Guide Contents

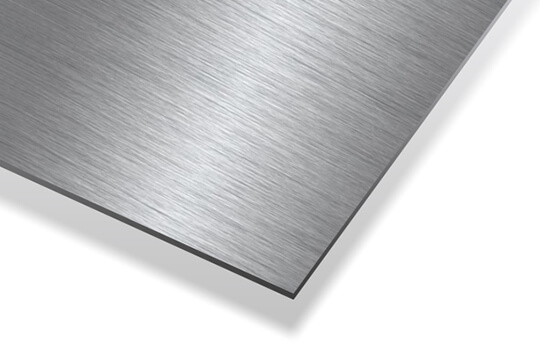

Project Insight: Brush Finish Stainless Steel

Why Speed and Precision Matter in Brush Finish Stainless Steel Manufacturing

The Challenge of Traditional Fabrication

Manual processes often lead to inconsistent finishes, extended lead times, and unexpected costs

Fragmented workflows between design, fabrication, and finishing stages create bottlenecks

Quality variations in brush finishes can compromise product aesthetics and functionality

Honyo’s Digital Manufacturing Ecosystem: Precision at Speed

Online Instant Quote: Get accurate pricing for brushed stainless steel in seconds via our AI-powered platform

AI-Powered Design Validation: Real-time feedback on manufacturability, tolerances, and finish optimization

5-7 Day Prototypes: Accelerate testing with rapid turnaround while maintaining tight tolerances

Seamless Scale-Up: Move from prototype to production without retooling or delays

Optimizing Cost and Quality Through Technology

Eliminate costly rework with automated error detection during the design phase

Consistent, high-quality brush finishes across all batch sizes using robotic precision

Material-efficient processes that reduce waste and lower total project costs

At Honyo Prototype, we transform stainless steel from a raw material into a precision-engineered asset. Our digital-first approach ensures your vision meets reality—faster, smarter, and with uncompromising quality.

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities for Brush Finish Stainless Steel

🚀 Instant Online Quoting

Real-time pricing for brush finishes on 304, 316, and 904L stainless steel with AI-driven cost optimization

Transparent, no-hidden-fee quotes generated in seconds—no manual quotes or delays

Dynamic adjustments for material grades, thickness, and finish complexity to maximize ROI

🌐 AI-Driven Manufacturing Platform

End-to-end digital workflow from CAD upload to finished part, eliminating manual intervention

CNC-guided brush finishing with precision Ra 0.8–1.6μm control for consistent texture

Seamless integration with SolidWorks, AutoCAD, and Fusion 360 for error-free design replication

⚡ Rapid Turnaround Guarantee

Prototype to 10,000+ units in 3–5 business days—no minimum order quantities for startups

Dedicated high-speed finishing lines with 48-hour expedited options for urgent projects

Scalable production lines that adapt instantly from single prototypes to mass production

🔬 ISO-Certified Quality Assurance

100% surface finish inspection using laser profilometry to ensure Ra consistency across batches

Traceable quality reports with every order, compliant with ISO 9001:2015 standards

In-process monitoring to prevent defects—zero tolerance for scratches, streaks, or uneven textures

Materials & Surface Finishes

Material Options & Finishes

Metal & Plastic Material Options

Stainless Steel: 304 (AISI 304), 316 (AISI 316), 201, 430

Aluminum: 6061-T6, 7075-T6, 5052

Titanium: Grade 5 (Ti-6Al-4V) for aerospace/medical applications

Copper & Brass: High conductivity and decorative finishes

Plastics: ABS, PC, Nylon, POM (Acetal), PEEK

Surface Finish Capabilities

Brushed Finish: Precision linear grain texture for aesthetic appeal, scratch resistance, and tactile quality—ideal for architectural, medical, and consumer products.

Anodizing: Enhanced corrosion resistance and color customization for aluminum.

Powder Coating: Eco-friendly, durable finish with 200+ color options and UV resistance.

Mirror Polishing: High-reflective surface for premium luxury applications.

Laser Engraving & Sandblasting: Custom textures, logos, or functional markings.

PVD Coating: Wear-resistant, decorative finishes for high-performance parts (e.g., aerospace, automotive).

Optimizing Brush Finish Stainless Steel Projects

Smart Grade Selection: Our AI-driven platform analyzes your application requirements to recommend the optimal stainless steel grade—304 for general use, 316 for marine/chemical environments, or 201 for cost-sensitive projects—ensuring performance and budget alignment.

Real-Time Cost Transparency: Brushed finish costs typically range $15–45/unit, but Honyo’s instant quote tool delivers precise pricing in seconds—no hidden fees, no manual calculations.

Rapid Turnaround: From prototype to production, our digital ecosystem delivers consistent finish quality with ±0.05mm tolerances and 3–5 day lead times for prototypes—accelerating your product launch.

End-to-End Integration: Leverage our one-stop solution to streamline material selection, machining, and finishing—all on a single platform—reducing supply chain complexity and accelerating time-to-market.

💡 Innovation Highlight: Honyo’s AI-powered platform dynamically optimizes brush finish parameters (grain direction, intensity, and surface prep) based on your design file—ensuring perfect aesthetics and functionality while minimizing waste. Get an instant quote today and see how we turn your vision into reality faster than ever.

From Quote to Part: Our Process

How It Works: From CAD to Part

Honyo’s AI-powered digital ecosystem delivers unparalleled speed and transparency for brushed stainless steel fabrication. Upload your design, receive an instant quote with full cost breakdown, optimize with DFM insights, and get your parts in days — all under one roof.

Step 1: Upload CAD File

Support for all major formats (STEP, STP, IGES, STL, etc.) with instant automated validation.

No manual review delays — our system flags potential issues before submission for faster processing.

Step 2: Get Instant Quote via AI Engine

Real-time pricing with full transparency: material, machining, and brushed finish costs calculated in seconds.

AI-driven cost breakdown eliminates guesswork — including dynamic pricing for brushed finishes based on surface area and complexity (typically $15–45/sq.ft depending on grade and finish type).

Step 3: AI-Powered DFM Analysis

Automated design feedback to optimize manufacturability and reduce costs — from wall thickness adjustments to tolerance suggestions.

Collaborative tool to refine your design with expert recommendations before production begins.

Step 4: Rapid Production & Delivery

Seamless in-house workflow from CNC machining to precision brushing — no third-party handoffs, ensuring quality and speed.

3–5 day prototype turnaround with real-time tracking and global shipping options.

Why It Matters: Honyo’s integrated digital ecosystem eliminates manual bottlenecks, so you focus on innovation — not logistics. From prototype to production, we turn complexity into clarity.

Start Your Project with Honyo

Start Your Project with Honyo

Effortless Brush Finish Stainless Steel Manufacturing

Instant Online Quotes

Get accurate pricing in seconds. Our AI-powered platform analyzes your design specs for brushed stainless steel, delivering transparent costs with no hidden fees.

Smart Cost Optimization

Maximize value with algorithms that recommend optimal material grades (304/316), thickness, and finishing parameters—balancing aesthetics, durability, and budget without compromise.

Rapid Production & Scalability

From 1 prototype to 10,000+ units, our Shenzhen/Dongguan digital manufacturing ecosystem delivers high-quality brushed finishes in 3–5 days with zero minimum order quantities.

Ready to Bring Your Idea to Life?

Founder Susan Leo and our team of manufacturing experts are here to help. Contact us today:

📧 [email protected]

📞 +86 139 2843 8620

🌐 Visit our Shenzhen/Dongguan facilities to see innovation in action

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.