Introduction: Navigating the Global Market for brown & sharpe tools

In an increasingly competitive global market, sourcing reliable Brown & Sharpe tools can present significant challenges for B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. The need for high-quality precision measuring and machining tools is essential for maintaining operational efficiency and ensuring product quality. This guide aims to empower international buyers by providing a comprehensive overview of Brown & Sharpe tools, including various types, applications, and essential considerations for supplier vetting.

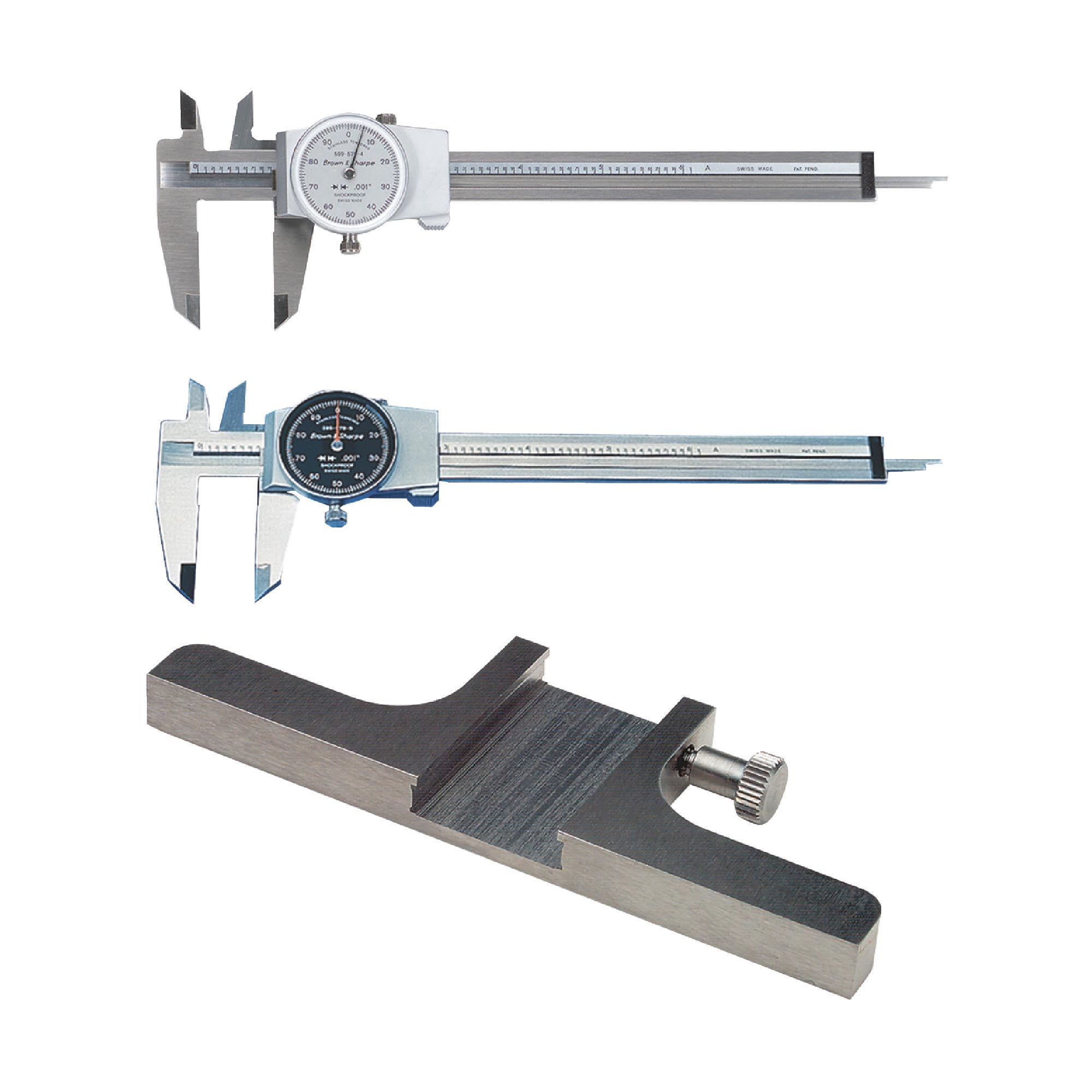

From precision measuring instruments like calipers and micrometers to advanced machining tools, the diverse range of Brown & Sharpe products caters to various industries, ensuring that businesses can meet their specific manufacturing needs. In this guide, we will delve into the critical factors influencing purchasing decisions, such as cost analysis, compatibility with existing machinery, and long-term reliability.

Moreover, we will address the importance of evaluating suppliers, highlighting key performance indicators that can aid buyers in selecting trustworthy partners. By equipping B2B buyers with actionable insights and expert recommendations, this guide will facilitate informed purchasing decisions, ultimately driving operational success and fostering long-term relationships in the global marketplace. Whether you are in Saudi Arabia or Germany, understanding the nuances of sourcing Brown & Sharpe tools will help you navigate your procurement journey with confidence.

Understanding brown & sharpe tools Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Precision Measuring Tools | Highly accurate tools including micrometers, calipers, and indicators | Quality control, precision machining | Pros: Exceptional accuracy, long lifespan. Cons: Higher initial investment. |

| Tool Holders | Durable holders designed for various screw machines | Automatic screw machining, turned parts production | Pros: Versatile compatibility, reliable performance. Cons: Limited to specific machine types. |

| Drilling and Chamfering Tools | Tools specifically designed for drilling and creating chamfers | Metalworking, fabrication | Pros: Enhanced efficiency, precise holes and edges. Cons: Requires skilled operation. |

| Adjustable Tool Holders | Customizable holders that can adapt to different tool sizes | Versatile machining operations | Pros: Flexibility in usage, cost-effective. Cons: Potential for misalignment if not adjusted correctly. |

| Boring Tool Holders | Holders designed for boring applications with high precision | Fine machining, hole enlarging | Pros: High precision, suitable for various materials. Cons: Specialized use may limit broader applicability. |

What Are Precision Measuring Tools and Their B2B Applications?

Precision measuring tools from Brown & Sharpe, such as micrometers and calipers, are essential in quality control and precision machining. These tools are renowned for their accuracy and reliability, making them indispensable in industries that require exact measurements. When purchasing, B2B buyers should consider the tool’s calibration, material durability, and brand reputation, as these factors significantly influence measurement accuracy and tool longevity.

How Do Tool Holders Enhance Production Efficiency?

Brown & Sharpe’s tool holders are engineered for compatibility with various automatic screw machines, providing a stable and dependable foundation for machining operations. Their durability ensures consistent performance across diverse production environments, particularly in turned parts production. Buyers should evaluate the specific machine compatibility and the holder’s material quality to ensure optimal performance and longevity.

Why Choose Drilling and Chamfering Tools for Metalworking?

Drilling and chamfering tools by Brown & Sharpe are designed to deliver precise holes and edges, enhancing the efficiency of metalworking and fabrication processes. Their specialized design allows for quick adjustments and consistent results, which is crucial in high-volume production settings. B2B purchasers should assess the tool’s compatibility with existing machinery and the level of precision required for their specific applications.

What Benefits Do Adjustable Tool Holders Offer?

Adjustable tool holders provide the flexibility to accommodate various tool sizes, making them a cost-effective solution for businesses with diverse machining needs. Their adaptability can lead to significant time savings during tool changes. However, buyers must ensure that the holders are adjusted correctly to avoid misalignment issues, which can affect machining quality.

When Are Boring Tool Holders Necessary?

Boring tool holders from Brown & Sharpe are crucial for applications requiring high precision in enlarging holes. They are particularly effective in fine machining, where tolerances are tight. B2B buyers should consider the specific material requirements and the precision level needed for their projects to ensure that the boring tool holders meet their operational standards.

Key Industrial Applications of brown & sharpe tools

| Industry/Sector | Specific Application of Brown & Sharpe Tools | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision measuring tools for component manufacturing | Enhanced accuracy in critical components, reducing errors | Certification for aerospace standards, lead time, and support |

| Automotive | Tool holders for CNC machines | Improved efficiency in high-volume production | Compatibility with existing machines, durability, and price |

| Electronics | Calibration tools for assembly line equipment | Ensures quality control and consistency in production | Availability of calibration services, international shipping options |

| Metal Fabrication | Boring tool holders for precision machining | Increased productivity and reduced downtime | Custom tooling options, material specifications, and delivery times |

| Oil & Gas | Measuring tools for drilling operations | Improved safety and accuracy in extreme conditions | Resistance to harsh environments, certifications, and service agreements |

What are the Key Applications of Brown & Sharpe Tools in Aerospace?

In the aerospace industry, Brown & Sharpe precision measuring tools play a vital role in the manufacturing of critical components such as turbine blades and fuselage structures. These tools ensure that parts are manufactured to exact specifications, minimizing the risk of failure in high-stakes environments. International buyers, particularly from regions like Europe and the Middle East, must ensure that the tools meet stringent aerospace standards and certifications, as well as consider the availability of local support for maintenance and calibration.

How are Brown & Sharpe Tools Utilized in the Automotive Sector?

In automotive manufacturing, Brown & Sharpe tool holders are essential for CNC machines that produce engine components and transmission systems. These tools enhance production efficiency by allowing for rapid tool changes and consistent performance under high-volume conditions. Buyers from South America and Africa should focus on sourcing tools that are compatible with their existing machinery, ensuring durability to withstand the rigors of mass production while also keeping an eye on competitive pricing.

What Role do Brown & Sharpe Tools Play in Electronics Manufacturing?

Brown & Sharpe calibration tools are critical in the electronics sector for ensuring the accuracy of assembly line equipment. These tools help maintain quality control, which is crucial in the production of sensitive electronic components where even minor deviations can lead to significant failures. Buyers should prioritize sourcing tools that come with comprehensive calibration services and consider international shipping options to facilitate quick replacements and support.

Why are Brown & Sharpe Tools Important for Metal Fabrication?

In metal fabrication, boring tool holders from Brown & Sharpe are utilized for precision machining operations that require tight tolerances. These tools significantly increase productivity by reducing downtime associated with tool changes and maintenance. For international B2B buyers, it is essential to assess custom tooling options and material specifications to ensure that the tools meet specific production needs while also considering lead times for delivery.

How do Brown & Sharpe Tools Enhance Operations in the Oil & Gas Industry?

In the oil and gas sector, Brown & Sharpe measuring tools are used extensively during drilling operations to ensure accuracy in extreme conditions. These tools are designed to withstand harsh environments, making them indispensable for maintaining safety and operational efficiency. Buyers should look for tools with appropriate certifications for use in hazardous environments and consider service agreements that provide ongoing support and maintenance.

3 Common User Pain Points for ‘brown & sharpe tools’ & Their Solutions

Scenario 1: Difficulty in Sourcing Compatible Parts for Brown & Sharpe Tools

The Problem: Many B2B buyers, particularly those in regions like Africa and South America, encounter challenges when sourcing compatible parts for their Brown & Sharpe tools. This often stems from a lack of local suppliers and limited access to the comprehensive catalog of parts and accessories. As a result, companies may experience prolonged downtimes, increased operational costs, and a frustrating search for the correct parts to maintain their machinery.

The Solution: To address this issue, buyers should establish relationships with reliable international distributors who specialize in Brown & Sharpe tools. Start by conducting thorough research on distributors who offer a wide range of parts and have a solid reputation for customer service. Utilize online platforms to connect with suppliers, and consider joining industry-specific forums or associations that can provide recommendations. Additionally, leveraging technology can streamline the ordering process; for instance, using digital catalogs to identify and order parts can help minimize errors and ensure compatibility. Buyers should also keep a detailed inventory of their current tools and the parts they frequently require, allowing for proactive reordering and reducing downtime.

Scenario 2: Ensuring Accuracy and Quality in Precision Measuring Tools

The Problem: Buyers in industries such as manufacturing and engineering often face difficulties in achieving the required precision and quality when using measuring tools from Brown & Sharpe. Variability in measurements can lead to costly errors, rework, and even product recalls. This pain point is especially critical for companies in Europe and the Middle East, where stringent quality standards are in place.

The Solution: To overcome accuracy issues, it is essential for B2B buyers to invest in calibration and maintenance training for their staff. Regular calibration of measuring tools, such as micrometers and calipers, ensures they are functioning within the required tolerances. Buyers should also implement a routine maintenance schedule for all Brown & Sharpe tools to prevent wear and tear that can lead to inaccuracies. Furthermore, engaging with a knowledgeable supplier who can provide insights into the correct usage and maintenance of these tools can enhance the reliability of measurements. Consider investing in advanced measuring instruments that offer higher precision levels and better durability, which can be particularly beneficial for high-volume production environments.

Scenario 3: Navigating Technical Specifications and Tool Selection

The Problem: Many international buyers struggle with understanding the technical specifications of Brown & Sharpe tools, leading to incorrect tool selection for specific applications. This is particularly common among companies in emerging markets where technical expertise may be limited. Incorrect tool selection can result in inefficiencies, increased costs, and lower product quality.

The Solution: To mitigate this issue, B2B buyers should prioritize educational resources and training programs that focus on tool specifications and applications. Manufacturers like Brown & Sharpe often provide technical documentation, training videos, and webinars that can help buyers understand the features and benefits of various tools. Additionally, buyers should consult with technical sales representatives who can provide personalized recommendations based on their specific production needs. Engaging in pilot projects with new tools can also help businesses assess performance before making larger investments. Keeping abreast of industry trends and innovations can further empower buyers to make informed decisions, ensuring they select the right tools for their operations and stay competitive in the market.

Strategic Material Selection Guide for brown & sharpe tools

What Are the Key Materials Used in Brown & Sharpe Tools?

When selecting tools from Brown & Sharpe, understanding the materials used in their construction is crucial for ensuring optimal performance and longevity. Below, we analyze four common materials utilized in Brown & Sharpe tools, focusing on their properties, advantages, disadvantages, and relevant considerations for international B2B buyers.

How Does High-Speed Steel (HSS) Perform in Brown & Sharpe Tools?

High-speed steel (HSS) is a popular material for cutting tools due to its excellent hardness and wear resistance. HSS can withstand high temperatures without losing its temper, making it suitable for high-speed applications.

Pros: HSS tools are durable and maintain sharpness longer than conventional steels, which translates to lower replacement costs over time. They are also relatively easy to manufacture and can be ground to a fine edge.

Cons: While HSS is cost-effective, it is more susceptible to corrosion compared to other materials like carbide. Additionally, HSS tools may not perform as well in extreme conditions, such as high-pressure environments.

Impact on Application: HSS is compatible with a variety of materials, including metals and plastics, making it versatile for different machining tasks.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with relevant standards such as DIN or ASTM. HSS tools are widely accepted and used globally, making them a reliable choice.

What Advantages Do Carbide Tools Offer for Precision Applications?

Carbide is another common material used in Brown & Sharpe tools, particularly for cutting and drilling applications. Carbide tools are known for their exceptional hardness and resistance to wear.

Pros: The key advantage of carbide tools is their ability to maintain sharpness under high-speed operations, significantly increasing productivity. They also exhibit excellent thermal stability, which is crucial in high-temperature applications.

Cons: Carbide tools tend to be more brittle than HSS, making them prone to chipping or breaking under excessive stress. Additionally, they are generally more expensive to manufacture, which can increase the overall cost of the tools.

Impact on Application: Carbide tools are ideal for machining hard materials, including stainless steel and titanium, which are often used in high-performance applications.

Considerations for International Buyers: Buyers should consider the availability of carbide tools in their region and ensure that they meet local standards. In markets like South America and Africa, where specific materials may be less accessible, understanding supply chain logistics is critical.

Why Are Stainless Steel Components Important in Tool Manufacturing?

Stainless steel is frequently used in components such as tool holders and fixtures due to its corrosion resistance and aesthetic appeal.

Pros: Stainless steel offers excellent durability and is resistant to rust and corrosion, making it suitable for environments where moisture is present. This material also provides a clean finish, which is beneficial for precision tools.

Cons: While stainless steel is durable, it is generally heavier than other materials, which may affect the tool’s handling and performance. Additionally, the manufacturing process can be more complex, leading to higher production costs.

Impact on Application: Stainless steel is particularly beneficial in applications where hygiene is paramount, such as in the food and pharmaceutical industries.

Considerations for International Buyers: Compliance with health and safety standards is crucial, especially in industries that require stringent regulations. Buyers in the Middle East and Europe should ensure that stainless steel tools meet standards like ISO or ASTM.

What Role Does Aluminum Play in Tool Design?

Aluminum is often used in the construction of lighter tool components due to its favorable weight-to-strength ratio.

Pros: Aluminum tools are lightweight, which can reduce operator fatigue and enhance maneuverability during use. They also have good corrosion resistance, making them suitable for various environments.

Cons: The primary disadvantage of aluminum is its lower hardness compared to steel, which can lead to quicker wear in high-stress applications. Additionally, aluminum tools may not be suitable for heavy-duty machining tasks.

Impact on Application: Aluminum is often used in non-ferrous machining applications and can be ideal for applications where weight is a critical factor.

Considerations for International Buyers: Buyers should be aware of the differences in aluminum grades and ensure that they select tools that meet their specific application requirements. Compliance with local standards is also essential.

Summary of Material Selection for Brown & Sharpe Tools

| Material | Typical Use Case for brown & sharpe tools | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High-Speed Steel | Cutting tools, drill bits | Excellent hardness and wear resistance | Susceptible to corrosion | Medium |

| Carbide | Precision cutting and drilling tools | Maintains sharpness under high speeds | Brittle, prone to chipping | High |

| Stainless Steel | Tool holders, fixtures | Corrosion resistant | Heavier, complex manufacturing | Medium |

| Aluminum | Lightweight tool components | Lightweight, good corrosion resistance | Lower hardness, quicker wear | Low |

Understanding the properties and applications of these materials will help B2B buyers make informed decisions when selecting Brown & Sharpe tools for their specific needs.

In-depth Look: Manufacturing Processes and Quality Assurance for brown & sharpe tools

What Are the Key Stages in the Manufacturing Process of Brown & Sharpe Tools?

Brown & Sharpe tools are renowned for their precision and durability, which can be attributed to a meticulous manufacturing process. The production of these tools typically involves several critical stages: material preparation, forming, assembly, and finishing.

Material Preparation: The first stage involves selecting high-quality raw materials, often high-speed steel or carbide, which are essential for ensuring the longevity and performance of the tools. The materials are subjected to rigorous testing to verify their composition and properties, ensuring they meet the required specifications.

Forming: In this stage, the prepared materials undergo various forming processes such as machining, forging, or casting. Advanced CNC (Computer Numerical Control) machines are employed to achieve precise shapes and dimensions. This automation not only enhances efficiency but also reduces the likelihood of human error, which is crucial for maintaining the high standards associated with Brown & Sharpe products.

Assembly: Following the forming stage, components are meticulously assembled. This process often includes the integration of intricate parts, such as gears and bearings, which require precise alignment and fitting. Skilled technicians oversee this stage to ensure that each tool functions as intended.

Finishing: The final stage involves surface treatment and finishing processes. Techniques such as polishing, coating, and heat treatment are applied to enhance durability and reduce wear. This stage is vital, as it contributes significantly to the tool’s performance and lifespan.

How Is Quality Assurance Implemented in Brown & Sharpe Tool Manufacturing?

Quality assurance (QA) is integral to the manufacturing of Brown & Sharpe tools. The company adheres to international standards and industry-specific regulations, ensuring that each tool meets rigorous quality criteria before reaching the market.

What International Standards Are Relevant for Quality Assurance?

Brown & Sharpe tools are manufactured in compliance with ISO 9001, a globally recognized standard for quality management systems. This certification signifies that the company consistently meets customer and regulatory requirements. Additionally, tools may also be certified under specific industry standards such as CE marking for compliance with European safety and health regulations, or API specifications for the oil and gas industry.

What Are the Quality Control Checkpoints?

Quality control (QC) is embedded at multiple checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): Raw materials are inspected upon receipt to ensure they meet specified standards. This step is critical to prevent defects from entering the production line.

-

In-Process Quality Control (IPQC): During the manufacturing stages, regular inspections are conducted to monitor dimensions, tolerances, and overall quality. This ongoing assessment helps identify and rectify any issues early in the process.

-

Final Quality Control (FQC): After assembly and finishing, each tool undergoes a final inspection. This includes functional testing and measurement verification to ensure that the tools meet the high standards expected of Brown & Sharpe products.

What Testing Methods Are Commonly Used in Quality Assurance?

Brown & Sharpe employs a variety of testing methods to validate the quality of their tools:

-

Dimensional Inspection: Using precision measuring instruments, such as micrometers and calipers, to verify that tools meet specified dimensions and tolerances.

-

Functional Testing: Tools are tested in real-world conditions to assess their performance and reliability.

-

Durability Testing: Tools are subjected to stress tests to determine their resistance to wear and failure under various operating conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are several methods to ensure that suppliers adhere to high-quality standards:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes, quality control measures, and compliance with international standards.

-

Quality Control Reports: Requesting detailed QC reports can help buyers understand the testing methods employed and the results achieved. This documentation is essential for assessing the reliability of the tools.

-

Third-Party Inspections: Engaging independent third-party inspectors can provide an unbiased evaluation of a supplier’s quality assurance practices. These inspectors can verify compliance with international standards and industry regulations.

What Are the Quality Control and Certification Nuances for International Buyers?

International buyers must navigate various quality control and certification nuances when sourcing Brown & Sharpe tools. Understanding regional regulations and standards is vital for ensuring compliance and avoiding delays in customs clearance.

-

Regional Certifications: Different regions may have specific certifications that must be met. For instance, tools sold in the European Union must have CE marking, while products in the Middle East may require compliance with local standards.

-

Documentation Requirements: Buyers should ensure that all necessary documentation, such as certificates of conformity and inspection reports, is available and meets the requirements of their respective countries.

-

Cultural and Market Considerations: Understanding local market expectations and cultural nuances can influence purchasing decisions. Buyers should engage with suppliers who are knowledgeable about these aspects to ensure smooth transactions and long-term partnerships.

Conclusion

In summary, the manufacturing processes and quality assurance practices of Brown & Sharpe tools are designed to uphold the highest standards of precision and reliability. By understanding these processes and implementing thorough verification methods, B2B buyers can confidently source tools that meet their operational needs and industry requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘brown & sharpe tools’

This guide serves as a practical checklist for international B2B buyers seeking to procure Brown & Sharpe tools. It provides a structured approach to ensure that you make informed decisions when sourcing precision measuring and machining tools, renowned for their quality and accuracy.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it’s essential to clearly outline your technical requirements. This includes understanding the specific tools needed, such as micrometers, calipers, or screw machine tools, and their respective tolerances. Having detailed specifications helps streamline communications with suppliers and ensures that the tools will meet your operational needs.

Step 2: Conduct Market Research on Suppliers

Research potential suppliers who specialize in Brown & Sharpe tools. Look for companies with a strong reputation in the industry, as well as those that have established distribution channels in your region, such as Africa, South America, the Middle East, and Europe. This step is vital for identifying reliable partners who can provide the quality and support you require.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Request company profiles, product catalogs, and case studies to gauge their experience and capabilities. Additionally, seek references from other clients in similar industries or regions to assess their reliability and quality of service. This due diligence minimizes risks associated with sourcing from unknown entities.

Step 4: Verify Certifications and Standards Compliance

Ensure that the suppliers you consider comply with relevant industry standards and hold necessary certifications. This includes ISO certifications or other quality assurance measures that validate their manufacturing processes. Compliance not only ensures product quality but also safeguards your business against potential legal issues.

Step 5: Review Warranty and Support Options

Examine the warranty terms and after-sales support offered by the supplier. A robust warranty and responsive customer service are crucial for addressing any issues that may arise post-purchase. Understanding these terms helps protect your investment and ensures ongoing support in maintaining the tools.

Step 6: Request Samples or Demonstrations

Whenever possible, request samples or arrange for demonstrations of the tools. This allows you to assess the quality, functionality, and user-friendliness of the products firsthand. Observing the tools in action can provide insights that specifications alone may not reveal, aiding in making a more informed purchasing decision.

Step 7: Negotiate Pricing and Terms

Once you have identified a suitable supplier, engage in negotiations to secure favorable pricing and payment terms. Consider factors such as bulk purchase discounts or long-term partnership agreements. Effective negotiation can lead to significant cost savings and improved terms that benefit your procurement strategy.

By following this structured checklist, B2B buyers can navigate the sourcing process for Brown & Sharpe tools more effectively, ensuring they obtain high-quality products that meet their operational requirements.

Comprehensive Cost and Pricing Analysis for brown & sharpe tools Sourcing

What Are the Key Components of the Cost Structure for Brown & Sharpe Tools?

When sourcing Brown & Sharpe tools, understanding the cost structure is crucial. The primary cost components include:

-

Materials: The selection of high-quality materials, such as high-speed steel and carbide, significantly impacts costs. These materials enhance durability and precision, which are essential for tools used in demanding applications.

-

Labor: Skilled labor is required for manufacturing, especially given Brown & Sharpe’s reputation for precision. Labor costs can vary based on geographic location and the expertise level required for production.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and indirect labor. Efficient manufacturing processes can help keep these costs manageable.

-

Tooling: Investment in specialized tooling for production is necessary. This includes molds and dies specific to Brown & Sharpe’s product line, impacting initial setup costs.

-

Quality Control (QC): Implementing stringent QC measures ensures that every tool meets industry standards. While this adds to the cost, it is vital for maintaining brand reputation and customer satisfaction.

-

Logistics: Shipping and handling costs can vary widely, especially for international buyers. Factors such as distance, shipping method, and customs duties play a significant role.

-

Margin: The profit margin set by suppliers will vary based on competition and market demand. Understanding this can aid in negotiating better pricing.

How Do Price Influencers Affect Sourcing Decisions for Brown & Sharpe Tools?

Several factors influence the pricing of Brown & Sharpe tools, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically result in lower per-unit costs due to economies of scale. Buyers should consider their inventory needs to leverage better pricing.

-

Specifications and Customization: Customized tools or those with specific specifications may come at a premium. Clear communication of requirements is essential to avoid unexpected costs.

-

Materials: The choice of materials not only affects the quality but also the price. High-grade materials will incur higher costs but provide better performance and longevity.

-

Quality Certifications: Tools that come with recognized certifications (e.g., ISO standards) may have higher prices due to the assurance of quality and performance.

-

Supplier Factors: The reputation, reliability, and service level of the supplier can influence pricing. Established suppliers with a history of quality often command higher prices.

-

Incoterms: The terms of trade (e.g., FOB, CIF) affect logistics costs. Understanding these terms can help in estimating the total landed cost of tools.

What Are the Best Practices for Negotiating Prices on Brown & Sharpe Tools?

B2B buyers can adopt several strategies to enhance cost-efficiency and negotiation outcomes:

-

Leverage Total Cost of Ownership (TCO): When evaluating tools, consider the TCO, which includes purchase price, operational costs, maintenance, and potential downtime. A higher initial price may be justified by lower operating costs.

-

Negotiate Based on Long-Term Relationships: Establishing a long-term relationship with suppliers can lead to better pricing and terms. Frequent orders can also incentivize suppliers to offer discounts.

-

Explore Multiple Suppliers: Comparing quotes from various suppliers can provide leverage during negotiations. This practice helps in understanding the market rates and finding competitive pricing.

-

Be Aware of Pricing Nuances for International Transactions: Buyers from regions like Africa, South America, the Middle East, and Europe should consider factors such as currency fluctuations, import taxes, and local regulations that can affect pricing.

-

Request Detailed Quotes: Ensure that quotes are comprehensive and itemized to understand what each cost component entails. This transparency can aid in negotiations.

Conclusion: What Should International Buyers Keep in Mind?

While sourcing Brown & Sharpe tools, international buyers should be aware that pricing can vary significantly based on multiple factors. Always seek detailed information on costs, negotiate terms effectively, and consider the long-term implications of your purchases. While this analysis provides a framework, it is essential to note that prices can fluctuate based on market conditions and supplier capabilities. Always verify current pricing and terms directly with suppliers.

Alternatives Analysis: Comparing brown & sharpe tools With Other Solutions

Exploring Alternatives to Brown & Sharpe Tools for Precision Measurement

In the realm of precision measurement and machining, various tools and technologies are available to meet specific operational needs. While Brown & Sharpe tools are renowned for their durability and accuracy, it is essential for B2B buyers to consider alternative solutions that may offer distinct advantages depending on their unique requirements. Below is a comparative analysis of Brown & Sharpe tools against two viable alternatives: Tesa Technology tools and Mitutoyo measuring instruments.

| Comparison Aspect | Brown & Sharpe Tools | Tesa Technology Tools | Mitutoyo Measuring Instruments |

|---|---|---|---|

| Performance | High precision, industry-standard repeatability | Advanced technology, specialized in height gauges | Exceptional accuracy, wide range of measuring tools |

| Cost | Mid to high-range pricing | Generally higher priced | Competitive pricing, various ranges available |

| Ease of Implementation | Moderate; requires skilled operators | Easy with clear instructions | User-friendly, many tools are intuitive |

| Maintenance | Low maintenance; robust design | Regular calibration needed | Low maintenance; generally durable |

| Best Use Case | General-purpose machining and measurement | Specialized height measurement | Versatile; suitable for various industries |

What Are the Advantages and Disadvantages of Tesa Technology Tools?

Tesa Technology, based in Switzerland, specializes in high-quality measuring instruments, particularly known for their height gauges. These tools integrate advanced technology, ensuring precise measurements that can significantly improve accuracy in machining environments. However, Tesa products generally come at a higher price point, which may not align with the budget constraints of all buyers. Additionally, while their tools are user-friendly, they may require regular calibration to maintain optimal performance, which can add to the operational overhead.

How Do Mitutoyo Measuring Instruments Compare?

Mitutoyo is another prominent player in the precision measurement market, offering a broad array of tools including calipers, micrometers, and indicators. Known for their exceptional accuracy and reliability, Mitutoyo instruments are competitively priced, making them accessible to a wider range of businesses. Their user-friendly designs often require less training for operators, which can lead to quicker implementation. However, the extensive range of products may sometimes overwhelm buyers who are unsure of which specific tools best fit their needs.

Choosing the Right Solution: How Can B2B Buyers Make an Informed Decision?

Selecting the appropriate measuring tools is critical for maintaining operational efficiency and ensuring product quality. B2B buyers should first assess their specific measurement requirements, including the type of materials being worked with and the precision needed. Cost considerations and maintenance capabilities are also vital; while Brown & Sharpe tools are built to last, alternatives like Tesa and Mitutoyo may offer specialized features that could enhance performance in specific applications. Ultimately, aligning the choice of tools with the operational goals and budget constraints will lead to better productivity and cost-effectiveness in manufacturing processes.

Essential Technical Properties and Trade Terminology for brown & sharpe tools

What Are the Essential Technical Properties of Brown & Sharpe Tools?

When considering Brown & Sharpe tools for your manufacturing needs, understanding their technical properties is crucial for making informed purchasing decisions. Here are some key specifications:

-

Material Grade

Brown & Sharpe tools are typically made from high-speed steel (HSS) or carbide. HSS offers excellent toughness and wear resistance, making it suitable for a range of machining applications. Carbide, on the other hand, provides superior hardness and is ideal for high-speed applications. For B2B buyers, selecting the appropriate material grade can significantly impact tool longevity and performance, ultimately reducing costs associated with tool replacement. -

Tolerance

Tolerance refers to the allowable deviation from a specified dimension. Brown & Sharpe tools are known for their precision, often achieving tolerances of ±0.001 inches or finer. This level of accuracy is critical in industries such as aerospace and automotive, where even minor discrepancies can lead to significant operational issues. By investing in tools with stringent tolerances, buyers can ensure higher product quality and compliance with industry standards. -

Durability

The durability of Brown & Sharpe tools is evidenced by their ability to withstand rigorous machining processes without compromising performance. Tools designed for high repeatability and robust construction are essential for maintaining production efficiency. For B2B buyers, durability translates to reduced downtime and maintenance costs, making it a vital consideration when selecting tools for production. -

Repeatability

This property indicates how consistently a tool can produce the same result over multiple uses. Brown & Sharpe tools are engineered for high repeatability, which is essential for automated machining processes. For businesses that rely on mass production, tools with superior repeatability can enhance operational efficiency and lower waste, leading to improved profit margins. -

Interchangeability

Many Brown & Sharpe tools feature interchangeable components, allowing for quick changes during production. This versatility is particularly beneficial in environments where different operations are performed on the same machine. B2B buyers should consider tools with high interchangeability to maximize flexibility and minimize setup times.

What Are Common Trade Terms Associated with Brown & Sharpe Tools?

Familiarity with industry jargon can help B2B buyers navigate procurement processes more effectively. Here are some essential trade terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of Brown & Sharpe, purchasing from an OEM ensures that you receive tools that are designed to meet specific performance criteria and compatibility standards. -

MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier requires to fulfill an order. Understanding MOQ is vital for B2B buyers to assess whether they can meet supplier requirements without overcommitting resources. This can also influence inventory management strategies. -

RFQ (Request for Quotation)

An RFQ is a document used to invite suppliers to bid on providing specific goods or services. It typically includes detailed specifications and quantities. For buyers, issuing an RFQ can help ensure competitive pricing and facilitate better negotiations with suppliers. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for B2B buyers to clarify shipping, insurance, and delivery responsibilities, minimizing misunderstandings in cross-border transactions. -

Lead Time

Lead time is the duration from the initiation of an order until its fulfillment. Knowledge of lead times helps businesses plan their production schedules effectively, ensuring that they maintain optimal inventory levels and avoid production delays.

By grasping these technical properties and trade terms, B2B buyers can make strategic decisions when investing in Brown & Sharpe tools, ultimately enhancing operational efficiency and product quality in their manufacturing processes.

Navigating Market Dynamics and Sourcing Trends in the brown & sharpe tools Sector

What Are the Key Market Trends Affecting Brown & Sharpe Tools?

The market for Brown & Sharpe tools is currently experiencing significant dynamics influenced by several global drivers. The push for automation and advanced manufacturing technologies is reshaping the landscape, as businesses seek efficiency and precision in production processes. As industries in regions like Africa, South America, the Middle East, and Europe (notably Saudi Arabia and Germany) increasingly adopt smart manufacturing techniques, the demand for high-quality precision tools is escalating. This trend is further amplified by the rise of Industry 4.0, where data analytics, IoT, and AI are integrated into manufacturing, necessitating tools that can meet these advanced requirements.

Moreover, the ongoing globalization of supply chains is prompting buyers to seek reliable partnerships that can deliver not only quality but also consistency in supply. As companies navigate these complexities, the emphasis on vendor reliability and product durability becomes paramount. International buyers are increasingly looking for suppliers that can provide comprehensive support, including technical assistance and efficient logistics, to streamline their operations.

How Is Sustainability Shaping the Sourcing of Brown & Sharpe Tools?

Sustainability is becoming a critical consideration in the sourcing of Brown & Sharpe tools. The environmental impact of manufacturing processes is under scrutiny, with buyers seeking suppliers committed to ethical practices and reduced carbon footprints. This shift is particularly relevant for B2B buyers in Europe, where stringent regulations and consumer preferences are driving the adoption of sustainable practices.

Ethical sourcing is not just a trend but a necessity. Buyers are increasingly demanding transparency in the supply chain, urging manufacturers to disclose their sourcing practices and material origins. Certifications such as ISO 14001 for environmental management and adherence to sustainable material standards are becoming essential for suppliers to demonstrate their commitment to green practices. Utilizing recycled materials or eco-friendly production processes can enhance a supplier’s appeal to conscientious buyers.

What Is the Historical Significance of Brown & Sharpe Tools in the Market?

The legacy of Brown & Sharpe tools is deeply intertwined with the evolution of precision engineering. Founded in 1833, the company pioneered innovations that set industry standards, particularly in the realm of screw machine tools and precision measuring instruments. Their developments in micrometers and lathes played a crucial role in the industrial revolution, facilitating mass production and quality control.

The historical significance of Brown & Sharpe lies not only in their technological advancements but also in their enduring reputation for quality and reliability. As international B2B buyers evaluate suppliers, the rich heritage and proven track record of Brown & Sharpe serve as a compelling factor in their decision-making processes. This historical perspective reinforces the brand’s position as a trusted partner in the precision tools sector, appealing to buyers who value both innovation and tradition.

Frequently Asked Questions (FAQs) for B2B Buyers of brown & sharpe tools

-

How do I choose the right Brown & Sharpe tools for my manufacturing needs?

Selecting the appropriate Brown & Sharpe tools involves assessing your specific production requirements. Consider the type of materials you work with, the precision needed for your operations, and the volume of production. Brown & Sharpe offers a range of products including micrometers, lathes, and screw machine tools that cater to various industries. Consulting with a technical representative or reviewing product specifications can help ensure you choose tools that maximize efficiency and meet your quality standards. -

What is the best Brown & Sharpe tool for precision measurement?

For precision measurement, the Brown & Sharpe micrometers and calipers are widely regarded as top choices. The BesTest® Indicator, known for its corrosion resistance and accuracy, is particularly effective in machining environments. Additionally, the Tesa-Hite height gauge offers advanced measurement capabilities for vertical dimensions. It’s essential to evaluate your specific measurement needs and select tools that provide the required accuracy and durability for your applications. -

How can I verify the authenticity of Brown & Sharpe tools from suppliers?

To ensure the authenticity of Brown & Sharpe tools, source them from authorized distributors or directly from the manufacturer. Request documentation, such as certificates of authenticity or proof of purchase. It’s also beneficial to read reviews or seek testimonials from other customers. Establishing a relationship with reputable suppliers who have a history of providing genuine products can further mitigate the risk of counterfeit tools. -

What are the minimum order quantities (MOQ) for Brown & Sharpe tools?

Minimum order quantities for Brown & Sharpe tools can vary based on the supplier and the specific product line. Typically, bulk orders may attract lower per-unit costs, while smaller quantities might be subject to higher pricing. It’s advisable to discuss your requirements with potential suppliers to find flexible options that suit your business needs, especially if you are operating in regions with varying demand levels. -

What payment terms should I expect when sourcing Brown & Sharpe tools internationally?

Payment terms can differ significantly between suppliers and regions. Common terms include advance payment, net 30, or net 60 days. For international transactions, consider using secure payment methods like letters of credit or escrow services to protect your investment. Always clarify terms before finalizing orders and ensure that they align with your company’s financial practices and cash flow management. -

How do I ensure quality assurance for Brown & Sharpe tools?

Quality assurance for Brown & Sharpe tools involves verifying that products meet industry standards and specifications. Look for suppliers that provide certifications and quality control documentation. Additionally, request samples or conduct inspections before placing larger orders. Establishing a quality agreement with your supplier can also ensure that the tools you receive consistently meet your operational requirements. -

What logistics considerations should I keep in mind when importing Brown & Sharpe tools?

When importing Brown & Sharpe tools, consider shipping costs, customs duties, and delivery timelines. Choose reliable freight forwarders with experience in handling industrial equipment. Be aware of the import regulations in your country, as they may affect shipping methods and costs. Planning for lead times and potential delays in customs can help ensure timely delivery and minimize disruptions to your production schedule. -

Can I customize Brown & Sharpe tools for specific applications?

Customization options for Brown & Sharpe tools may be available, depending on the product and supplier. Many manufacturers offer tailored solutions to meet specific operational needs, such as unique sizes or configurations. It’s important to communicate your requirements clearly and discuss them with your supplier to explore available customization options. This can enhance the efficiency and effectiveness of the tools in your specific manufacturing processes.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Brown & Sharpe Tools Manufacturers & Suppliers List

1. Brown & Sharpe – Tool Holders and Accessories

Domain: brown-sharpe.com

Registered: 2006 (19 years)

Introduction: Brown & Sharpe Screw Machine Tools, a division of Lester Detterbeck Enterprises Ltd, offers a range of tool holders and accessories for automatic screw machines. Key products include: Box Tools with Carbide ‘V’ Rests, Roller Back Box Tools, Balance Turning Tools, Slide Tools for Turrets, Drilling and Chamfering Tools, Adjustable Tool Holders, Floating Adjusting Reamer Holders, Stub Collet Holders,…

2. TESA Brown & Sharpe – Precision Measuring Tools

Domain: penntoolco.com

Registered: 1997 (28 years)

Introduction: TESA Brown & Sharpe is a brand known for high-quality precision measuring tools, including micrometers, calipers, indicators, and height gages. TESA Technology, based in Renens, Switzerland, specializes in advanced measuring tools, particularly height gages under the Tesa-Hite trade name. Brown & Sharpe, founded in 1833 in Providence, Rhode Island, became the world’s largest manufacturer of precis…

3. Brown & Sharpe – Precision Tools & Equipment

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Brown & Sharpe products for sale include a variety of tools and equipment such as:

– Brown & Sharpe 0-1 Micrometer (Pre-Owned) – Starting bid $1.00, $9.35 shipping

– Brown Sharpe 796 Vintage Precision 6 Screwdriver Set (Pre-Owned) – Price $75.00 or Best Offer, $11.00 shipping

– Brown & Sharpe 599-579-5 Shockproof Stainless Tempered Swiss Dial Caliper (Pre-Owned) – Price $55.00 or Best Offer, Free …

4. Brown & Sharpe – Industrial Tools & Supplies

Domain: allindustrial.com

Registered: 2003 (22 years)

Introduction: Brown & Sharpe Products include a wide range of industrial tools and supplies such as abrasives (brushes, files, belts, discs), deburring tools, dressing tools, grinding wheels, honing and lapping tools, fasteners (bolts, screws, nuts), hydraulic systems, air tools, hand and power tools, holemaking tools, and various accessories. They offer free shipping on orders over $250 and provide options for…

5. Grainger – Precision Measuring Tools

Domain: grainger.com

Registered: 1994 (31 years)

Introduction: This company, Grainger – Precision Measuring Tools, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. TESA – Portable Quality Control Solutions

Domain: tesatechnology.com

Registered: 2014 (11 years)

Introduction: TESA µ-FINDER: SET 31 AND SET 22 – Combined solution for portable quality control including probe, display unit, and magnetic support. TESA INTRIMIK – Internal micrometer unaffected by temperature variations. TESA TWIN-T10 – Portable display for inductive probes, enabling sub-micron accuracy for CMM checks. New range of TESA dial gauges – Resolutions from 0.1 mm to 0.001 mm, measuring ranges up to…

7. MSC Direct – Carbide Test Indicator Contact Point

Domain: mscdirect.com

Registered: 1996 (29 years)

Introduction: This company, MSC Direct – Carbide Test Indicator Contact Point, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Brown and Sharpe – Precision Measurement Tools

Domain: higherprecision.com

Registered: 2010 (15 years)

Introduction: Brown and Sharpe offers a comprehensive range of precision measurement tools, including: Air Gaging, Angle Plates, CMM Fixtures, CMM Probes, CMM Systems, CNC Measuring Systems, CNC Tool Carts, Collet Chucks, Collets, Fixture Accessories, Laser Fixtures, Linear Gages, Lockers, Profile Projectors, Roundness Measuring Machines, Sine Plates, Taps, Tooltowers, Vises, Vision Fixtures, Vision Measuring S…

9. Brown & Sharpe – Digital Tool Set 00591007

Domain: willrich.com

Registered: 1998 (27 years)

Introduction: Brown & Sharpe Digital Tool Set 00591007

Strategic Sourcing Conclusion and Outlook for brown & sharpe tools

In navigating the complexities of global sourcing, Brown & Sharpe tools stand out as a benchmark for quality and reliability. With a heritage dating back to 1833, these tools have shaped the standards of precision engineering, making them an invaluable asset for manufacturers across various industries. The strategic sourcing of Brown & Sharpe products ensures not only operational efficiency but also enhances the precision of manufacturing processes, vital for maintaining competitiveness in today’s market.

International buyers from regions such as Africa, South America, the Middle East, and Europe can leverage Brown & Sharpe’s extensive range of precision tools—from micrometers to screw machine tools—to elevate their production capabilities. As industries increasingly focus on quality and innovation, integrating these tools into your operations can lead to significant improvements in productivity and cost-effectiveness.

Looking forward, embracing a strategic sourcing approach with Brown & Sharpe tools positions your business for growth and success. By prioritizing quality and reliability, you can meet the evolving demands of your market. Engage with suppliers who understand your specific needs and explore how Brown & Sharpe can become a cornerstone of your manufacturing excellence.