycled Car Part Furniture | Furniture made from repurposed car parts | Eco-friendly businesses, automotive enthusiasts | Pros: Sustainable; unique stories behind each piece. Cons: Variability in quality; may not have mass appeal. |

What are the Characteristics of Engine Block Coffee Tables?

Engine block coffee tables are crafted from authentic engine blocks, giving them a distinctive and robust appearance. These tables typically feature polished or painted finishes, showcasing the intricate details of the automotive components. Ideal for man caves or automotive-themed businesses, they serve as conversation starters and symbolize a passion for cars. Buyers should consider the weight and dimensions for transportation and placement, as well as the investment required, as these pieces can be quite expensive.

How Do Classic Car Replicas Stand Out?

Classic car replica furniture mimics the design of iconic vehicles, such as the 1957 Chevy or Ford Mustang. These pieces often combine comfort with nostalgia, making them popular in showrooms and automotive museums. While they attract attention and celebrate automotive history, buyers should weigh the aesthetic appeal against practical considerations like space and maintenance, as these items may require special care to preserve their condition.

What Makes Custom Automotive Furniture a Smart Choice?

Custom automotive furniture is tailored to meet the specific needs of businesses or collectors, allowing for unique branding opportunities. This type of furniture can be designed to fit various themes, colors, and functionalities, making it suitable for corporate offices or promotional events. However, buyers must consider longer lead times and potentially higher costs associated with custom orders, ensuring that the investment aligns with their overall branding strategy.

Why are Functional Game Tables Beneficial for Businesses?

Functional game tables, often designed with automotive themes, provide entertainment options in venues like bars, restaurants, or man caves. These tables can enhance customer engagement and create a fun atmosphere, making them appealing for businesses looking to attract a specific demographic. However, buyers should assess their target audience to ensure that such niche offerings will resonate, as these tables may not appeal to a broader market.

What are the Advantages of Upcycled Car Part Furniture?

Upcycled car part furniture is made from repurposed automotive components, appealing to eco-conscious buyers. These pieces tell a unique story and can serve as sustainable conversation starters in various settings, from eco-friendly businesses to automotive enthusiast spaces. However, buyers should be cautious about variability in quality and craftsmanship, as well as the potential for limited appeal among mainstream consumers.

Key Industrial Applications of car part table

| Industry/Sector | Specific Application of car part table | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Retail | Showroom Displays | Enhances customer engagement and brand identity | Quality of materials, design uniqueness, and durability |

| Event Management | Themed Event Furniture | Creates immersive environments for automotive events | Customization options, logistics for transport, and assembly |

| Hospitality | Unique Restaurant or Bar Furniture | Attracts customers with a distinctive automotive theme | Compliance with safety standards, aesthetic alignment, and comfort |

| Home Decor | Man Cave and Garage Furnishing | Appeals to car enthusiasts, enhancing personal spaces | Style variety, customization capabilities, and price points |

| Advertising & Marketing | Promotional Displays for Auto Shows | Captivates audience attention and promotes brand image | Size compatibility, visibility, and ease of assembly |

How are car part tables utilized in automotive retail settings?

In automotive retail, car part tables serve as striking showroom displays that capture the attention of customers. These tables, often designed from actual engine parts or iconic vehicle components, not only enhance the aesthetic appeal of the showroom but also reinforce the brand’s automotive identity. For international buyers, particularly those in regions like Europe or South America, sourcing high-quality, durable tables that align with their brand image is crucial. They must consider local regulations regarding materials and safety standards.

What role do car part tables play in event management?

Car part tables are increasingly popular in event management, particularly for automotive-themed events. They can be used as unique furniture pieces that create an immersive experience for attendees. By integrating these tables into their setups, event planners can elevate the ambiance and engage visitors more effectively. Buyers in Africa and the Middle East should focus on customization options that reflect local automotive culture and ensure that the tables are easy to transport and assemble, given the logistics involved in event setups.

How do car part tables enhance the hospitality industry?

In the hospitality sector, car part tables are utilized as unique furniture in restaurants and bars, adding a distinctive automotive flair that attracts car enthusiasts. These tables can be conversation starters and help create a memorable dining experience. For B2B buyers in regions like Germany, considerations for sourcing include compliance with local safety and health regulations, as well as ensuring that the tables are comfortable and visually appealing to enhance the overall customer experience.

In what ways do car part tables contribute to home decor?

Car part tables serve as a popular choice for man caves and garage furnishings, appealing to automotive enthusiasts who wish to showcase their passion at home. These tables can be customized to fit personal styles and preferences, providing a unique centerpiece that speaks to the owner’s interests. Buyers from South America and Europe should prioritize sourcing options that offer various styles, customization capabilities, and price points to meet diverse consumer demands.

How are car part tables effective in advertising and marketing?

Car part tables can be utilized as promotional displays at auto shows, effectively capturing audience attention and promoting brand image. Their unique design can set a brand apart from competitors, drawing in potential customers. For international buyers, especially in emerging markets, it’s essential to consider the size and visibility of the tables to ensure they fit within exhibition spaces and can be easily assembled and disassembled for transport.

3 Common User Pain Points for ‘car part table’ & Their Solutions

Scenario 1: Difficulty in Customization for Unique Spaces

The Problem: Many B2B buyers face challenges when trying to fit car part tables into unique environments, such as showrooms, automotive workshops, or themed spaces. Customization needs can vary significantly based on the aesthetics of the space, the type of clientele, and the intended use of the table. Buyers often struggle to find suppliers that offer bespoke options that meet their specific design requirements without sacrificing quality or functionality. This can lead to frustration and delays in outfitting their spaces effectively.

The Solution: To overcome customization challenges, B2B buyers should prioritize suppliers who specialize in bespoke furniture solutions. Engage directly with manufacturers or distributors that offer customizable car part tables. This can include options for materials, finishes, and dimensions tailored to your specific needs. Request samples or prototypes to evaluate how well a design fits within your environment. Additionally, establish clear communication about your requirements upfront, including aesthetics, durability, and budget constraints, to ensure that the final product aligns perfectly with your vision. Utilizing a collaborative approach with suppliers can lead to innovative solutions that enhance the overall ambiance of your space.

Scenario 2: Quality Assurance and Durability Concerns

The Problem: B2B buyers often express concerns about the quality and durability of car part tables, particularly when sourcing from international suppliers. Given the heavy usage in environments like garages or showrooms, tables must withstand wear and tear while maintaining their aesthetic appeal. Subpar quality can lead to dissatisfaction, increased costs due to replacements, and damage to a company’s reputation.

The Solution: To ensure high-quality purchases, buyers should conduct thorough research on potential suppliers. Look for manufacturers with a proven track record and positive reviews from other B2B clients. Request certifications or product warranties that speak to the durability of the materials used. Furthermore, consider visiting the supplier’s facility or requesting detailed product information, including construction methods and material specifications. Establishing a long-term relationship with reputable suppliers can also lead to better quality assurance practices, such as regular inspections and adherence to international quality standards.

Scenario 3: Navigating Import Regulations and Costs

The Problem: International buyers often encounter complex import regulations and unexpected costs when sourcing car part tables from overseas. These challenges can include tariffs, shipping fees, and compliance with local safety standards. This complexity can lead to delays in delivery and increased overall costs, complicating budgeting and inventory planning for businesses.

The Solution: To navigate these hurdles, B2B buyers should familiarize themselves with both local and international trade regulations relevant to automotive furniture. Engaging a logistics partner or freight forwarder who specializes in international shipping can provide invaluable insights into the most efficient shipping methods and potential costs. Additionally, buyers should clarify all costs upfront with suppliers, including shipping and handling fees, to avoid surprises. It can also be beneficial to explore suppliers that offer all-inclusive pricing that covers tariffs and shipping, making budgeting more straightforward. Building relationships with customs brokers can further streamline the import process and ensure compliance with all regulations, allowing for smoother transactions and timely deliveries.

Strategic Material Selection Guide for car part table

What are the Key Properties of Common Materials Used in Car Part Tables?

When selecting materials for car part tables, it’s essential to consider their properties, performance, and suitability for various applications. Here, we analyze four common materials: aluminum, steel, wood, and fiberglass.

Aluminum: A Lightweight and Corrosion-Resistant Option

Aluminum is widely recognized for its lightweight nature and excellent corrosion resistance. It can withstand moderate temperatures and pressure, making it suitable for various automotive applications.

Pros: Aluminum is durable and resistant to rust, which is particularly advantageous in humid or coastal environments. It is also relatively easy to manufacture and can be shaped into intricate designs, enhancing aesthetic appeal.

Cons: The primary drawback is its cost, which tends to be higher than some other materials. Additionally, while aluminum is strong, it is not as robust as steel, making it less suitable for heavy-duty applications.

Impact on Application: Aluminum’s compatibility with various media, such as oils and fuels, makes it a versatile choice for car part tables.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider local availability and import costs, as aluminum can be more expensive to source. Compliance with international standards such as ASTM and DIN is also crucial for ensuring quality.

Steel: The Strong and Durable Choice

Steel is known for its strength and durability, making it a popular choice for car part tables that require heavy lifting or support.

Pros: Steel’s high tensile strength allows it to handle significant weight without deformation. It is also readily available and cost-effective compared to aluminum.

Cons: The main disadvantage is its susceptibility to rust and corrosion if not properly treated. This necessitates additional protective coatings, which can increase manufacturing complexity.

Impact on Application: Steel is compatible with various automotive fluids, but its weight can be a concern for mobile applications.

Considerations for International Buyers: Buyers in Europe, particularly Germany, should ensure compliance with European standards for steel quality and safety. Additionally, the cost of shipping heavy steel products can be a significant factor for buyers in regions with high logistics costs.

Wood: A Classic and Aesthetic Material

Wood is often used in car part tables for its aesthetic appeal and versatility.

Pros: Wood offers a unique look and can be customized easily. It is generally less expensive than metals and can be sourced locally, reducing transportation costs.

Cons: However, wood is less durable than metal options and can be susceptible to warping, especially in humid environments. It also requires regular maintenance to prevent decay.

Impact on Application: While wood can be compatible with some automotive fluids, it is not recommended for applications involving high temperatures or moisture.

Considerations for International Buyers: Buyers should consider local wood species and sustainability practices, especially in regions like South America where deforestation is a concern. Compliance with environmental regulations is also essential.

Fiberglass: A Lightweight and Customizable Alternative

Fiberglass is gaining popularity for its lightweight and customizable properties.

Pros: It is resistant to corrosion and can be molded into various shapes, allowing for creative designs. Fiberglass is also lightweight, making it easier to transport.

Cons: The main limitation is its cost, which can be higher than wood and some metals. Additionally, fiberglass may not be as strong as steel, limiting its use in heavy-duty applications.

Impact on Application: Fiberglass is compatible with most automotive fluids, making it a safe choice for car part tables.

Considerations for International Buyers: Buyers should be aware of the manufacturing standards for fiberglass in their region, as quality can vary significantly. Compliance with international safety standards is also critical.

Summary Table of Material Selection for Car Part Tables

| Material | Typical Use Case for car part table | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight tables for casual use | Corrosion resistance | Higher cost compared to steel | High |

| Steel | Heavy-duty tables for industrial applications | High tensile strength | Susceptible to rust | Medium |

| Wood | Decorative tables for showrooms | Aesthetic appeal | Less durable, requires maintenance | Low |

| Fiberglass | Customizable tables for unique designs | Lightweight and moldable | Higher cost, less strength than steel | Medium |

This analysis provides a comprehensive overview of the materials commonly used in car part tables, enabling international B2B buyers to make informed decisions based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for car part table

What Are the Key Stages in the Manufacturing Process of Car Part Tables?

The manufacturing process for car part tables is multifaceted, involving several critical stages to ensure the final product meets both functional and aesthetic standards. Understanding these stages is essential for B2B buyers seeking quality and reliability in their purchases.

Material Preparation: How Are Raw Materials Selected and Processed?

The first step in manufacturing car part tables involves sourcing high-quality raw materials. Typically, this includes metals such as steel or aluminum for structural components, and wood or composite materials for tabletops. Suppliers must ensure that materials meet international standards, particularly regarding strength and durability.

Once sourced, materials undergo preparation, which includes cutting, shaping, and surface treatment. For example, metal components may be cut using laser or plasma technology, ensuring precision. Wood surfaces often receive treatments to enhance aesthetics and durability, such as staining or varnishing.

What Forming Techniques Are Commonly Used in Car Part Table Manufacturing?

Forming is the next stage, where prepared materials are shaped into their final forms. This can involve several techniques:

-

Casting: Engine blocks and other heavy components are often cast from molten metal, providing intricate designs and robust structures.

-

Welding: For metal parts, welding is used to join components securely, ensuring structural integrity. Advanced welding techniques, such as TIG (Tungsten Inert Gas) welding, may be employed for high-quality finishes.

-

Molding: Some tables may feature molded parts, particularly those made from synthetic materials or fiberglass that replicate classic car designs.

-

Machining: Precision machining is often necessary for components that require exact dimensions or finishing touches.

How Is the Assembly Process Conducted for Car Part Tables?

Once the parts are formed, assembly begins. This stage may involve manual labor as well as automated processes. Key steps include:

- Joining Components: Parts are assembled using screws, bolts, or adhesive, depending on the materials involved and the design specifications.

- Quality Checkpoints: Assembly lines often include checkpoints where components are inspected for fit and finish before proceeding to the next stage.

B2B buyers should inquire about assembly methods, as well-assembled products often reflect higher quality and durability.

What Finishing Techniques Enhance the Aesthetics and Durability of Car Part Tables?

Finishing is a crucial stage that not only enhances the visual appeal of the table but also protects it from wear and tear. Common finishing techniques include:

-

Painting and Powder Coating: These methods provide a protective layer while allowing for customization in color and texture. Powder coating, in particular, is known for its durability.

-

Polishing and Buffing: Metal components may undergo polishing to achieve a high-gloss finish that highlights craftsmanship and quality.

-

Sealing: Wooden surfaces are often sealed to prevent moisture damage, ensuring longevity.

What Quality Assurance Practices Are Essential in Car Part Table Manufacturing?

Quality assurance (QA) is critical to ensure that car part tables meet the required standards throughout the manufacturing process. Internationally recognized standards, such as ISO 9001, guide manufacturers in establishing effective QA systems.

Which International Standards Are Relevant for Car Part Table Quality Assurance?

B2B buyers should be aware of various international and industry-specific standards that may apply, including:

-

ISO 9001: Focuses on quality management systems and is essential for any manufacturer looking to establish credibility.

-

CE Marking: Particularly relevant in Europe, it indicates conformity with health, safety, and environmental protection standards.

-

API Standards: For manufacturers dealing with automotive parts, adherence to American Petroleum Institute standards may be necessary, especially for tables incorporating engine components.

What Are the Key Quality Control Checkpoints Throughout the Manufacturing Process?

Quality control (QC) involves systematic checks at different stages of the manufacturing process. Key checkpoints include:

-

Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specifications.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing checks ensure that processes remain within defined parameters.

-

Final Quality Control (FQC): The completed product undergoes thorough testing and inspection before packaging and shipping.

What Testing Methods Are Commonly Used to Ensure Product Quality?

Several testing methods are employed to verify the quality and durability of car part tables:

-

Mechanical Testing: This includes stress tests to evaluate the strength and durability of materials.

-

Environmental Testing: Products may be subjected to conditions simulating extreme temperatures or humidity to ensure they can withstand various environments.

-

Aesthetic Evaluation: Visual inspections ensure that finishes are flawless and meet design specifications.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, verifying the quality control measures of suppliers is crucial. Here are some strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess manufacturing practices, quality control processes, and adherence to standards firsthand.

-

Quality Reports: Requesting documentation of quality control processes and results can provide insights into a supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of product quality before shipment, ensuring compliance with international standards.

What Are the Quality Control Nuances for International B2B Buyers?

Understanding the nuances of quality control is essential for B2B buyers, especially when dealing with suppliers from different regions. Factors to consider include:

-

Cultural Differences: Different regions may have varying approaches to quality management. Buyers should be aware of these differences and be prepared to adapt their expectations accordingly.

-

Regulatory Compliance: Familiarity with local regulations and standards is crucial, particularly for buyers in Africa, South America, the Middle East, and Europe. Ensuring that suppliers comply with these regulations can mitigate risks associated with product quality.

-

Communication: Clear communication with suppliers regarding quality expectations and standards is vital for establishing a successful partnership.

In summary, understanding the manufacturing processes and quality assurance practices behind car part tables is essential for B2B buyers. By focusing on material preparation, forming techniques, assembly, finishing, and robust quality control measures, buyers can make informed decisions that align with their quality requirements and business objectives.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘car part table’

In the competitive landscape of automotive-themed furniture, sourcing car part tables requires careful consideration and strategic planning. This guide aims to provide B2B buyers with a clear checklist to streamline the procurement process, ensuring that you secure high-quality products that meet your specific needs.

Step 1: Define Your Technical Specifications

Understanding your requirements is crucial before initiating the sourcing process. Clearly outline the dimensions, materials, and design elements that are essential for your car part table. Consider factors such as the intended use (e.g., commercial, decorative), weight capacity, and aesthetic preferences. This clarity will help you communicate effectively with potential suppliers.

Step 2: Research Potential Suppliers

Conduct thorough market research to identify suppliers that specialize in automotive furniture. Look for companies with a strong reputation and a diverse product range. Utilize online platforms, industry directories, and trade shows to gather a list of potential vendors. Pay attention to their experience, customer reviews, and previous projects to gauge reliability.

Step 3: Evaluate Supplier Certifications

Before proceeding, verify the certifications and compliance of your shortlisted suppliers. This step ensures that they adhere to industry standards and regulations. Look for certifications related to quality management (e.g., ISO 9001) and environmental sustainability. Suppliers with recognized certifications are more likely to deliver products that meet your quality expectations.

Step 4: Request Samples and Prototypes

Once you have narrowed down your options, request samples or prototypes of the car part tables. This allows you to assess the quality, craftsmanship, and overall aesthetics of the products firsthand. Pay attention to details such as finish, durability, and functionality. A tangible product can provide insights that images and descriptions cannot.

Step 5: Negotiate Pricing and Terms

Engage in discussions with your chosen suppliers regarding pricing, minimum order quantities, and payment terms. Ensure that you understand the total cost, including shipping and any potential tariffs, especially if sourcing internationally. Don’t hesitate to negotiate for better terms, as many suppliers are willing to accommodate bulk orders or long-term partnerships.

Step 6: Assess Shipping and Logistics Options

Consider the logistics involved in transporting your order from the supplier to your location. Evaluate shipping methods, delivery times, and associated costs. For international purchases, ensure that the supplier can handle customs clearance and that you are aware of any import regulations in your country. Proper logistics planning can prevent delays and additional expenses.

Step 7: Finalize Contracts and Agreements

Once all terms are agreed upon, ensure that you have a formal contract in place. This document should outline product specifications, delivery schedules, payment terms, and any warranties or return policies. A well-structured agreement protects both parties and establishes clear expectations, reducing the likelihood of disputes in the future.

By following this step-by-step checklist, you can streamline your sourcing process for car part tables, ensuring a successful procurement experience that meets your business needs.

Comprehensive Cost and Pricing Analysis for car part table Sourcing

What Are the Key Cost Components in Sourcing Car Part Tables?

When sourcing car part tables, understanding the comprehensive cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality metals, fiberglass, and wood can drive prices up. For instance, tables made from engine blocks or custom-designed elements often command premium prices due to their unique aesthetics and durability.

-

Labor: Labor costs vary depending on the region and the complexity of the manufacturing process. Skilled craftsmen who create bespoke pieces may add to the labor costs but can also enhance the product’s quality and uniqueness.

-

Manufacturing Overhead: This includes costs related to utilities, rent, equipment maintenance, and other fixed expenses that contribute to the production process. Buyers should inquire about these costs when assessing suppliers.

-

Tooling: Custom designs often require specialized tooling, which can significantly increase upfront costs. Understanding the tooling requirements can help buyers budget accordingly.

-

Quality Control (QC): Ensuring that products meet specific standards is crucial, especially in international markets. QC processes may add costs but are essential for maintaining quality and compliance with regulations.

-

Logistics: Transportation costs, including shipping, customs duties, and insurance, can vary greatly based on the origin and destination. For international buyers, understanding these logistics can prevent unexpected expenses.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary based on market demand, exclusivity, and the supplier’s business model.

How Do Price Influencers Affect Car Part Table Costs?

Several factors can influence the pricing of car part tables, making it crucial for buyers to consider:

-

Volume and Minimum Order Quantity (MOQ): Suppliers may offer discounts based on order volume. Understanding the MOQ can help buyers plan their purchases effectively.

-

Specifications and Customization: Custom designs or specific features (like integrated lighting or unique finishes) can significantly increase costs. Buyers should assess whether customization aligns with their needs and budget.

-

Materials and Quality Certifications: Higher-quality materials or certifications (like ISO or CE) can increase costs. Buyers should weigh the benefits of these certifications against their budget constraints.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can impact pricing. Established suppliers with a track record of quality may charge more but could offer better reliability.

-

Incoterms: The terms of shipping and delivery (Incoterms) can affect costs and responsibilities. Understanding whether costs include shipping, insurance, and duties is vital for total cost evaluation.

What Are the Best Negotiation Tips for International B2B Buyers?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, effective negotiation can yield significant savings:

-

Research and Prepare: Understand market prices and supplier capabilities. Being informed allows for stronger negotiation positions.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, durability, and potential resale value to understand the long-term implications of a purchase.

-

Leverage Relationships: Building rapport with suppliers can lead to better terms and pricing. Long-term relationships often yield benefits such as priority service and exclusive offers.

-

Be Open to Alternatives: Sometimes, suppliers can suggest alternative materials or designs that meet your needs at a lower cost. Flexibility can lead to significant savings.

-

Consider Payment Terms: Negotiating favorable payment terms can improve cash flow and reduce upfront costs. Longer payment periods or installment options can ease financial pressure.

What Should Buyers Keep in Mind Regarding Pricing Nuances?

Finally, buyers should remain aware of pricing nuances, especially in international contexts. Currency fluctuations can impact costs, as can changes in trade policies or tariffs. Always account for potential additional costs that may arise post-purchase, such as import duties or local taxes.

Disclaimer: Prices mentioned in market research may vary and should be considered indicative. Always consult suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing car part table With Other Solutions

Understanding Alternatives to the Car Part Table

In the realm of automotive decor and furniture, the car part table stands out as a unique offering that blends functionality with aesthetic appeal. However, businesses exploring options for automotive-themed furniture may find themselves weighing the benefits of this product against other viable alternatives. This analysis will compare the car part table with several alternative solutions, helping international B2B buyers make informed decisions tailored to their specific needs.

| Comparison Aspect | Car Part Table | Engine Block Coffee Table | Vintage Car Replicas |

|---|---|---|---|

| Performance | Durable, unique centerpiece | High durability, functional use | Aesthetic appeal, variable comfort |

| Cost | $1,500 – $13,499 | $1,499 – $3,500 | $6,495 – $12,995 |

| Ease of Implementation | Ready to use, limited setup | Requires some assembly | Custom orders may lead to delays |

| Maintenance | Low maintenance | Moderate; requires occasional cleaning | Varies; may require upholstery care |

| Best Use Case | Man caves, offices, showrooms | Bars, lounges, entertainment areas | Living rooms, collector spaces |

What Are the Advantages and Disadvantages of an Engine Block Coffee Table?

The engine block coffee table is a popular alternative that embodies a rugged, industrial aesthetic. Made from real engine blocks, these tables are not only visually striking but also extremely durable. They typically cost between $1,499 and $3,500, making them a more budget-friendly option compared to high-end car part tables. However, their weight and bulk can complicate placement and transportation. Maintenance is relatively low, but they may require occasional cleaning to maintain their appearance.

How Do Vintage Car Replicas Compare to Car Part Tables?

Vintage car replicas, including couches and tables designed to mimic classic vehicles, offer a nostalgic charm that appeals to automotive enthusiasts. Ranging from $6,495 to $12,995, these pieces serve as statement furniture in living rooms or collector spaces. While they provide a unique aesthetic, their comfort level can vary significantly based on design and materials used. Additionally, sourcing these items may involve longer lead times due to customization options, making them less convenient for immediate needs.

What Should B2B Buyers Consider When Choosing Between These Options?

When selecting between a car part table and its alternatives, B2B buyers should consider several factors. The primary focus should be on the intended use of the furniture—whether for aesthetic appeal or functional purposes. Understanding the budget is crucial, as prices can vary widely based on the complexity and materials involved. Ease of implementation is another key aspect; some options may require more assembly or customization than others. Finally, maintenance considerations can impact long-term satisfaction with the purchase.

In summary, while the car part table presents a distinctive choice for automotive-themed decor, alternatives like engine block coffee tables and vintage car replicas offer unique advantages. By evaluating performance, cost, ease of implementation, maintenance, and best use cases, buyers can make informed decisions that align with their specific requirements and enhance their spaces.

Essential Technical Properties and Trade Terminology for car part table

What Are the Key Technical Properties for Car Part Tables in B2B Transactions?

When dealing with car part tables, understanding the technical properties is crucial for ensuring that the furniture meets both functional and aesthetic needs. Here are several critical specifications:

-

Material Grade

The material used in manufacturing car part tables can greatly impact durability and appearance. Common materials include steel, aluminum, fiberglass, and wood. For instance, tables made from high-grade steel offer superior strength and longevity, making them ideal for high-traffic environments like garages or showrooms. B2B buyers should assess material grade to ensure it aligns with their intended use and environmental conditions. -

Weight Capacity

This specification defines the maximum load the table can support safely. For commercial buyers, especially those in automotive settings, knowing the weight capacity is essential to prevent accidents and damage. Tables designed to hold heavy engine parts or tools need to have higher weight ratings, which can vary widely depending on construction methods and materials. -

Finish and Coating

The finish applied to a car part table affects not only its aesthetics but also its resistance to wear and corrosion. Options may include powder coating, chrome plating, or varnishing. A durable finish is especially important for outdoor or industrial applications where exposure to the elements can lead to rapid degradation. -

Tolerance Levels

Tolerance refers to the acceptable limits of variation in a dimension or physical property. In the context of car part tables, it can relate to the precision of dimensions for fitting purposes or the consistency of material thickness. Understanding tolerance is important for ensuring compatibility with existing setups, particularly in professional environments. -

Dimensions and Configurations

The size and shape of the table are critical for space planning and functionality. B2B buyers should consider the specific dimensions that will best fit their workspace, as well as whether they need custom configurations. This can include considerations for height, width, and depth, as well as features like integrated storage.

What Are Common Trade Terms Related to Car Part Tables?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts that are used in the manufacturing of vehicles. For car part tables, OEMs may create custom furniture based on specific vehicle designs. Understanding the OEM relationship can help buyers ensure they are sourcing authentic products. -

MOQ (Minimum Order Quantity)

MOQ defines the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is essential for budgeting and inventory management. It can also affect pricing; larger orders often lead to discounts. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific items or services. B2B buyers should use RFQs to gather information from multiple suppliers, which can aid in making informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are standardized terms that define the responsibilities of buyers and sellers in international trade. Understanding Incoterms is vital for B2B transactions, as they clarify who is responsible for shipping, insurance, and tariffs, helping to mitigate risks associated with international logistics. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. For B2B buyers, understanding lead times is crucial for project planning and inventory management. Longer lead times can affect production schedules, so it’s important to communicate expectations clearly with suppliers. -

Customization Options

This term refers to the ability to modify standard products to meet specific customer requirements. In the context of car part tables, customization can include changes in size, color, material, or design features. Understanding the extent of customization available can help buyers meet unique branding or operational needs.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their purchasing strategy and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the car part table Sector

Market Overview & Key Trends in the Car Part Table Sector

The car part table sector is experiencing significant growth, driven by a blend of consumer interest in automotive memorabilia and the increasing trend of bespoke home decor. Globally, the market is fueled by a rising number of automotive enthusiasts, particularly in regions like Africa, South America, the Middle East, and Europe. In Germany and Brazil, for instance, the automotive culture is deeply embedded, leading to a higher demand for unique and custom furniture pieces that resonate with car aficionados.

Emerging trends in B2B sourcing include the integration of e-commerce platforms that cater specifically to niche markets, allowing buyers to access a broader range of products with ease. Digital marketplaces are increasingly popular, providing international buyers with the opportunity to compare prices, quality, and craftsmanship from various suppliers. Additionally, advancements in technology are enabling manufacturers to offer customizable options, appealing to a market that values personalization.

Sustainability is also becoming a key consideration for B2B buyers. As consumers and businesses alike become more environmentally conscious, there is a growing demand for furniture made from recycled or sustainably sourced materials. This shift is prompting manufacturers to innovate and adapt their sourcing strategies to meet these expectations, making sustainability a competitive advantage.

How Can Sustainability & Ethical Sourcing Impact the Car Part Table Sector?

In the context of the car part table sector, sustainability and ethical sourcing are paramount. The environmental impact of manufacturing processes can be significant, with traditional methods often contributing to waste and pollution. As a result, B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices, such as using reclaimed materials from old vehicles or adopting eco-friendly production processes.

Ethical supply chains are also gaining importance. Buyers are scrutinizing the origins of materials and the labor practices of manufacturers, looking for certifications that indicate responsible sourcing. Certifications such as FSC (Forest Stewardship Council) for wood products or recycled content labels are becoming essential for suppliers aiming to attract conscientious buyers.

Furthermore, the use of ‘green’ materials in the production of car part tables not only enhances the appeal of these products but also aligns with the values of a growing segment of consumers who prioritize sustainability. By focusing on ethical sourcing and environmental responsibility, businesses can differentiate themselves in a competitive market, appealing to buyers who are willing to invest in high-quality, sustainable products.

What is the Brief Evolution/History of Car Part Tables in the B2B Market?

The evolution of car part tables as a niche market can be traced back to the rise of automotive culture in the mid-20th century. Initially, car enthusiasts began repurposing old car parts into furniture as a form of creative expression and utility. Over the decades, this trend gained traction, evolving from simple DIY projects to a sophisticated industry with professional artisans and manufacturers specializing in automotive-themed furniture.

As the global interest in vintage cars and automotive memorabilia grew, so did the market for car part tables. Today, these unique pieces are not just functional items but also serve as conversation starters and statement pieces in homes, garages, and showrooms. This evolution reflects a broader trend in consumer preferences towards unique, personalized home decor that tells a story, highlighting the intersection of automotive passion and design innovation.

Frequently Asked Questions (FAQs) for B2B Buyers of car part table

-

How do I choose the right car part table for my business needs?

Selecting the right car part table involves considering both functionality and aesthetics. Evaluate the space available for installation, the specific automotive theme that aligns with your brand, and the materials used in construction for durability. Additionally, consider the table’s purpose—whether it serves as a display for products, a workspace for mechanics, or a decorative piece for showrooms. Research suppliers to ensure they offer customization options that meet your specifications, as tailored solutions often enhance customer engagement. -

What are the typical materials used in manufacturing car part tables?

Car part tables are often crafted from durable materials such as repurposed metal, fiberglass, and wood. Engine blocks from classic vehicles are a popular choice for coffee tables, offering both strength and a unique aesthetic. High-quality finishes, such as powder coating or varnishing, can enhance longevity and appeal. When sourcing, inquire about the sourcing of materials to ensure they are sustainable and compliant with international standards, especially if you are purchasing from suppliers in different regions. -

What customization options are available when sourcing car part tables?

Many suppliers offer customization options that allow you to tailor the design, size, and finish of car part tables. You can select colors, logos, and even specific vehicle models that resonate with your brand identity. Some manufacturers may also allow for modifications to dimensions to fit your space better. Ensure you discuss your vision with potential suppliers and request samples or mock-ups to visualize the final product before placing a bulk order. -

What are the minimum order quantities (MOQ) for car part tables?

Minimum order quantities can vary significantly among suppliers, typically ranging from a single unit to hundreds, depending on the manufacturer. For custom designs, MOQs may be higher due to the costs associated with production setup. When negotiating with suppliers, clarify their MOQ policies and explore whether lower quantities can be accommodated, especially if you are testing the market or just starting your business. -

How can I vet suppliers for car part tables effectively?

Vetting suppliers involves conducting thorough research to assess their credibility and reliability. Check their industry experience, customer reviews, and certifications. Request samples to evaluate product quality firsthand. Additionally, consider visiting their manufacturing facilities if possible, or utilize third-party inspection services to verify production standards. Engaging in direct communication can also provide insights into their responsiveness and customer service practices. -

What payment terms should I expect when purchasing car part tables internationally?

Payment terms can vary widely depending on the supplier and the nature of the transaction. Common terms include advance payment, letter of credit, or payment upon delivery. Discuss terms upfront and consider using secure payment methods that offer buyer protection. It’s crucial to understand any additional fees related to international transactions, such as currency conversion costs, taxes, or tariffs, which could impact your overall budget. -

What quality assurance measures should I look for when sourcing car part tables?

When sourcing car part tables, inquire about the quality assurance processes in place at the manufacturing facility. Look for certifications that demonstrate adherence to international quality standards, such as ISO certifications. Request documentation on material testing and product durability assessments. Establishing a clear return policy and warranty terms can also safeguard your investment and ensure you receive products that meet your expectations. -

How do logistics and shipping impact the procurement of car part tables?

Logistics and shipping play a crucial role in the procurement process, affecting lead times and overall costs. Understand the supplier’s shipping capabilities, including their partnerships with freight carriers and their experience in handling international shipments. Discuss shipping methods, estimated delivery times, and customs clearance processes to avoid unexpected delays. Additionally, consider the impact of shipping costs on your budget, and explore options for bulk shipping discounts or consolidated shipments to optimize your expenses.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Car Part Table Manufacturers & Suppliers List

1. Ben’s Auto Decor – Custom Engine Coffee Table

Domain: bensautodecor.com

Registered: 2016 (9 years)

Introduction: [{‘name’: ‘Custom Engine Coffee Table for Gearheads’, ‘price’: ‘£1,816’, ‘description’: ‘Man Cave Furniture’}, {‘name’: ‘BMW Table Wine Rack’, ‘price’: ‘£1,508’, ‘description’: ‘BMW Engine End Table With Bottle Storage, Upcycled Bar Furniture’}, {‘name’: ‘Porsche Engine Wine Rack’, ‘price’: ‘£2,805’, ‘description’: ‘Wine Storage Table, Unique Man Cave and Bar Furniture’}, {‘name’: ‘Mercedes V12 En…

2. Etsy – Unique Car Part Furniture

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – Unique Car Part Furniture, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Pinterest – Steampunk Industrial Furniture

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Steampunk Industrial Table made from Antique Ford Model T Radiator and Headlamps; Barnwood Table #2187 sold; Classic car gauge cluster upcycled into a coat/key hook; Bus dash desk by Bel & Bel; Front Grill of SEAT 132 turned into Car Desk; Coat rack made from 1956 Chevy valve cover.

4. Car Furniture – Deluxe Accessory Set

Domain: carfurniture.com

Registered: 2004 (21 years)

Introduction: Deluxe Accessory Set: $299.00

1965 Mustang Console Table: $6,995.00

1965 Ford Mustang Rear Console Table: $6,495.00

Pure Muscle Canvas Art: $100.00

Desert Snakes: $1,499.00

’65 Mustang Front End Wall Hanging: $7,995.00

Wally Classic – Vintage European Car Front: $699.00

1957 Chevy 210 Couch Sofa: $12,995.00

’57 Chevy Desk: $11,995.00

1969 Camaro Couch (Reversed): $9,995.00

Camaro Neon Clock: $99.0…

5. Furniture Roots – Custom Car Sofas

Domain: furnitureroots.com

Registered: 2018 (7 years)

Introduction: Car & Automobile Furniture includes custom-built car sofas and couches made from original car parts, automobile-inspired tables, bar counters, and barstools. The furniture is designed for automotive-themed pubs, bars, cafes, and restaurants. Key products include:

– Car Sofas: Made from original car parts for man-caves and hospitality establishments.

– Automobile Tables: Upcycled and fabricated tab…

6. F1® – Authentic Car Part Tables

Domain: us.f1authentics.com

Registered: 2019 (6 years)

Introduction: F1® Tables crafted from car parts, officially licensed by F1®, guaranteed authenticity, one of a kind memorabilia. Categories include F1® Wheel Rim Tables, F1® Brake Disc Tables, and F1® Engine Cover Tables.

7. Homecrux – Unique Automotive Furniture

Domain: homecrux.com

Registered: 2012 (13 years)

Introduction: 1. Lamborghini Table – Price: $4,899, Material: Fiberglass and wood, Ideal for man cave.

2. Volkswagen Pickup Truck Bed – Price: $4,040, Handmade, Perfect for kids’ room.

3. Mustang Parts Desk – Handcrafted by Unibro Design, Attention-grabbing piece.

4. Seat 132 Desk – Individually-sized, Original front grill and headlights included.

5. Baloch M1300 Turbo Dining Table – Features etched “BALOCH” lo…

Strategic Sourcing Conclusion and Outlook for car part table

In navigating the dynamic landscape of car part tables, strategic sourcing emerges as a critical driver for success among international B2B buyers. The market for automotive-themed furniture is expanding, offering unique opportunities for those looking to differentiate their product offerings. By leveraging insights from reputable suppliers and understanding market trends, buyers can identify high-quality, custom pieces that resonate with car enthusiasts and collectors.

The value of strategic sourcing lies not only in cost savings but also in enhancing brand reputation through quality and innovation. As buyers from regions like Africa, South America, the Middle East, and Europe explore options, they should prioritize partnerships with manufacturers that emphasize craftsmanship, sustainability, and customization. This ensures that the products not only meet aesthetic standards but also align with the growing consumer demand for unique, high-value items.

Looking ahead, the potential for growth in this niche market is significant. As car culture continues to thrive globally, there is an increasing appetite for distinctive furniture that reflects this passion. Now is the time for international B2B buyers to engage with suppliers, explore bespoke options, and invest in high-quality automotive furniture that can enhance their offerings and elevate customer experiences.