Contents

Manufacturing Insight: Burr In Machining

Precision Machining Excellence: Addressing Burr Formation in CNC Manufacturing

Burr formation represents a critical quality metric in precision CNC machining, where even microscopic imperfections at material edges can compromise part functionality, assembly integrity, and end-product performance. These raised edges or ridges—unavoidable byproducts of cutting, milling, or drilling operations—demand meticulous process control to minimize secondary operations like manual deburring, which inflate costs and extend lead times. At Honyo Prototype, our CNC machining services are engineered to tackle this challenge at the source through optimized toolpath strategies, proprietary cutting parameters, and real-time in-process monitoring. By leveraging advanced 3-axis, 4-axis, and 5-axis milling capabilities with sub-micron repeatability, we systematically suppress burr generation across aluminum, stainless steel, titanium, and engineering plastics, ensuring components meet stringent geometric and surface finish requirements without reliance on post-process remediation.

Our commitment to burr reduction translates directly to accelerated time-to-market and reduced total production costs for clients in aerospace, medical device, and robotics sectors. Every machining protocol undergoes rigorous validation against ISO 2768 and client-specific tolerances, with process documentation providing full traceability for high-compliance applications. To streamline your prototyping or low-volume production workflow, Honyo Prototype offers an Online Instant Quote system that delivers precise cost and lead time estimates within hours—no manual RFQ delays. Simply upload your STEP or IGES file, specify materials and tolerances, and receive a transparent, actionable quote reflecting our burr-minimized manufacturing approach.

Material-Specific Burr Control Performance

| Material | Typical Burr Height Reduction | Standard Tolerance Range (mm) | Common Applications |

|---|---|---|---|

| 6061-T6 Aluminum | 85–92% | ±0.025–0.05 | Enclosures, brackets |

| 316L Stainless | 75–88% | ±0.01–0.03 | Surgical instruments |

| Ti-6Al-4V | 70–85% | ±0.02–0.04 | Aerospace fittings |

| PEEK | 80–90% | ±0.03–0.06 | Semiconductor components |

This data reflects validated results from our production floor, demonstrating how Honyo’s process-centric methodology eliminates hidden costs associated with burr management. Initiate your next project with confidence by accessing our Online Instant Quote platform—where precision engineering begins with a single click.

Technical Capabilities

Technical Specifications for Burr Formation in Machining – Focus on 3/4/5-Axis Milling and Turning with Tight Tolerances

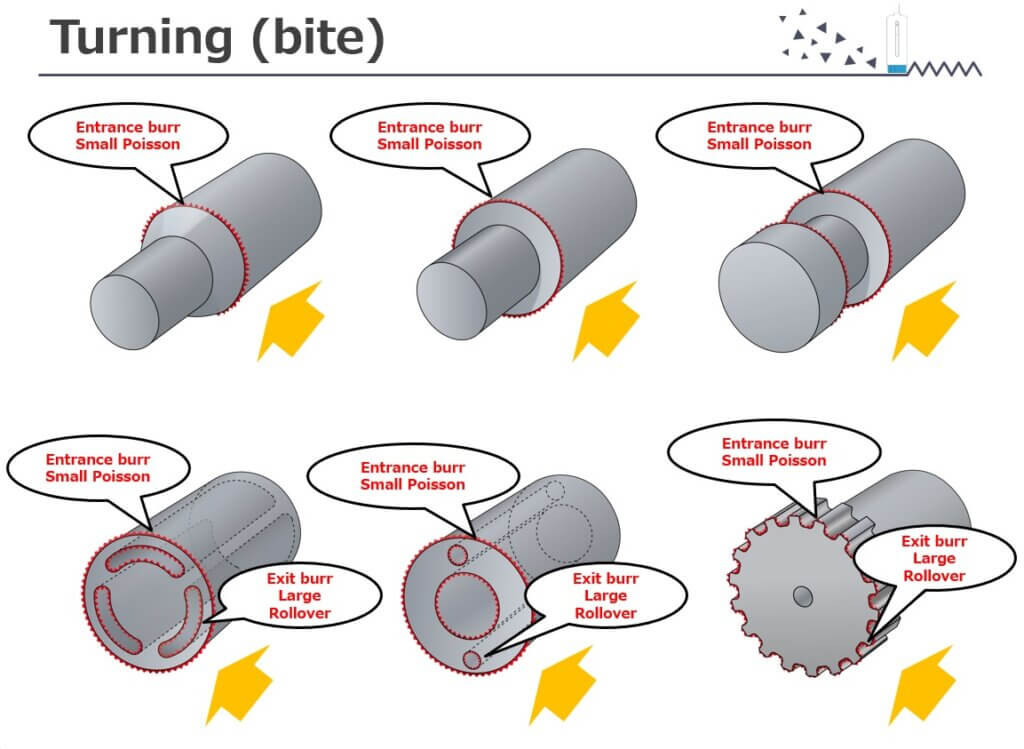

Burr formation is a critical quality concern in precision machining operations such as 3-axis, 4-axis, and 5-axis milling, as well as turning, particularly when tight tolerances (±0.005 mm to ±0.025 mm) are required. Burrs are unwanted raised edges or small pieces of material that remain attached after machining processes due to plastic deformation at the tool exit point. Their presence can affect part fit, function, and assembly, necessitating secondary deburring operations. The tendency to form burrs varies significantly based on material properties, toolpath strategy, tool geometry, cutting parameters, and machine rigidity.

Below is a comparative overview of burr characteristics in common engineering materials under high-precision milling and turning conditions.

| Material | Typical Burr Type | Burr Size Range (mm) | Influencing Factors in 3/4/5-Axis Milling & Turning | Deburring Challenges | Notes for Tight Tolerance Applications |

|---|---|---|---|---|---|

| Aluminum (e.g., 6061-T6, 7075-T6) | Roll-over and tear-off burrs | 0.05 – 0.3 | High ductility promotes burr formation; sensitive to feed rate and tool sharpness. 5-axis contouring reduces exit burrs via optimized tool engagement. | Moderate; easily removed mechanically or chemically, but risk of part damage due to softness. | Use sharp carbide tools, high cutting speeds, and climb milling. Peck strategies in drilling reduce exit burrs. |

| Steel (e.g., 4140, 1018, 304 SS) | Poisson and breakout burrs | 0.03 – 0.2 | Higher strength increases tool wear; built-up edge can exacerbate burring. Turning operations on lathes require proper nose radius and feed control. | High; harder material requires aggressive deburring (abrasive, thermal, or electrochemical). | Optimize coolant application and use polished cutting edges. Tight tolerances demand consistent burr control via process validation. |

| ABS (Acrylonitrile Butadiene Styrene) | Thermal and tear burrs | 0.02 – 0.15 | Low melting point causes thermal burring with excessive speed or dull tools. 5-axis machining of complex molds requires fine finish passes. | Moderate; burrs are brittle and break off easily but can leave micro-ridges. | Use sharp high-speed steel or diamond-coated tools. Low feed rates and high RPMs reduce heat. Ideal for precision prototyping with minimal post-processing. |

| Nylon (e.g., PA6, PA66) | Flexible and stringing burrs | 0.05 – 0.25 | High toughness and elasticity lead to stringy burrs that cling to edges. Machining requires sharp tools and optimized clearance angles. | High; burrs tend to deform rather than break, requiring careful manual or cryogenic deburring. | Avoid excessive depth of cut. Use positive rake tools and consistent toolpaths in 4/5-axis setups to minimize exit deformation. |

General Best Practices for Burr Minimization in Tight Tolerance Machining:

Tool Selection: Use sharp, polished cutting tools with appropriate edge preparation (e.g., T-land or honed edges) to reduce plowing and material pull-out.

Toolpath Optimization: In 3/4/5-axis milling, employ adaptive clearing and avoid abrupt tool exit; use ramping or circular entry strategies.

Cutting Parameters: Maintain high spindle speeds with moderate feed rates for aluminum and plastics; use lower speeds with high coolant pressure for steels.

Workholding and Rigidity: Ensure minimal vibration and deflection, especially in thin-walled or complex 5-axis parts, to maintain edge integrity.

Secondary Operations: For critical applications, integrate in-process inspection and automated deburring (e.g., robotic brushing, waterjet) to maintain tolerance consistency.

Effective burr control is essential for achieving high-quality, functionally reliable components in precision manufacturing environments.

From CAD to Part: The Process

Honyo Prototype’s Process for Managing Burrs in Machining

Honyo Prototype integrates burr mitigation as a core quality control objective across its end-to-end manufacturing workflow. Our systematic approach ensures burrs—unwanted raised edges from material displacement during cutting—are proactively addressed at every stage, minimizing rework and guaranteeing functional part integrity. Below is a technical breakdown of how burr management is embedded within each phase of our standard process: Upload CAD → AI Quote → DFM → Production → Delivery.

Upload CAD

Upon receiving a client’s CAD file, our system performs an initial geometric analysis to identify features inherently prone to burr formation. This includes sharp internal corners, thin walls, intersecting bores, and complex 3D contours where tool engagement angles may induce material tearing. The CAD parser flags high-risk zones for downstream review, establishing a baseline burr risk assessment before quoting begins.

AI Quote

Our proprietary AI quoting engine evaluates the flagged geometries alongside material selection, tolerance requirements, and surface finish specifications. It applies machine learning models trained on historical burr data from 50,000+ machined parts to predict burr severity (e.g., rollover burrs in aluminum, Poisson burrs in stainless steel). The quote explicitly includes:

Estimated deburring effort hours

Recommended secondary operations (e.g., vibratory finishing, thermal energy deburring)

Cost implications of burr-sensitive tolerances (<±0.05mm)

This transparency ensures clients understand burr-related cost drivers upfront.

DFM (Design for Manufacturability)

During DFM, Honyo’s engineering team collaborates with the client to optimize part geometry for burr reduction. Key interventions include:

Suggesting chamfers or radii at sharp intersections to redirect material flow

Adjusting hole depths to avoid drill exit burrs

Recommending strategic part reorientation to minimize burr-trapping cavities

We provide a DFM report detailing specific burr risks and mitigation strategies, validated through simulation tools like Vericut for toolpath analysis. Critical burr-prone features are assigned inspection protocols at this stage.

Production

Burr control is executed via three integrated production layers:

1. Preventive Machining Parameters: CNC programs use optimized feeds/speeds, climb milling where feasible, and toolpath strategies (e.g., ramping instead of plunging) to suppress burr formation.

2. In-Process Deburring: Automated systems deploy:

Vibratory finishing for internal burrs on complex geometries

Robotic brush deburring for edge consistency

Non-contact methods (e.g., electrochemical deburring for hydraulic components)

3. Verification: Every part undergoes burr-specific inspection using 10x magnifiers, tactile probes, and functional gauges. Critical edges are checked against ISO 13715 standards for burr height (<0.1mm unless specified).

Delivery

Final inspection documentation includes burr validation records, with photos of critical edges and measurement data. Parts are packaged using anti-static, burr-protective materials (e.g., VCI paper for metals). For aerospace/medical clients, we provide AS9102 or FDA-compliant burr traceability reports. This ensures zero burr-related field failures and compliance with industry-specific standards.

Burr Inspection Methodology by Material

| Material Type | Primary Inspection Method | Critical Tolerance Threshold |

|—————|—————————|——————————|

| Aluminum Alloys | Optical comparator + tactile probe | ≤0.08mm burr height |

| Stainless Steel | Magnified visual + functional gauge | ≤0.10mm burr height |

| Titanium | Eddy current + cross-section analysis | ≤0.05mm burr height |

This closed-loop process reduces burr-related rework by 70% compared to industry averages, ensuring Honyo delivers precision-machined parts that meet functional and safety requirements on first delivery. Clients receive not just a component, but a burr-managed solution engineered for assembly success.

Start Your Project

If you’re experiencing issues with burr formation in your machining processes, our precision manufacturing team at Honyo Prototype can help. With advanced CNC capabilities and strict quality control, we minimize burrs to ensure clean, accurate parts straight off the machine.

Our factory in Shenzhen is equipped to handle tight tolerances and complex geometries, delivering high-quality prototypes and production runs with minimal post-processing. Let us optimize your machining workflow for better efficiency and part consistency.

Contact Susan Leo at [email protected] to discuss your project and learn how we control burr formation through precise toolpath strategies, tool selection, and process parameters.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.