Introduction: Navigating the Global Market for c17200 beryllium copper

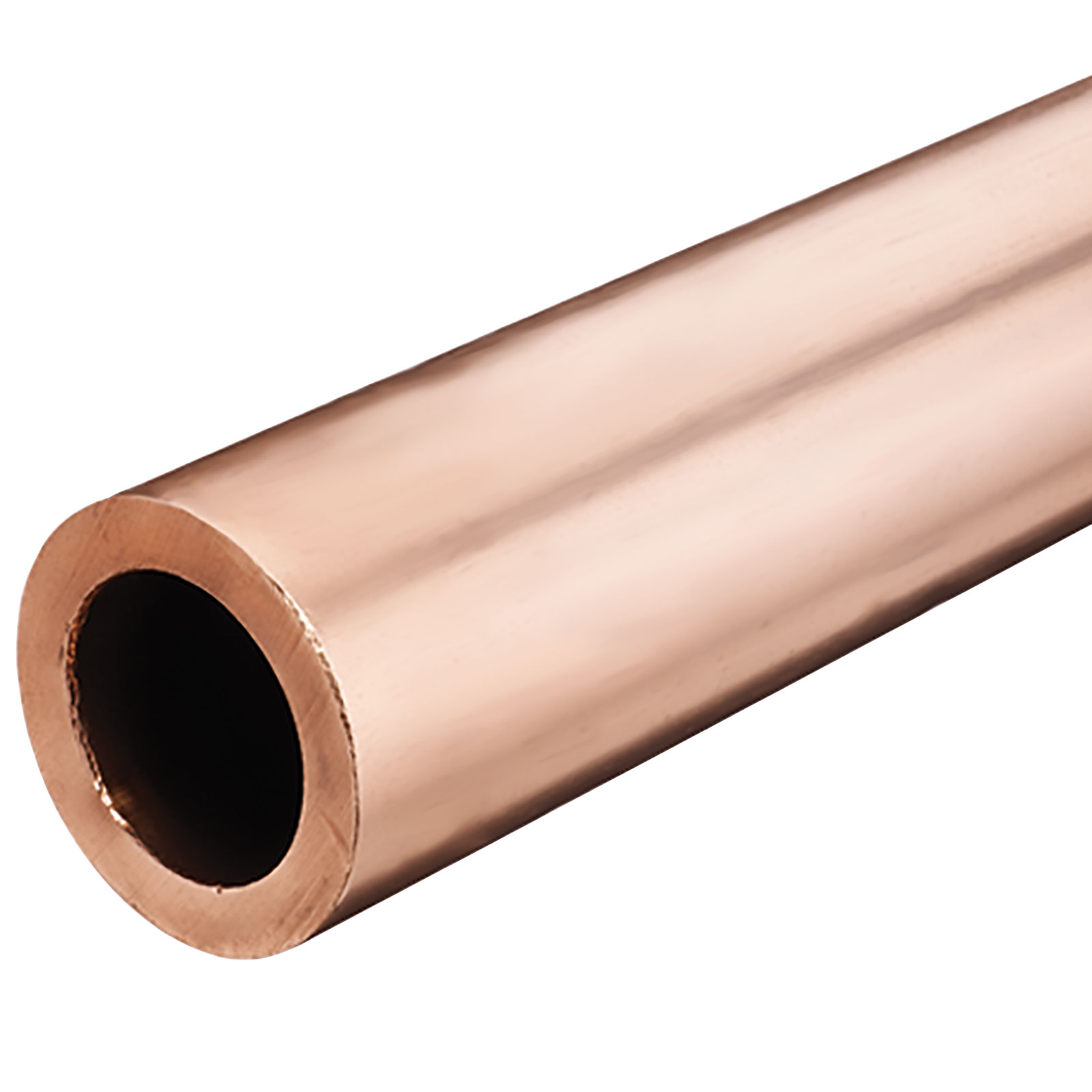

In an increasingly competitive global landscape, sourcing high-quality materials like C17200 beryllium copper can be a daunting challenge for international B2B buyers. This alloy, renowned for its exceptional strength, hardness, and electrical conductivity, is pivotal in various industries, from electronics to aerospace. However, navigating the complexities of sourcing, including identifying reliable suppliers and understanding market dynamics, can significantly impact your procurement strategy and operational efficiency.

This comprehensive guide delves into the multifaceted world of C17200 beryllium copper, addressing critical aspects such as types of alloy, applications, and the nuances of supplier vetting. We will explore the unique properties that make C17200 a preferred choice for demanding applications, alongside insights into cost considerations and market trends. By equipping buyers with actionable information, this guide empowers decision-makers in Africa, South America, the Middle East, and Europe—regions where the demand for high-performance materials is rising.

With a focus on informed purchasing, our aim is to simplify the process of sourcing C17200 beryllium copper, ensuring you can confidently navigate the global market. Leverage this resource to enhance your procurement strategy, mitigate risks, and ultimately secure the best value for your organization.

Understanding c17200 beryllium copper Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| C17200-TF00 (Precipitation Hardened) | High strength and hardness; excellent fatigue resistance. | Electrical connectors, high-stress components. | Pros: Superior mechanical properties; Cons: More expensive due to processing. |

| C17200-TH04 (Hard Temper) | Good balance of strength and ductility; high hardness. | Industrial components, springs, and fasteners. | Pros: Versatile; easy to machine; Cons: Lower conductivity than softer grades. |

| C17200-TM02 (Mill-Hardened) | Good strength; lower hardness; excellent for forming. | General fabrication, forming applications. | Pros: Good workability; Cons: Less strength compared to heat-treated types. |

| C17200-TM08 (Extra Hard) | Maximum hardness; very high tensile strength. | High-performance applications, aerospace. | Pros: Exceptional wear resistance; Cons: Brittle; limited machinability. |

| C17200-TD01 (Solution Heat Treated) | Enhanced ductility and conductivity; moderate strength. | Electrical switch parts, low-stress applications. | Pros: Good electrical properties; Cons: Lower strength than precipitation-hardened types. |

What are the Characteristics of C17200-TF00 (Precipitation Hardened) Beryllium Copper?

C17200-TF00 is renowned for its exceptional strength and hardness, making it ideal for demanding applications. This variant undergoes a precipitation hardening process, enhancing its fatigue resistance and ensuring longevity in high-stress environments. B2B buyers should consider this type for electrical connectors and components where mechanical integrity is crucial. However, the higher processing costs may be a consideration for budget-sensitive projects.

How Does C17200-TH04 (Hard Temper) Compare to Other Types?

C17200-TH04 strikes a balance between strength and ductility, offering high hardness suitable for various industrial applications. Its versatility makes it a popular choice for springs and fasteners, where both strength and machinability are essential. Buyers should note that while it provides good mechanical properties, its electrical conductivity is lower than softer grades, which could be a factor in electrical applications.

What Makes C17200-TM02 (Mill-Hardened) Suitable for General Fabrication?

C17200-TM02 features good strength while maintaining lower hardness, making it excellent for forming and fabrication processes. This type is particularly suitable for applications that require good workability, such as general fabrication tasks. Buyers should appreciate its machinability, although it may not provide the same strength as heat-treated variants, which could limit its use in high-stress scenarios.

Why Choose C17200-TM08 (Extra Hard) for Aerospace Applications?

C17200-TM08 is characterized by its maximum hardness and tensile strength, making it particularly well-suited for high-performance applications like aerospace. Its exceptional wear resistance is a significant advantage in environments where durability is critical. However, buyers should be cautious of its brittleness and limited machinability, which could complicate production processes.

What are the Advantages of C17200-TD01 (Solution Heat Treated) for Electrical Components?

C17200-TD01 offers enhanced ductility and electrical conductivity, making it ideal for low-stress applications like electrical switch parts. While its strength is moderate compared to other variants, its excellent electrical properties make it a preferred choice for components where conductivity is paramount. Buyers should weigh the benefits of conductivity against the trade-off in strength when selecting this type for their applications.

Key Industrial Applications of c17200 beryllium copper

| Industry/Sector | Specific Application of c17200 beryllium copper | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electrical Engineering | Electrical Switch and Relay Blades | High electrical conductivity ensures efficient power transfer, reducing energy losses. | Ensure compliance with international standards (ASTM, AMS) and verify the supplier’s quality certifications. |

| Aerospace | Connectors and Fasteners | Exceptional strength-to-weight ratio enhances durability and reliability in critical applications. | Source from suppliers with aerospace certifications and a proven track record in high-performance alloys. |

| Automotive | Non-sparking Safety Tools | Reduces risk in explosive environments, ensuring safety and compliance with regulations. | Verify the alloy’s certifications for safety applications and assess the supplier’s ability to meet stringent industry requirements. |

| Industrial Manufacturing | Wear Plates and Pump Components | High wear resistance extends the lifespan of machinery, reducing downtime and maintenance costs. | Consider suppliers who offer customization options and can provide detailed material specifications. |

| Oil and Gas | Valve Seats and Diaphragms | Superior corrosion resistance enhances reliability in harsh environments, ensuring operational efficiency. | Ensure sourcing from suppliers with experience in oil and gas applications and verify the material’s performance under extreme conditions. |

How is C17200 Beryllium Copper Applied in Electrical Engineering?

C17200 beryllium copper is widely used in the production of electrical switch and relay blades due to its remarkable electrical conductivity and mechanical strength. These properties ensure efficient power transfer while minimizing energy losses. For international buyers, particularly from regions such as Africa and South America, it is essential to source this alloy from suppliers who can guarantee compliance with international standards, such as ASTM and AMS, to ensure product reliability and performance.

What Role Does C17200 Play in Aerospace Applications?

In the aerospace sector, C17200 is utilized for connectors and fasteners, where its exceptional strength-to-weight ratio is crucial. This alloy provides the durability needed for critical applications, enhancing the overall performance and safety of aerospace components. Buyers in Europe and the Middle East should prioritize sourcing from suppliers with aerospace certifications and proven expertise in high-performance alloys to ensure compliance with stringent industry standards.

Why is C17200 Essential for Automotive Safety Tools?

C17200 beryllium copper is also employed in manufacturing non-sparking safety tools within the automotive industry. This application is vital for reducing risks in potentially explosive environments, thereby ensuring compliance with safety regulations. Buyers, particularly in regions with growing automotive sectors like Brazil and Vietnam, should verify the alloy’s certifications and the supplier’s ability to meet rigorous industry requirements for safety applications.

How Does C17200 Enhance Industrial Manufacturing?

In industrial manufacturing, C17200 is commonly used for wear plates and pump components. Its high wear resistance significantly extends the lifespan of machinery, which translates into reduced downtime and lower maintenance costs. For B2B buyers, it is crucial to consider suppliers who offer customization options and can provide detailed specifications, ensuring that the material meets specific operational demands.

What Benefits Does C17200 Offer in Oil and Gas Applications?

C17200 beryllium copper is favored for valve seats and diaphragms in the oil and gas industry due to its superior corrosion resistance. This characteristic enhances reliability in harsh environments, ensuring operational efficiency and safety. International buyers should ensure that they are sourcing from suppliers experienced in oil and gas applications, as well as verifying the material’s performance under extreme conditions to meet industry standards.

3 Common User Pain Points for ‘c17200 beryllium copper’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality C17200 Beryllium Copper

The Problem:

B2B buyers often struggle to find reliable suppliers of C17200 beryllium copper that meet specific quality standards. This challenge is particularly pronounced for companies operating in regions with limited access to advanced materials or stringent import regulations. Buyers may face issues such as inconsistent material quality, lack of certifications, and varying specifications that do not align with their production requirements. This can lead to production delays, increased costs, and potential failures in the end product, impacting both reputation and profitability.

The Solution:

To effectively source quality C17200 beryllium copper, buyers should establish relationships with reputable suppliers who have a proven track record. This can be achieved by leveraging industry directories and trade associations, such as the Copper Development Association, to find certified manufacturers. When engaging with suppliers, it is essential to request detailed documentation, including material certifications (e.g., ASTM standards), and to conduct quality audits if possible. Buyers should also consider collaborating with suppliers who offer comprehensive technical support, including guidance on material selection based on specific applications. Establishing long-term partnerships can ensure consistent supply and quality, reducing the risks associated with sourcing.

Scenario 2: Challenges in Machining C17200 Beryllium Copper

The Problem:

Machining C17200 beryllium copper can present unique challenges due to its hardness and strength properties. Buyers often report difficulties in achieving precise tolerances and surface finishes, which can lead to increased scrap rates and higher manufacturing costs. Additionally, improper machining techniques can result in tool wear and reduced efficiency, further complicating the production process.

The Solution:

To overcome machining challenges, buyers should invest in proper tooling and machining techniques specifically designed for beryllium copper. Utilizing carbide or ceramic tools with appropriate coatings can significantly enhance tool life and performance. It is advisable to consult machining guidelines from suppliers or industry experts to determine the best cutting speeds, feeds, and coolant methods. Additionally, performing preliminary tests on scrap material can help fine-tune machining parameters before full-scale production. Training machinists on the unique properties of C17200 and conducting regular maintenance on equipment can also lead to better machining outcomes and reduced costs.

Scenario 3: Compliance with Safety Regulations Regarding Beryllium Exposure

The Problem:

B2B buyers in industries that utilize C17200 beryllium copper often face stringent safety regulations concerning beryllium exposure. This concern is heightened in manufacturing environments where machining or welding processes can release harmful particles into the air. Companies may struggle to comply with occupational health regulations, risking fines and jeopardizing worker safety.

The Solution:

To address compliance issues, it is critical for buyers to implement robust safety protocols that minimize exposure to beryllium dust and fumes. This includes investing in appropriate ventilation systems, personal protective equipment (PPE), and implementing strict housekeeping practices to reduce dust accumulation. Buyers should stay informed about local and international beryllium regulations and ensure that all employees receive training on safe handling practices. Additionally, collaborating with suppliers who provide safety data sheets (SDS) and guidance on the safe use of beryllium copper can help organizations maintain compliance. Regular audits and assessments of workplace safety can further ensure adherence to regulations and promote a culture of safety within the organization.

Strategic Material Selection Guide for c17200 beryllium copper

What Are the Key Properties of C17200 Beryllium Copper?

C17200 beryllium copper, also known as Alloy 25, is renowned for its exceptional mechanical properties, including high strength and hardness comparable to steel. This alloy exhibits a tensile strength of approximately 200 ksi and a Rockwell hardness of 45, making it suitable for demanding applications. Its electrical conductivity is about 22% IACS, which is essential in electrical components. Additionally, C17200 has excellent resistance to wear and fatigue, making it ideal for applications that require durability under stress.

What Are the Pros and Cons of Using C17200 Beryllium Copper?

The primary advantages of C17200 include its high strength-to-weight ratio, excellent corrosion resistance, and good thermal and electrical conductivity. These properties make it suitable for a wide range of applications, from electrical switch components to aerospace parts. However, the key disadvantages include its relatively high cost compared to other copper alloys and the complexity involved in its fabrication. The alloy is sensitive to overheating during processing, which can lead to a loss of properties. Therefore, manufacturers must adhere to strict temperature controls during machining and heat treatment.

How Does C17200 Beryllium Copper Impact Specific Applications?

C17200 is particularly effective in applications involving electrical components, such as connectors, relay blades, and Belleville washers, where both strength and electrical conductivity are critical. Its compatibility with various media, including corrosive environments, makes it a preferred choice in industries such as aerospace, automotive, and electronics. However, international buyers should be aware of the alloy’s beryllium content, which may require compliance with specific regulations regarding handling and disposal.

What Should International B2B Buyers Consider When Sourcing C17200 Beryllium Copper?

For buyers in regions like Africa, South America, the Middle East, and Europe, it is crucial to consider compliance with international standards such as ASTM, DIN, and JIS when sourcing C17200. Understanding local regulations regarding beryllium is essential, as some countries have strict guidelines for its use due to health concerns. Additionally, buyers should evaluate suppliers based on their ability to provide certifications and documentation that meet these standards, ensuring the material’s quality and traceability.

| Material | Typical Use Case for c17200 beryllium copper | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| C17200 Beryllium Copper | Electrical connectors and switch components | High strength and excellent electrical conductivity | Higher cost compared to standard copper alloys | High |

| C17200 Beryllium Copper | Belleville washers for mechanical applications | Superior fatigue resistance and durability | Sensitive to overheating during fabrication | High |

| C17200 Beryllium Copper | Aerospace components like valve seats | Corrosion resistance and lightweight | Complex manufacturing process | High |

| C17200 Beryllium Copper | Industrial tools and non-sparking safety tools | Excellent thermal and electrical properties | Requires compliance with beryllium regulations | High |

This strategic material selection guide provides essential insights for B2B buyers looking to leverage the unique properties of C17200 beryllium copper in their applications. Understanding the advantages and limitations of this alloy will help in making informed purchasing decisions that align with industry standards and regional regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for c17200 beryllium copper

What Are the Key Manufacturing Processes for C17200 Beryllium Copper?

The manufacturing of C17200 beryllium copper involves several critical stages, each designed to enhance the material’s performance characteristics. The main stages of the manufacturing process include material preparation, forming, assembly, and finishing.

How Is Material Prepared for C17200 Beryllium Copper?

Material preparation begins with sourcing high-purity copper and beryllium, with strict adherence to specified chemical compositions. The raw materials undergo thorough inspections to ensure they meet the required standards before being processed. This includes chemical analysis to confirm the alloy’s composition aligns with ASTM B196 and other relevant specifications.

Once the materials are confirmed, they are subjected to melting in controlled environments to avoid contamination. The molten alloy is then poured into molds or cast into ingots, which will be further processed into various shapes, including sheets, rods, and wires.

What Forming Techniques Are Commonly Used?

The forming process includes several techniques, such as forging, rolling, and extrusion, which are essential for shaping the material into its final forms.

- Forging involves shaping the metal using compressive forces, which enhances its strength and ductility. This is particularly important for applications requiring high fatigue resistance, such as in aerospace and automotive industries.

- Rolling is typically used to produce flat sheets and plates, where the alloy is passed through rollers to achieve the desired thickness and surface finish.

- Extrusion allows for the creation of complex shapes, such as tubes and profiles, by forcing the heated alloy through a die.

Each of these techniques is selected based on the end-use application and the specific mechanical properties required.

How Is Assembly Handled in the Manufacturing Process?

In some cases, the manufacturing process may include assembly, particularly for components that require joining different parts. This could involve methods such as soldering, brazing, or welding. For C17200 beryllium copper, soldering and brazing are favored due to their ability to create strong joints without compromising the material’s integrity.

However, oxyacetylene welding is generally not recommended due to the risk of introducing defects. Instead, gas shielded arc welding and coated metal arc welding are preferred for their compatibility with this alloy.

What Quality Assurance Practices Are Essential for C17200 Beryllium Copper?

Quality assurance (QA) is a fundamental aspect of the manufacturing process for C17200 beryllium copper, ensuring that the final products meet both international standards and customer specifications.

Which International Standards Should Be Considered?

Suppliers of C17200 beryllium copper must comply with various international standards such as ISO 9001 for quality management systems. Additionally, industry-specific certifications, such as CE marking for products sold in Europe, and API specifications for oil and gas applications, are crucial. Compliance with these standards not only assures product quality but also enhances supplier credibility in international markets.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process. These include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During production, samples are taken at various stages to monitor the processes and identify any deviations from quality standards.

- Final Quality Control (FQC): Before shipping, finished products undergo comprehensive testing to verify their mechanical properties, dimensional accuracy, and surface finish.

What Testing Methods Are Commonly Used for C17200 Beryllium Copper?

Common testing methods include:

- Tensile Testing: To assess the material’s strength and ductility.

- Hardness Testing: Typically using Rockwell or Brinell methods to determine the hardness of the alloy.

- Electrical Conductivity Testing: Essential for applications requiring high electrical performance.

- Impact Testing: To evaluate the material’s toughness under sudden loads.

These tests are critical for ensuring that the C17200 beryllium copper meets the required specifications and performance standards.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is essential for mitigating risks associated with product quality.

What Methods Can Be Used for Supplier Verification?

-

Audits: Conducting supplier audits helps buyers assess the supplier’s manufacturing processes and quality control systems. This can be done through on-site visits or remote assessments using video conferencing.

-

Quality Reports: Requesting detailed quality reports, including results from IQC, IPQC, and FQC, provides insight into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s processes and products, ensuring compliance with international standards.

What Are the Nuances of Quality Certification for International Buyers?

Different regions may have specific requirements or certifications that are critical for doing business. For example, buyers in Europe may prioritize CE marking, while those in the Middle East might look for compliance with local standards. Understanding these nuances can significantly impact procurement decisions and supplier selection.

In conclusion, the manufacturing processes and quality assurance practices for C17200 beryllium copper are vital for ensuring product performance and reliability. By understanding these processes, B2B buyers can make informed decisions, fostering successful partnerships and ensuring the procurement of high-quality materials.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘c17200 beryllium copper’

In the realm of industrial materials, sourcing C17200 beryllium copper requires a strategic approach to ensure quality, compliance, and suitability for your specific applications. This guide provides a structured checklist to help international B2B buyers navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Before initiating your search, clearly outline the technical specifications required for your application. This includes understanding the mechanical properties, such as tensile strength, hardness, and electrical conductivity. Be aware of the specific forms you need (e.g., bars, sheets, or tubes) and the temper conditions that suit your operational requirements.

Step 2: Research Qualified Suppliers

Compile a list of potential suppliers with a proven track record in providing C17200 beryllium copper. Look for suppliers who specialize in high-performance alloys and have experience in your industry. Utilize platforms like industry directories, trade shows, and referrals from industry peers to identify reputable sources.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers possess relevant certifications, such as ISO 9001, ASTM standards, and material traceability. Certifications ensure that the supplier adheres to quality management systems and industry regulations. Additionally, inquire about their compliance with environmental and safety standards, which can impact your company’s reputation and operational integrity.

Step 4: Request Material Samples

Before making a bulk order, request samples of C17200 beryllium copper to assess its quality and suitability. Conduct tests to verify mechanical properties, chemical composition, and compatibility with your production processes. This step is crucial to prevent costly errors and ensure that the material meets your specifications.

Step 5: Understand Pricing Structures

Engage with suppliers to gain a comprehensive understanding of their pricing models. Consider factors such as volume discounts, payment terms, and shipping costs. Transparent pricing structures will help you budget effectively and avoid unexpected expenses during procurement.

Step 6: Check for Lead Times and Availability

Confirm the lead times for the delivery of C17200 beryllium copper. Ensure that the supplier can meet your production schedules and has adequate stock to fulfill your orders promptly. Long lead times can disrupt your operations, so assess the supplier’s ability to provide timely delivery.

Step 7: Establish Communication Protocols

Clear communication is vital throughout the procurement process. Set up regular check-ins with your chosen supplier to discuss order status, address any issues, and ensure alignment on expectations. Effective communication fosters a collaborative relationship and helps mitigate potential misunderstandings.

By following these structured steps, B2B buyers can streamline the sourcing process for C17200 beryllium copper, ensuring they secure high-quality materials that meet their operational needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for c17200 beryllium copper Sourcing

What Are the Key Cost Components in Sourcing c17200 Beryllium Copper?

When sourcing c17200 beryllium copper, understanding the cost structure is essential for effective budgeting and financial planning. The primary cost components include:

-

Materials: The price of raw beryllium copper can fluctuate based on market demand, geopolitical factors, and mining costs. As of recent trends, prices for high-quality copper alloys can range significantly, necessitating a close watch on market reports.

-

Labor: Labor costs vary by region and are influenced by local wage standards and the complexity of the manufacturing processes. Skilled labor may command higher wages, particularly in regions with limited availability of specialized workers.

-

Manufacturing Overhead: This encompasses costs related to utilities, equipment maintenance, and factory management. Efficient manufacturing processes can help reduce overhead costs, impacting the final pricing of the alloy.

-

Tooling: Custom tooling may be necessary for specific shapes or sizes of c17200 products, which adds to the initial investment. This cost can be amortized over larger production runs to improve cost efficiency.

-

Quality Control (QC): Ensuring the alloy meets specific standards (such as ASTM or AMS) incurs costs for testing and inspections. Investing in robust QC processes can prevent costly recalls or defects.

-

Logistics: Transportation costs, especially for international shipments, can significantly influence total costs. Factors such as distance, mode of transport, and packaging requirements must be considered.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and ensure sustainability. This margin can vary based on supplier reputation and product quality.

How Do Price Influencers Affect c17200 Beryllium Copper Pricing?

Several factors influence the pricing of c17200 beryllium copper, including:

-

Volume/MOQ: Minimum order quantities (MOQs) can affect pricing. Larger orders often lead to discounts, whereas small orders may incur higher per-unit costs.

-

Specifications and Customization: Custom specifications or unique requirements can lead to increased costs. Buyers should clearly define their needs to avoid unexpected expenses.

-

Materials: The quality of raw materials directly impacts pricing. Higher-grade materials typically command a premium, but they also offer better performance and longevity.

-

Quality and Certifications: Products that come with certifications (such as ISO or military standards) may be priced higher due to the assurance of quality and compliance.

-

Supplier Factors: Supplier reputation, reliability, and location can influence prices. Established suppliers may charge more for their expertise and customer service.

-

Incoterms: The agreed Incoterms (International Commercial Terms) determine who bears the costs and risks during shipping. Understanding these terms can help buyers manage logistics costs effectively.

What Tips Can Help Buyers Negotiate Better Prices for c17200 Beryllium Copper?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, negotiating favorable prices for c17200 beryllium copper requires strategic considerations:

-

Negotiate Based on Volume: Leverage bulk purchasing to negotiate lower prices. Discussing potential future orders can also provide leverage.

-

Understand Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, durability, and operational efficiency. A higher initial cost may be justified by lower long-term costs.

-

Research Supplier Markets: Familiarize yourself with different suppliers and their pricing structures. This knowledge can provide leverage during negotiations.

-

Be Aware of Pricing Nuances: Understand regional market conditions and supply chain dynamics. Prices may vary significantly based on geopolitical stability or local demand.

-

Request Multiple Quotes: Solicit quotes from several suppliers to compare costs and terms. This practice can reveal competitive pricing and help in negotiations.

What Should Buyers Keep in Mind Regarding Indicative Prices?

While indicative prices provide a baseline for budgeting, they are subject to change based on market fluctuations and other external factors. Buyers should remain flexible and prepared for price adjustments, particularly in volatile markets. Engaging with suppliers regularly for updates can help in anticipating changes and making informed purchasing decisions.

Alternatives Analysis: Comparing c17200 beryllium copper With Other Solutions

Understanding Alternatives to C17200 Beryllium Copper

When evaluating materials for industrial applications, it’s crucial to consider alternatives that can meet specific performance criteria while aligning with budget constraints and operational needs. C17200 beryllium copper is recognized for its exceptional strength, hardness, and electrical conductivity. However, other materials may also serve similar purposes depending on the application requirements. Below, we compare C17200 beryllium copper with two viable alternatives: Aluminum Bronze and Stainless Steel.

Comparison of C17200 Beryllium Copper and Alternatives

| Comparison Aspect | C17200 Beryllium Copper | Aluminum Bronze | Stainless Steel |

|---|---|---|---|

| Performance | High strength and hardness; excellent electrical conductivity (22% IACS) | Good corrosion resistance; decent strength and conductivity | Excellent corrosion resistance; moderate strength |

| Cost | Generally higher due to alloying and processing costs | Moderate; more affordable than beryllium copper | Typically lower; widely available |

| Ease of Implementation | Requires specific handling due to beryllium toxicity; good machinability | Easier to work with; can be cast or forged | Readily available; versatile in fabrication |

| Maintenance | Low maintenance; resistant to wear | Moderate; can corrode in harsh environments | Low; highly resistant to rust and corrosion |

| Best Use Case | Electrical applications, precision tools, and components requiring high strength | Marine applications, valves, and pumps | General-purpose applications, structural components, and fasteners |

Detailed Breakdown of Alternatives

Aluminum Bronze

Aluminum bronze is a copper alloy that includes aluminum as the primary alloying element, providing excellent corrosion resistance and moderate strength. This material is particularly suited for marine environments and applications involving seawater, making it ideal for shipbuilding and offshore structures. While it does not match the electrical conductivity of C17200 beryllium copper, its ease of fabrication and lower cost make it an attractive alternative for specific applications. However, it is not as strong or hard, which may limit its use in high-stress environments.

Stainless Steel

Stainless steel is a widely used material known for its exceptional corrosion resistance and strength. It is a cost-effective alternative to beryllium copper, particularly in applications where electrical conductivity is not the primary concern. Stainless steel is versatile and can be easily fabricated into various shapes and forms, making it suitable for a broad range of industrial applications. However, it typically has lower electrical conductivity compared to C17200, which may be a disadvantage in electrical applications. Its durability and low maintenance requirements make it a favorite in many sectors, but it may not perform as well in high-stress scenarios as beryllium copper.

How Can B2B Buyers Choose the Right Solution?

When selecting the right material for an application, B2B buyers should carefully evaluate the specific requirements of their projects. Factors such as performance specifications, budget limitations, and environmental conditions play a crucial role in the decision-making process. For applications requiring high strength and conductivity, C17200 beryllium copper remains a superior choice. However, for applications where cost and ease of fabrication are prioritized, alternatives like aluminum bronze or stainless steel may provide a more effective solution. Ultimately, understanding the unique advantages and limitations of each material will empower buyers to make informed choices that align with their operational needs.

Essential Technical Properties and Trade Terminology for c17200 beryllium copper

What Are the Key Technical Properties of C17200 Beryllium Copper?

C17200 beryllium copper, also known as Alloy 25, is recognized for its exceptional strength, hardness, and corrosion resistance. Here are some critical specifications that B2B buyers should consider:

-

Material Grade: C17200 is classified as a high-strength beryllium copper alloy, often used in applications requiring both mechanical strength and electrical conductivity. Its composition includes approximately 1.8-2.0% beryllium, providing enhanced properties compared to other copper alloys. This material grade is vital for industries such as aerospace, electronics, and automotive.

-

Tensile Strength: The tensile strength of C17200 can reach up to 200 ksi in peak aged condition. This strength is comparable to that of steel, making it suitable for demanding applications where durability and resistance to deformation are essential. Understanding tensile strength helps buyers assess the performance of components under stress.

-

Electrical Conductivity: With a minimum electrical conductivity of 22% IACS, C17200 is excellent for electrical applications. This property is crucial for components like connectors and switch parts, where efficient electrical flow is necessary. Buyers should evaluate conductivity levels to ensure optimal performance in their applications.

-

Rockwell Hardness: C17200 typically exhibits a Rockwell hardness of 45 on the C scale. This hardness level indicates its ability to withstand wear and tear, making it suitable for parts subjected to friction and mechanical stress. The hardness rating is a key consideration for manufacturers seeking long-lasting materials.

-

Fabrication Properties: C17200 is known for its good workability, with suitable ratings for various fabrication techniques such as soldering, brazing, and cold working. This versatility allows manufacturers to easily produce complex shapes and components, thus enhancing efficiency in production processes.

-

Corrosion Resistance: This alloy demonstrates excellent resistance to corrosion, making it ideal for use in harsh environments. Industries such as oil and gas, marine, and chemical processing benefit from this property, as it ensures longevity and reliability of components.

What Are Common Trade Terminology and Their Importance in C17200 Beryllium Copper Transactions?

Understanding trade terminology is crucial for B2B transactions involving C17200 beryllium copper. Here are some common terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is essential for buyers seeking reliable sources for their components, ensuring quality and compatibility.

-

MOQ (Minimum Order Quantity): MOQ specifies the smallest quantity of a product that a supplier is willing to sell. This term is significant for buyers in budgeting and inventory management, as it directly impacts the cost-effectiveness of procurement.

-

RFQ (Request for Quotation): An RFQ is a document sent by buyers to suppliers to request pricing and terms for specific products. This process is critical for obtaining competitive pricing and understanding the market landscape for C17200 beryllium copper.

-

Incoterms (International Commercial Terms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Knowledge of Incoterms is vital for understanding shipping, insurance, and risk allocation, which are essential for smooth cross-border transactions.

-

Lead Time: This term refers to the time it takes from placing an order until the product is delivered. Recognizing lead times is crucial for planning production schedules and inventory management, ensuring that operations run smoothly without interruptions.

-

Certification: This refers to documents proving that materials meet specific industry standards (e.g., ASTM, AMS). Buyers should prioritize suppliers who provide certifications to guarantee the quality and compliance of C17200 beryllium copper products.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing C17200 beryllium copper, ensuring they meet their operational needs effectively.

Navigating Market Dynamics and Sourcing Trends in the c17200 beryllium copper Sector

What Are the Current Market Dynamics and Key Trends Affecting the C17200 Beryllium Copper Sector?

The C17200 beryllium copper market is currently experiencing robust growth, driven by increasing demand across various industries, including aerospace, automotive, electronics, and telecommunications. As international markets rebound post-pandemic, buyers from regions like Africa, South America, the Middle East, and Europe are navigating a landscape characterized by heightened competition and evolving technological advancements. Key trends include the integration of digital sourcing platforms that streamline procurement processes, enabling buyers to access a broader pool of suppliers and enhance decision-making through data analytics.

Moreover, sustainability is becoming a pivotal consideration in sourcing decisions. Buyers are increasingly prioritizing suppliers that adhere to ethical practices and demonstrate environmental responsibility, particularly in the extraction and processing of raw materials. The rise of Industry 4.0 technologies, such as IoT and AI, is also reshaping the way manufacturers engage with suppliers, enhancing supply chain visibility and efficiency. Furthermore, geopolitical factors, such as trade tariffs and regional conflicts, are influencing sourcing strategies, compelling buyers to diversify their supplier base to mitigate risks.

How Is Sustainability Impacting Sourcing Decisions in the C17200 Beryllium Copper Market?

Sustainability and ethical sourcing are becoming paramount in the C17200 beryllium copper sector, reflecting a broader trend in global manufacturing. The environmental impact of mining beryllium, particularly regarding habitat disruption and waste management, is prompting buyers to seek suppliers committed to sustainable practices. This includes the use of recycled materials and adherence to stringent environmental regulations, which not only help in minimizing ecological footprints but also enhance brand reputation.

Moreover, certifications such as ISO 14001 (Environmental Management Systems) and Responsible Minerals Initiative (RMI) are increasingly sought after by international buyers. These certifications provide assurance that suppliers maintain environmentally friendly practices and uphold ethical labor standards. As a result, companies that prioritize sustainability in their sourcing strategies are likely to gain a competitive advantage, appealing to eco-conscious consumers and stakeholders. Additionally, the implementation of circular economy principles is gaining traction, encouraging businesses to design products that allow for reuse and recycling, thus extending the lifecycle of materials like C17200 beryllium copper.

What Is the Historical Context of C17200 Beryllium Copper and Its Relevance Today?

The C17200 beryllium copper alloy, also known as Alloy 25, has a rich history rooted in its development during the 20th century when it was first introduced for its exceptional strength and conductivity. Initially utilized in military applications, its properties soon found relevance across various sectors, including telecommunications and aerospace. As industries evolved, the demand for high-performance materials that could withstand extreme conditions led to the widespread adoption of C17200 beryllium copper.

Today, this alloy is recognized for its superior mechanical properties, such as high tensile strength and excellent fatigue resistance, making it an indispensable material in critical applications. The ongoing advancements in metallurgy and processing techniques continue to enhance its performance characteristics, ensuring that C17200 remains a vital component in innovative manufacturing solutions. For B2B buyers, understanding the alloy’s historical significance provides context for its current applications and the ongoing trends that shape its market dynamics.

Frequently Asked Questions (FAQs) for B2B Buyers of c17200 beryllium copper

-

How do I identify reliable suppliers for c17200 beryllium copper?

When sourcing c17200 beryllium copper, it is essential to perform thorough due diligence on potential suppliers. Start by checking their industry certifications, such as ISO 9001, which indicate a commitment to quality management. Additionally, request references and case studies from previous clients, focusing on their experience with similar products. Utilize platforms like Alibaba or ThomasNet to compare supplier ratings and reviews. Engage in direct communication to assess their responsiveness and willingness to meet your specific needs. This process will help ensure you choose a reliable supplier. -

What are the typical applications for c17200 beryllium copper?

C17200 beryllium copper is widely used in various industries due to its exceptional strength and electrical conductivity. Common applications include electrical switch and relay blades, connectors, and fasteners such as washers and clips. It is also utilized in the manufacturing of non-sparking tools, valve components, and aerospace parts. When selecting c17200, consider your application’s specific requirements for strength, corrosion resistance, and conductivity to ensure optimal performance. -

What are the minimum order quantities (MOQ) for c17200 beryllium copper?

Minimum order quantities for c17200 beryllium copper can vary significantly between suppliers. Generally, MOQs may range from 100 kg to several tons, depending on the supplier’s production capabilities and inventory levels. It is advisable to inquire about MOQs upfront and consider negotiating if you require smaller quantities. Some suppliers may offer flexibility for first-time buyers or bulk purchases, which can be beneficial for establishing a long-term relationship. -

What payment terms should I expect when purchasing c17200 beryllium copper?

Payment terms can differ based on the supplier’s policies and your negotiation leverage. Common arrangements include full payment in advance, a deposit with the balance due upon shipment, or net 30/60 terms. For larger orders, suppliers may be more open to extended payment terms. It’s crucial to discuss and agree on payment terms before finalizing the order to avoid misunderstandings later on. -

How can I ensure the quality of c17200 beryllium copper during sourcing?

To guarantee the quality of c17200 beryllium copper, request material certifications, such as ASTM or AMS standards, which provide assurance that the product meets specific criteria. Conducting a pre-shipment inspection can also be beneficial, allowing you to verify the material’s properties and dimensions. Additionally, consider establishing a quality assurance agreement with the supplier, outlining your expectations and the procedures for addressing any discrepancies. -

What are the logistics considerations when importing c17200 beryllium copper?

When importing c17200 beryllium copper, consider logistics factors such as shipping methods, customs regulations, and delivery times. Choose a reliable freight forwarder experienced in handling metal imports to ensure compliance with international shipping laws. Additionally, familiarize yourself with any import duties or tariffs applicable in your country to calculate total landed costs accurately. Coordinating closely with your supplier and logistics provider can streamline the shipping process and minimize delays. -

Are there customization options available for c17200 beryllium copper products?

Many suppliers offer customization options for c17200 beryllium copper products, including specific dimensions, shapes, and heat treatment processes. Discuss your requirements with potential suppliers to determine their capabilities and willingness to accommodate custom orders. Providing detailed specifications and drawings can facilitate the customization process. Keep in mind that custom orders may require longer lead times and could affect pricing, so it’s essential to plan accordingly. -

What are the common challenges when sourcing c17200 beryllium copper internationally?

Sourcing c17200 beryllium copper internationally can present challenges such as fluctuating exchange rates, varying quality standards, and different regulatory requirements. Language barriers may also complicate communication with suppliers. To mitigate these issues, establish clear communication channels, and consider working with local representatives or agents who understand the market dynamics. Additionally, staying informed about geopolitical factors that could impact trade relations can help you navigate potential disruptions effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 C17200 Beryllium Copper Manufacturers & Suppliers List

1. Aviva Metals – C17200 Beryllium Copper Alloy

Domain: avivametals.com

Registered: 2017 (8 years)

Introduction: C17200 Copper (CDA 172), also known as Alloy 25, is the most commonly utilized beryllium copper alloy, notable for its high strength and hardness comparable to steel. Ultimate tensile strength is in the 200 ksi range, and Rockwell hardness is RC 45, with electrical conductivity of 22% IACS minimum. Standards include ASTM B196, AMS 4533, SAE J461, RWMA CLASS IV, CuBe2 2.1247. Available shapes and s…

2. Alro – 172 Beryllium Copper

Domain: alro.com

Registered: 1996 (29 years)

Introduction: {“Product Name”: “172 Beryllium Copper”, “Alloy”: “C17200 (Alloy 25)”, “Chemical Composition”: {“Copper”: “Remainder (nominal 98.1%)”, “Aluminum”: “.20 max.”, “Beryllium”: “1.8 / 2.0”, “Cobalt”: “.20 min.”, “Silicon”: “.20 max.”}, “Properties”: {“Ultimate Tensile Strength”: “200 ksi”, “Rockwell Hardness”: “RC 45”, “Electrical Conductivity”: “22% IACS minimum”, “Soldering”: “Good”, “Brazing”: “Good…

3. Azom – Beryllium Copper UNS C17200

Domain: azom.com

Registered: 1999 (26 years)

Introduction: Product Name: Beryllium Copper UNS C17200

Key Details:

– Ductile and produced in mill hardened and heat treatable tempers.

– High strength, stiffness, and good conductivity.

– Tensile strength: over 1380 MPa (200 ksi).

Chemical Composition:

– Cu: 97.9%

– Be: 1.9%

– Co: 0.20%

Physical Properties:

– Density: 8.25 g/cm³ (0.298 lb/in³)

– Melting Point: 866°C (1590°F)

Mechanical Properties:

– Hardn…

4. Farmers Copper – C17200 Beryllium Copper

Domain: farmerscopper.com

Registered: 1998 (27 years)

Introduction: C17200 Beryllium Copper – Alloy 25 supplier | Farmers Copper, LTD. Specifications: ASTM B196, AMS 4533, DIN 2.1247, BS 2870 CB101, BS 2871 CB101, BS 2874 CB101, EN CW101C. Key Characteristics: Excellent response to precipitation-hardening treatments, excellent thermal conductivity, resistance to stress relaxation, high strength. Available Forms: Round rod, bar, tube, and strip. Heat Treatment: Low…

5. Materion – High-Strength Copper-Beryllium Alloys

Domain: materion.com

Registered: 1999 (26 years)

Introduction: High-strength Copper-Beryllium Alloys from Materion offer high strength, conductivity, hardness, and corrosion resistance for demanding applications in aerospace, automotive, defense, energy, industrial, and telecom sectors. Key alloys include:

– **Alloy 25**: Highest strength (up to 200 ksi), hardness approaching HRC 45, minimum electrical conductivity of 22% IACS. Available in various forms (s…

6. Vincent Metals – C17200 Beryllium Copper

Domain: vincentmetals.com

Registered: 2009 (16 years)

Introduction: {“product_name”: “C17200 Beryllium Copper”, “supplier”: “Vincent Metals”, “address”: “9341 Penn Ave S, Bloomington, MN 55431”, “phone”: “800-447-3317”, “forms_available”: [“Bar and Rod”, “Wire”, “Cut Plate”, “Sheet”, “Strip”], “common_names”: [“Alloy 25”, “RWMA Class 4”], “properties”: {“strength”: “highest of all copper alloys”, “hardness”: “highest of all copper alloys”}, “chemical_data”: {“Alum…

7. National Bronze – C17200 Beryllium Copper

Domain: nationalbronze.com

Registered: 1998 (27 years)

Introduction: C17200 Beryllium Copper is an excellent material for various applications, known for its high compressive strengths and excellent bearing properties. It has significant non-corrosive properties in harsh conditions and great galling resistance. The alloy has a relative magnetic permeability close to 1.00, making it transparent to magnetic fields, and it is non-sparking. Common applications include …

8. HP Metals – Beryllium Copper 25

Domain: hpmetals.com

Registered: 1996 (29 years)

Introduction: Beryllium Copper 25 • UNS C17200

– Type: Copper base alloy

– Strengthening: Precipitation heat treatment

– Key Properties: Best combination of electrical conductivity, corrosion resistance, and mechanical strength

– Fabrication: Good formability and joining characteristics; can be soldered, brazed, and welded using standard techniques

– Brazing Temperature: Must be kept under 1450º F; cycle time m…

9. Smith Metal – Alloy 25 (UNS C17200)

Domain: smithmetal.com

Registered: 1997 (28 years)

Introduction: Alloy 25 (UNS C17200) is a high-performance copper-beryllium alloy known for its strength, fatigue resistance, nonmagnetic properties, conductivity, and corrosion resistance. It is fully heat treated with certified mechanical properties, requiring no additional treatment. Alloy 25 exhibits excellent galling resistance under high load conditions, making it suitable for bearing and bushing applicati…

Strategic Sourcing Conclusion and Outlook for c17200 beryllium copper

As global demand for high-performance materials rises, c17200 beryllium copper stands out for its exceptional strength, hardness, and conductivity. This alloy is an ideal choice for industries ranging from electronics to aerospace, where reliability and performance are critical. Strategic sourcing of c17200 can yield significant advantages, including cost efficiency, enhanced product performance, and reduced lead times. Buyers should prioritize establishing relationships with reputable suppliers who understand the unique properties and applications of this alloy.

Investing in c17200 beryllium copper not only meets immediate project requirements but also positions companies to leverage future innovations in technology and manufacturing processes. As the market continues to evolve, staying informed about material advancements and supplier capabilities will be crucial for maintaining a competitive edge.

For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, the opportunity to integrate c17200 beryllium copper into your supply chain is ripe for exploration. Engage with trusted suppliers and consider the long-term benefits of incorporating this high-performance alloy into your operations. Embrace the future of manufacturing with c17200—your projects deserve the best materials available.