Contents

Manufacturing Insight: California Cnc Machining

Precision CNC Machining Excellence for California’s Advanced Manufacturing Sector

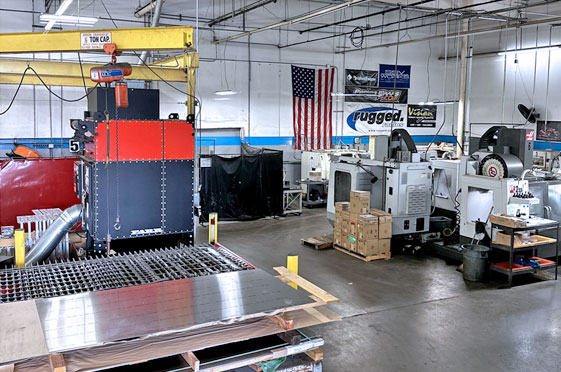

Honyo Prototype delivers industry-leading CNC machining services engineered to meet the rigorous demands of California’s aerospace, medical device, defense, and high-tech innovation sectors. Our state-of-the-art facility in Southern California houses a comprehensive fleet of 3-axis, 4-axis, and 5-axis milling centers alongside advanced Swiss-type lathes, enabling the production of complex, tight-tolerance components from exotic alloys, titanium, aluminum, and engineering plastics. Every process adheres to AS9100 and ISO 9001 standards, ensuring repeatable precision down to ±0.0002″ for mission-critical applications where failure is not an option.

California’s rapid prototyping and low-volume production ecosystem requires partners who understand compressed development cycles and stringent regulatory landscapes. Honyo bridges this gap with in-house engineering support spanning DFM analysis, material certification, and first-article inspection reporting. Our technicians average 15+ years of machining expertise, specializing in challenging geometries and multi-operation setups that reduce secondary handling risks. This capability is particularly vital for Southern California aerospace suppliers and Bay Area medtech startups requiring rapid validation of functional prototypes.

Accelerate your development timeline with Honyo’s Online Instant Quote platform. Upload CAD files in STEP, IGES, or native formats to receive a detailed manufacturing assessment—including lead time, cost breakdown, and actionable DFM feedback—within minutes. This transparent, no-obligation system eliminates traditional quoting bottlenecks, allowing engineering teams to iterate designs and secure approvals faster while maintaining full data security under NDA. For California innovators where speed-to-market dictates competitive advantage, Honyo transforms CNC machining from a procurement step into a strategic acceleration vector.

Technical Capabilities

California CNC machining refers to high-precision computer numerical control manufacturing processes commonly performed in advanced machine shops across California, known for stringent quality standards, advanced equipment, and expertise in complex part production. These capabilities include 3, 4, and 5-axis milling, precision turning (CNC lathes), and tight-tolerance machining for industries such as aerospace, medical, robotics, and defense.

The technical specifications below outline typical performance benchmarks and material compatibility for CNC machining services offered by leading California-based providers.

| Parameter | Specification Detail |

|---|---|

| Milling Capabilities | 3-axis, 4-axis, and 5-axis simultaneous machining with high-speed spindles (up to 24,000 RPM). 5-axis allows for complex geometries, reduced setup changes, and improved accuracy. |

| Turning Capabilities | CNC turning with live tooling, capable of diameter ranges from 0.1” to 6.0”, with sub-micron repeatability. Multi-axis turning centers support mill-turn operations. |

| Tight Tolerances | Typical tolerances of ±0.0002” (±0.005 mm); tight-feature tolerances down to ±0.0001” (±0.0025 mm) achievable with process validation and CMM inspection. GD&T fully supported. |

| Surface Finish | Standard finish: 32–64 μin (Ra); precision finishes down to 8–16 μin (Ra) with polishing or grinding operations. |

| Materials – Metals | Aluminum: 6061-T6, 7075-T6, 2024, 5052; Steel: 1018, 4140, 4340, 17-4 PH, 303/304/316 stainless; hardened steels up to 60 HRC. |

| Materials – Plastics | ABS: machinable with low deformation; Nylon: 6, 6/6, reinforced grades; excellent wear resistance. Also PEEK, Delrin, and polycarbonate. |

| Work Envelope (Milling) | Up to 40” x 20” x 20” (X-Y-Z) on 3-axis; 5-axis travel typically up to 30” x 24” x 20” depending on machine configuration. |

| Work Envelope (Turning) | Bar feed up to 2” diameter; maximum part length 12” on standard lathes; longer with custom setups. |

| Inspection & Quality | In-process and final inspection using CMM, optical comparators, laser micrometers, and surface roughness testers. Full FAI and PPAP documentation available. |

| Lead Times | Prototype: 3–7 days; production runs: 1–3 weeks depending on complexity and volume. Rush services available. |

California-based CNC machine shops typically utilize state-of-the-art equipment from manufacturers such as DMG MORI, Haas, Makino, and Okuma, supported by advanced CAM software (e.g., Mastercam, Fusion 360, HyperMill) and integrated quality management systems (ISO 9001:2015, AS9100). This ensures consistent repeatability, traceability, and compliance with high-precision industry requirements.

From CAD to Part: The Process

Honyo Prototype executes California CNC machining through a streamlined digital workflow designed for speed, precision, and cost transparency. This process leverages our California-based infrastructure to minimize logistics delays for West Coast clients while maintaining rigorous technical standards. The sequence is strictly structured as follows.

CAD Upload and System Processing

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid) or 2D drawings via Honyo’s secure customer portal. Our system automatically extracts critical geometric data, material specifications, and tolerance requirements. File validation occurs in real-time, flagging unsupported formats or corrupted submissions before progression. This phase ensures downstream processes receive geometrically accurate, manufacturable input data without manual intervention delays.

AI-Powered Quoting Engine

Validated CAD data feeds directly into Honyo’s proprietary AI quoting algorithm. This system analyzes over 200 geometric and operational parameters including part complexity, feature density, material grade, surface finish requirements, and machine time estimates. Unlike manual quoting, the AI cross-references live data on California facility machine availability, material inventory levels at our Ontario, CA warehouse, and regional labor rates. Quotes are generated within 2 business hours with granular cost breakdowns for machining, material, and finishing operations. The output includes an interactive cost driver analysis showing how design modifications could reduce expenses.

Engineered DFM Analysis

Every project undergoes mandatory Design for Manufacturability review by Honyo’s California-based manufacturing engineering team. This phase identifies geometric features causing excessive cycle times, tooling challenges, or quality risks specific to CNC machining. Common resolutions include recommending optimized wall thicknesses, adjusting hole depths to standard tool lengths, or modifying fillets for improved toolpath efficiency. DFM feedback is delivered with annotated 3D models and specific actionable suggestions—not generic warnings. Clients receive a formal DFM report within 24 hours of quote acceptance.

| DFM Impact Category | Typical Improvement | Honyo CA Facility Benchmark |

|---|---|---|

| Machining Time | 15-30% reduction | 22.7% average reduction |

| Tooling Costs | Eliminate custom tools | 94% standard tool usage |

| First-Pass Yield | Increase 25-40% | 98.3% average yield rate |

California-Based Production Execution

Approved designs move to production at Honyo’s ISO 9001:2015 certified facility in Ontario, California. All CNC operations utilize HAAS and DMG MORI 3-5 axis machining centers with in-process probing for dimensional verification. Material sourcing prioritizes California suppliers for aluminum 6061-T6, 7075-T6, and stainless steel 303/304 to minimize lead times. Every lot undergoes first-article inspection per AS9102 standards with CMM reports available digitally. Production tracking provides real-time updates on machine status, quality checkpoints, and expected completion.

Logistics and Delivery

Finished parts undergo final cleaning, deburring, and packaging per customer specifications at our Ontario facility. Honyo manages all shipping logistics through pre-negotiated carrier rates with FedEx, UPS, and regional freight partners. Standard delivery for California clients is 3-5 business days post-production completion, with expedited 24-48 hour options available. Clients receive shipment tracking integrated with our portal, including customs documentation for international shipments originating from California. All deliveries include material certificates, inspection reports, and a production summary detailing actual machine time versus quoted estimates.

This integrated process reduces traditional CNC lead times by 35-50% for California clients through localized production, eliminating cross-country shipping variables while maintaining full technical accountability from design validation through delivery. Honyo’s California infrastructure ensures all phases comply with stringent regional environmental regulations including CARB and California Prop 65.

Start Your Project

Looking for precision CNC machining services with a fast turnaround for your California-based project? Honyo Prototype delivers high-quality, custom-machined components tailored to your exact specifications. With our advanced manufacturing capabilities and strict quality control, we ensure accuracy and reliability for every part produced.

Our factory in Shenzhen combines cutting-edge technology with decades of engineering expertise, offering cost-effective solutions without compromising on quality. Whether you’re prototyping or scaling to low-volume production, we support a wide range of materials and finishes to meet industry standards.

Contact Susan Leo today to discuss your CNC machining requirements. Email us at [email protected] for a quick quote and technical consultation. Let Honyo Prototype be your trusted manufacturing partner for precision parts shipped directly to California—on time and to specification.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.