Introduction: Navigating the Global Market for build shipping crate

In the competitive landscape of international trade, the ability to effectively build shipping crates can significantly impact logistics efficiency and cost management. Many businesses face the challenge of sourcing reliable and cost-effective solutions for packaging goods, particularly when shipping across diverse markets like Africa, South America, the Middle East, and Europe. This guide on building shipping crates is designed to address these challenges head-on, offering a comprehensive exploration of crate types, construction methods, applications, and supplier vetting processes.

By delving into the specifics of materials, tools, and techniques necessary for crafting durable shipping crates, this resource empowers B2B buyers to make informed decisions that optimize their shipping strategies. Whether you are shipping fragile items, heavy machinery, or valuable artwork, understanding the nuances of crate construction can lead to significant savings and enhanced protection for your goods.

Moreover, this guide will provide insights into cost considerations, enabling businesses to budget effectively while ensuring their products arrive safely at their destinations. With expert advice tailored to the unique requirements of different regions, buyers will be equipped to navigate the complexities of the global market confidently. Ultimately, this comprehensive guide is an essential tool for any international B2B buyer looking to streamline their shipping processes and enhance their operational efficiency.

Understanding build shipping crate Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Wooden Crate | Made from 1×4 or 2×4 lumber, customizable dimensions, durable. | Heavy machinery, electronics, fragile items | Pros: Cost-effective, sturdy. Cons: Heavy, less moisture-resistant. |

| Plywood Crate | Constructed from plywood, lighter than wooden crates, smooth finish. | Electronics, artwork, sensitive equipment | Pros: Lightweight, easier to handle. Cons: Less robust than solid wood. |

| Foam-Lined Crate | Includes foam padding to protect delicate items, custom shapes. | Art pieces, high-value merchandise | Pros: Superior protection, custom fit. Cons: Higher cost, limited reusability. |

| Collapsible Crate | Designed for easy assembly/disassembly, space-saving. | E-commerce, retail shipping | Pros: Space-efficient, reusable. Cons: May lack strength for heavy items. |

| Pallet Base Crate | Built on a pallet base for easy transport, often reinforced. | Furniture, large equipment | Pros: Forklift compatible, robust. Cons: Bulky, may require more material. |

What Are the Characteristics of a Standard Wooden Crate?

Standard wooden crates are typically constructed using 1×4 or 2×4 lumber, providing a strong and durable structure. These crates can be customized to specific dimensions, making them suitable for shipping a wide range of items, including heavy machinery and electronics. When considering a wooden crate, B2B buyers should evaluate the weight of the crate against the items being shipped, as they can be quite heavy, potentially increasing shipping costs. Additionally, while they are cost-effective, they may not be moisture-resistant, which is a consideration for international shipping.

How Do Plywood Crates Differ from Wooden Crates?

Plywood crates are lighter than traditional wooden crates, as they utilize thinner plywood panels instead of solid lumber. This makes them easier to handle and transport, particularly for fragile items such as electronics and artwork. Plywood crates can also provide a smoother finish, which is beneficial for branding and presentation. However, buyers should consider that while they are lightweight, they may not offer the same level of robustness as solid wood options, making them less suitable for extremely heavy or bulky items.

What Makes Foam-Lined Crates Ideal for Sensitive Items?

Foam-lined crates are designed specifically for the protection of delicate or high-value items. They incorporate custom foam padding that can be shaped to fit the item being shipped, ensuring a snug fit that minimizes movement during transit. This type of crate is particularly popular for shipping artwork, sensitive equipment, and other fragile merchandise. While they provide superior protection, buyers should be aware of the higher costs associated with foam-lined crates and consider their reusability, as they may not be as durable over multiple shipments.

Why Choose a Collapsible Crate for E-commerce?

Collapsible crates are designed for easy assembly and disassembly, making them an excellent choice for businesses focused on space efficiency. They are particularly useful in e-commerce and retail shipping, where storage space can be limited. These crates can be reused multiple times, making them a sustainable option. However, buyers should consider that collapsible crates may not be as strong as fixed designs, so they are best suited for lighter items rather than heavy machinery or equipment.

What Are the Benefits of Using a Pallet Base Crate?

Pallet base crates are constructed on a pallet foundation, making them forklift-compatible and easy to transport. This design is particularly advantageous for shipping larger items such as furniture or heavy equipment. The reinforced structure ensures that the crate can withstand significant weight and rough handling. However, the bulkiness of pallet base crates can be a drawback for some businesses, as they may require more material and space during storage and transport. Buyers should weigh these factors against the benefits of durability and ease of handling.

Key Industrial Applications of build shipping crate

| Industry/Sector | Specific Application of build shipping crate | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Shipping heavy machinery and equipment | Reduces shipping damage and costs, enhances safety | Durability of materials, weight capacity, customization options |

| Arts and Entertainment | Transporting props and set pieces for productions | Ensures safe transport and easy handling | Size specifications, padding materials, ease of assembly |

| Agriculture | Exporting perishable goods like fruits and vegetables | Maintains product integrity and freshness during transit | Insulation properties, moisture resistance, ventilation features |

| Electronics | Shipping sensitive electronic components | Protects against static, moisture, and physical damage | Anti-static materials, cushioning, compliance with international standards |

| Furniture | Delivering custom furniture pieces | Minimizes damage during transit and enhances customer satisfaction | Custom dimensions, ease of assembly/disassembly, aesthetic considerations |

How is ‘build shipping crate’ utilized in manufacturing?

In the manufacturing sector, building custom shipping crates is essential for transporting heavy machinery and equipment. These crates are designed to withstand significant weight and protect against damage during transit. For international B2B buyers, it’s crucial to consider the durability of materials, as well as the crate’s weight capacity. Customization options may also be necessary to accommodate specific machinery dimensions, ensuring a secure fit that minimizes movement and potential damage.

What role do shipping crates play in the arts and entertainment industry?

In the arts and entertainment industry, shipping crates are vital for transporting props and set pieces for theater productions and film sets. These crates are designed for easy handling and to provide maximum protection against damage during transit. Buyers in this sector must focus on size specifications and the use of appropriate padding materials to safeguard delicate items. The ease of assembly is also important, as it allows for quick setup and breakdown during busy production schedules.

How do shipping crates benefit the agriculture industry?

The agriculture sector utilizes build shipping crates for exporting perishable goods, such as fruits and vegetables. These crates help maintain product integrity and freshness throughout the shipping process. For international buyers, sourcing crates with insulation properties and moisture resistance is critical to prevent spoilage. Additionally, incorporating ventilation features can help regulate temperature and humidity levels, ensuring that perishable items arrive in optimal condition.

Why are shipping crates important in the electronics sector?

In the electronics industry, shipping crates are essential for transporting sensitive components that require protection from static electricity, moisture, and physical damage. Custom-built crates can be designed with anti-static materials and cushioning to ensure the safe arrival of electronic goods. Buyers should prioritize compliance with international shipping standards and consider the specific protective features necessary for their products to mitigate the risk of damage during transit.

How do shipping crates enhance customer satisfaction in the furniture industry?

The furniture industry relies on custom shipping crates to deliver bespoke pieces safely to customers. These crates minimize damage during transit, which is crucial for maintaining product quality and enhancing customer satisfaction. Buyers must consider custom dimensions to fit various furniture styles and the ease of assembly or disassembly for efficient shipping and storage. Aesthetic considerations can also play a role, as visually appealing crates may enhance the unboxing experience for customers.

3 Common User Pain Points for ‘build shipping crate’ & Their Solutions

Scenario 1: Ensuring Safe Shipment of Fragile Goods

The Problem: International B2B buyers often face the daunting challenge of shipping fragile items, such as delicate machinery or art pieces, without incurring damage during transit. This concern is particularly pronounced in regions with varying climates, where humidity and temperature fluctuations can affect packaging integrity. Additionally, the cost of professional crating services can be prohibitively expensive, leading many businesses to seek cost-effective DIY solutions that still maintain a high level of protection for their goods.

The Solution: To effectively build a shipping crate for fragile items, start by selecting the right materials. Use 1/2” thick plywood or OSB for the crate’s walls to provide a sturdy structure. Reinforce the interior with foam padding, ensuring a snug fit for the item being shipped to prevent movement. When designing the crate, incorporate a double-layered foam system, where one layer is permanently affixed inside the crate and the other is removable for easy access to the item. This not only provides cushioning but also absorbs shocks during transit. Additionally, consider including moisture-absorbing packets within the crate to mitigate humidity-related issues, particularly when shipping to or from regions with significant climate variability.

Scenario 2: Navigating Compliance and Regulatory Challenges

The Problem: B2B buyers shipping goods internationally must navigate a maze of compliance and regulatory requirements, which can vary significantly from one country to another. This includes adhering to specific packaging standards, labeling regulations, and customs requirements that can be overwhelming for businesses unfamiliar with these guidelines. Failure to comply can lead to delays, fines, or even the rejection of shipments, causing significant losses and reputational damage.

The Solution: To overcome compliance challenges, buyers should invest time in researching the specific regulations for their destination countries. Utilizing resources such as government export websites, trade associations, or consulting with logistics providers can provide valuable insights into necessary packaging standards and documentation. When building a shipping crate, ensure that it meets the International Safe Transit Association (ISTA) standards for packaging. Label the crate clearly with all necessary information, including contents, destination, and handling instructions. Additionally, consider pre-emptively contacting customs brokers or freight forwarders who can assist in ensuring that all paperwork is in order and that the crate complies with both local and international regulations. This proactive approach can help streamline the shipping process and reduce the risk of delays.

Scenario 3: Balancing Cost and Quality in Crate Construction

The Problem: Many businesses are caught in the dilemma of balancing cost with quality when it comes to building shipping crates. While it’s crucial to keep expenses low, compromising on the quality of materials or construction methods can lead to inadequate protection for the items being shipped. This is particularly vital for high-value goods, where even a minor mishap can result in substantial financial losses.

The Solution: To strike a balance between cost and quality, buyers should prioritize investing in high-quality materials that offer durability without breaking the bank. For example, sourcing locally available materials like treated plywood can reduce costs while ensuring the crate withstands various environmental conditions. When constructing the crate, utilize efficient designs that minimize waste, such as creating modular crates that can be easily disassembled and reused for future shipments. Additionally, implementing a systematic approach to crate construction, including detailed planning and a checklist of required materials and steps, can help streamline the process and reduce labor costs. Leveraging technology, such as crate-building calculators, can also aid in determining the optimal dimensions and materials needed, further enhancing cost efficiency while maintaining the structural integrity necessary for safe shipping.

Strategic Material Selection Guide for build shipping crate

What Are the Best Materials for Building Shipping Crates?

When selecting materials for building shipping crates, it’s essential to consider their properties, advantages, and limitations. The right choice can significantly impact the durability and safety of the cargo during transit, especially for international shipments. Below, we analyze four common materials used in constructing shipping crates: plywood, OSB (Oriented Strand Board), solid wood, and metal.

How Does Plywood Perform as a Material for Shipping Crates?

Plywood is a popular choice for shipping crates due to its strength and versatility. It is made from thin layers of wood veneer glued together, which provides excellent resistance to warping and cracking. Key properties include a high strength-to-weight ratio and good moisture resistance, making it suitable for various environmental conditions.

Pros: Plywood is relatively lightweight, cost-effective, and easy to work with, allowing for quick assembly. It also offers a smooth surface, which is beneficial for branding and labeling.

Cons: While plywood is durable, it may not withstand extreme temperatures or heavy impacts as well as solid wood or metal. Additionally, lower-quality plywood may have voids that can compromise structural integrity.

Impact on Application: Plywood is compatible with a wide range of products, including fragile items that require a cushioned environment. However, it is crucial to ensure that the plywood meets international standards, such as ASTM or DIN, particularly for shipments to Europe and the Middle East.

What Advantages Does OSB Offer for Shipping Crate Construction?

OSB is an engineered wood product made from strands of wood, which are bonded together with adhesives. It is known for its strength and affordability, making it an attractive option for budget-conscious buyers.

Pros: OSB is generally cheaper than plywood and provides good load-bearing capacity. It is also readily available in various thicknesses, allowing for customization based on specific shipping needs.

Cons: OSB is more susceptible to moisture damage compared to plywood, which can lead to swelling and loss of structural integrity if not properly treated. Its surface is rougher, which may not be ideal for branding.

Impact on Application: OSB is suitable for shipping heavier items but may require additional protective measures, such as moisture barriers, especially in humid climates like those found in parts of Africa and South America.

Why Choose Solid Wood for Shipping Crates?

Solid wood is often favored for high-value or delicate items due to its robustness and natural cushioning properties. It can handle significant weight and provides excellent protection against impacts.

Pros: Solid wood is highly durable and offers superior insulation against temperature fluctuations. It can be easily repaired if damaged, extending the crate’s lifespan.

Cons: The cost of solid wood can be significantly higher than engineered alternatives, and it is heavier, which may increase shipping costs. Additionally, solid wood may require treatment to comply with international shipping regulations (e.g., ISPM 15).

Impact on Application: Solid wood is ideal for shipping valuable items, such as electronics or art. Buyers in Europe, particularly Germany, may prefer solid wood due to its sustainability and compliance with strict environmental standards.

What Role Does Metal Play in Shipping Crate Construction?

Metal crates, often made from aluminum or steel, offer unparalleled strength and durability. They are particularly useful for heavy machinery or equipment that requires maximum protection.

Pros: Metal crates are resistant to moisture, pests, and extreme temperatures. They provide a high level of security and can be reused multiple times without significant wear.

Cons: The initial cost of metal crates is typically high, and they are heavier than wood alternatives, which can increase shipping expenses. Additionally, they may require specialized tools for assembly and disassembly.

Impact on Application: Metal crates are suitable for high-value, heavy, or sensitive equipment. International buyers must consider compliance with various regulations regarding metal shipping containers, especially in regions like the Middle East.

Summary Table of Material Selection for Shipping Crates

| Material | Typical Use Case for build shipping crate | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plywood | General shipping of various products | Lightweight and cost-effective | May not withstand extreme conditions | Medium |

| OSB | Budget-friendly crates for heavier items | Affordable and customizable | Susceptible to moisture damage | Low |

| Solid Wood | Shipping high-value or delicate items | Highly durable and repairable | Higher cost and heavier weight | High |

| Metal | Heavy machinery or sensitive equipment | Maximum protection and durability | High initial cost and requires special tools | High |

In conclusion, the choice of material for building shipping crates should align with the specific needs of the cargo, budget constraints, and compliance with international standards. Understanding the properties and limitations of each material will help B2B buyers make informed decisions that enhance the safety and efficiency of their shipping operations.

In-depth Look: Manufacturing Processes and Quality Assurance for build shipping crate

What Are the Main Stages in the Manufacturing Process for Building Shipping Crates?

When it comes to manufacturing shipping crates, there are several key stages involved. Understanding these stages can help B2B buyers assess the quality and suitability of suppliers.

1. Material Preparation

The first step in the manufacturing process involves selecting and preparing the right materials. Common materials include lumber, plywood, and foam padding. The choice of materials can significantly affect the durability and functionality of the crate. For instance, using high-quality plywood ensures a robust structure that can withstand the rigors of international shipping.

Materials are typically sourced from local suppliers or large distributors, and they must meet specific standards to ensure consistency. Buyers should inquire about the origin of materials and whether they comply with relevant international regulations, especially when shipping to or from regions like Africa, South America, and Europe.

2. Forming

Once materials are prepared, the next stage is forming. This involves cutting the lumber and plywood to precise dimensions, often using table saws or CNC machines for accuracy. Forming also includes creating any necessary joints or reinforcements, which are critical for structural integrity.

In this stage, manufacturers may employ various techniques such as dado cuts or rabbet joints to strengthen the corners and edges of the crate. For lightweight or smaller items, manufacturers might opt for a simpler design, while heavier items may require more complex structures to ensure safe transport.

3. Assembly

The assembly process is where the individual components come together to create the final product. This typically involves using screws, nails, or wood glue to join the panels and frame. Manufacturers may also use clamps to hold pieces in place during assembly, ensuring a tight fit and reducing the risk of misalignment.

Quality control during assembly is crucial. Any misaligned panels or poorly secured joints can compromise the crate’s durability. Manufacturers should follow specific assembly protocols to minimize human error, and B2B buyers should request documentation of assembly techniques used.

4. Finishing

The finishing stage involves applying any necessary treatments to the crate, such as sanding to smooth edges or applying a protective coating. This step is particularly important for crates that will be exposed to moisture or harsh environmental conditions.

Finishing may also include labeling or marking the crates for easy identification during shipping. Buyers should confirm that any finishes used comply with international shipping standards, especially for crates that will be transported across different climates.

How Does Quality Assurance Fit into the Manufacturing Process?

Quality assurance (QA) is integral to the manufacturing of shipping crates, ensuring that the final product meets both customer expectations and regulatory standards.

What International Standards Should B2B Buyers Be Aware Of?

For B2B buyers, understanding international standards such as ISO 9001 is essential. ISO 9001 outlines requirements for a quality management system, focusing on continuous improvement and customer satisfaction. Suppliers who adhere to these standards demonstrate a commitment to quality, making them more reliable partners.

In addition to ISO standards, buyers should also be aware of industry-specific certifications like CE (Conformité Européenne) for products sold within the European Economic Area and API (American Petroleum Institute) standards for crates used in oil and gas industries.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are vital throughout the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, various checks are performed to monitor the assembly and construction process.

- Final Quality Control (FQC): After assembly, the completed crates undergo thorough inspections to verify that they meet all design and safety requirements.

B2B buyers should inquire about the specific checkpoints employed by their suppliers and the criteria used to assess quality at each stage.

How Can B2B Buyers Verify Supplier Quality Control?

When sourcing shipping crates, B2B buyers should take proactive steps to verify the quality control practices of their suppliers.

What Documentation Should Buyers Request?

Buyers should ask for detailed documentation regarding the supplier’s quality management system, including any certifications, inspection reports, and records of past audits. This documentation can provide insight into the supplier’s commitment to quality and adherence to international standards.

Should Buyers Consider Third-Party Inspections?

Engaging third-party inspection services can be an effective way to ensure quality. These independent organizations can conduct audits and inspections at various stages of the manufacturing process, providing unbiased assessments of the supplier’s practices.

Buyers should consider incorporating third-party inspections into their procurement processes, especially for high-value or sensitive items that require extra care during shipping.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers operating in diverse regions such as Africa, South America, the Middle East, and Europe may face unique challenges concerning quality control.

How Do Regional Regulations Affect Quality Assurance?

Different regions may have varying regulations regarding materials and manufacturing processes. For instance, some countries may impose strict rules on the use of treated wood to prevent pest infestations. Buyers should familiarize themselves with these regulations to ensure compliance and avoid delays during shipping.

What Should Buyers Know About Cultural Differences?

Cultural differences can also impact quality assurance practices. For example, in some cultures, verbal agreements may hold significant weight, while in others, written contracts are essential. Buyers should establish clear communication with suppliers to ensure mutual understanding of quality expectations.

Conclusion

In summary, a thorough understanding of the manufacturing processes and quality assurance measures for shipping crates is crucial for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, buyers can assess the quality of their suppliers effectively. Additionally, awareness of international standards, quality control checkpoints, and verification methods will empower buyers to make informed decisions that ensure the safe and reliable transport of their goods.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘build shipping crate’

Introduction

This guide provides a comprehensive checklist for B2B buyers interested in sourcing materials and services for building shipping crates. Constructing your own shipping crates can significantly reduce costs while ensuring your goods are packed securely for international transport. By following these steps, you can streamline your sourcing process and enhance the efficiency of your shipping operations.

Step 1: Define Your Shipping Requirements

Understanding the specific requirements of your shipping project is crucial. Consider the dimensions, weight, and fragility of the items you will be shipping. This information will guide your material selection and crate design, ensuring optimal protection during transit.

- Determine Dimensions: Measure the length, width, and height of the items to calculate the crate size.

- Assess Weight: Identify the weight of the shipment to select appropriate materials that can support the load.

Step 2: Identify Suitable Materials

Selecting the right materials is essential for durability and protection. Common materials include 2×4 lumber, plywood, and foam insulation, which provide structural integrity and cushioning.

- Lumber: Choose high-quality, untreated wood to avoid warping and ensure strength.

- Plywood: Opt for exterior-grade plywood to withstand moisture during shipping.

- Foam Padding: Consider using foam sheets for cushioning; ensure they are thick enough to absorb shocks.

Step 3: Evaluate Potential Suppliers

Thoroughly vet suppliers to ensure they meet your quality and reliability standards. Request company profiles, product samples, and references from other businesses in your industry.

- Assess Experience: Look for suppliers with a proven track record in providing materials for shipping crates.

- Check Certifications: Verify any industry-specific certifications or compliance with international shipping standards.

Step 4: Review Cost and Pricing Structures

Analyze the pricing models of potential suppliers to find the best value for your budget. Be aware of any hidden costs such as shipping fees, taxes, or bulk order discounts.

- Compare Quotes: Obtain quotes from multiple suppliers to understand the price range for materials.

- Negotiate Terms: Don’t hesitate to negotiate for better pricing or payment terms, especially for bulk orders.

Step 5: Confirm Lead Times and Availability

Understanding lead times is vital to ensure timely delivery of materials. Confirm the availability of your chosen materials and any potential delays in the supply chain.

- Ask About Stock Levels: Ensure the supplier has sufficient stock to meet your needs.

- Inquire About Shipping Times: Confirm how long it will take to receive your order, considering international shipping times if applicable.

Step 6: Plan for Assembly and Testing

Before finalizing your order, consider how you will assemble the crates. Ensure you have the necessary tools and manpower for assembly, and plan for testing the crate’s sturdiness.

- Gather Tools: Ensure you have access to tools like drills, saws, and clamps for efficient assembly.

- Conduct Test Runs: Consider building a prototype crate to test its effectiveness before mass production.

Step 7: Establish Quality Control Measures

Implement quality control measures to ensure that all crates meet your specifications before they are shipped. This step is crucial to avoid potential damages during transit.

- Inspect Materials: Conduct a thorough inspection of materials upon delivery.

- Test Crate Durability: Perform drop tests or weight tests on a sample crate to ensure it can withstand shipping conditions.

By following this checklist, B2B buyers can effectively source materials and services for building shipping crates, ensuring their products are well-protected during transportation.

Comprehensive Cost and Pricing Analysis for build shipping crate Sourcing

What Are the Key Cost Components for Building a Shipping Crate?

Building a shipping crate involves several cost components that significantly influence the overall price. The primary components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

Materials: The choice of materials directly affects cost. Common materials such as 2×4 lumber, OSB (oriented strand board), and foam insulation are relatively inexpensive, typically ranging from $20 to $100 per crate, depending on size and quality. For international buyers, material availability can vary by region, influencing local costs.

Labor: Labor costs depend on the skill level required for crate assembly. DIY assembly can save costs, but for larger operations, hiring skilled labor may be necessary, which can increase expenses.

Manufacturing Overhead: This includes costs related to facilities, equipment, and utilities. For companies producing crates at scale, overhead can be spread across multiple units, reducing the cost per crate.

Tooling: If specialized tools are required, such as saws and drills, initial investments can be significant. However, for companies that frequently build crates, these costs can be amortized over time.

Quality Control: Ensuring the structural integrity of crates is essential, especially for valuable or fragile items. Implementing QC processes incurs additional costs but mitigates risks associated with shipping damage.

Logistics: Transportation of materials and finished crates adds to costs, especially for international shipping, which can be affected by tariffs and freight rates.

Margin: Suppliers typically add a profit margin to cover their risks and business expenses. This margin can fluctuate based on market demand and competition.

How Do Price Influencers Impact Crate Sourcing Decisions?

Several factors influence the pricing of shipping crates, especially for B2B buyers in different regions.

Volume/MOQ: Bulk purchasing usually leads to lower per-unit costs. Suppliers often offer discounts for larger orders, making it essential for buyers to assess their needs carefully.

Specifications and Customization: Custom crates designed to fit specific products may incur additional costs due to unique dimensions or materials. Buyers must weigh the benefits of customization against budget constraints.

Material Quality and Certifications: High-quality materials and certifications (e.g., ISPM 15 for international shipping) can increase costs but are crucial for compliance and protection of goods during transport.

Supplier Factors: The reliability and reputation of suppliers can affect pricing. Established suppliers may charge more due to their experience and service levels, but they can also offer better quality assurance.

Incoterms: Understanding Incoterms is vital for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears the shipping costs and risks, impacting overall pricing strategies.

What Are Essential Buyer Tips for Cost-Efficient Crate Sourcing?

International buyers should consider several strategies to ensure cost-effective crate sourcing.

Negotiation: Engage in discussions with suppliers to negotiate better terms, especially for large orders. Understanding market rates and competitor pricing can strengthen your position.

Focus on Total Cost of Ownership (TCO): Look beyond initial pricing to assess the total cost, including maintenance, potential damage during shipping, and resale value of reusable crates. This broader perspective can lead to better long-term investments.

Pricing Nuances for International Buyers: Buyers in Africa, South America, the Middle East, and Europe should be aware of regional pricing variances due to local economic conditions, material availability, and shipping regulations. Conducting thorough market research can provide insights into fair pricing.

Be Cautious with Indicative Prices: Prices can fluctuate based on market conditions, and quotes may vary significantly between suppliers. Always request detailed quotes and clarify what factors may influence final pricing.

By understanding these cost components, price influencers, and buyer tips, international B2B buyers can make informed decisions when sourcing shipping crates, ensuring that they achieve both cost efficiency and quality in their shipping solutions.

Alternatives Analysis: Comparing build shipping crate With Other Solutions

Exploring Alternatives to Building Shipping Crates

When shipping valuable or fragile items, businesses often face the challenge of selecting the most effective packaging solution. While building custom shipping crates is a viable option, several alternatives exist that may better suit specific needs based on factors like cost, ease of use, and performance. This analysis compares the traditional method of building shipping crates with two alternatives: purchasing pre-made shipping crates and using heavy-duty cardboard boxes.

Comparison Table

| Comparison Aspect | Build Shipping Crate | Pre-Made Shipping Crate | Heavy-Duty Cardboard Box |

|---|---|---|---|

| Performance | Highly customizable; strong and durable | Reliable but may lack customization | Good for lightweight items; less durable |

| Cost | Low material costs; labor-intensive | Higher upfront costs; no labor involved | Generally lower cost; less durable |

| Ease of Implementation | Requires tools and skills; time-consuming | Quick and straightforward; no assembly | Easy to use; minimal setup required |

| Maintenance | Reusable and repairable; long lifespan | Limited reusability; usually single-use | Often disposable; low maintenance |

| Best Use Case | High-value, fragile items needing protection | Standardized shipping for various goods | Lightweight items; non-fragile products |

Detailed Breakdown of Alternatives

1. Pre-Made Shipping Crates

Pre-made shipping crates are commercially available options that provide a convenient alternative to building crates from scratch. These crates offer reliable protection and standardization for shipping goods. However, they can be more expensive upfront compared to DIY solutions. The main advantage is the time saved in not having to build the crate, making it ideal for businesses with tight shipping schedules. On the downside, pre-made crates may not fit all items perfectly, leading to potential damage if the contents shift during transport.

2. Heavy-Duty Cardboard Boxes

Heavy-duty cardboard boxes are another alternative that can be suitable for less fragile items. They are lightweight and often come in various sizes, making them versatile for different shipping needs. While they are typically less expensive than wooden crates, their durability is limited, especially for heavy or fragile items. Cardboard boxes also lack the customization options that wooden crates offer, which can be a drawback when shipping high-value items. However, their ease of use and low maintenance requirements make them a popular choice for businesses shipping non-fragile goods.

Conclusion: Choosing the Right Shipping Solution for Your Needs

When selecting a shipping solution, B2B buyers must consider several factors, including the type of items being shipped, budget constraints, and the desired level of protection. Building a shipping crate may be the best option for high-value or fragile items that require customization and durability. Conversely, pre-made crates are ideal for businesses that prioritize speed and convenience, while heavy-duty cardboard boxes suit lighter, non-fragile goods. Ultimately, the right choice will depend on a company’s specific shipping requirements and operational capabilities, ensuring that items arrive safely and efficiently at their destination.

Essential Technical Properties and Trade Terminology for build shipping crate

What Are the Key Technical Properties for Building a Shipping Crate?

When constructing a shipping crate, understanding the essential technical properties is crucial for ensuring the safety and integrity of the items being shipped. Here are some critical specifications that B2B buyers should consider:

-

Material Grade

The material grade refers to the quality and strength of the wood or plywood used in crate construction. Common materials include 2×4 lumber and OSB (Oriented Strand Board). Selecting higher-grade materials increases durability and resistance to environmental factors, which is vital for international shipping where crates may be exposed to varying climates. For example, using marine-grade plywood can provide additional water resistance, making it suitable for humid or wet conditions. -

Load Capacity

This specification indicates the maximum weight a crate can safely hold. It is essential to calculate the load capacity based on the weight and dimensions of the items being shipped. Overloading a crate can lead to structural failure during transport, resulting in damage or loss of goods. A well-defined load capacity helps in selecting the appropriate materials and design for the crate. -

Tolerance

Tolerance refers to the allowable variation in dimensions during the manufacturing process. In crate construction, maintaining tight tolerances is crucial for ensuring that the crate fits the items snugly, minimizing movement during transit. This property is particularly important for fragile or high-value items, where even minor shifts can lead to damage. -

Environmental Resistance

This property encompasses the crate’s ability to withstand various environmental conditions, such as moisture, temperature fluctuations, and pests. Using treated wood or specialized coatings can enhance environmental resistance. For B2B buyers, this means selecting crates that will protect their products throughout the shipping process, especially for long-distance transport. -

Reusability

The design of the crate should allow for easy disassembly and reassembly, facilitating reuse for multiple shipments. Crates designed for reusability not only reduce waste but also lower overall shipping costs over time. B2B companies looking to establish sustainable practices may prioritize crates that can be reused effectively.

What Are Common Trade Terms in Crating and Shipping?

Understanding industry jargon is essential for effective communication and negotiation in the shipping crate market. Here are some common terms that B2B buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of shipping crates, an OEM may provide specific crate designs tailored for particular products. Knowing the OEM can help buyers ensure they receive high-quality, compatible crates. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is important for B2B buyers as it can affect budgeting and inventory management. Understanding the MOQ helps in planning purchases, especially when considering bulk orders for shipping crates. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and other details for specific products or services. For buyers looking to source shipping crates, issuing an RFQ allows them to compare offers from multiple suppliers, facilitating better purchasing decisions. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers as they specify who is responsible for costs and risks during shipping. This knowledge helps buyers negotiate better shipping terms and ensures compliance with international regulations. -

FOB (Free on Board)

FOB indicates the point at which ownership and responsibility for goods transfer from the seller to the buyer. For shipping crates, this term is vital in determining shipping costs and liability during transit. Buyers should clarify FOB terms to avoid unexpected charges or risks.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing shipping crates, ensuring their products are well-protected during transport.

Navigating Market Dynamics and Sourcing Trends in the build shipping crate Sector

What Are the Key Market Trends Driving the Build Shipping Crate Sector?

The global build shipping crate market is currently shaped by several key drivers, including increasing international trade, the rise of e-commerce, and a growing demand for customized shipping solutions. As businesses expand their reach into new markets, particularly in regions like Africa, South America, and the Middle East, the need for reliable and cost-effective shipping solutions becomes paramount. In response, suppliers are increasingly offering customizable crate solutions that cater to specific product dimensions and protection needs, enabling businesses to ship goods securely without incurring high costs.

Emerging technologies are also transforming the sourcing landscape. Digital platforms and supply chain management software are streamlining the procurement process, allowing buyers to compare materials, suppliers, and prices more efficiently. This trend is particularly beneficial for international B2B buyers from countries like Brazil and Germany, where logistical challenges can complicate sourcing decisions. Moreover, the integration of automation and robotics in crate manufacturing is enhancing production efficiency and reducing lead times, making it easier for businesses to adapt to fluctuating demand.

How Is Sustainability Influencing Sourcing Trends for Build Shipping Crates?

Sustainability has become a critical consideration for businesses in the build shipping crate sector. The environmental impact of packaging materials, particularly single-use plastics and non-recyclable wood, has led to a shift towards more eco-friendly alternatives. Buyers are increasingly prioritizing suppliers that offer sustainable materials, such as responsibly sourced wood and biodegradable packaging, reflecting a broader commitment to reducing their carbon footprint.

Ethical sourcing practices are also gaining traction, with businesses seeking suppliers that adhere to fair labor standards and environmentally friendly manufacturing processes. Certifications such as FSC (Forest Stewardship Council) for wood products and ISO 14001 for environmental management systems are becoming important benchmarks for B2B buyers. This focus not only enhances a company’s brand reputation but also aligns with the values of environmentally conscious consumers, creating a competitive advantage in the marketplace.

How Has the Build Shipping Crate Sector Evolved Over Time?

The evolution of the build shipping crate sector reflects broader trends in global trade and logistics. Initially, shipping crates were predominantly standardized and produced using basic materials, primarily designed for one-time use. However, as international trade expanded and e-commerce gained momentum, the demand for more durable, customizable, and reusable shipping solutions emerged. This led to innovations in materials and design, allowing companies to create crates that not only protect goods during transit but can also be disassembled and reused, providing long-term value.

Today, the sector is characterized by a diverse range of materials and configurations, reflecting the unique needs of various industries, from delicate electronics to heavy machinery. This evolution continues to be driven by technological advancements, sustainability considerations, and changing consumer preferences, ensuring that the build shipping crate sector remains dynamic and responsive to market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of build shipping crate

-

1. How do I ensure my shipping crate is suitable for international transport?

When building a shipping crate for international transport, ensure it meets international shipping standards, such as ISPM 15 regulations, which require wood packaging material to be treated and marked. Use durable materials like plywood or hardwood, reinforced at corners and joints to withstand handling and transit. Additionally, consider the crate’s dimensions, ensuring it fits standard shipping containers and can be efficiently loaded and unloaded. Finally, include appropriate cushioning or padding to protect your goods from shock and vibration during transit. -

2. What is the best material for building a shipping crate?

The best material for a shipping crate largely depends on the nature of the items being shipped. For heavier or fragile items, using 3/4″ plywood or hardwood offers strength and durability. For lighter items, OSB (Oriented Strand Board) can be sufficient. Consider weather-resistant materials if shipping to humid or wet climates. Additionally, ensure that any material used complies with international shipping standards to avoid delays or fines at customs. -

3. How can I customize my shipping crate for unique items?

Customizing your shipping crate involves accurately measuring your items and designing the crate to provide optimal protection. Utilize foam inserts or custom-cut padding to secure the item within the crate, preventing movement during transit. Incorporate features such as handles for easier lifting or ventilation holes for sensitive items. If your items have specific weight or size requirements, consult with a packaging specialist to ensure the crate meets those needs while remaining cost-effective. -

4. What are the minimum order quantities (MOQ) for custom shipping crates?

Minimum order quantities for custom shipping crates can vary significantly based on the supplier and the complexity of the design. Generally, suppliers may require a MOQ of 10 to 50 units for custom builds to justify production costs. However, if you are looking for a one-off or small batch, some suppliers may accommodate your request at a higher per-unit price. Always discuss your needs with suppliers to find the best balance between MOQ and pricing. -

5. What payment terms should I expect when sourcing shipping crates internationally?

When sourcing shipping crates internationally, payment terms can vary by supplier. Common terms include a deposit (often 30-50%) upfront, with the balance due upon completion or prior to shipping. Some suppliers may offer net 30 or net 60 terms, allowing you to pay after receiving the crates. It’s essential to negotiate terms that suit your cash flow while ensuring the supplier is comfortable with the arrangement. Always confirm the payment methods accepted, as options may vary by region. -

6. How do I vet suppliers for building shipping crates?

Vetting suppliers involves researching their reputation, experience, and customer reviews. Look for suppliers with a history of delivering quality products and good customer service. Request references from previous clients and check their compliance with international shipping standards, such as ISPM 15. Additionally, consider their production capabilities, lead times, and flexibility in accommodating custom orders. Attending trade shows or industry events can also help you meet potential suppliers face-to-face. -

7. What quality assurance measures should I implement when sourcing shipping crates?

To ensure the quality of your shipping crates, implement a multi-step quality assurance process. Begin with specifying clear requirements for materials, dimensions, and construction methods in your purchase order. Request samples before full production to assess quality. During production, consider conducting periodic inspections and requiring certification of compliance with international standards. Finally, upon receipt, inspect the crates for any damage or defects before accepting the shipment. -

8. What logistics considerations are important when shipping crates internationally?

When shipping crates internationally, consider logistics factors such as shipping methods (air, sea, or land), transit times, and costs. Understand the customs regulations for both exporting and importing countries to avoid delays. Choose a reliable freight forwarder who can handle documentation and ensure compliance with shipping regulations. Additionally, factor in insurance for your shipment to protect against loss or damage during transit, especially for high-value items.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 10 Build Shipping Crate Manufacturers & Suppliers List

1. Custom Crate – Cost-Effective Shipping Solution

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Custom crate for shipping, cost-effective (under $100), materials include 2x4s, 4×4, 1/2″ OSB or plywood, 1/2″ foam insulator sheet, screws (2.5″ and 1.25″), tools required: cordless drills, chop saw, table saw, optional bandsaw. Crate dimensions can vary based on item being shipped; example size: 40″ x 46″ x 26″ high. Assembly involves creating a pallet base, framing sides, and adding foam insula…

2. Volpin Props – Shipping Crate Construction Guide

Domain: volpinprops.com

Registered: 2010 (15 years)

Introduction: The blog post details the construction of a shipping crate for props, highlighting key elements such as: 1. Basic construction using four 3/8″ thick plywood panels framed with 1.5″ x 1.5″ lumber supports. 2. Use of a shipping crate calculator for ease of design. 3. Assembly involves nailing plywood over a lumber frame with wood glue, and securing frames together with 2.5″ wood screws and additiona…

3. Reddit – Custom Shipping Crates

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Shipping crate made from 3/4″ plywood, 4x4s, 2x4s, and 1/4″ OSB. The crate was a $4,000 job and the builder produces roughly 15 crates a day.

4. Ark Transportation – Crate Specifications

Domain: arktransportation.com

Registered: 2000 (25 years)

Introduction: 1. Crate Size: Keep under 92″ height for standard trailers; width should be below 49″ to avoid extra charges. 2. Wood Specifications: Use at least 2x4s for the frame and ½ inch plywood for sides; use treated wood for international shipments. 3. Support Beams: Add support beams for long or wide crates to prevent damage. 4. Access Door Security: Secure access doors with wing nuts to prevent opening …

5. V1E – Convenient Packing Solutions

Domain: forum.v1e.com

Registered: 2006 (19 years)

Introduction: This company, V1E – Convenient Packing Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Specialty Crate – Custom Wood Shipping Crates

Domain: specialtycrate.com

Registered: 2007 (18 years)

Introduction: Wooden shipping crates, Custom Wood Crating, ISPM-15 Certified for Export, Heavy-duty custom wood shipping crates and skids, Standard/Industrial Crates, Reusable Skids & Pallets, Certified heat treated international wood shipping crates, Domestic wood shipping crates, Crate panel/wall assemblies made from 2×4 or 2×6 framing, Minimum 1/2″ plywood up to 3/4″ ply, Pre-drilled and screwed together wit…

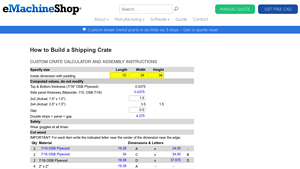

7. eMachineShop – Shipping Crate Assembly Guide

Domain: emachineshop.com

Registered: 1999 (26 years)

Introduction: How to build a shipping crate: Assemble using nails spaced ~2″ from ends and ~12 inches apart, through panels into strips. Strips should be flush with panel edges. Nail items A to A, B to B, and C to C. On the floor, clamp panels together with strips on the outside and nail together. Use 3″ screws to attach a D panel to (3) 2x4s, with 3 screws for each 2×4. Flip the D assembly and place it on top …

8. Craters & Freighters Nashville – Key Product Details

Domain: cratersandfreightersnashville.com

Registered: 2007 (18 years)

Introduction: Key product details for building a crate for international shipping include: 1. Materials needed: 4 pieces of plywood or ISPM-15 certified wood, wood glue, screws, electric saw, drill, Styrofoam board, bubble wrap, strapping tape, plastic wrap. 2. Steps for building: Measure the item, weigh the item, determine packing material, cut the boards, assemble the crate, add packaging materials, enclose t…

9. FormaSpace – Custom Shipping Crates

Domain: formaspace.com

Registered: 2006 (19 years)

Introduction: Custom shipping crates designed for safe and secure transport of large items. Built using low-cost recycled materials, including plywood, melamine, and OSB. Crates can be constructed quickly (in 5-10 minutes) by employees. Options for open style wood frame crates for short-distance shipping and fully enclosed crates for LTL shipping. Custom crates can be made with a base out design, incorporating …

10. Facebook – Shipping Crate Building Guide

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Shipping Crate Building Guide, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for build shipping crate

How Can Strategic Sourcing Optimize Your Shipping Crate Solutions?

In conclusion, building custom shipping crates offers a cost-effective and efficient solution for international B2B logistics. By leveraging strategic sourcing, companies can identify affordable materials, optimize labor costs, and ensure high-quality construction tailored to their specific shipping needs. The insights provided in this guide underscore the importance of understanding local material availability, necessary tools, and assembly techniques, which can significantly reduce shipping costs and improve the reliability of deliveries.

As B2B buyers from Africa, South America, the Middle East, and Europe (including Brazil and Germany) navigate the complexities of global shipping, investing in well-constructed crates becomes vital. These crates not only protect valuable goods but also enhance the overall shipping experience, leading to improved customer satisfaction and reduced returns.

Moving forward, companies are encouraged to adopt innovative strategies in sourcing and crate construction. By collaborating with local suppliers and utilizing advanced materials, businesses can create more sustainable and efficient shipping solutions. Embrace this opportunity to streamline your logistics and ensure your products arrive safely and securely, establishing a competitive edge in the global marketplace.