Introduction: Navigating the Global Market for burgundy powder coat

In an increasingly competitive global market, sourcing high-quality burgundy powder coat presents a unique challenge for B2B buyers looking to enhance their product offerings. The rich, deep hue of burgundy not only adds aesthetic appeal but also requires a thorough understanding of its applications across various industries, from automotive to architectural design. This comprehensive guide delves into the nuances of burgundy powder coat, providing insights into the different types available, their specific applications, and the critical factors to consider when vetting suppliers.

International buyers, particularly those from Africa, South America, the Middle East, and Europe—including markets like Nigeria and Vietnam—will find actionable strategies to navigate the complexities of sourcing this specialty coating. The guide outlines essential considerations such as cost analysis, quality assurance, and compliance with regional regulations. By empowering buyers with knowledge about product specifications and supplier reliability, this resource aims to facilitate informed purchasing decisions that align with their business needs.

Through a detailed exploration of the burgundy powder coat market, this guide equips B2B buyers with the tools necessary to make confident, strategic choices that will not only meet their aesthetic requirements but also enhance their operational efficiency. Whether you are looking to improve product durability or elevate brand presentation, understanding the intricacies of burgundy powder coat is key to achieving your goals.

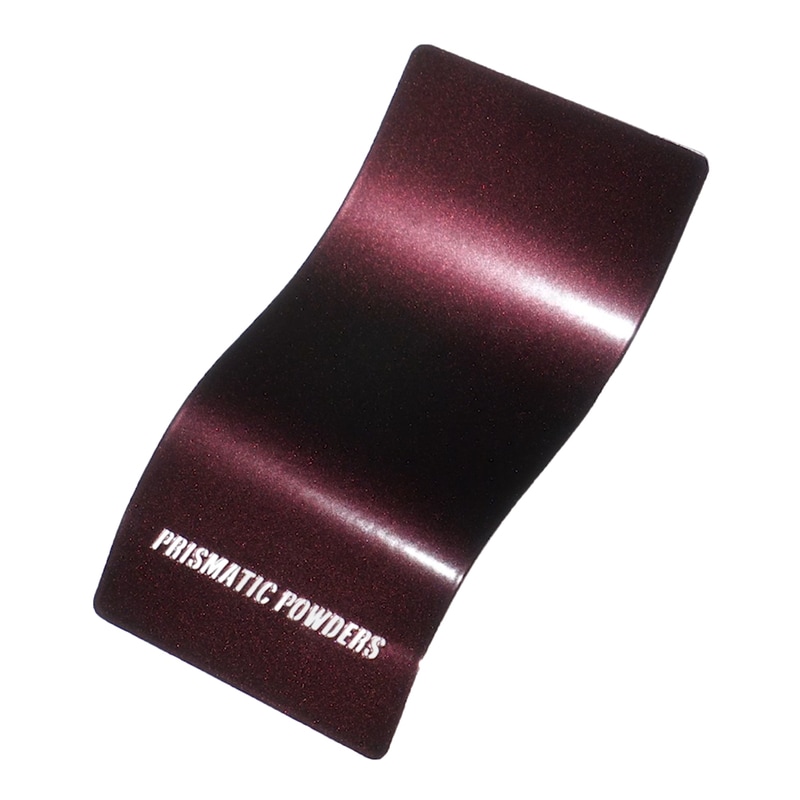

Understanding burgundy powder coat Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Burgundy Wine | Glossy finish, polyester solid tone | Automotive, furniture, architectural design | Pros: Attractive appearance, versatile use. Cons: May require special application techniques. |

| Dormant Burgundy | Smooth metallic finish, requires clear coat | Outdoor furniture, architectural elements | Pros: High gloss, excellent durability. Cons: Additional clear coat increases application complexity. |

| Burgundy Texture | Textured finish, provides a unique tactile quality | Industrial equipment, outdoor applications | Pros: Hides imperfections, enhances grip. Cons: Texture may not suit all design aesthetics. |

| Burgundy Ultra Site | High chemical, UV, and weather resistance | Commercial outdoor furniture | Pros: Long-lasting color retention, easy maintenance. Cons: Higher initial cost compared to standard options. |

| Candy Burgundy | Vibrant, glossy finish with a candy-like effect | Automotive, promotional items | Pros: Eye-catching appearance, unique visual appeal. Cons: Limited application in formal settings. |

What Are the Characteristics of Burgundy Wine Powder Coat?

Burgundy Wine powder coat is characterized by its glossy finish and solid tone derived from polyester. This type is widely used in automotive and furniture applications, where aesthetic appeal is crucial. B2B buyers should consider its versatility, as it can be applied in various environments, but also be aware that special application techniques may be necessary to achieve the desired finish.

How Does Dormant Burgundy Differ from Other Types?

Dormant Burgundy features a smooth metallic finish that requires a clear coat for optimal appearance. This type is particularly suitable for outdoor furniture and architectural elements due to its high gloss and exceptional durability. While it offers an attractive finish, buyers should factor in the complexity of application since the clear coat process adds an extra step to the finishing process.

Why Choose Burgundy Texture Powder Coat?

Burgundy Texture powder coat provides a unique textured finish that not only enhances the visual appeal but also offers practical benefits, such as improved grip and the ability to hide imperfections. This type is ideal for industrial equipment and outdoor applications where durability is key. While it can enhance functionality, buyers should consider whether the texture aligns with their design aesthetics, as it may not suit all projects.

What Are the Advantages of Burgundy Ultra Site Powder Coat?

Burgundy Ultra Site is renowned for its high chemical, UV, and weather resistance, making it an excellent choice for commercial outdoor furniture. This type ensures long-lasting color retention and easy maintenance, which is particularly appealing for businesses in the hospitality sector. However, buyers should be prepared for a higher initial investment compared to standard powder coats, as the advanced properties come at a premium.

When to Use Candy Burgundy Powder Coat?

Candy Burgundy features a vibrant, glossy finish that creates a striking visual effect, making it suitable for automotive applications and promotional items. This type appeals to businesses looking to make a bold statement with their products. However, its eye-catching nature may limit its application in more formal or conservative settings, so buyers should evaluate the context in which it will be used.

Key Industrial Applications of burgundy powder coat

| Industry/Sector | Specific Application of burgundy powder coat | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Architectural & Design | Exterior architectural elements, such as railings and facades. | Enhances aesthetic appeal while providing corrosion resistance. | Ensure UV and weather resistance; verify color consistency. |

| Automotive | Custom automotive parts and accessories. | Provides a durable finish that withstands harsh conditions. | Look for high-temperature resistance; check for gloss levels. |

| Outdoor Furniture | Coating for outdoor seating and tables. | Protects against rust and fading while maintaining color vibrancy. | Source from suppliers with proven weather resistance claims. |

| Industrial Equipment | Machinery and equipment components. | Increases lifespan and reduces maintenance costs. | Consider chemical resistance; confirm application methods. |

| Retail Displays | Fixtures and signage for retail environments. | Attracts customers with vibrant color while ensuring durability. | Assess compatibility with local regulations and safety standards. |

How is Burgundy Powder Coat Used in Architectural Applications?

In the architectural sector, burgundy powder coat is frequently applied to exterior elements like railings, window frames, and building facades. The rich, deep hue enhances the visual appeal of structures while offering significant protection against the elements. For international buyers, particularly in regions with high humidity or UV exposure, sourcing powder coats with robust weather and UV resistance is essential to ensure longevity. Additionally, the color consistency across batches is crucial for maintaining aesthetic coherence in large projects.

What Role Does Burgundy Powder Coat Play in the Automotive Industry?

The automotive industry utilizes burgundy powder coat for custom parts, including wheels, chassis components, and decorative elements. This finish not only provides a visually striking appearance but also protects against corrosion and wear from road conditions. Buyers from diverse markets should prioritize suppliers who offer high-temperature resistant powders, as automotive components often undergo significant thermal stress. Furthermore, ensuring that the powder coat meets industry standards for durability is vital for maintaining vehicle integrity.

How is Burgundy Powder Coat Beneficial for Outdoor Furniture?

Outdoor furniture manufacturers often opt for burgundy powder coat to finish items like benches, tables, and chairs. This coating protects metal surfaces from rust and fading due to sun exposure, ensuring that products remain attractive over time. For B2B buyers in tropical or arid climates, sourcing powder coats with proven weather resistance is critical. Additionally, understanding the application process can help ensure a smooth, long-lasting finish that withstands the rigors of outdoor use.

In What Ways Does Burgundy Powder Coat Enhance Industrial Equipment?

Burgundy powder coat finds applications in the industrial sector, particularly for machinery and equipment components. The coating provides a tough, protective layer that extends the lifespan of equipment by resisting scratches, chemicals, and corrosion. International buyers must consider the specific requirements for chemical resistance based on their operational environments. Additionally, confirming the supplier’s ability to meet industry standards for safety and performance can help mitigate risks associated with equipment failure.

How Does Burgundy Powder Coat Improve Retail Displays?

In retail, burgundy powder coat is commonly used for fixtures and signage, enhancing the overall shopping experience. The vibrant color attracts customers while the durable finish withstands the wear and tear of high-traffic environments. Buyers in this sector should assess the compatibility of the powder coat with local regulations regarding safety and environmental standards. Additionally, sourcing from suppliers who can provide samples for color matching is essential to ensure brand consistency in marketing materials.

3 Common User Pain Points for ‘burgundy powder coat’ & Their Solutions

Scenario 1: Difficulty in Color Consistency Across Batches

The Problem: A frequent challenge for B2B buyers of burgundy powder coat is achieving consistent color across multiple batches. Variations can occur due to differences in manufacturing processes or even the substrates being coated. For businesses that rely on uniformity—such as furniture manufacturers or automotive parts suppliers—these discrepancies can lead to customer dissatisfaction and potential loss of contracts.

The Solution: To ensure color consistency, buyers should establish a relationship with reputable suppliers who provide color swatch samples prior to large orders. Requesting a test batch of the burgundy powder coat allows businesses to assess color accuracy on their specific substrates. It’s also crucial to maintain stringent application processes, as variations in curing temperatures and times can affect the final appearance. Additionally, using color-matching software can help identify any discrepancies and ensure the same shade is achieved across all production runs.

Scenario 2: Concerns Over Durability and Environmental Factors

The Problem: Another common issue is the concern regarding the durability of burgundy powder coat finishes in various environmental conditions. Buyers in regions with extreme weather, such as high humidity or intense UV exposure, often worry that the coating will degrade or lose its color over time, affecting the quality of their products and their reputation in the market.

The Solution: To combat these concerns, buyers should select burgundy powder coats specifically formulated for enhanced durability, such as those with UV resistance and chemical resistance features. It is advisable to thoroughly review technical data sheets and product specifications before making a purchase. Additionally, applying a protective clear coat can further enhance the longevity of the powder finish. Regular maintenance and inspections of coated products can help identify any early signs of wear, allowing for timely interventions to preserve the finish and protect the investment.

Scenario 3: Navigating Regulatory Compliance and Safety Standards

The Problem: B2B buyers must navigate a complex landscape of regulatory compliance and safety standards when sourcing powder coatings, including burgundy powder coat. Many countries impose strict regulations regarding the use of certain chemicals, particularly those that may pose health risks. This can create confusion and anxiety for buyers who want to ensure their products are compliant while also meeting their quality expectations.

The Solution: To effectively address compliance issues, buyers should engage with suppliers who provide comprehensive safety data sheets (SDS) and are transparent about the chemical makeup of their products. It is essential to stay informed about local regulations and guidelines, particularly those concerning VOC (Volatile Organic Compounds) emissions and hazardous materials. Collaborating with suppliers who offer environmentally friendly, TGIC-free formulations can alleviate concerns related to safety and compliance. Additionally, conducting regular training sessions for staff on proper handling and application techniques will ensure adherence to safety protocols, reducing liability and promoting a safer working environment.

Strategic Material Selection Guide for burgundy powder coat

What Are the Key Materials for Burgundy Powder Coating?

When selecting materials for burgundy powder coating, it is essential to consider the properties, advantages, and limitations of various substrates. Below are analyses of four common materials used in conjunction with burgundy powder coat, focusing on their performance, application impact, and considerations for international buyers.

1. Steel

Key Properties: Steel substrates provide excellent strength and durability, with a high temperature rating that can withstand the curing process of powder coating. They also exhibit good corrosion resistance when treated properly.

Pros & Cons: The primary advantage of using steel is its robustness, making it suitable for heavy-duty applications. However, it can be susceptible to rust if not adequately pre-treated or coated. The manufacturing complexity can increase with the need for additional corrosion-resistant treatments, which can add to the overall cost.

Impact on Application: Steel is compatible with various media, including industrial and architectural applications. However, the surface preparation must be thorough to ensure proper adhesion of the powder coat.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local standards for corrosion resistance, such as ASTM or ISO certifications. The cost of steel can vary significantly based on local market conditions.

2. Aluminum

Key Properties: Aluminum is lightweight and has excellent corrosion resistance, making it ideal for outdoor applications. Its temperature rating is also sufficient for most powder coating processes.

Pros & Cons: The main advantage of aluminum is its resistance to corrosion and lightweight nature, which reduces shipping costs. However, it can be more expensive than steel and may require specific pre-treatment processes to enhance adhesion.

Impact on Application: Aluminum is suitable for a wide range of applications, including automotive and architectural finishes. Its smooth surface allows for a high-quality finish when powder coated.

Considerations for International Buyers: Buyers must consider the availability of aluminum in their local markets and the associated costs. Compliance with international standards for aluminum coatings, such as JIS or DIN, is also crucial.

3. Galvanized Steel

Key Properties: Galvanized steel combines the strength of steel with a zinc coating that provides excellent corrosion resistance. It can withstand harsh environmental conditions, making it suitable for outdoor applications.

Pros & Cons: The key advantage of galvanized steel is its durability and resistance to rust, which extends the lifespan of the powder-coated finish. However, the initial cost can be higher due to the galvanization process, and surface preparation is critical to ensure proper adhesion of the powder coat.

Impact on Application: Galvanized steel is often used in construction and outdoor furniture. The powder coating must be applied correctly to avoid issues with adhesion due to the zinc surface.

Considerations for International Buyers: Compliance with local and international standards for galvanized coatings is essential. Buyers should also evaluate the availability of galvanized steel in their regions, as it may vary significantly.

4. Stainless Steel

Key Properties: Stainless steel offers exceptional corrosion resistance and strength, with a high-temperature rating suitable for powder coating processes.

Pros & Cons: The primary advantage of stainless steel is its aesthetic appeal and resistance to corrosion, making it ideal for high-end applications. However, it is generally more expensive than other materials, and the manufacturing process can be complex.

Impact on Application: Stainless steel is commonly used in architectural applications and high-end consumer products. Its smooth surface allows for a premium finish with burgundy powder coat.

Considerations for International Buyers: Buyers should be aware of the varying grades of stainless steel and their corresponding properties. Compliance with international standards, such as ASTM, is critical to ensure quality and performance.

Summary Table of Material Selection for Burgundy Powder Coat

| Material | Typical Use Case for burgundy powder coat | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Industrial and heavy-duty applications | High strength and durability | Susceptible to rust without treatment | Medium |

| Aluminum | Automotive and architectural finishes | Lightweight and corrosion-resistant | Higher cost and specific pre-treatments | High |

| Galvanized Steel | Outdoor furniture and construction | Excellent corrosion resistance | Higher initial cost and adhesion issues | Medium |

| Stainless Steel | High-end consumer products and architecture | Premium finish and durability | High cost and complex manufacturing | High |

This comprehensive analysis provides B2B buyers with essential insights into the strategic selection of materials for burgundy powder coating, enabling informed decisions that align with their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for burgundy powder coat

What Are the Key Stages in the Manufacturing Process of Burgundy Powder Coat?

The manufacturing process of burgundy powder coat involves several critical stages, ensuring that the final product meets the aesthetic and functional requirements of various industries, from automotive to architectural applications. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: What Raw Materials Are Used?

The primary raw materials for burgundy powder coat include polyester resins, pigments, and additives. Polyester resins are favored for their excellent durability, UV resistance, and color retention, making them ideal for outdoor applications. The pigments are crucial for achieving the desired burgundy shade, with various formulations available to cater to specific performance characteristics. Additives may include flow agents and curing agents that enhance application properties and overall finish quality.

Before production begins, materials undergo rigorous quality checks to ensure they meet specified standards. This step includes verifying the consistency of color and particle size, which are vital for achieving a uniform finish.

How Is the Powder Coat Formulated and Processed?

Once the raw materials are prepared, they are mixed in precise ratios according to the desired formulation. The mixing process typically involves high-shear mixing techniques to ensure that the pigments are evenly distributed throughout the resin.

After mixing, the blend is extruded through a process called compounding, where it is heated and forced through a die to create uniform pellets. This stage is crucial as it influences the flow and application characteristics of the powder. The extruded material is then cooled and ground into a fine powder, which can vary in particle size based on the intended application.

What Finishing Techniques Are Commonly Used?

The finishing stage of burgundy powder coat production can involve several techniques to enhance the final product’s properties. Common methods include:

- Electrostatic Spraying: This technique allows for a uniform application of powder to metal surfaces, ensuring even coverage and reduced overspray.

- Curing: The applied powder coat is then cured in an oven at high temperatures, typically around 180-200 degrees Celsius. This process causes the powder to melt and chemically react, forming a durable and resistant finish.

These finishing techniques are essential for achieving the desired gloss level, texture, and durability of the burgundy powder coat.

What Quality Assurance Practices Are Implemented?

Quality assurance (QA) is a fundamental aspect of the manufacturing process, ensuring that the burgundy powder coat meets international standards and customer expectations.

Which International Standards Are Relevant for Burgundy Powder Coat?

For B2B buyers, understanding the relevant international standards is crucial. The ISO 9001 standard for quality management systems is widely recognized and ensures that manufacturers consistently meet customer and regulatory requirements. Additionally, industry-specific certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards for oil and gas applications may apply.

These certifications not only provide assurance of quality but also facilitate smoother trade across international borders, particularly for buyers in Africa, South America, the Middle East, and Europe.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are established at various stages of the manufacturing process to identify any defects early on. Common checkpoints include:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials before they enter the production line. It helps to ensure that only materials meeting specified standards are used.

- In-Process Quality Control (IPQC): During production, samples are taken at various intervals to monitor the quality of the powder being produced. This includes checking for consistency in color, particle size, and flow characteristics.

- Final Quality Control (FQC): After production, the final powder coat is tested for performance characteristics such as adhesion, chemical resistance, and durability. This ensures that the product meets all specifications before it is packaged and shipped.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must be proactive in verifying the quality control practices of potential suppliers. Here are several strategies:

-

Audits: Conducting supplier audits can provide insights into their manufacturing processes and quality assurance protocols. This can help buyers assess whether suppliers adhere to international standards and best practices.

-

Quality Reports: Requesting regular quality reports from suppliers can help buyers stay informed about product performance and any issues that may arise during production.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes. These inspections can verify compliance with international standards and ensure that products meet specified requirements.

What QC and Certification Nuances Should International Buyers Consider?

For international buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is essential. This includes:

-

Regulatory Compliance: Different regions may have varying regulatory requirements. Buyers should familiarize themselves with local regulations regarding product safety and environmental impact.

-

Cultural Considerations: Understanding cultural differences in business practices can aid in building strong relationships with suppliers and ensuring clear communication regarding quality expectations.

-

Logistics and Supply Chain: The logistics of importing powder coat products can be complex. Buyers should consider factors such as shipping times, customs regulations, and potential tariffs when evaluating suppliers.

By thoroughly understanding the manufacturing processes and quality assurance practices associated with burgundy powder coat, B2B buyers can make informed decisions, ensuring they select suppliers that meet their quality standards and business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘burgundy powder coat’

To effectively procure burgundy powder coat for your business needs, it’s essential to follow a systematic approach. This checklist serves as a comprehensive guide for international B2B buyers, ensuring that you make informed decisions throughout the sourcing process.

Step 1: Define Your Technical Specifications

Start by identifying the specific requirements for your powder coating project. Consider factors such as the desired gloss level, color accuracy, and any industry standards that must be met. Knowing these specifications will help you communicate effectively with potential suppliers and ensure the product meets your performance needs.

Step 2: Research and Identify Reliable Suppliers

Conduct thorough research to find reputable suppliers of burgundy powder coat. Utilize industry directories, trade shows, and online marketplaces to compile a list of potential vendors. Pay attention to their track record, customer reviews, and industry experience, which can provide insight into their reliability and product quality.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. Assess their production capabilities, quality assurance processes, and delivery timelines to ensure they align with your project requirements.

Step 4: Request Samples for Color Matching

To ensure the burgundy powder coat meets your expectations, request physical samples from shortlisted suppliers. This step is vital as colors may appear differently on screens due to monitor settings. Testing the samples in your application will help you confirm the desired finish and compatibility with your products.

Step 5: Inquire About Compliance and Safety Standards

Verify that the suppliers adhere to relevant safety and environmental regulations. This includes checking for compliance with international standards such as ISO or ASTM, as well as local regulations in your target market. Understanding these standards will help mitigate risks associated with product safety and environmental impact.

Step 6: Negotiate Pricing and Terms

Once you’ve narrowed down your options, initiate negotiations regarding pricing, minimum order quantities, and payment terms. Ensure that you consider bulk purchase discounts and shipping costs, especially when dealing with international suppliers. Clear communication during this phase will help establish a mutually beneficial agreement.

Step 7: Establish a Quality Assurance Process

Before finalizing your order, implement a quality assurance process to monitor product quality upon delivery. This may involve setting up inspection protocols or third-party quality checks. Ensuring that the burgundy powder coat meets your specifications upon arrival will prevent costly production delays and rework.

By following these steps, you can streamline the procurement process for burgundy powder coat, ensuring that you select the right supplier and product for your business needs. This careful approach will ultimately contribute to the success of your projects and the satisfaction of your customers.

Comprehensive Cost and Pricing Analysis for burgundy powder coat Sourcing

What are the Key Cost Components in Burgundy Powder Coat Sourcing?

When evaluating the costs associated with burgundy powder coat, buyers should consider several key components that contribute to the overall pricing structure. The primary cost elements include:

-

Materials: The base materials used in powder coating, such as polyester and resin, significantly influence the cost. Burgundy powders, particularly those with specialized finishes like metallic or textured options, may incur higher material costs.

-

Labor: Labor costs vary based on the complexity of production and the location of the manufacturing facility. Skilled labor is essential for quality assurance during the coating process, impacting overall pricing.

-

Manufacturing Overhead: This encompasses costs related to facility maintenance, utilities, and equipment depreciation. Higher overhead costs are often seen in regions with strict environmental regulations, which can affect the final price.

-

Tooling: Custom tooling may be required for specific applications or finishes. This one-time investment can be amortized over large orders, but it can raise upfront costs for smaller volumes.

-

Quality Control (QC): Ensuring that the powder coat meets specific standards requires rigorous testing and quality assurance processes, adding to the overall cost. Certifications for durability, UV resistance, and chemical resistance can further increase expenses.

-

Logistics: Transportation and handling costs play a significant role, especially for international shipments. The choice of shipping methods and distances will impact the total cost significantly.

-

Margin: Suppliers typically include a profit margin that reflects their operational costs and market conditions. This margin can vary widely based on the supplier’s business model and market competition.

What Influences the Pricing of Burgundy Powder Coating?

Several factors can influence the pricing of burgundy powder coat, particularly for international B2B buyers:

-

Volume and Minimum Order Quantities (MOQ): Pricing often benefits from economies of scale. Larger orders can lead to discounts, while smaller orders may incur higher per-unit costs due to increased handling and production setup expenses.

-

Specifications and Customization: Custom formulations or specific color matches may result in additional costs. Buyers should be clear about their requirements to avoid unexpected charges.

-

Materials Quality and Certifications: Higher quality materials with certifications for environmental and performance standards typically come at a premium. Buyers should assess their needs carefully to determine if these certifications are necessary.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can greatly affect pricing. Suppliers with advanced technology may offer better quality and efficiency, justifying higher prices.

-

Incoterms: Understanding the terms of shipping and delivery (Incoterms) is crucial. These terms define responsibilities for costs and risks, impacting the total landed cost of the product.

What Tips Can Help Buyers Negotiate Better Prices for Burgundy Powder Coating?

B2B buyers looking to source burgundy powder coat should consider the following tips to enhance their purchasing strategy:

-

Negotiate Volume Discounts: Engage suppliers in discussions about volume pricing. Committing to larger orders can provide significant savings.

-

Evaluate Total Cost of Ownership (TCO): Look beyond initial pricing to assess the TCO. Factors such as durability, maintenance, and the lifespan of the coating can impact overall costs in the long term.

-

Understand Pricing Nuances for International Transactions: Buyers from regions like Africa, South America, and the Middle East should factor in currency fluctuations, import duties, and taxes when evaluating prices.

-

Request Samples: Before making bulk purchases, request samples to ensure color accuracy and quality. This can prevent costly mistakes and enhance satisfaction with the final product.

-

Stay Informed about Market Trends: Awareness of market conditions, such as material shortages or shifts in demand, can provide leverage in negotiations and help anticipate price changes.

Disclaimer on Indicative Prices

Prices for burgundy powder coat vary significantly based on the factors discussed, and the figures provided in this analysis are indicative. Actual prices may differ based on supplier, location, and specific requirements. Always consult with suppliers for the most accurate and up-to-date pricing information tailored to your needs.

Alternatives Analysis: Comparing burgundy powder coat With Other Solutions

Introduction to Alternative Solutions for Burgundy Powder Coating

When considering finishing options for metal products, burgundy powder coating stands out for its aesthetic appeal and durability. However, various alternatives exist that may better suit specific applications or budget constraints. This analysis explores some viable alternatives, evaluating their performance, cost, ease of implementation, maintenance needs, and best use cases.

| Comparison Aspect | Burgundy Powder Coat | Liquid Paint | Anodizing |

|---|---|---|---|

| Performance | High durability, UV and weather resistant | Moderate durability, less UV resistance | Excellent corrosion resistance, limited color options |

| Cost | Moderate to high | Low to moderate | High |

| Ease of Implementation | Requires specialized equipment and processes | Easier application, available in various forms | Requires specialized processes and equipment |

| Maintenance | Low maintenance | Moderate maintenance | Low maintenance |

| Best Use Case | Automotive, outdoor furniture, decorative items | Indoor applications, consumer goods | Aerospace, architectural elements |

What Are the Pros and Cons of Liquid Paint as an Alternative?

Liquid paint is a well-known alternative to powder coating, offering a wide range of color options and finishes. Its application is generally easier, as it can be sprayed or brushed on without specialized equipment. However, the durability of liquid paint is often less than that of powder coatings, as it may be more susceptible to fading and chipping over time. For B2B buyers seeking a cost-effective solution for indoor applications or consumer goods, liquid paint can be a suitable choice, provided that they are prepared for more frequent maintenance and potential reapplication.

How Does Anodizing Compare to Burgundy Powder Coating?

Anodizing is a specialized electrochemical process that enhances the natural oxide layer on metal surfaces, primarily aluminum. This process provides excellent corrosion resistance and a sleek, matte finish. While anodizing is durable and low-maintenance, its color options are limited compared to powder coating. Additionally, the initial setup cost for anodizing can be higher due to the specialized equipment required. Anodizing is ideal for applications in aerospace and architecture, where corrosion resistance and a premium finish are critical, but may not be the best fit for projects requiring a broader color palette.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate finishing solution hinges on specific project requirements, budget, and desired aesthetic. Burgundy powder coating excels in durability and aesthetic appeal, making it ideal for outdoor and decorative applications. However, alternatives like liquid paint and anodizing offer unique advantages that may better align with particular project needs. B2B buyers should assess the performance characteristics, cost implications, and maintenance needs of each option to make informed decisions that best serve their business objectives. Whether prioritizing cost-effectiveness, ease of application, or premium finishes, understanding these alternatives is crucial for optimizing product outcomes.

Essential Technical Properties and Trade Terminology for burgundy powder coat

What Are the Key Technical Properties of Burgundy Powder Coat?

When selecting burgundy powder coat for industrial applications, understanding its critical properties is essential for ensuring product quality and performance. Here are some of the key specifications that B2B buyers should consider:

-

Material Composition

Burgundy powder coat is typically composed of polyester or epoxy resin. Polyester is favored for its excellent outdoor durability, UV resistance, and color retention, making it suitable for exterior applications. Epoxy, while providing superior adhesion and corrosion resistance, is more suitable for indoor use due to its lower UV resistance. Understanding the material composition helps buyers choose the right powder coat for specific environmental conditions. -

Gloss Level

The gloss level of a powder coat, usually measured in gloss units, indicates the sheen of the finished surface. A typical gloss level for burgundy powder coat can range from 71 to 85 gloss units. Higher gloss levels are often preferred for aesthetic appeal and ease of cleaning. Buyers should consider the desired finish for their application, as gloss levels can affect both the appearance and maintenance of the coated surface. -

Curing Temperature and Time

The curing process is critical for achieving the desired hardness and adhesion of the powder coat. Burgundy powder coats typically require a curing temperature of around 400°F (204°C) for approximately 10 minutes at the part metal temperature (PMT). Ensuring that the curing parameters are met is vital for maximizing durability and performance, especially in high-stress environments. -

Chemical and UV Resistance

Burgundy powder coats should exhibit resistance to chemicals, UV rays, and weather conditions. This is particularly important for applications in outdoor environments or industries where exposure to harsh chemicals is likely. Buyers should request specific performance data, such as salt spray testing results, which indicate the powder coat’s longevity and resistance to corrosion. -

Theoretical Coverage

The theoretical coverage of burgundy powder coat refers to the area that can be coated per pound of powder, typically expressed in square feet per pound. A common theoretical coverage for burgundy powder coat is around 51.5 sq. ft/lb. This metric is crucial for budget planning and estimating the quantity of powder needed for a project.

What Are Common Trade Terms Related to Burgundy Powder Coat?

Navigating the procurement of burgundy powder coat requires familiarity with industry-specific terminology. Here are some common terms that B2B buyers should understand:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of powder coating, knowing the OEM specifications can help ensure that the coating meets the quality standards required for specific applications. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of product that a supplier is willing to sell. For powder coatings, MOQs can vary significantly based on the supplier and product type. Understanding MOQs is important for managing inventory costs and ensuring supply chain efficiency. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. B2B buyers often use RFQs to compare offers and negotiate better deals on bulk purchases of powder coatings, including burgundy shades. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping and delivery terms. Familiarity with Incoterms is crucial for managing logistics and understanding potential liabilities in cross-border transactions. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. This is a critical factor for B2B buyers, as it affects project timelines and inventory management. Understanding lead times for burgundy powder coat can help in planning production schedules more effectively. -

Color Matching

Color matching is the process of ensuring that the powder coat color aligns with specific standards or samples. This is particularly important in industries where branding and aesthetics are key. Buyers should inquire about color matching services to ensure consistency across products.

In conclusion, understanding these essential properties and trade terms can empower B2B buyers to make informed decisions regarding burgundy powder coat, ultimately leading to successful projects and satisfied customers.

Navigating Market Dynamics and Sourcing Trends in the burgundy powder coat Sector

What Are the Current Market Dynamics and Key Trends in the Burgundy Powder Coat Sector?

The burgundy powder coat market is experiencing notable growth driven by an increase in demand across various industries, including automotive, furniture, and architecture. This trend is particularly evident in regions such as Africa, South America, the Middle East, and Europe, where buyers are increasingly looking for durable and aesthetically pleasing finishes. The rise of e-commerce has facilitated easier access to diverse suppliers, allowing international buyers to source high-quality burgundy powder coats more efficiently.

Technological advancements also play a significant role in this sector. Innovations in powder coating technology have led to improved formulations that enhance adhesion, chemical resistance, and UV stability. Furthermore, the integration of digital tools for color matching and visualization has streamlined the sourcing process, enabling buyers to make informed decisions before purchasing. As global supply chains evolve, buyers are prioritizing suppliers who can demonstrate flexibility and responsiveness to market changes.

Additionally, the trend toward customization is reshaping the market landscape. B2B buyers are increasingly seeking unique finishes that align with their brand identity, prompting manufacturers to offer a wider variety of shades and finishes. This shift underscores the importance of understanding customer preferences and adapting product offerings accordingly.

How Are Sustainability and Ethical Sourcing Influencing the Burgundy Powder Coat Market?

Sustainability has become a critical consideration in the burgundy powder coat sector, as both consumers and businesses increasingly demand environmentally responsible products. The production process of powder coatings typically generates fewer volatile organic compounds (VOCs) compared to traditional liquid paints, making them a more eco-friendly choice. However, buyers should look for suppliers who adhere to sustainable practices, such as using recycled materials and minimizing waste throughout the manufacturing process.

Ethical sourcing is also paramount. B2B buyers are encouraged to engage with suppliers who prioritize transparency and social responsibility in their supply chains. This includes ensuring fair labor practices and responsible sourcing of raw materials. Certifications such as ISO 14001 (Environmental Management) and GREENGUARD can serve as indicators of a supplier’s commitment to sustainability.

Moreover, as regulatory frameworks around environmental impact tighten globally, companies that proactively adopt green practices may gain a competitive edge. By sourcing burgundy powder coats from manufacturers committed to sustainability, buyers not only enhance their brand reputation but also contribute to a more sustainable future.

What Is the Evolution of Burgundy Powder Coating Technology and Its Relevance for B2B Buyers?

The evolution of burgundy powder coating technology can be traced back several decades, initially gaining prominence in the automotive industry due to its durability and finish quality. Over time, advancements in powder formulation have led to the development of a variety of finishes, including glossy, matte, and textured options, catering to diverse aesthetic and functional needs.

The introduction of polyester and TGIC-free powders has further enhanced the appeal of burgundy powder coats, providing options that are not only visually striking but also environmentally friendly. The ability to customize colors and finishes has become a significant advantage for manufacturers, allowing them to meet specific client requirements more effectively.

For B2B buyers, understanding this evolution is crucial as it highlights the importance of selecting suppliers who invest in research and development. Suppliers that stay ahead of technological advancements can offer superior products that meet current market demands, ensuring that businesses can maintain a competitive edge in their respective industries.

Frequently Asked Questions (FAQs) for B2B Buyers of burgundy powder coat

-

How do I choose the right burgundy powder coat for my application?

Selecting the appropriate burgundy powder coat involves considering several factors. First, assess the specific requirements of your project, such as the desired finish (glossy or matte), durability, and resistance to environmental factors like UV rays and chemicals. Next, consult with suppliers to obtain sample swatches, which allow for accurate color matching and texture evaluation. Finally, verify that the powder coat complies with relevant industry standards to ensure quality and performance for your intended use. -

What is the best application method for burgundy powder coat?

The best application method for burgundy powder coat typically involves electrostatic spray coating, which ensures an even and efficient application. This method enhances adhesion and minimizes waste, allowing for a smoother finish. Other options include fluidized bed dipping for thicker coatings or manual spray techniques for smaller projects. Always follow the manufacturer’s guidelines regarding curing temperatures and times to achieve optimal results, as improper application can lead to defects in the finish. -

What are the minimum order quantities (MOQs) for burgundy powder coat?

Minimum order quantities for burgundy powder coat can vary significantly based on the supplier and product type. Generally, MOQs range from 10 to 50 pounds for standard colors, while custom formulations may require larger orders. It’s advisable to discuss your specific needs with potential suppliers to determine their policies. Additionally, consider the potential cost savings of bulk purchasing, especially if you anticipate ongoing projects that will require consistent color and quality. -

How can I ensure the quality of burgundy powder coat before purchasing?

To ensure quality, request samples and conduct thorough testing on your substrates. Evaluate factors such as adhesion, durability, and resistance to environmental conditions through tests like salt spray or UV exposure. Additionally, inquire about the supplier’s quality assurance processes, certifications, and customer reviews. Establishing a solid relationship with a reputable supplier who can provide consistent quality is crucial for long-term satisfaction. -

What should I consider regarding logistics when sourcing burgundy powder coat internationally?

When sourcing burgundy powder coat internationally, consider factors such as shipping costs, delivery times, and customs regulations. Collaborate with suppliers who have experience in exporting to your region, ensuring they can handle necessary documentation and compliance. Additionally, factor in the lead time for production and shipping to avoid project delays. Developing a reliable logistics plan will help streamline the procurement process and mitigate potential disruptions. -

What payment terms are commonly offered for bulk purchases of burgundy powder coat?

Payment terms for bulk purchases of burgundy powder coat can vary by supplier but often include options such as advance payment, net 30, or letter of credit. It’s essential to discuss and negotiate terms upfront to align with your cash flow and project timelines. Some suppliers may offer discounts for early payment or bulk orders, providing an opportunity for cost savings. Always ensure that the payment methods are secure and reputable. -

Can I customize the color or finish of my burgundy powder coat order?

Yes, many suppliers offer customization options for burgundy powder coat, including variations in shade, gloss level, and texture. When requesting a custom formulation, provide detailed specifications and, if possible, a physical color sample for accurate matching. Be aware that custom orders may have higher MOQs and longer lead times. Engaging in clear communication with your supplier will ensure that your expectations are met and that you receive a product that aligns with your project requirements. -

How do I address potential supply chain disruptions when sourcing burgundy powder coat?

To mitigate supply chain disruptions, maintain open communication with your suppliers and stay informed about global market conditions. Diversifying your supplier base can also reduce reliance on a single source, providing alternative options if one supplier encounters issues. Implementing a just-in-time inventory system can help manage stock levels effectively while also preparing for potential delays. Additionally, consider establishing long-term contracts with suppliers to secure pricing and availability during volatile market conditions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 Burgundy Powder Coat Manufacturers & Suppliers List

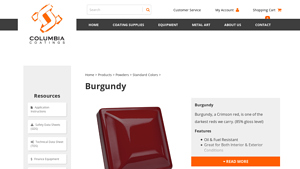

1. Columbia Coatings – Burgundy Coating

Domain: columbiacoatings.com

Registered: 2001 (24 years)

Introduction: {“name”: “Burgundy”, “description”: “Burgundy, a Crimson red, is one of the darkest reds we carry.”, “gloss_level”: “85% gloss level”, “features”: [“Oil & Fuel Resistant”, “Great for Both Interior & Exterior Conditions”], “availability”: “In Stock”, “shipping”: “Usually ships In 1-2 Business Days”, “price_per_pound”: {“1-10”: “$16.13”, “11-24”: “$15.94”, “25-49”: “$14.64”, “50-99”: “$10.41”, “100+…

2. All Powder Paints – Burgundy Metallic

Domain: allpowderpaints.com

Registered: 2011 (14 years)

Introduction: Burgundy: APP | All Powder Paints

– Product ID: Not specified

– Available Products:

– BURGUNDY METALLIC: $16.17

– BURGUNDY WRINKLE: $26.07 (Out of stock)

– BLACK RED: $14.37

– BURGY RED: $19.22

– BURPLE RED FLIP FLOP: $19.22

– CANDY MAROON (Transparent): $15.98

– CRIMSON RED: $17.40

– CRYSTAL CLARET RED: Price not specified

– Color Category: Burgundy

– Price Range: $14.37 – $26.0…

3. PPG – 1LB High Gloss Burgundy Powder Coating Paint

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “1LB HIGH GLOSS BURGUNDY Powder Coating Paint”, “Weight”: “1LB”, “Color”: “Burgundy”, “Finish”: “High Gloss”, “Durability”: “Ultra Durable”, “Country of Manufacture”: “USA”, “Brand”: “PPG”, “Application Method”: “Spray”, “Type”: “Powder Coating”, “Features”: [“For Interior”, “For Outdoor Use”], “Suitable For”: “Metal”, “Condition”: “New”, “Shipping Cost”: “$9.00”, “Returns”: “30 d…

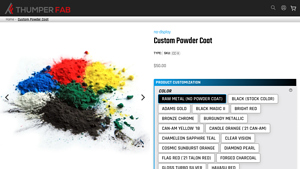

4. Thumper Fab – Custom Powder Coat

Domain: thumperfab.com

Registered: 2019 (6 years)

Introduction: {“product_name”: “Custom Powder Coat”, “price”: “$50.00”, “available_colors”: [“Raw Metal (no powder coat)”, “Black (Stock Color)”, “Adams Gold”, “Black Magic II”, “Bright Red”, “Bronze”, “Chrome”, “Burgundy Metallic”, “Can-Am Yellow ’18”, “Candle Orange (’21 Can-Am)”, “Chameleon Sapphire”, “Teal”, “Clear Vision”, “Cosmic Sunburst Orange”, “Diamond Pearl”, “Flag Red (’21 Talon Red)”, “Forged Charc…

Strategic Sourcing Conclusion and Outlook for burgundy powder coat

In conclusion, strategic sourcing of burgundy powder coat offers significant advantages for international B2B buyers, particularly in emerging markets like Africa, South America, the Middle East, and Europe. The diverse applications of burgundy powder coat—from automotive to architectural finishes—underscore its versatility and appeal. Buyers can leverage competitive pricing, as bulk purchasing offers substantial cost savings, with prices decreasing significantly per pound with higher volume orders.

Understanding the specific performance characteristics, such as chemical and UV resistance, allows businesses to select the right product for their needs, ensuring longevity and aesthetic appeal. Moreover, aligning with reputable suppliers who prioritize quality and sustainability can enhance brand reputation and customer satisfaction.

As the demand for decorative and protective coatings continues to grow, now is the opportune time for businesses to refine their sourcing strategies. Engage with suppliers who can offer not only competitive pricing but also customization options to meet unique project requirements. Embrace the opportunity to innovate and differentiate your offerings in the market by integrating high-quality burgundy powder coats into your product lines. The future is bright for those who act decisively and strategically in their sourcing endeavors.