Introduction: Navigating the Global Market for buy plastic online

In today’s global marketplace, sourcing high-quality plastic materials online presents unique challenges for B2B buyers, especially those in emerging markets like Africa, South America, the Middle East, and Europe. With a diverse array of products ranging from acrylic sheets to HDPE rods, the task of purchasing plastic online can be daunting, particularly when it comes to ensuring product quality, supplier reliability, and cost-effectiveness. This comprehensive guide serves as an essential resource for international buyers looking to navigate the complexities of buying plastic online.

Within these pages, you will find detailed insights into various types of plastics, their applications across industries, and tips for effectively vetting suppliers. We address crucial factors such as pricing structures, shipping logistics, and customization options that can significantly impact your procurement strategy. Whether you are in Saudi Arabia seeking durable materials for construction or in Brazil looking for eco-friendly options for packaging, this guide equips you with the knowledge needed to make informed purchasing decisions.

By empowering B2B buyers with actionable insights and practical advice, we aim to simplify the sourcing process and foster successful partnerships in the ever-evolving plastic market. Dive in to discover how to optimize your purchasing strategy and leverage the vast opportunities available in the global plastic supply chain.

Understanding buy plastic online Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Acrylic | High optical clarity, excellent weather resistance | Signage, displays, protective barriers | Pros: Lightweight, easy to fabricate. Cons: Can scratch easily. |

| Polycarbonate | High impact resistance, lightweight glass alternative | Safety shields, automotive components | Pros: Very durable, good thermal insulation. Cons: Higher cost than acrylic. |

| HDPE | Chemical and corrosion resistance, UV stability | Packaging, construction, marine applications | Pros: Strong, versatile, and easy to fabricate. Cons: Limited color options. |

| PVC | Cost-effective, good chemical resistance | Plumbing, electrical insulation, signage | Pros: Affordable and widely available. Cons: Less durable than other plastics. |

| Nylon | Superior wear resistance, excellent machinability | Gears, bearings, automotive parts | Pros: High strength and durability. Cons: Can absorb moisture, affecting dimensions. |

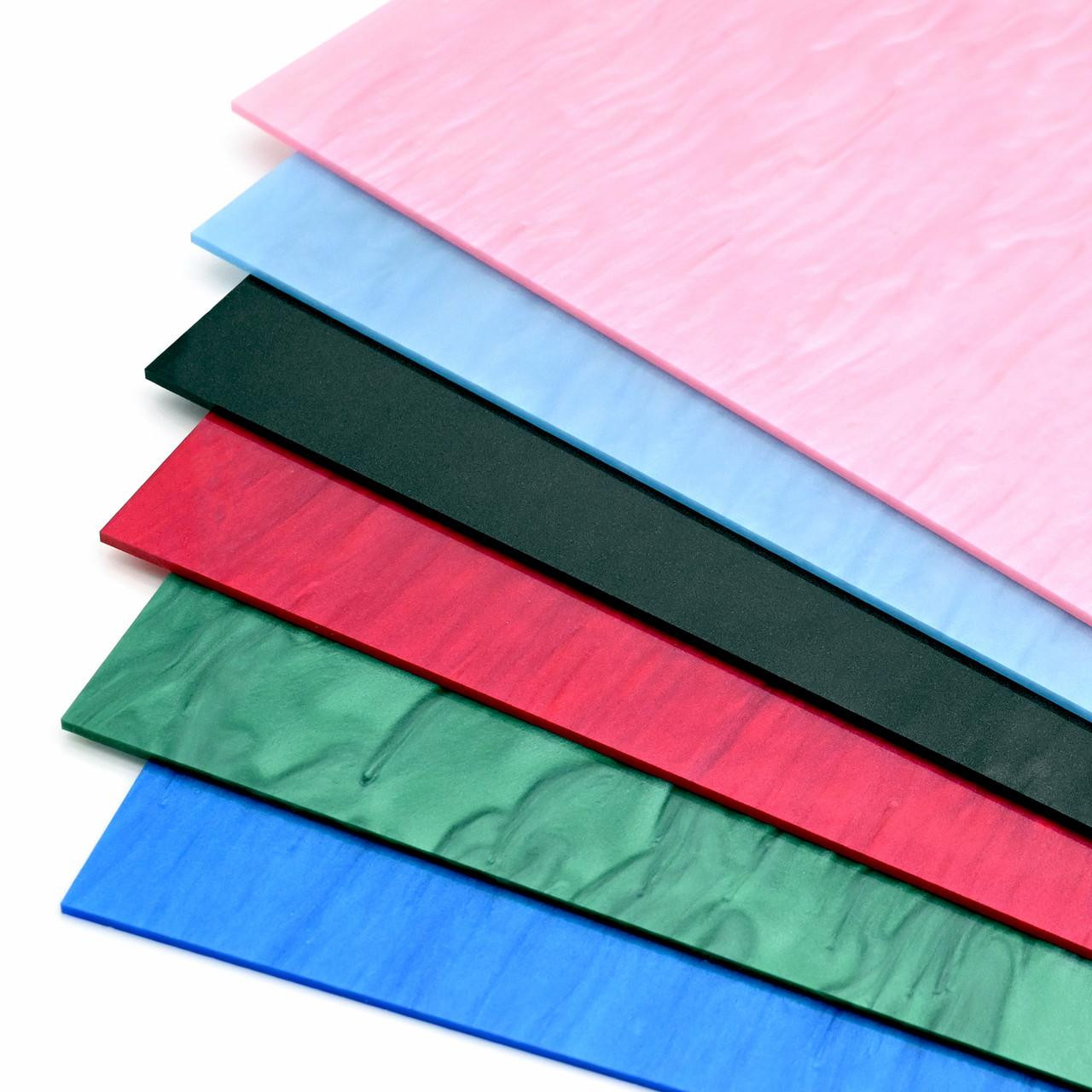

What are the Key Characteristics of Acrylic Plastic for B2B Buyers?

Acrylic, also known as polymethyl methacrylate (PMMA), stands out for its high optical clarity and exceptional weather resistance. It is an ideal choice for applications such as signage and displays where visibility and aesthetics are paramount. When purchasing acrylic, B2B buyers should consider thickness, color options, and fabrication capabilities, as acrylic can be easily cut, shaped, and fabricated into various forms. However, it is essential to note that while acrylic is lightweight and easy to work with, it can be prone to scratching, necessitating careful handling.

How Does Polycarbonate Compare to Other Plastics in the B2B Market?

Polycarbonate is recognized for its remarkable impact resistance, making it an excellent lightweight alternative to glass. This characteristic makes it suitable for applications such as safety shields and automotive components. B2B buyers should weigh the benefits of polycarbonate’s durability and thermal insulation against its higher cost compared to acrylic. Additionally, polycarbonate can be easily molded and fabricated, which is advantageous for custom projects. However, buyers must also be aware that polycarbonate can discolor over time if exposed to UV light without proper treatment.

What Advantages Does HDPE Offer for Industrial Applications?

High-Density Polyethylene (HDPE) is renowned for its chemical and corrosion resistance, making it a popular choice in industries such as packaging, construction, and marine applications. Its UV stability ensures longevity in outdoor settings. When sourcing HDPE, B2B buyers should focus on the material’s thickness, color options, and the type of fabrication processes available. While HDPE is versatile and easy to work with, it is limited in color choices, which may not suit all branding requirements.

Why is PVC a Popular Choice Among B2B Buyers?

Polyvinyl Chloride (PVC) is a cost-effective plastic known for its good chemical resistance, making it widely used in plumbing, electrical insulation, and signage. B2B buyers should consider the specific grades of PVC available, as they vary in durability and application. The affordability of PVC makes it an attractive option for bulk purchasing, although it is generally less durable than other plastic types like polycarbonate and HDPE. Buyers should also evaluate the environmental impact of PVC, as sustainability is becoming increasingly important in purchasing decisions.

What Makes Nylon a Preferred Material for Mechanical Applications?

Nylon is celebrated for its superior wear resistance and excellent machinability, making it a preferred material for gears, bearings, and automotive parts. B2B buyers looking for high-strength and durable materials will find nylon advantageous, especially in applications requiring precision and reliability. When purchasing nylon, considerations should include moisture absorption, as it can affect the material’s dimensions over time. Additionally, the availability of different grades and thicknesses allows buyers to tailor their selections to specific applications.

Key Industrial Applications of buy plastic online

| Industry/Sector | Specific Application of buy plastic online | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Custom plastic components for machinery | Reduces lead time and material waste; enhances production efficiency | Quality certifications, material specifications, and customization options |

| Construction | Plastic sheeting for temporary structures | Provides weather resistance and structural integrity; lowers overall project costs | Availability of various thicknesses, UV resistance, and quick shipping options |

| Agriculture | Agricultural film and greenhouse coverings | Increases crop yield and protects against harsh weather; promotes sustainability | Compatibility with local climates, durability, and ease of installation |

| Medical | Medical-grade plastic for equipment | Ensures safety and compliance with health regulations; enhances product reliability | Compliance with international standards, material purity, and customization for specific applications |

| Signage and Displays | Acrylic and polycarbonate for signage | Offers high optical clarity and durability; allows for creative designs | Color options, thickness variations, and ease of fabrication or engraving |

How is ‘buy plastic online’ utilized in manufacturing and what are the benefits?

In the manufacturing sector, businesses often require custom plastic components to enhance machinery performance. By purchasing plastic online, companies can reduce lead times and minimize waste through precise cut-to-size options. This is particularly beneficial for international buyers in regions like Africa and South America, where shipping times can be lengthy. Ensuring that suppliers provide quality certifications and material specifications is crucial for maintaining production efficiency and compliance with local standards.

What role does plastic sheeting play in construction projects?

Plastic sheeting is extensively used in construction for temporary structures, providing essential weather resistance and structural integrity. Online purchasing allows construction firms to quickly source various thicknesses and UV-resistant materials, which can lead to significant cost savings on projects. For B2B buyers in the Middle East and Europe, it is vital to consider suppliers that offer rapid shipping and customizable options, ensuring that materials are available when needed without delays.

How does plastic benefit agricultural applications?

In agriculture, plastic films and greenhouse coverings are critical for increasing crop yield and protecting plants from adverse weather conditions. Buying these materials online provides farmers with access to a wide range of products tailored to local climates, which can significantly enhance sustainability efforts. International buyers must focus on the durability and ease of installation of these products, as well as their compatibility with the specific agricultural practices in their regions.

Why is medical-grade plastic crucial for healthcare equipment?

Medical-grade plastics are essential for producing reliable healthcare equipment that complies with stringent safety regulations. By sourcing these materials online, medical manufacturers can ensure consistent quality and availability, which is vital for maintaining compliance with international health standards. Buyers should prioritize suppliers that guarantee material purity and can customize products to meet specific equipment requirements, especially in regions with diverse healthcare needs.

How can acrylic and polycarbonate enhance signage and displays?

Acrylic and polycarbonate are favored materials for signage due to their high optical clarity and durability. Businesses can effectively use online platforms to procure these materials in various colors and thicknesses, facilitating creative and eye-catching designs. For B2B buyers, especially in Europe and South America, it is important to consider factors such as ease of fabrication and engraving options, ensuring that the final product meets aesthetic and functional requirements.

3 Common User Pain Points for ‘buy plastic online’ & Their Solutions

Scenario 1: Difficulty in Sizing and Customization of Plastic Products

The Problem: Many B2B buyers struggle with finding the right size and type of plastic for their specific applications. This issue is exacerbated when they require custom dimensions or specialized materials. For instance, a manufacturer may need a specific thickness of polycarbonate sheets for safety barriers, but standard sizes available online don’t meet their requirements. This can lead to wasted time, increased costs, and potential project delays, as sourcing the correct materials becomes a cumbersome process.

The Solution: To effectively address sizing and customization challenges, buyers should prioritize suppliers that offer a robust cut-to-size service. Before placing an order, it’s crucial to communicate specific needs clearly, including dimensions, thickness, and material specifications. Many online plastic suppliers provide tools or templates to help calculate the necessary sizes. Buyers should also inquire about the supplier’s capabilities for custom orders and the lead time for such requests. Establishing a strong relationship with a reliable supplier can also facilitate future orders, allowing buyers to streamline their processes and ensure timely delivery of precisely what they need.

Scenario 2: Concerns Over Quality and Material Specifications

The Problem: B2B buyers often face uncertainty regarding the quality of plastic products purchased online, especially when dealing with suppliers located in different regions. The risk of receiving subpar materials that do not meet industry standards can lead to significant operational disruptions, particularly in sectors like construction or manufacturing where material integrity is critical. For example, a construction firm may order HDPE sheets for a project only to discover upon arrival that the sheets do not meet the necessary strength and durability requirements.

The Solution: To mitigate quality concerns, buyers should conduct thorough research before selecting a supplier. This includes reviewing certifications (such as ISO 9001:2015) that indicate adherence to quality management standards. Buyers should also request samples before committing to larger orders. Understanding the specifications of the material is essential; therefore, buyers should seek detailed product descriptions and technical data sheets. Engaging in discussions with sales representatives can provide insights into the manufacturing processes and quality control measures employed by the supplier. Establishing a consistent feedback loop with suppliers can also help improve product quality over time.

Scenario 3: Complicated Shipping and Delivery Logistics

The Problem: International buyers often encounter shipping and delivery challenges when purchasing plastic materials online. Issues such as unexpected shipping costs, customs delays, or inadequate tracking can lead to frustration and can disrupt project timelines. For instance, a company based in Brazil may place a large order for acrylic sheets from a supplier in Europe, only to face weeks of delay due to customs clearance issues, jeopardizing their project schedule.

The Solution: To navigate shipping and delivery logistics effectively, buyers should work with suppliers that have a proven track record in international shipping. It’s beneficial to discuss shipping options upfront, including costs, estimated delivery times, and the process for handling customs documentation. Buyers should also inquire about the supplier’s experience with shipping to their specific region and ask for references or testimonials from other international clients. Implementing a reliable tracking system can enhance transparency, allowing buyers to monitor their orders in real-time. Additionally, considering freight forwarders who specialize in shipping plastics can help streamline the process and reduce potential delays.

Strategic Material Selection Guide for buy plastic online

What Are the Key Properties of Common Plastic Materials for B2B Applications?

When purchasing plastic online, understanding the properties of different materials is crucial for making informed decisions. Here, we analyze four common plastic materials used in various industries, focusing on their performance, advantages, limitations, and considerations for international buyers.

How Does Acrylic Perform in B2B Applications?

Acrylic, known for its high optical clarity and excellent weather resistance, is often used in applications requiring transparency and durability. It has a temperature rating of up to 80°C (176°F) and is resistant to UV light, making it suitable for outdoor applications.

Pros: Acrylic is lightweight, easy to fabricate, and has superior impact resistance compared to glass. It is also available in various colors, enhancing its versatility for aesthetic applications.

Cons: While durable, acrylic can scratch easily and may not withstand high temperatures as well as some other plastics. It is also more expensive than standard polycarbonate.

Impact on Application: Acrylic is ideal for signage, displays, and protective barriers. Its clarity makes it suitable for applications where visibility is critical.

Considerations for International Buyers: Compliance with standards like ASTM D4802 is essential. Buyers should also consider shipping costs and local availability, especially in regions like Africa and South America.

What Are the Benefits of Polycarbonate in Industrial Settings?

Polycarbonate is a robust plastic known for its high impact resistance and lightweight nature. It can withstand temperatures ranging from -40°C to 120°C (-40°F to 248°F), making it suitable for various environments.

Pros: Polycarbonate is virtually unbreakable and offers excellent thermal stability. It is also easy to machine and can be molded into complex shapes.

Cons: The material can be more expensive than acrylic and may yellow over time when exposed to UV light unless treated.

Impact on Application: Commonly used in safety glasses, automotive components, and electronic housings, polycarbonate is suitable for applications requiring high durability.

Considerations for International Buyers: Compliance with international standards such as ISO 9001 is crucial. Buyers should also be aware of local regulations regarding flame retardancy, especially in the Middle East.

Why Choose HDPE for Heavy-Duty Applications?

High-Density Polyethylene (HDPE) is a versatile plastic known for its strength and resistance to impact and chemicals. It can handle temperatures up to 120°C (248°F) and is resistant to many solvents.

Pros: HDPE is cost-effective, easy to fabricate, and highly resistant to corrosion and moisture. It is also recyclable, making it an environmentally friendly choice.

Cons: While durable, HDPE can be less rigid than other materials, which may limit its use in certain structural applications.

Impact on Application: HDPE is commonly used in packaging, containers, and piping systems, making it suitable for industries such as agriculture and construction.

Considerations for International Buyers: Buyers should ensure that their HDPE products meet local standards such as DIN 8074. Additionally, understanding local recycling capabilities can influence purchasing decisions.

What Makes Polypropylene a Popular Choice for B2B Buyers?

Polypropylene is a lightweight plastic known for its versatility and resistance to chemical solvents. It has a temperature rating of up to 100°C (212°F) and is often used in applications requiring flexibility and durability.

Pros: Polypropylene is relatively inexpensive and offers good fatigue resistance. It is also easy to weld and fabricate, making it suitable for various custom applications.

Cons: While it has good chemical resistance, polypropylene can be less durable under UV exposure unless treated.

Impact on Application: Commonly used in automotive parts, textiles, and packaging, polypropylene is ideal for applications requiring lightweight and durable materials.

Considerations for International Buyers: Compliance with standards such as JIS K 6726 is important. Buyers should also consider the availability of specific grades of polypropylene in their region.

Summary Table of Material Selection for B2B Buyers

| Material | Typical Use Case for buy plastic online | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Acrylic | Signage, displays, protective barriers | High optical clarity | Scratches easily | Medium |

| Polycarbonate | Safety glasses, automotive components | High impact resistance | Can yellow over time | High |

| HDPE | Packaging, containers, piping systems | Cost-effective, moisture resistant | Less rigid | Low |

| Polypropylene | Automotive parts, textiles, packaging | Good fatigue resistance | Less durable under UV exposure | Low |

This guide provides a strategic overview of material selection for B2B buyers looking to purchase plastic online, emphasizing the importance of understanding material properties and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for buy plastic online

What Are the Key Stages in the Manufacturing Processes for Online Plastic Purchases?

When considering purchasing plastic online, understanding the manufacturing process is essential for B2B buyers. The manufacturing of plastic products typically involves several key stages: material preparation, forming, assembly, and finishing. Each of these stages utilizes specific techniques to ensure that the final product meets the required specifications and quality standards.

Material Preparation

The first stage in the manufacturing process is material preparation. This involves selecting the appropriate raw materials, which could include various types of plastics such as acrylic, polycarbonate, or high-density polyethylene (HDPE). These materials are often sourced from reputable suppliers to ensure quality. Once sourced, the materials undergo testing to verify their properties, such as tensile strength and impact resistance, before they are approved for production.

Forming Techniques

The second stage is forming, where the prepared materials are shaped into the desired forms. Common techniques include extrusion, injection molding, and thermoforming.

- Extrusion involves forcing melted plastic through a die to create continuous shapes, such as sheets or tubes.

- Injection molding is used for creating complex shapes by injecting molten plastic into a mold.

- Thermoforming involves heating plastic sheets until pliable, then forming them over a mold.

Each method has its advantages and is chosen based on the specific requirements of the product being manufactured.

Assembly and Finishing Processes

Following forming, assembly may be necessary for products that consist of multiple components. This stage may involve welding, adhesive bonding, or mechanical fastening, depending on the design.

Finishing processes include trimming, polishing, and coating. These processes enhance the aesthetics and functionality of the product. For instance, surfaces may be polished for clarity in acrylic products or coated for UV resistance in outdoor applications.

How Is Quality Assurance Implemented in Plastic Manufacturing?

Quality assurance (QA) is critical in ensuring that the final products meet international and industry-specific standards. For B2B buyers, understanding these QA measures can help verify the reliability of suppliers.

Relevant International Standards

ISO 9001:2015 is a widely recognized standard for quality management systems (QMS) applicable to various industries, including plastics. Companies adhering to this standard demonstrate their commitment to quality through systematic processes and continuous improvement. Other industry-specific standards may include CE marking for European markets, which indicates compliance with safety and environmental requirements, and API standards for plastics used in oil and gas applications.

Quality Control Checkpoints

Quality control (QC) checkpoints are integral to the manufacturing process. These checkpoints typically include:

- Incoming Quality Control (IQC): This stage checks the quality of raw materials before production begins, ensuring that only compliant materials are used.

- In-Process Quality Control (IPQC): During production, various tests are conducted to monitor the quality of the process and the products. This may include dimensional checks and visual inspections.

- Final Quality Control (FQC): Once production is complete, the final products undergo rigorous testing and inspection to ensure they meet the specified standards and customer requirements.

Common Testing Methods Used in Quality Assurance

B2B buyers should be aware of common testing methods employed in quality assurance. These may include:

- Mechanical testing: Evaluating properties such as tensile strength and impact resistance.

- Thermal testing: Assessing the material’s behavior under temperature variations.

- Chemical resistance testing: Ensuring the material can withstand exposure to various chemicals without degrading.

How Can B2B Buyers Verify Supplier Quality Assurance?

Verifying a supplier’s quality assurance processes is crucial for international B2B buyers, especially those from regions such as Africa, South America, the Middle East, and Europe. Here are several strategies to ensure that suppliers maintain high-quality standards:

Conducting Supplier Audits

One of the most effective methods to assess a supplier’s QC processes is through audits. Buyers can request audits to be performed by either their own team or a third-party organization. These audits should evaluate the supplier’s adherence to international standards, the effectiveness of their quality management systems, and their manufacturing processes.

Requesting Quality Assurance Reports

Buyers should also request detailed quality assurance reports from suppliers. These reports should outline the QC measures in place, results from testing methods, and any certifications obtained. A transparent supplier will readily provide this information, which can help build trust.

Engaging Third-Party Inspection Services

For added assurance, B2B buyers can engage third-party inspection services to conduct independent evaluations of the supplier’s products and processes. These services can verify compliance with specified standards and provide an unbiased assessment of product quality.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers face unique challenges regarding quality control due to varying regulations and standards across countries. It is essential to consider these nuances when sourcing plastic products online:

Understanding Local Regulations

Different regions may have specific regulations regarding plastic materials, such as safety standards and environmental compliance. Buyers should familiarize themselves with these regulations to ensure that the products sourced from suppliers meet local requirements.

Navigating Language and Cultural Barriers

Language differences and cultural nuances can complicate communication regarding quality standards. Buyers should establish clear communication channels and, if necessary, employ translators or local representatives to facilitate effective discussions with suppliers.

Building Long-Term Relationships with Suppliers

Establishing long-term relationships with suppliers can enhance quality assurance. Regular communication, feedback, and collaboration on quality improvement initiatives can lead to better alignment on quality expectations and standards.

In conclusion, understanding the manufacturing processes and quality assurance measures in the plastics industry is essential for B2B buyers. By being proactive in verifying supplier quality and navigating the complexities of international sourcing, buyers can ensure they receive high-quality plastic products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘buy plastic online’

In today’s global marketplace, sourcing plastic materials online can be a daunting task for B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. This guide aims to streamline the process and ensure you make informed decisions when purchasing plastic products online.

Step 1: Define Your Technical Specifications

Before initiating the buying process, clearly outline your technical requirements. This includes the type of plastic (e.g., acrylic, HDPE, polycarbonate) and the dimensions you need. Understanding these specifications helps you communicate effectively with suppliers and ensures that you receive the correct products.

- Consider application needs: Different plastics serve various purposes; for instance, polycarbonate is ideal for high-impact applications while acrylic offers clarity and aesthetics.

- Thickness and size: Specify the thickness and size to avoid waste and additional costs.

Step 2: Research Potential Suppliers

Identifying reputable suppliers is crucial for a successful purchase. Conduct thorough research using online platforms, industry directories, and trade associations.

- Check reviews and testimonials: Look for feedback from previous customers to gauge reliability and product quality.

- Assess their product range: A supplier with a diverse inventory can better meet your needs over time.

Step 3: Evaluate Supplier Certifications

Ensure that potential suppliers have the necessary certifications, such as ISO 9001:2015. These certifications indicate that the supplier adheres to international quality standards.

- Ask for documentation: Request copies of certifications to validate their claims.

- Understand compliance with regulations: This is especially important if you are sourcing for industries like food processing or medical applications.

Step 4: Request Samples

Before placing a bulk order, request samples of the materials you intend to purchase. This step allows you to evaluate quality, color, and texture firsthand.

- Assess performance: Ensure the sample meets your specifications and application requirements.

- Check for consistency: Consistent quality in samples is a good indicator of what to expect in larger orders.

Step 5: Negotiate Pricing and Terms

Once you’ve narrowed down your suppliers, engage in discussions about pricing, payment terms, and delivery schedules.

- Inquire about bulk discounts: Many suppliers offer lower prices for larger orders, which can significantly reduce costs.

- Clarify payment terms: Understand the payment options available and any potential credit terms for long-term partnerships.

Step 6: Verify Shipping and Handling Policies

Understanding shipping and handling is essential for timely delivery and cost management. Check the supplier’s shipping options and costs.

- Inquire about lead times: Ensure that the supplier can meet your required delivery timelines.

- Assess packaging standards: Proper packaging prevents damage during transit, which is vital for maintaining product integrity.

Step 7: Establish Communication Channels

Effective communication is key to a successful sourcing experience. Establish clear lines of communication with your supplier.

- Designate a point of contact: Having a specific representative can streamline inquiries and order tracking.

- Utilize technology: Leverage online tools for order management and updates to facilitate smooth interactions.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing plastic online, ensuring that they procure the right materials for their business needs.

Comprehensive Cost and Pricing Analysis for buy plastic online Sourcing

What Are the Key Cost Components in Buying Plastic Online?

Understanding the cost structure associated with sourcing plastic products online is crucial for international B2B buyers. The primary cost components include:

-

Materials: The type of plastic selected (e.g., acrylic, HDPE, polypropylene) significantly influences the base cost. High-performance plastics typically command a premium due to their enhanced properties such as durability and chemical resistance.

-

Labor: Labor costs can vary widely based on the manufacturing location. In regions with higher labor costs, this component will be more significant. Additionally, labor involved in custom cutting or fabrication will add to the overall expense.

-

Manufacturing Overhead: This encompasses all indirect costs related to production, including utilities, rent, and equipment maintenance. Suppliers with efficient manufacturing processes may offer more competitive pricing.

-

Tooling: For custom or specialized products, tooling costs can be substantial. These costs are often amortized over larger production runs, making it more economical to order in bulk.

-

Quality Control (QC): Implementing rigorous QC procedures ensures that the products meet specific standards. While this adds to the upfront cost, it can reduce long-term expenses related to defects and returns.

-

Logistics: Shipping and handling costs can vary based on the origin and destination of the goods, transportation mode, and packaging. International buyers must consider potential tariffs and taxes that could affect overall pricing.

-

Margin: Suppliers will typically apply a markup to cover their costs and profit margin. Understanding the margin structure can help buyers negotiate better terms.

How Do Price Influencers Affect the Cost of Plastic Products?

Several factors can influence the pricing of plastic products sourced online:

-

Volume/MOQ: Suppliers often have minimum order quantities (MOQ) that can impact pricing. Higher volumes typically result in lower per-unit costs due to economies of scale.

-

Specifications and Customization: Custom sizes or specifications can significantly increase costs. Buyers should evaluate whether standard sizes meet their needs to avoid unnecessary expenses.

-

Materials: The choice of material not only affects the price but also the product’s performance characteristics. For example, specialized plastics like polycarbonate may be more expensive than standard PVC.

-

Quality and Certifications: Products that meet specific industry standards or certifications (e.g., ISO, FDA compliance) may come at a premium. However, these certifications can enhance product reliability and marketability.

-

Supplier Factors: The reputation and location of the supplier can influence pricing. Established suppliers may charge more due to their reliability, while newer suppliers might offer competitive pricing to gain market share.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly affect overall costs.

What Are Effective Buyer Tips for Cost-Efficient Plastic Sourcing?

To maximize cost-efficiency in sourcing plastic products, international B2B buyers should consider the following strategies:

-

Negotiation: Engage in discussions with suppliers to negotiate prices, especially for larger orders. Suppliers may be willing to offer discounts based on volume or long-term contracts.

-

Total Cost of Ownership (TCO): Evaluate the TCO, which includes not only the purchase price but also logistics, storage, and potential waste. This holistic view can lead to better decision-making regarding suppliers and products.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and shipping costs that can impact the final price. Understanding the financial landscape of the supplier’s country can provide insights into potential cost-saving opportunities.

-

Evaluate Supplier Relationships: Establishing long-term relationships with suppliers can lead to better pricing and priority service. A reliable partner can also provide insights into market trends and material availability.

By understanding these cost components, influencers, and strategies, B2B buyers can navigate the complexities of sourcing plastic online more effectively, ensuring they make informed purchasing decisions that align with their business objectives.

Alternatives Analysis: Comparing buy plastic online With Other Solutions

Introduction to Comparing Plastic Procurement Solutions

In the global marketplace, businesses often seek the most efficient and cost-effective methods to procure materials, including plastics. While buying plastic online has gained traction due to its convenience and accessibility, it’s essential to explore alternative solutions that may better suit specific operational needs. This analysis compares the online purchasing of plastic materials with two viable alternatives: local suppliers and custom fabrication services.

| Comparison Aspect | Buy Plastic Online | Local Suppliers | Custom Fabrication Services |

|---|---|---|---|

| Performance | High-quality materials with quick shipping | Variable quality; dependent on supplier | Tailored solutions to precise specifications |

| Cost | Competitive pricing, potential bulk discounts | May offer competitive pricing; varies widely | Higher upfront costs due to customization |

| Ease of Implementation | Straightforward ordering process | May involve negotiations and longer lead times | More complex due to design and approval stages |

| Maintenance | Minimal; depends on product choice | Varies by supplier; typically low maintenance | Ongoing support available, but may require training |

| Best Use Case | Standardized products, quick turnaround | Local projects needing immediate supply | Unique projects requiring specific dimensions |

Detailed Breakdown of Alternatives

What Are the Benefits and Drawbacks of Local Suppliers?

Local suppliers can provide immediate access to plastic materials, which is crucial for urgent projects. This option allows for face-to-face interaction, enabling buyers to assess the quality of materials before purchase. However, the performance can be inconsistent, depending on the supplier’s inventory and quality control processes. Additionally, while local sourcing may reduce shipping costs and times, the pricing can fluctuate based on market conditions, and the variety of materials available may be limited.

How Does Custom Fabrication Offer Tailored Solutions?

Custom fabrication services specialize in creating plastic products tailored to specific needs, making them an ideal choice for businesses requiring unique dimensions or properties. These services can provide high-performance materials and personalized solutions that standard products may not meet. However, the initial costs can be higher due to the design and production process. Moreover, the implementation may require more time, as designs must be finalized and approved before production begins. While this method can deliver exceptional results, it may not be suitable for projects with tight timelines.

Conclusion: How Should B2B Buyers Choose the Right Plastic Procurement Method?

When selecting the appropriate procurement method for plastic materials, B2B buyers should consider their specific requirements, including project timelines, budget constraints, and material specifications. Buying plastic online offers convenience and a wide range of options suitable for standard needs. In contrast, local suppliers may be more beneficial for urgent requirements, while custom fabrication is ideal for specialized projects. Ultimately, understanding the advantages and limitations of each option enables buyers to make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for buy plastic online

What Are the Key Technical Properties to Consider When Buying Plastic Online?

When purchasing plastic materials online, understanding specific technical properties is crucial for ensuring that the selected products meet your application needs. Here are several critical specifications to consider:

-

Material Grade

The material grade indicates the quality and characteristics of the plastic, such as strength, flexibility, and resistance to environmental factors. Different grades are suitable for various applications; for instance, high-density polyethylene (HDPE) is favored in construction for its durability, while acrylic is chosen for its optical clarity in signage. Knowing the material grade helps businesses select the right type of plastic for their specific industry needs, ensuring performance and longevity. -

Tolerance

Tolerance refers to the allowable variation in dimensions for cut-to-size products. This is particularly important in precision applications where exact measurements are critical, such as in medical or aerospace industries. Understanding tolerances helps buyers avoid costly errors and ensures that components fit correctly within assemblies. -

Impact Resistance

Impact resistance measures a material’s ability to withstand sudden forces without breaking. This property is essential for applications in construction, automotive, and consumer products. Selecting plastics with high impact resistance can enhance safety and durability, reducing the likelihood of product failure. -

Thermal Stability

Thermal stability indicates how well a plastic can maintain its properties under varying temperature conditions. For instance, polycarbonate is known for its excellent thermal stability, making it suitable for outdoor applications where temperature fluctuations are common. Buyers must consider the thermal properties to ensure that the plastic can perform effectively in its intended environment. -

Chemical Resistance

This property assesses how well a plastic can resist degradation from exposure to chemicals. Materials such as polypropylene and PTFE (Teflon) are known for their superior chemical resistance, making them ideal for applications in the chemical processing industry. Understanding chemical resistance is vital to prevent premature material failure and ensure compliance with safety standards. -

UV Resistance

UV resistance is crucial for plastics that will be exposed to sunlight. Materials like HDPE and certain acrylics are engineered to withstand UV degradation, which is essential for outdoor applications like signage and marine products. Knowing the UV resistance of a plastic can help buyers ensure their products maintain integrity and appearance over time.

What Are Common Trade Terms Used in the Plastic Industry?

Navigating the world of online plastic purchasing also requires familiarity with specific industry jargon. Here are some commonly used terms that every B2B buyer should know:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can be crucial for buyers who need specific components for their products. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest amount of product that a supplier is willing to sell. This term is important for buyers to understand as it can impact inventory levels and purchasing strategies, especially for smaller businesses. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. This is a standard practice in B2B transactions to compare prices and terms from multiple vendors, ensuring competitive pricing and better procurement decisions. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risk management, and delivery obligations, which are critical for global sourcing. -

Lead Time

Lead time is the duration between placing an order and receiving the product. Knowing lead times is essential for supply chain management, allowing businesses to plan their production schedules and avoid delays. -

Certification Standards

This term refers to specific industry standards that products must meet to ensure safety and quality. Understanding certification requirements, such as ISO 9001 or FDA compliance, is vital for buyers in regulated industries to ensure their materials meet necessary legal and performance standards.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when purchasing plastic materials online, ensuring they meet both operational needs and compliance standards.

Navigating Market Dynamics and Sourcing Trends in the buy plastic online Sector

What Are the Current Market Dynamics and Sourcing Trends in the Buy Plastic Online Sector?

The online plastic purchasing landscape is undergoing significant transformation driven by global demand and technological advancements. As industries worldwide, particularly in Africa, South America, the Middle East, and Europe, continue to expand, the need for efficient and reliable sourcing channels has become paramount. Key trends include the rise of just-in-time inventory management, which reduces storage costs and optimizes supply chains. B2B buyers are increasingly seeking suppliers that can provide custom-cut products with rapid turnaround times, reflecting a shift towards personalization and efficiency.

Emerging technologies, such as artificial intelligence and machine learning, are being integrated into supply chain management, enabling enhanced forecasting and inventory management. Additionally, the increasing use of e-commerce platforms for bulk purchasing allows businesses to compare prices, quality, and delivery options easily. With shipping logistics also evolving, suppliers offering same-day dispatch services and global shipping capabilities are gaining a competitive edge. This is particularly relevant for international buyers from regions like Saudi Arabia and Brazil, where timely delivery is crucial for maintaining operational efficiency.

The plastic market is also witnessing a diversification of materials, with businesses exploring alternatives to traditional plastics. The demand for high-performance materials, such as polycarbonate and HDPE, is on the rise, driven by industries ranging from construction to automotive. Buyers are encouraged to stay informed about these trends to leverage opportunities that can enhance their procurement strategies.

How Is Sustainability and Ethical Sourcing Impacting B2B Buyers in the Plastic Sector?

As sustainability becomes a central focus for businesses globally, B2B buyers in the plastic sector are increasingly prioritizing ethical sourcing and environmentally friendly materials. The environmental impact of plastic production has prompted many companies to seek suppliers that adhere to sustainable practices, such as using recycled materials or offering products that are easier to recycle. This shift is not only beneficial for the planet but also aligns with the growing consumer demand for sustainable products, which can enhance brand reputation and marketability.

Buyers should look for suppliers that hold recognized environmental certifications, such as ISO 14001 or other eco-labels, which indicate a commitment to sustainable practices. Additionally, sourcing from manufacturers that prioritize energy-efficient processes and reduced waste can significantly lower the overall environmental footprint. For instance, companies that utilize biodegradable plastics or sustainable alternatives can provide a competitive advantage in markets that are increasingly favoring ‘green’ solutions.

Moreover, ethical sourcing extends beyond materials to encompass fair labor practices and transparency within the supply chain. B2B buyers are encouraged to conduct due diligence on their suppliers, ensuring that their sourcing decisions align with corporate social responsibility goals. By prioritizing sustainability and ethical sourcing, businesses not only contribute to environmental preservation but also build stronger relationships with environmentally conscious consumers.

How Has the Buy Plastic Online Sector Evolved Over Time?

The evolution of the buy plastic online sector is marked by significant technological advancements and changing market demands. Initially, the procurement of plastic materials was dominated by traditional wholesalers and local suppliers, often resulting in limited options and longer lead times. However, the advent of e-commerce has transformed this landscape, enabling businesses to access a wider range of products and suppliers from around the globe.

Over the past two decades, online platforms have emerged that specialize in cut-to-size plastic sheets, rods, and tubes, catering to the specific needs of B2B buyers. This shift not only provides greater flexibility and customization options but also enhances price competitiveness as buyers can easily compare products and suppliers. The introduction of advanced supply chain technologies has further streamlined operations, allowing for real-time tracking and improved inventory management.

Today, the sector is characterized by a focus on innovation, with suppliers continually expanding their product lines to include sustainable materials and advanced polymers. As the market continues to evolve, B2B buyers must remain agile and informed, leveraging these developments to optimize their sourcing strategies and meet the demands of their respective industries.

Frequently Asked Questions (FAQs) for B2B Buyers of buy plastic online

-

1. How do I ensure the quality of plastic products when buying online?

To ensure quality when purchasing plastic products online, start by researching potential suppliers. Look for ISO certifications, customer reviews, and case studies that demonstrate their track record in quality assurance. Request samples of the materials before making bulk purchases, and inquire about their quality control processes. Additionally, consider suppliers that offer guarantees or warranties on their products, as this can provide further assurance of their quality standards. -

2. What types of plastic are best for my specific application?

The best type of plastic depends on your specific application requirements. For high-impact resistance, polycarbonate is ideal, while acrylic offers excellent optical clarity. HDPE is recommended for outdoor applications due to its UV resistance, and polypropylene is suitable for chemical resistance. Consult with suppliers about your intended use, and they can recommend the most appropriate materials based on properties like strength, flexibility, and environmental resistance. -

3. How can I customize plastic products to meet my needs?

Most suppliers offer customization options, such as cut-to-size sheets or specific thicknesses. When placing an order, provide detailed specifications regarding dimensions, colors, and any additional features you require. Some suppliers may also offer advanced fabrication services, including machining or engraving. Always discuss your needs with the supplier to explore all customization possibilities and ensure that the final product meets your expectations. -

4. What are the typical minimum order quantities (MOQs) for plastic products?

Minimum order quantities can vary significantly among suppliers and product types. Some suppliers may have a low MOQ for standard sheets, while others may require larger quantities for custom orders. It’s essential to check the supplier’s policy or directly inquire about MOQs. If your needs are smaller, consider looking for suppliers that cater specifically to small businesses or offer flexible ordering options. -

5. How do I navigate international shipping and customs for plastic purchases?

Navigating international shipping involves understanding the supplier’s shipping policies, costs, and delivery timelines. Ensure the supplier can handle customs documentation and provide necessary shipping details. Additionally, be aware of import regulations and tariffs in your country, as these can affect the overall cost and delivery time. Collaborate with your supplier to ensure all paperwork is accurate and complete to avoid delays at customs. -

6. What payment terms should I expect when buying plastic online?

Payment terms can vary widely among suppliers, often depending on the size of the order and the relationship with the buyer. Common terms include upfront payments, partial payments with balance upon delivery, or net terms (e.g., net 30, net 60). Discuss payment options with your supplier to find terms that work best for both parties. Additionally, consider using secure payment methods to protect your financial information during transactions. -

7. How do I vet suppliers when sourcing plastic products internationally?

To vet suppliers effectively, conduct thorough research including checking their business credentials, certifications, and customer testimonials. Request references from other clients and review their product samples. Additionally, consider their responsiveness and customer service quality during your inquiries. Establishing a good communication line is vital, as it reflects their reliability and willingness to address your concerns. -

8. What should I do if there are issues with my order?

If you encounter issues with your order, promptly contact the supplier’s customer service team. Clearly explain the problem, whether it’s a quality issue, incorrect dimensions, or delivery delays. A reputable supplier will have a resolution process in place, often providing options for refunds, replacements, or discounts. Document all communications and keep records of your order to facilitate a smooth resolution process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Buy Plastic Online Manufacturers & Suppliers List

1. Curbell Plastics – Plastic Sheets, Rods & Tubes

Domain: curbellplastics.com

Registered: 2000 (25 years)

Introduction: Shop Plastic Materials | Buy Plastic Sheets, Rods, & Tubes Online At Curbell Plastics. Categories include: ABS, Acetal, Acrylic, Aluminum Composite Material, EVA, Expanded PVC, FEP, Foam Boards, HDPE, High Impact Polystyrene, KYDEX®, LDPE, Nylon, PEEK, PET, Polycarbonate, Polyester Film, Polypropylene, PVC, PTFE, UHMW, Ultem®, and more. Specialty products include adhesives, prototyping tools, and …

2. Professional Plastics – Plastic Sheets & Rods

Domain: professionalplastics.com

Registered: 1997 (28 years)

Introduction: This company, Professional Plastics – Plastic Sheets & Rods, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Eplastics – Plastic Sheets & Shapes

Domain: eplastics.com

Registered: 1998 (27 years)

Introduction: This company, Eplastics – Plastic Sheets & Shapes, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. ShapesPlastics – Custom Cut Plastic Sheets

Domain: shapesplastics.com

Registered: 2019 (6 years)

Introduction: ShapesPlastics offers a variety of cut-to-size plastic sheets including:

– Polycarbonate: Clear, Colored, Abrasion Resistant, UV-Resistant, Twinwall, Hurricane Storm Shutter.

– Acrylic/Plexiglass: Clear, Colored, Patterned, Mirror, UV-Resistant, Patio Table Top.

– High-Density Polyethylene (HDPE): Standard Sheets, Marine Board, Cutting Board.

– Ultra High Molecular Weight Polyethylene (UHMW). …

5. Online Metals – Plastic Supply

Domain: onlinemetals.com

Registered: 1997 (28 years)

Introduction: Plastic Supply | Buy Plastic Cut to Size | Online Metals. Types of plastics available: ABS, Acetal, Acrylic, GPO-3, HDPE, Kydex-T, Nylon, PEEK, PET, PTFE, PVC, Polycarbonate, Polypropylene, Torlon, UHMW, Ultem. Applications include gears, bearings, windows, automotive parts, shields, cases, barriers, signs, skylights. Features: durable, versatile, chemical/weather resistant, high strength-to-weigh…

Strategic Sourcing Conclusion and Outlook for buy plastic online

In the evolving landscape of global trade, the strategic sourcing of plastic materials online presents immense opportunities for international B2B buyers. Key takeaways highlight the importance of leveraging suppliers who offer customizable solutions, quick shipping options, and a diverse range of high-quality products. By focusing on suppliers with robust inventory management and ISO certifications, businesses can ensure compliance and reliability, minimizing risks associated with procurement.

The value of strategic sourcing extends beyond mere cost savings; it fosters long-term partnerships that can enhance supply chain resilience. For buyers in regions like Africa, South America, the Middle East, and Europe, establishing connections with reputable suppliers can lead to optimized operations and increased competitive advantage in their respective markets.

Looking ahead, it is crucial for B2B buyers to remain proactive in their sourcing strategies. Embrace the digital marketplace to identify innovative materials and technologies that can meet your specific needs. As you navigate this dynamic environment, prioritize collaboration with suppliers who understand your unique challenges and can provide tailored solutions. Start exploring your options today and position your business for success in the global plastic market.