Contents

Manufacturing Insight: C N C Machining

Precision CNC Machining Solutions Engineered for Performance

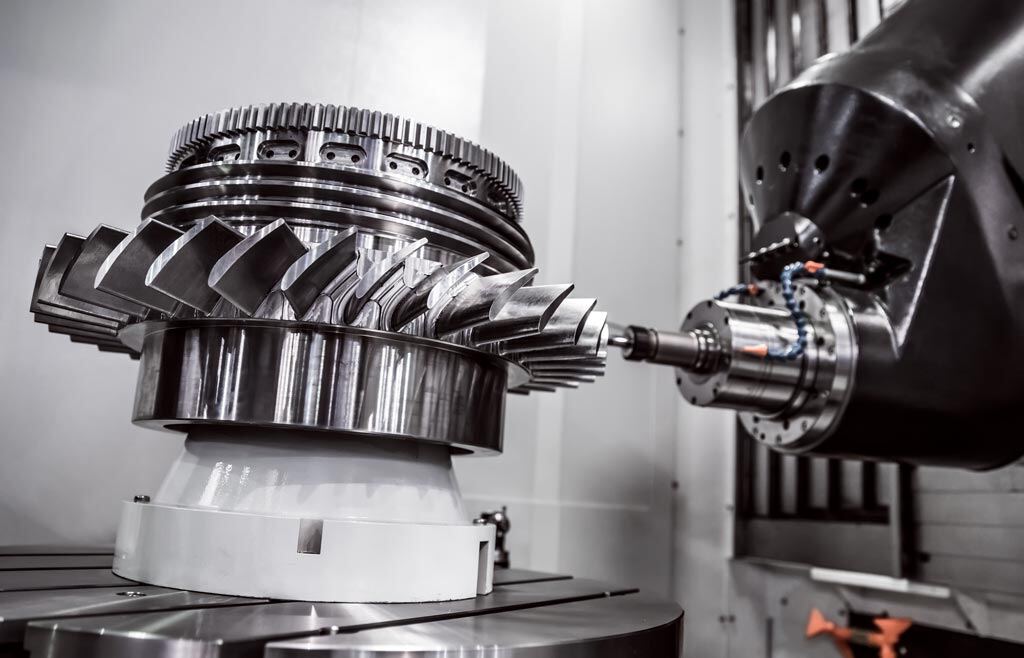

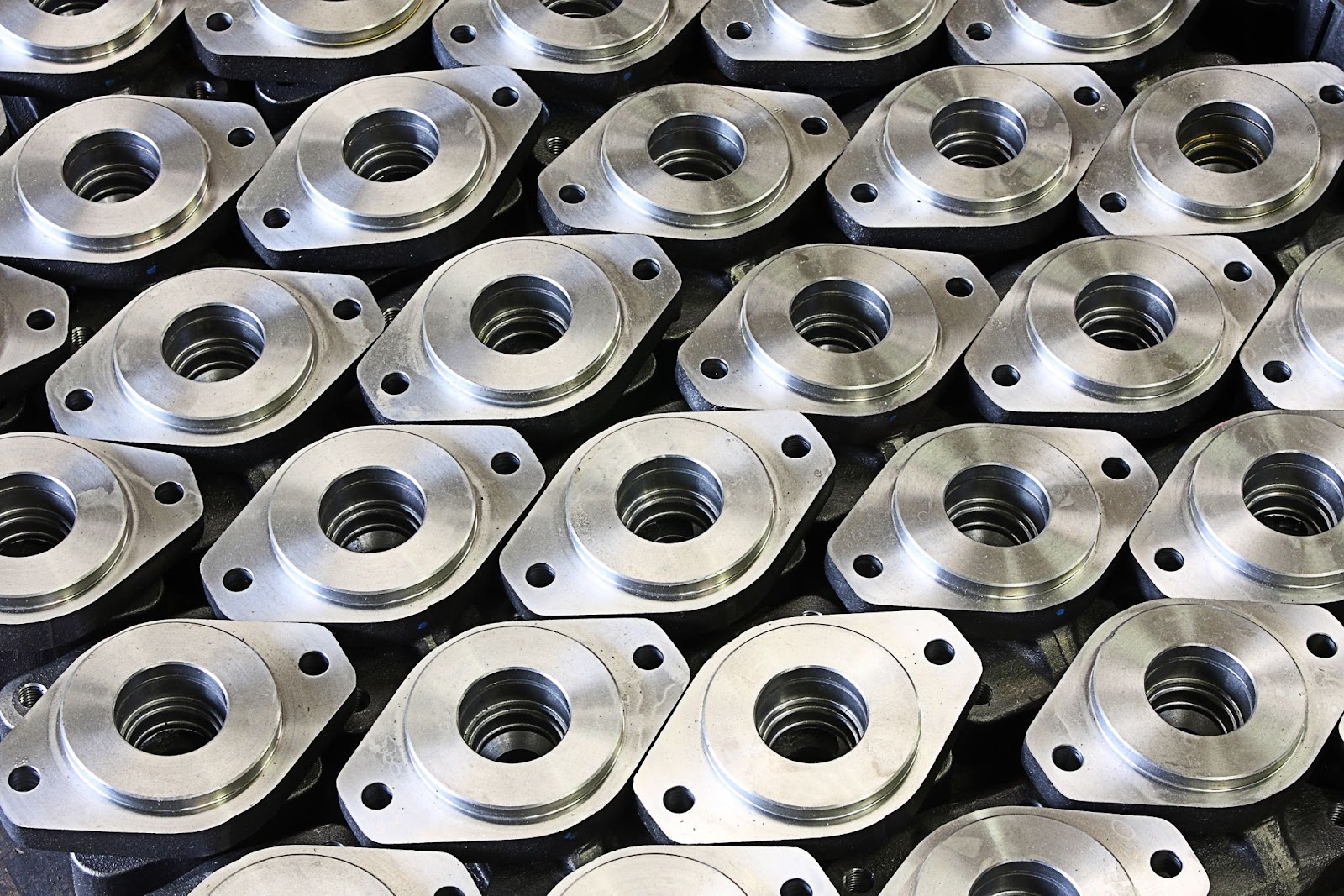

At Honyo Prototype, we transform complex engineering designs into high-integrity components through advanced CNC machining services. Our dedicated manufacturing facility leverages state-of-the-art multi-axis milling and turning centers to deliver parts meeting stringent aerospace, medical, and industrial specifications. With capabilities spanning 3-axis, 4-axis, and 5-axis machining, we achieve tolerances as tight as ±0.0002″ across diverse materials including aluminum alloys, stainless steels, titanium, brass, and engineering plastics. Every process is governed by ISO 9001-certified quality protocols, ensuring repeatability, dimensional accuracy, and surface finishes optimized for functional performance.

Our technical team collaborates closely with design engineers to resolve manufacturability challenges early, reducing iteration cycles and accelerating time-to-market. Whether producing single prototypes, bridge tooling, or low-volume production runs, Honyo integrates cutting-edge CAM programming with rigorous in-process inspection to eliminate waste and guarantee first-article success. Material waste is minimized through intelligent nesting algorithms and chip management systems, supporting both cost efficiency and sustainable manufacturing practices.

Accelerate your prototyping and production timelines with Honyo’s Online Instant Quote platform. Upload CAD files in STEP, IGES, or native formats to receive a detailed manufacturability analysis and competitive pricing within hours—not days. This digital workflow provides transparent cost visibility while our engineering team proactively identifies potential design optimizations. For projects demanding precision, speed, and technical partnership, Honyo Prototype delivers CNC machining solutions where quality is non-negotiable. Submit your CAD files today to experience seamless quoting and execution.

Technical Capabilities

CNC Machining Technical Specifications

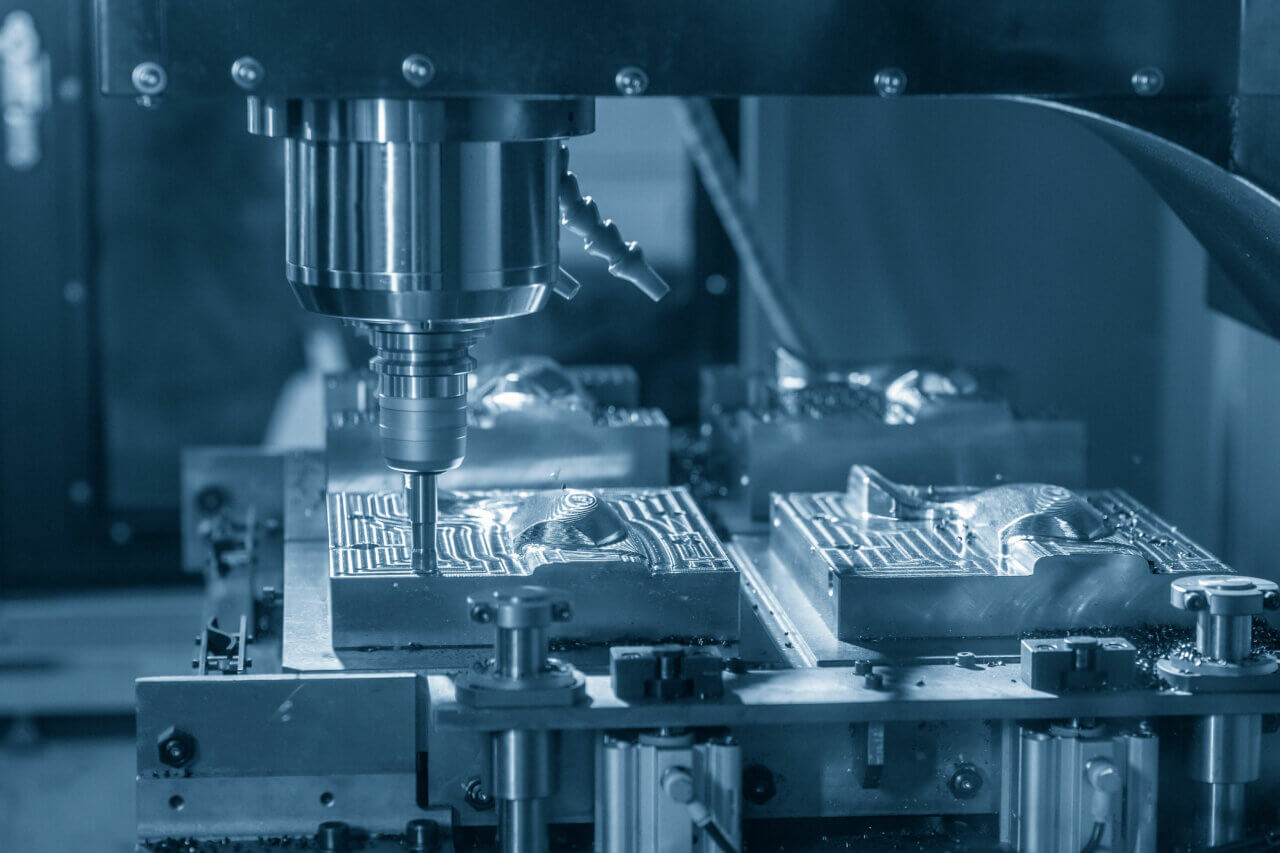

CNC machining is a subtractive manufacturing process that utilizes computer-controlled tools to produce high-precision components. The following table outlines key technical specifications for 3-axis, 4-axis, and 5-axis milling, as well as CNC turning, with an emphasis on tight tolerance capabilities across common engineering materials.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|---|---|---|---|---|

| Axes of Motion | X, Y, Z | X, Y, Z, A (rotary around X) | X, Y, Z, A, B (or C) | X, Z (with optional C-axis) |

| Typical Tolerance | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) |

| Tight Tolerance Capability | Up to ±0.0025 mm (±0.0001″) | Up to ±0.0025 mm (±0.0001″) | Up to ±0.0025 mm (±0.0001″) | Up to ±0.0025 mm (±0.0001″) |

| Surface Finish (Ra) | 0.8 – 3.2 µm (32–125 µin) | 0.8 – 3.2 µm (32–125 µin) | 0.4 – 1.6 µm (16–63 µin) | 0.4 – 1.6 µm (16–63 µin) |

| Max Work Envelope (Typical) | 1000 x 600 x 500 mm | 800 x 500 x 400 mm | 600 x 500 x 400 mm | Ø300 x 500 mm (diameter x length) |

| Spindle Speed (Max) | 24,000 RPM | 20,000 RPM | 20,000 RPM | 6,000 RPM (high-speed options up to 15,000 RPM) |

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.003 mm | ±0.005 mm |

| Repeatability | ±0.002 mm | ±0.002 mm | ±0.001 mm | ±0.002 mm |

Compatible Materials and Machinability Notes:

Aluminum (e.g., 6061, 7075)

Excellent machinability with high material removal rates. Ideal for tight tolerance parts due to dimensional stability and low cutting forces. Commonly used in aerospace and automotive applications.

Steel (e.g., 4140, 1018, Stainless 303/304)

Moderate to challenging machinability depending on alloy and hardness. Requires rigid setups and appropriate tooling. Capable of achieving tight tolerances with proper thermal management.

ABS (Acrylonitrile Butadiene Styrene)

Thermoplastic with good machinability but prone to melting if cutting speeds are too high. Requires sharp tools and low heat input. Suitable for prototypes and non-structural components.

Nylon (e.g., PA6, PA66)

Semi-crystalline thermoplastic with good wear resistance. Can be challenging due to elasticity and tendency to absorb moisture. Dimensional stability requires post-machining conditioning. Tolerances may require compensation for hygroscopic expansion.

General Notes:

5-axis milling enables complex geometries with reduced setup time and improved accuracy. Turning is optimal for cylindrical parts, often combined with milling operations in live-tooling CNC lathes. All processes support tight tolerance requirements when supported by precision tooling, environmental controls, and in-process inspection.

From CAD to Part: The Process

Honyo Prototype employs a rigorously defined CNC machining workflow designed for precision, efficiency, and client transparency. This integrated process ensures manufacturability while minimizing lead times and cost overruns. The sequence progresses as follows:

CAD Upload and Initial Processing

Clients initiate the process by uploading native or neutral format CAD files (STEP, IGES, Parasolid, SolidWorks) via our secure customer portal. Our system performs an immediate automated validation check for file integrity, unit consistency, and basic geometric feasibility. This step confirms the dataset is suitable for downstream processing and establishes the foundational geometry for quoting and DFM.

AI-Driven Quoting with Engineering Validation

Uploaded geometry feeds into our proprietary AI quoting engine, which analyzes part complexity, volume, feature density, and material requirements against real-time machine availability, tooling costs, and labor rates. The AI generates a preliminary cost and lead time estimate within minutes. Crucially, this estimate undergoes mandatory review by our senior manufacturing engineering team. Engineers validate the AI output, adjusting for nuanced factors like fixturing complexity, secondary operations, or material-specific machining challenges, ensuring the final quote reflects achievable production parameters. Clients receive a formal quotation with detailed cost breakdown and timeline commitment.

Collaborative DFM Analysis and Approval

Upon quote acceptance, our DFM phase begins. Our engineers conduct a comprehensive manufacturability review using specialized CAM simulation software. We identify potential issues such as non-optimal wall thicknesses, problematic undercuts, excessive tolerance stacking, or inefficient tool access. A formal DFM report is generated, highlighting actionable recommendations for design refinement to improve yield, reduce cycle time, or lower costs. This is not a unilateral assessment; we engage in direct engineering dialogue with the client to discuss findings, incorporate feedback, and secure formal sign-off on the optimized manufacturing plan before any metal is cut. This step is critical for risk mitigation and schedule adherence.

Precision Production Execution

With DFM approval, the job enters production. Our CNC programming team develops optimized toolpaths using Mastercam and Fusion 360, rigorously simulating for collisions and efficiency. Parts are machined on calibrated Haas, DMG MORI, or Makino centers with strict adherence to documented work instructions. In-process inspections occur at critical stages using CMMs, optical comparators, and surface roughness testers. Final First Article Inspection (FAI) per AS9102 or client-specified standards is performed, with full dimensional reports provided. All materials are traceable to certified mill certificates, and environmental controls maintain ISO Class 8 cleanroom conditions for critical components.

Quality-Controlled Delivery

Completed parts undergo final visual and functional inspection against the approved drawing. We package components using industry-standard ESD-safe or anti-corrosion materials based on part requirements. Shipping documentation includes the FAI report, material certs, and process validation records. Orders ship via client-preferred carriers (DHL, FedEx, or dedicated logistics partners) with real-time tracking provided through our portal. Standard lead times vary by complexity and material as shown below:

| Material Category | Typical Lead Time (Business Days) | Key Factors Influencing Timeline |

|---|---|---|

| Aluminum Alloys (6061, 7075) | 5-8 | Feature density, anodizing requirements |

| Engineering Plastics (PEEK, Delrin) | 7-10 | Moisture conditioning, stress relief |

| Stainless Steel (303, 316) | 8-12 | Passivation, tolerance stringency |

| Titanium Alloys | 10-15 | Specialized tooling, lower RPM cycles |

This closed-loop process guarantees that every CNC-machined component meets Honyo’s stringent quality benchmarks while providing clients with predictable timelines and actionable engineering insights at every stage. The integration of AI acceleration with human engineering oversight ensures both speed and reliability in low-to-mid volume prototype and bridge production runs.

Start Your Project

Looking for precision CNC machining services? Contact Susan Leo at [email protected] to discuss your project requirements.

Honyo Prototype operates a fully equipped manufacturing facility in Shenzhen, providing high-quality CNC machining solutions for rapid prototyping and low-volume production.

From 3-axis to 5-axis machining, we support tight tolerances, fast turnaround times, and expert engineering support.

Reach out today to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.