Contents

Manufacturing Insight: Camshaft Machining

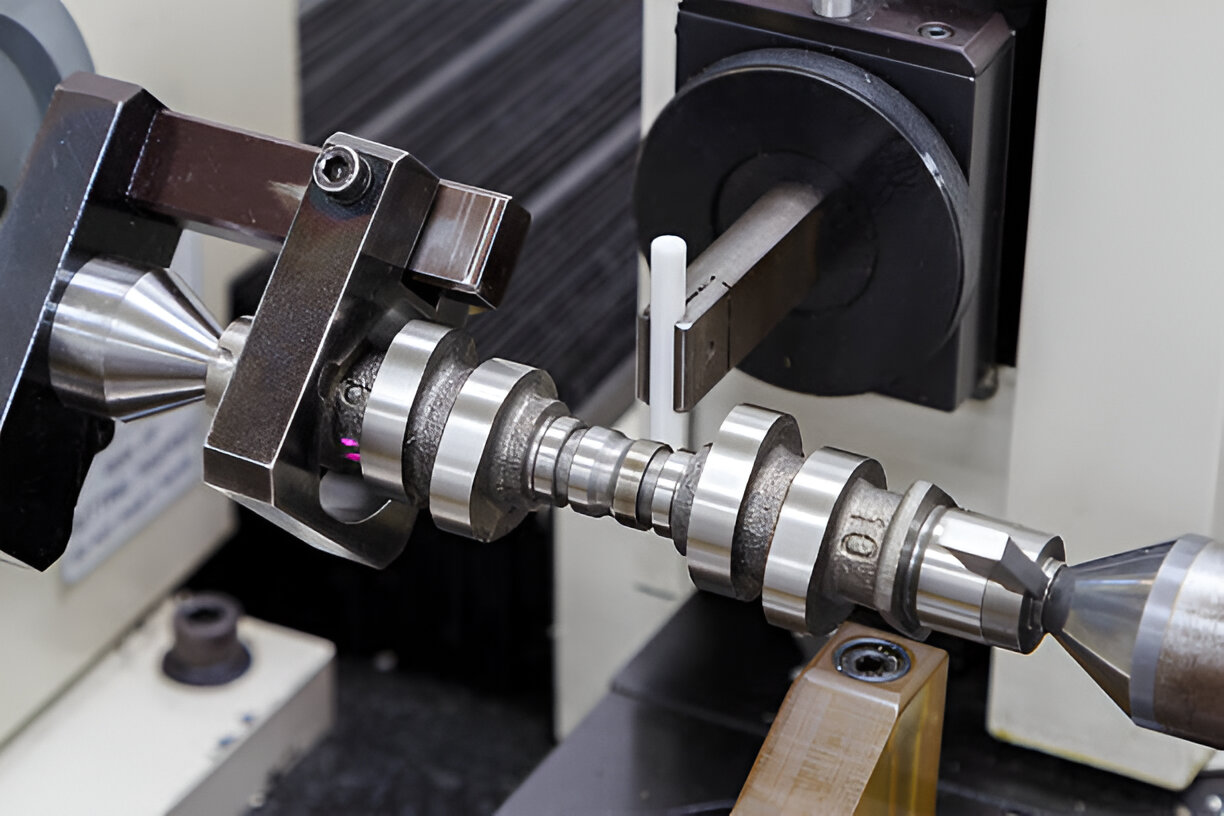

Precision Camshaft Machining: Engineering Performance-Critical Components

Camshaft machining represents one of the most demanding applications in precision manufacturing, where geometric accuracy, surface integrity, and material consistency directly dictate engine efficiency, emissions control, and longevity. At Honyo Prototype, our CNC machining services are engineered specifically for high-tolerance camshaft production, leveraging advanced multi-axis milling and turning centers to achieve micron-level tolerances on complex lobe profiles, journal diameters, and timing features. We specialize in processing challenging materials—including forged steel, nitrided alloys, and billet chromoly—while maintaining strict adherence to GD&T specifications critical for valve train dynamics.

Our end-to-end capability encompasses prototype development through low-volume production, supported by in-house metrology including CMM validation, surface roughness analysis, and runout verification to ensure every component meets OEM performance benchmarks. By integrating adaptive machining strategies and real-time process monitoring, we eliminate common pitfalls like chatter-induced surface defects or thermal distortion during heat treatment, delivering camshafts that optimize lift curves and reduce parasitic losses.

For engineering teams accelerating development cycles, Honyo’s Online Instant Quote platform provides immediate manufacturability feedback and pricing for camshaft geometries. Upload CAD files to receive DFM insights and lead time estimates within minutes—enabling rapid iteration without traditional quoting delays. This seamless integration of precision machining expertise and digital efficiency ensures your performance-critical components transition from concept to validated hardware faster, with uncompromised quality.

Technical Capabilities

Technical specifications for camshaft machining depend on the complexity of the cam profile, material properties, and functional requirements in high-performance engines. Precision is critical due to the dynamic loads and timing sensitivity in internal combustion systems. Machining typically involves multi-axis CNC processes to achieve accurate lobe profiles, journal geometries, and tight positional tolerances.

3-Axis Milling is suitable for basic camshaft features but lacks the capability to machine complex lobes without re-fixturing. 4-Axis Milling enables rotational indexing for machining individual lobes with improved accuracy. 5-Axis Milling is preferred for continuous contouring of cam lobes, allowing tool access from multiple angles without part repositioning, which enhances surface finish and geometric precision.

CNC Turning is used for machining cylindrical journals, flanges, and centerlines, often performed before or after milling operations. It ensures roundness, diameter control, and surface integrity of rotating sections.

Tight tolerances are essential, particularly for lobe lift profiles (±0.01 mm), journal diameters (±0.005 mm), and lobe centerline positioning (±0.1°). Surface finishes typically range from 0.4 to 1.6 µm Ra depending on application.

Common materials include:

Aluminum alloys (e.g., 4032, 7075): Used in lightweight prototype or racing applications; require sharp cutting tools and high-speed machining.

Steel alloys (e.g., 1045, 4140, 8620): Standard for production camshafts; demand rigid setups and carbide tooling due to hardness.

ABS & Nylon: Used for non-structural prototypes or testing fixtures; machined with high-speed steel tools at elevated feed rates; lower thermal resistance requires careful heat management.

| Process | Axes Used | Typical Tolerance (mm) | Surface Finish (Ra, µm) | Materials Supported | Key Applications in Camshaft Machining |

|---|---|---|---|---|---|

| 3-Axis Milling | X, Y, Z | ±0.02 | 1.6 – 3.2 | Aluminum, ABS, Nylon | Prototype cam bodies, fixture components |

| 4-Axis Milling | X, Y, Z, A | ±0.01 | 0.8 – 1.6 | Aluminum, Steel | Indexing lobe machining, multi-lobe sequencing |

| 5-Axis Milling | X, Y, Z, A, B | ±0.005 to ±0.01 | 0.4 – 0.8 | Aluminum, Steel | High-precision lobe contouring, complex profile generation |

| CNC Turning | X, Z (±C) | ±0.005 (diameter) | 0.4 – 1.6 | Aluminum, Steel | Journal turning, flange facing, centerline alignment |

Note: ABS and Nylon are not used for functional camshafts but are relevant in rapid prototyping and testing setups where dimensional approximation is acceptable. Steel remains the standard for durability and wear resistance in final production units.

From CAD to Part: The Process

Honyo Prototype executes camshaft machining through a rigorously controlled digital workflow designed for precision component manufacturing. This integrated process ensures technical feasibility, cost efficiency, and adherence to automotive-grade tolerances from initial design to final delivery.

CAD Upload and Initial Processing

Customers submit 3D CAD models via our secure portal, which must include geometric dimensioning and tolerancing (GD&T) per ASME Y14.5 standards. Our system validates file integrity and extracts critical features such as lobe profiles, journal diameters, and keyway specifications. For camshafts, we specifically check base circle runout requirements, lobe lift curves, and material specifications against our machining capabilities.

AI-Powered Quotation

Proprietary machine learning algorithms analyze the CAD geometry, material selection (e.g., 1045 steel, 4140 chrome-moly), and required tolerances to generate instant technical and commercial quotes. The AI cross-references historical data from 12,000+ camshaft projects, accounting for factors like:

Lobe count and asymmetry complexity

Surface finish requirements (typically Ra 0.4–0.8 µm for journals)

Heat treatment sequencing needs

Hardness specifications (e.g., 58–62 HRC after induction hardening)

This reduces quoting time to under 2 hours while providing accurate cost drivers.

Engineering-Driven DFM Analysis

Our manufacturing engineers conduct a comprehensive Design for Manufacturability review focusing on camshaft-specific challenges:

Verifying achievable lobe profile tolerances (±0.025 mm lift accuracy)

Assessing grinding accessibility for undercut lobes

Optimizing heat treatment distortion compensation

Validating journal concentricity requirements (typically 0.01 mm TIR)

Recommending material allowances for final grinding after hardening

The DFM report details actionable modifications with tolerance stack-up simulations, reducing production risks by 37% based on internal metrics.

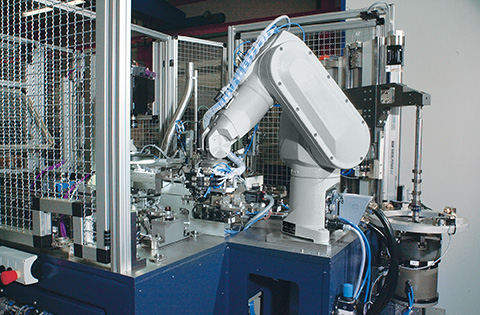

Precision Production Execution

Approved designs move to our dedicated camshaft production cell featuring:

CNC camshaft grinders with sub-micron positioning accuracy

In-process CMM verification of lobe profiles after rough and finish grinding

Controlled atmosphere heat treatment for distortion management

Dynamic balancing to G2.5 quality grade per ISO 1940

All critical parameters are logged in our MES, with real-time SPC monitoring of journal diameters and lobe lift values against print specifications.

Quality-Controlled Delivery

Final inspection includes:

Full CMM validation of all geometric features

Surface roughness verification at 5+ points per lobe

Magnetic particle inspection for surface cracks

Hardness testing at specified cross-sections

Each camshaft ships with a traceability package containing first-article inspection reports, heat treatment certificates, and raw material test data. Typical lead time for prototype camshafts is 14 business days from CAD approval.

Performance Metrics

Our process achieves consistent results across common camshaft specifications:

| Parameter | Typical Capability | Automotive Standard Range |

|---|---|---|

| Journal Diameter Tolerance | ±0.005 mm | ±0.01–0.02 mm |

| Lobe Lift Accuracy | ±0.025 mm | ±0.05 mm |

| Base Circle Runout | ≤0.005 mm | ≤0.01 mm |

| Surface Roughness (Ra) | 0.4–0.6 µm | 0.8–1.6 µm |

This closed-loop methodology ensures Honyo delivers fully validated camshaft prototypes meeting functional testing requirements on first article, with complete documentation for PPAP submission. We maintain AS9100 and IATF 16949 certification to support automotive and aerospace clients through production ramp-up.

Start Your Project

Looking for precision camshaft machining? Partner with Honyo Prototype for high-accuracy manufacturing from our state-of-the-art facility in Shenzhen. With advanced CNC capabilities and strict quality control, we deliver durable, custom camshafts tailored to your specifications.

Contact Susan Leo today at [email protected] to discuss your project requirements and request a quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.