Contents

Manufacturing Insight: Cad Cnc Machine

Precision CNC Machining Services from Honyo Prototype: Transforming CAD Designs into High-Fidelity Parts

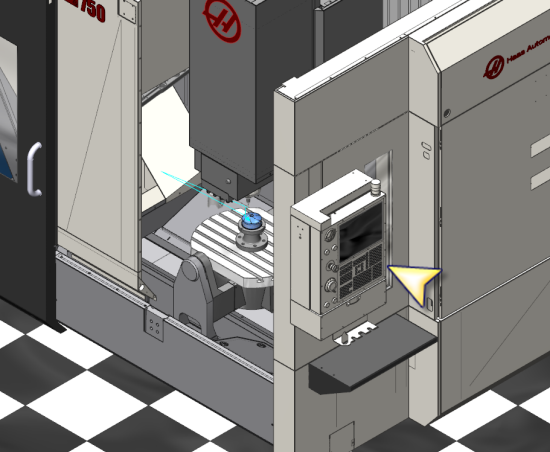

At Honyo Prototype, we specialize in advanced CNC machining services engineered to convert your CAD designs into precision-critical components with uncompromising accuracy and efficiency. Our capabilities span 3-axis, 4-axis, and 5-axis milling, as well as multi-axis turning, enabling us to tackle complex geometries across aerospace, medical, automotive, and industrial sectors. Leveraging state-of-the-art Haas, DMG MORI, and Makino equipment, we consistently achieve tight tolerances down to ±0.005mm while supporting a broad material spectrum—from aluminum alloys and stainless steels to titanium, plastics, and exotic composites.

Our seamless integration of CAD data into the manufacturing workflow ensures dimensional integrity from digital model to physical part, eliminating interpretation errors and accelerating time-to-market. Every project undergoes rigorous in-process inspection using calibrated CMMs and optical comparators, guaranteeing compliance with AS9100 and ISO 9001 standards. For rapid validation of manufacturability and cost, our Online Instant Quote system provides detailed pricing, lead times, and DFM feedback within minutes—no manual RFQ submission required. Simply upload your STEP or IGES file, specify materials and quantities, and receive actionable insights to optimize your design for CNC production.

Honyo Prototype delivers more than machining; we provide a streamlined, technology-driven partnership where your CAD files become precision-engineered assets faster, with full transparency from quote to shipment.

Technical Capabilities

Technical Specifications for CAD-Integrated CNC Machining Systems

Modern CAD-integrated CNC machines are engineered for high-precision manufacturing across 3-axis, 4-axis, and 5-axis milling platforms, as well as CNC turning centers. These systems accept direct CAD file inputs (e.g., STEP, IGES, Parasolid) and utilize CAM software to generate toolpaths, ensuring accurate translation of digital designs into physical components. Below are key technical specifications relevant to multi-axis milling and turning operations, with emphasis on tight-tolerance capabilities and compatibility with common engineering materials.

| Specification | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Notes |

|---|---|---|---|---|---|

| Axis Configuration | X, Y, Z linear axes | X, Y, Z + A (rotary around X) | X, Y, Z + A, B (or C) rotary axes | X, Z linear + C-axis (rotary spindle) | 5-axis allows simultaneous tool motion in all five axes |

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.005 mm | ±0.003 mm | Measured per ISO 230-2 |

| Repeatability | ±0.002 mm | ±0.002 mm | ±0.002 mm | ±0.001 mm | Critical for batch consistency |

| Spindle Speed Range | 8,000 – 24,000 rpm | 8,000 – 24,000 rpm | 10,000 – 30,000 rpm | 3,000 – 10,000 rpm | High-speed spindles enhance surface finish |

| Maximum Tool Capacity (ATC) | 20–30 tools | 20–30 tools | 30–60 tools | 8–12 tools (turret) | Automatic Tool Changer (ATC) standard |

| Tight Tolerance Capability | ±0.01 mm (standard), down to ±0.005 mm | ±0.01 mm, ±0.005 mm with advanced setup | ±0.005 mm typical, ±0.002 mm achievable | ±0.005 mm (diametrical), ±0.01 mm length | Tight tolerances require thermal stability and calibration |

| Surface Finish (Ra) | 0.8 – 1.6 µm | 0.8 – 1.6 µm | 0.4 – 0.8 µm | 0.8 – 1.6 µm | 5-axis enables superior finishes on complex geometries |

| Compatible Materials | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon, Titanium, Inconel | Aluminum, Steel, ABS, Nylon (bar stock) | Material selection affects tooling and feed rates |

| Typical Applications | Flat surfaces, prismatic parts | Indexing rotary features (e.g., ports) | Complex contours, aerospace components | Cylindrical parts, shafts, bushings | 5-axis ideal for organic and asymmetric forms |

| Coolant System | Flood, mist, or high-pressure through-spindle | Flood or high-pressure | High-pressure through-spindle | Flood or mist | Improves tool life and chip evacuation |

| Control System | Fanuc, Siemens, or Heidenhain | Fanuc, Siemens, or Heidenhain | Siemens 840D, Heidenhain TNC7 | Fanuc 0i-TF, Siemens 828D | CAD/CAM integration via STEP/IGES import |

Material-Specific Considerations

Aluminum and ABS are commonly machined due to their low cutting forces and excellent chip evacuation. Steel and Nylon require optimized toolpaths and tooling—steel for increased tool wear, Nylon for potential melting if heat is not managed. 5-axis systems reduce setups for complex parts, improving accuracy, especially when holding tight tolerances across multiple features. CNC turning centers achieve high repeatability for rotational parts, often used in conjunction with milling for turn-mill operations.

From CAD to Part: The Process

Honyo Prototype CAD-to-CNC Manufacturing Workflow

Honyo Prototype delivers precision CNC machined parts through a digitally integrated workflow designed for speed and manufacturability. The process begins when a customer uploads a native CAD file (STEP, IGES, or Parasolid) to our secure online portal. This triggers our proprietary AI-driven quoting system, which analyzes geometric complexity, material requirements, tolerances, and feature density against real-time machine availability and material costs. The AI generates a preliminary quote within 2 hours, including lead time estimates and cost drivers, but all quotes undergo final validation by a Senior Manufacturing Engineer to ensure accuracy.

Design for Manufacturability (DFM) Review

Following quote acceptance, our engineering team conducts a rigorous DFM analysis. This phase identifies potential production risks such as non-optimal wall thicknesses, problematic undercuts, or tolerance conflicts that could increase cost or delay delivery. Key DFM checks include:

| DFM Parameter | Standard Check | Resolution Pathway |

|---|---|---|

| Tool Access | Verification of 3-axis/5-axis toolpath feasibility | Suggest fillet adjustments or feature relocation |

| Wall Thickness | Minimum thickness vs. material stability | Recommend geometry modification or material change |

| Tolerance Stack-up | GD&T analysis against ISO 2768-mK standards | Propose relaxed tolerances or secondary operations |

| Material Utilization | Billet size optimization | Adjust stock dimensions to reduce waste |

The DFM report is shared with the customer within 24 hours, including actionable recommendations. Customer approval of the DFM report is required before production launch.

CNC Production Execution

Approved designs move to our certified ISO 9001:2015 production floor. Each job is assigned to optimized CNC resources:

3-axis milling for prismatic geometries using HAAS VF-2YT machines

5-axis simultaneous milling for complex organic shapes via DMG MORI CMX 600V

Turn-mill centers (Mazak Quick Turn Nexus 200) for rotational parts

All machines operate under SPC-controlled environments with in-process CMM verification at critical stages. Material certifications and first-article inspection reports (FAIR) are generated per AS9102 standards for aerospace/medical clients.

Delivery and Traceability

Completed parts undergo final cleaning, deburring, and metrology validation against the original CAD model. Every shipment includes:

Dimensional inspection report with deviation heatmaps

Material traceability documentation (mill certificates)

Real-time shipment tracking via customer portal

Standard lead time from DFM approval to delivery is 5-7 business days for 1-100 units, with expedited 72-hour options for critical path components. All packaging meets ISTA 3A standards for shock and moisture protection, ensuring zero in-transit damage across 99.2% of shipments in 2023.

This closed-loop process eliminates traditional quoting bottlenecks while ensuring manufacturability, with 87% of first-time designs requiring zero DFM revisions due to our AI-guided pre-validation. The workflow is optimized for speed without compromising the geometric fidelity critical to prototyping and low-volume production.

Start Your Project

Interested in precision CAD/CNC machining services? Contact Susan Leo at [email protected] for expert support. Our advanced manufacturing facility is located in Shenzhen, ensuring high-quality prototyping and production with fast turnaround times. Let Honyo Prototype be your trusted partner for accurate, reliable CNC solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.