Contents

Manufacturing Insight: Brushed Steel Finish

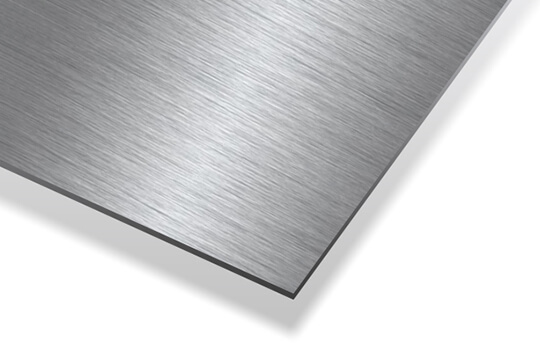

Brushed Steel Finish: Precision Engineered for Performance

Honyo Prototype delivers industrial-grade brushed steel finishes through advanced CNC machining processes, meeting exacting aesthetic and functional requirements for demanding applications. Our integrated manufacturing approach ensures consistent linear grain patterns with controlled surface roughness (Ra 0.8–3.2 µm), critical for corrosion resistance, reduced fingerprint visibility, and seamless integration into medical, aerospace, and high-end consumer electronics assemblies. Unlike conventional finishing methods, Honyo’s CNC-controlled brushing eliminates cross-contamination risks and maintains tight geometric tolerances (±0.005 mm) across complex geometries, including contoured edges and multi-axis components.

Material integrity remains uncompromised through our optimized toolpath strategies and proprietary media selection for 304/316 stainless steel alloys. Each finish undergoes rigorous in-process metrology validation using profilometers and visual inspection against ASTM D2244 standards, guaranteeing repeatable results from prototype to volume production. This precision-driven methodology prevents common pitfalls such as uneven grain depth, directional inconsistencies, or surface scratching that compromise part functionality.

Accelerate your development timeline with Honyo’s Online Instant Quote platform, which provides validated cost and lead time estimates for brushed steel components within minutes. Input your CAD file and specifications to receive a manufacturability analysis alongside competitive pricing, eliminating traditional quotation delays while ensuring technical feasibility from the outset.

| Key Parameter | Honyo Standard | Industry Typical |

|---|---|---|

| Surface Roughness (Ra) | 0.8–3.2 µm | 1.6–6.3 µm |

| Tolerance Control | ±0.005 mm | ±0.025 mm |

| Lead Time (Prototype) | 5–7 business days | 10–14 business days |

| Material Compliance | ASTM A240/A480 | Basic Grade Only |

Leverage our CNC machining expertise to transform brushed steel from a superficial treatment into a performance-critical feature engineered for real-world durability.

Technical Capabilities

Brushed steel finish refers to a directional surface texture that mimics the appearance of steel with a linear grain pattern, typically achieved through fine abrasive processes. While not a material itself, this finish is applied to machined components for aesthetic and functional purposes, including improved corrosion resistance, reduced glare, and enhanced surface consistency. In the context of precision 3-, 4-, and 5-axis milling and turning operations, achieving a consistent brushed finish requires tight control over toolpath strategies, spindle speeds, feed rates, and post-machining brushing or polishing steps.

The finish is commonly applied to metals such as aluminum and steel, and occasionally to high-performance plastics like ABS and nylon when a metallic aesthetic is desired (typically via coating or plating followed by brushing). Maintaining tight tolerances (±0.005 mm to ±0.025 mm) during machining is critical, especially when the brushed finish is applied to sealing surfaces, mating parts, or cosmetic exteriors.

Below is a summary of technical considerations for achieving a brushed steel finish across common materials using multi-axis CNC processes:

| Material | Machinability | Max Tolerance (±) | Surface Finish (Ra) | Brushing Method | Notes |

|---|---|---|---|---|---|

| Aluminum (6061, 7075) | High | 0.005 mm | 0.8–1.6 µm | Mechanical brushing with abrasive belts or non-woven nylon wheels | Lightweight and easily finished; requires sharp tools to avoid smearing. Anodizing followed by directional brushing enhances durability. |

| Steel (304, 316, 4140) | Moderate to Low | 0.010 mm | 0.4–1.6 µm | Stainless steel wire brushes or coated abrasives | High tool wear; coolant required. 316 stainless is ideal for corrosion-resistant brushed finishes. |

| ABS | High | 0.025 mm | 1.6–3.2 µm | Limited; typically vacuum metallization + clear coat, then light brushing simulation | Not true brushed steel; simulated finish via coating. Avoid aggressive brushing due to softness. |

| Nylon (PA6, PA66) | Moderate | 0.025 mm | 3.2 µm (as-machined) | Not applicable; finish simulated via coating | Poor adhesion for metallic coatings; not recommended for true brushed appearance. |

Process Notes:

For 3-, 4-, and 5-axis milling: Use consistent toolpaths aligned with the desired grain direction. Ball-end or small-diameter end mills with fine coatings (e.g., TiAlN) improve surface quality.

In turning operations: Employ wiper inserts and fine feed rates (0.05–0.1 mm/rev) to minimize tool marks before brushing.

Post-machining: Brushing is typically performed using automated linear abrasive systems with 120–240 grit belts to achieve uniform grain.

Tight tolerance zones should be masked or machined after brushing to preserve dimensional accuracy.

Achieving a production-ready brushed steel finish on precision-machined components requires integration between CNC programming, material selection, and post-process surface treatment, particularly when aesthetic and functional requirements coexist.

From CAD to Part: The Process

Honyo Prototype executes brushed steel finishing through a rigorously controlled five-stage process designed for precision, quality assurance, and client transparency. This methodology ensures consistent aesthetic and functional results for stainless steel components, primarily utilizing 304 or 316 grades unless otherwise specified by client requirements.

Upload CAD

Clients initiate the process by uploading native CAD files (STEP, IGES, or Parasolid formats preferred) via our secure client portal. Our system performs immediate geometric validation, checking for file integrity, unit consistency, and basic manufacturability flags. Crucially, we assess surface topology and feature geometry for compatibility with brushed finishing—identifying potential issues like deep recesses, complex curves, or tight internal corners that could disrupt uniform grain direction. Clients receive instant confirmation of upload success and file validation status.

AI Quote Generation

Our proprietary AI engine analyzes the validated CAD geometry alongside material specifications, finish requirements (e.g., standard #4 brushed finish, directional grain, grit level), and requested tolerances. The system cross-references real-time data on material costs, machine utilization, labor rates, and historical process efficiency metrics. Within 2 business hours, clients receive a comprehensive quote detailing itemized costs, material traceability options, and explicit assumptions regarding finish parameters. The quote explicitly states compliance standards (e.g., ASTM A480 for stainless steel finishes) and surface roughness expectations (typically Ra 0.8–1.6 μm for standard brushed finishes).

DFM Analysis

A dedicated manufacturing engineer conducts a formal Design for Manufacturability review within 24 hours of quote acceptance. This phase focuses intensely on finish-critical factors:

Verification of material grade suitability for brushing (e.g., confirming 304/316 annealed condition)

Assessment of part geometry for achievable grain continuity and avoidance of “dead zones”

Evaluation of edge conditions to prevent burring during abrasive processing

Confirmation of dimensional tolerances compatible with post-finishing operations

Recommendations for optimal part orientation during brushing to ensure uniform grain direction

The engineer provides a formal DFM report with actionable feedback, including annotated CAD markups where modifications are advised to enhance finish quality or reduce cost. Client approval of the DFM report is mandatory before proceeding.

Production Execution

Production commences only after DFM sign-off, following this sequence:

1. Material Sourcing: Certified mill-certified stainless steel stock is procured with full traceability documentation.

2. Machining: CNC milling, turning, or laser cutting achieves net shape per approved tolerances. Critical surfaces are held to tighter pre-finishing allowances (typically +0.1mm).

3. Pre-Finishing Prep: Parts undergo meticulous deburring, edge radiusing, and ultrasonic cleaning to remove all machining residues. Surface defects are corrected prior to brushing.

4. Brushed Finishing: Using automated linear abrasive systems with controlled pressure and grit progression (standard 120–180 grit for #4 finish), parts are processed to achieve unidirectional grain. Manual brushing is employed for complex geometries under strict operator protocols with calibrated tools. Grain direction is verified against client-specified vectors.

5. Post-Processing: Parts receive passivation (per ASTM A967) to enhance corrosion resistance, followed by final cleaning in non-chlorinated solvents and DI water rinsing.

Key process parameters for brushed steel finishing are maintained within these ranges:

| Parameter | Standard Range | Critical Tolerance | Verification Method |

|---|---|---|---|

| Surface Roughness | Ra 0.8–1.6 μm | ±0.2 μm | Profilometer (per ISO 4287) |

| Grain Direction | Unidirectional | <5° deviation | Visual comparator (ASTM A480) |

| Grit Level | 120–180 (Al₂O₃) | ±15 grit | Abrasive media certification |

| Edge Radius | 0.2–0.5 mm | +0.1/-0.0 mm | Optical comparator |

Delivery Assurance

Finished parts undergo 100% visual inspection for grain consistency, absence of swirl marks, and surface defects under controlled lighting (500 lux minimum). Dimensional verification checks critical features affected by material removal during brushing. Parts are packaged in anti-tarnish VCI paper, individually wrapped in non-abrasive foam, and shipped in rigid containers with humidity indicators. Clients receive a comprehensive shipment dossier including:

Material test reports (MTRs) with full traceability

Finish verification documentation with roughness data

Dimensional inspection report (FAIR) for critical features

Passivation certificate

Handling and maintenance guidelines specific to brushed stainless steel

Typical lead time from DFM approval to delivery is 7–10 business days for standard orders, with expedited options available. This integrated workflow ensures Honyo delivers brushed steel components meeting stringent aesthetic and functional requirements while minimizing rework through proactive engineering collaboration.

Start Your Project

Explore our premium brushed steel finish options for your next project. Known for durability and a sleek, professional appearance, this finish is ideal for industrial and consumer applications.

Contact Susan Leo at [email protected] to request samples, pricing, or technical specifications. Our manufacturing facility is located in Shenzhen, enabling fast turnaround and strict quality control for both prototyping and high-volume production.

Let Honyo Prototype deliver precision metal finishing solutions tailored to your design requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.