Introduction: Navigating the Global Market for brown & sharpe tooling

Navigating the complexities of sourcing Brown & Sharpe tooling can present significant challenges for international B2B buyers, particularly those operating in diverse markets across Africa, South America, the Middle East, and Europe. As industries evolve, the demand for high-quality, reliable tooling solutions becomes increasingly critical. This comprehensive guide aims to equip buyers with the knowledge to effectively identify, evaluate, and procure Brown & Sharpe products, ensuring they meet specific operational requirements and standards.

Within this guide, we delve into a range of essential topics, including the various types of Brown & Sharpe tooling available, their applications across different manufacturing processes, and strategies for vetting suppliers. We also provide insights into pricing structures and cost considerations, helping buyers make informed financial decisions. The objective is to empower organizations to navigate the global market with confidence, minimizing risks and maximizing value in their tooling investments.

By understanding the unique features and benefits of Brown & Sharpe tooling, buyers can enhance their operational efficiency and product quality. This guide serves as a vital resource for international B2B buyers seeking to leverage the legacy and innovation of Brown & Sharpe in their manufacturing endeavors, ultimately driving growth and competitiveness in their respective markets.

Understanding brown & sharpe tooling Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tool Holders | High repeatability, durable design, compatibility with various machines | Automatic screw machines, turned parts production | Pros: Versatile, reliable; Cons: Initial cost can be high. |

| Precision Measuring Tools | High accuracy, robust construction, range of types (calipers, micrometers) | Quality control, machining, assembly operations | Pros: Exceptional precision; Cons: Requires calibration and maintenance. |

| Boring Tool Holders | Adjustable configurations, suitable for various boring operations | Metalworking, manufacturing industries | Pros: Flexibility in applications; Cons: Complexity may lead to higher learning curve. |

| Releasing Die Holders | Self-opening mechanism, ease of use | Threading, metal forming | Pros: Increases efficiency; Cons: May require specific compatibility checks. |

| Trepanning Tools | Adjustable design for different diameters, efficient material removal | Aerospace, automotive, heavy machinery | Pros: Reduces waste, increases speed; Cons: Limited to specific machining tasks. |

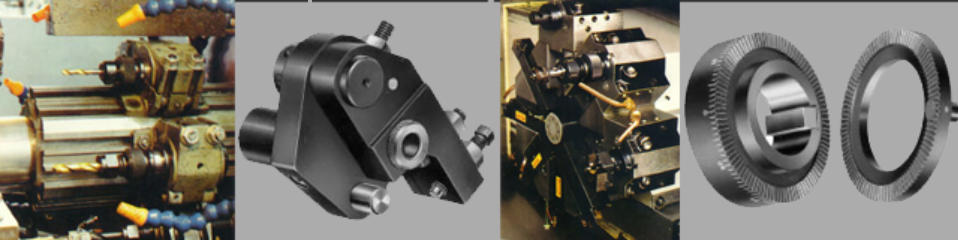

What Are the Key Characteristics of Tool Holders?

Tool holders are foundational components in the Brown & Sharpe tooling lineup, known for their high repeatability and robust construction. They are designed to fit a variety of automatic screw machines, making them versatile for manufacturers focused on turned parts production. When purchasing tool holders, businesses should consider the compatibility with existing machinery and the expected volume of production, as the initial investment can be offset by long-term durability and performance.

Why Are Precision Measuring Tools Essential in B2B Operations?

Precision measuring tools, including calipers and micrometers, are integral for quality control and precision machining. These tools are built to deliver exceptional accuracy, which is crucial for maintaining product standards and minimizing waste. For B2B buyers, key considerations include the tool’s measurement range, ease of use, and the frequency of calibration required. Investing in high-quality measuring tools can significantly impact overall operational efficiency and product quality.

How Do Boring Tool Holders Enhance Manufacturing Processes?

Boring tool holders are characterized by their adjustable configurations, allowing for versatile applications in various boring operations. They are commonly used in metalworking and manufacturing industries, where precise hole dimensions are critical. Buyers should assess the range of adjustability and compatibility with their existing tools. While they offer flexibility, the complexity of setup may require additional training for operators.

What Advantages Do Releasing Die Holders Provide?

Releasing die holders feature a self-opening mechanism that enhances operational efficiency in threading and metal forming applications. Their ease of use can streamline production processes, making them a valuable addition to machining setups. However, buyers should ensure compatibility with their specific machinery to avoid operational disruptions. The efficiency gains can outweigh the initial investment, especially in high-volume production environments.

What Makes Trepanning Tools Valuable in Specific Industries?

Trepanning tools are designed with adjustable features to accommodate different diameters, making them ideal for efficient material removal in sectors like aerospace and automotive manufacturing. Their design minimizes waste while maximizing speed, which is crucial for maintaining competitiveness in production. B2B buyers should evaluate their specific machining needs and consider the tool’s capabilities to ensure it aligns with operational goals, recognizing that these tools may be limited to particular tasks.

Key Industrial Applications of brown & sharpe tooling

| Industry/Sector | Specific Application of Brown & Sharpe Tooling | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision measuring tools for component manufacturing | Ensures high accuracy and compliance with stringent safety standards | Certification of tools, precision tolerances, and delivery timelines |

| Automotive | Tool holders for automatic screw machines | Increases production efficiency and reduces downtime | Compatibility with existing machines, durability, and cost-effectiveness |

| Oil & Gas | Specialized drilling and chamfering tools | Enhances operational reliability in challenging environments | Material quality, resistance to corrosion, and adaptability to various drilling conditions |

| Electronics Manufacturing | Micrometers and calipers for circuit board production | Provides precise measurements critical for component performance | Calibration services, support for international standards, and lead times |

| Medical Devices | Custom tooling for high-precision medical equipment | Ensures patient safety and device reliability | Compliance with medical regulations, traceability of tooling, and supplier stability |

How is Brown & Sharpe Tooling Used in the Aerospace Industry?

In the aerospace sector, Brown & Sharpe tooling is essential for manufacturing high-precision components that meet strict safety regulations. Tools such as micrometers and height gauges are employed to measure parts with extreme accuracy. This is critical as even minor discrepancies can lead to catastrophic failures in flight. International buyers must ensure that the tools sourced are certified and meet the necessary aerospace standards, along with robust support for calibration and maintenance.

What Role Does Brown & Sharpe Tooling Play in Automotive Manufacturing?

The automotive industry relies heavily on Brown & Sharpe tool holders designed for automatic screw machines. These tools enhance production efficiency by allowing for quick changes and setups, which significantly reduces machine downtime. Buyers in this sector should focus on the compatibility of these tools with existing machinery and their durability under continuous use, ensuring a cost-effective solution that maximizes output.

Why are Specialized Drilling Tools Important in Oil & Gas?

In the oil and gas industry, specialized drilling and chamfering tools from Brown & Sharpe are vital for operations in harsh environments. These tools must withstand extreme pressures and corrosive materials, making quality and reliability paramount. International buyers should consider the material composition and performance specifications of the tooling to ensure they can operate efficiently in diverse conditions.

How Do Precision Measuring Tools Benefit Electronics Manufacturing?

Brown & Sharpe’s precision measuring tools, including micrometers and calipers, are crucial in electronics manufacturing, particularly in the production of circuit boards. These tools ensure that components fit correctly and perform as intended, which is vital for device functionality. Buyers in this field should prioritize sourcing tools that comply with international calibration standards and offer reliable support services, ensuring consistent quality in production.

What Custom Tooling Solutions are Needed for Medical Devices?

In the medical device sector, custom tooling solutions from Brown & Sharpe facilitate the production of high-precision equipment necessary for patient safety. These tools must comply with rigorous medical regulations, making sourcing from reputable suppliers critical. International buyers should seek suppliers who can provide documentation for traceability and quality assurance, ensuring that the tools meet the stringent demands of the medical industry.

3 Common User Pain Points for ‘brown & sharpe tooling’ & Their Solutions

Scenario 1: Struggling with Tool Compatibility Across Machines

The Problem: B2B buyers often face challenges when integrating Brown & Sharpe tooling into diverse manufacturing environments. Many facilities use a mix of older and newer machines, and finding tooling that is compatible across all these platforms can be daunting. This lack of compatibility can lead to increased downtime, higher costs due to frequent tool changes, and frustration among machine operators who must adapt to varying tool requirements.

The Solution: To address compatibility issues, B2B buyers should conduct a thorough assessment of their existing machinery before sourcing Brown & Sharpe tooling. This involves identifying the specifications of each machine, such as spindle sizes and tool holder types. Brown & Sharpe offers a range of adjustable tool holders designed to fit various machines. Buyers can benefit from consulting with Brown & Sharpe’s technical support team to ensure they are selecting tools that will work effectively across their equipment. Additionally, investing in multi-functional tools that can be easily adjusted or interchanged can streamline operations and reduce the complexity of managing multiple tool types.

Scenario 2: Inconsistent Measurement Accuracy Affecting Production Quality

The Problem: Quality control is paramount in manufacturing, and inconsistent measurement accuracy can lead to defective products. B2B buyers using Brown & Sharpe measuring tools may encounter issues with calibration or tool wear, resulting in measurements that do not meet specifications. This inconsistency can cause delays in production and increased waste, ultimately impacting profitability.

The Solution: To ensure measurement accuracy, it is crucial for buyers to establish a regular calibration schedule for all Brown & Sharpe measuring tools. This includes using certified calibration standards and maintaining logs of calibration results to track tool performance over time. Buyers should also invest in proper training for their staff on the correct usage and maintenance of these precision tools. Brown & Sharpe’s extensive documentation and training resources can provide insights into best practices. Furthermore, selecting tools with advanced features, such as digital readouts and self-calibrating mechanisms, can enhance measurement reliability and minimize human error.

Scenario 3: Difficulty in Finding Specialized Tools for Unique Applications

The Problem: Many B2B buyers in niche industries struggle to find specialized Brown & Sharpe tools tailored to their unique manufacturing needs. This can result in delays as they search for the right tools, which can be a time-consuming process, especially if the required tools are not readily available in their region. This lack of access can hamper production schedules and lead to potential losses in revenue.

The Solution: To overcome this challenge, buyers should leverage online catalogs and distributor networks that specialize in Brown & Sharpe tooling. Engaging with authorized distributors can provide access to the full range of products and specialized tools that may not be available locally. Additionally, buyers should communicate their specific requirements clearly to suppliers to facilitate tailored recommendations. Brown & Sharpe’s customer support can also assist in identifying custom solutions or modifications for unique applications. Establishing a relationship with a dedicated sales representative can further streamline the process of sourcing specialized tools, ensuring that buyers are informed of new product releases that could meet their needs effectively.

Strategic Material Selection Guide for brown & sharpe tooling

What Are the Key Materials Used in Brown & Sharpe Tooling?

When selecting tooling for precision applications, understanding the materials used in manufacturing Brown & Sharpe tooling is crucial. The choice of material impacts not only the performance and durability of the tools but also their cost and suitability for specific applications. Below is an analysis of four common materials used in Brown & Sharpe tooling, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

How Does High-Speed Steel (HSS) Perform in Brown & Sharpe Tooling?

High-Speed Steel (HSS) is a popular choice for cutting tools due to its ability to withstand high temperatures without losing hardness. HSS tools can maintain their cutting edge even under extreme conditions, making them suitable for a variety of machining applications.

Pros: HSS offers excellent toughness and wear resistance, which translates to longer tool life. It is also relatively easy to manufacture and sharpen, allowing for cost-effective maintenance.

Cons: While HSS is durable, it is not as hard as carbide, which limits its performance in high-speed machining applications. Additionally, it can be more expensive than other materials, depending on the grade.

Impact on Application: HSS is compatible with various materials, including steel, aluminum, and plastics, making it versatile for different machining tasks.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should be aware of compliance with standards such as DIN and ASTM when sourcing HSS tooling.

What Role Does Carbide Play in Brown & Sharpe Tooling?

Carbide is known for its exceptional hardness and wear resistance, making it ideal for high-performance cutting tools. It can maintain its hardness at elevated temperatures, which is essential for high-speed machining.

Pros: Carbide tools provide superior cutting performance and longevity, resulting in lower overall costs due to reduced tool changes. They are also capable of machining harder materials.

Cons: The brittleness of carbide can lead to chipping or breaking under shock loads. Additionally, carbide tooling is generally more expensive than HSS.

Impact on Application: Carbide is particularly effective for machining hard metals and is often used in applications requiring precision and efficiency.

Considerations for International Buyers: Compliance with international standards is crucial, especially for buyers in Africa and South America, where local regulations may dictate specific material certifications.

How Do Tool Steel and Alloy Steel Compare in Brown & Sharpe Tooling?

Tool steel, particularly in its alloyed forms, is engineered for specific applications requiring high hardness and wear resistance. It is often used for making dies and molds.

Pros: Tool steel offers excellent toughness and can be heat-treated to achieve desired hardness levels. It is also cost-effective for producing high-volume tooling.

Cons: Tool steel can be susceptible to corrosion and may require additional coatings for protection. The manufacturing process can be complex, leading to higher costs.

Impact on Application: Tool steel is suitable for applications involving heavy-duty machining and forming operations.

Considerations for International Buyers: Buyers should ensure that tool steel meets relevant standards such as JIS for Japanese manufacturers and ASTM for U.S. suppliers, particularly in regions with stringent quality controls.

What Advantages Does Stainless Steel Offer for Brown & Sharpe Tooling?

Stainless steel is favored for its corrosion resistance and aesthetic appeal, making it a popular choice for precision measuring tools.

Pros: Stainless steel tools are durable and resistant to rust, which is advantageous in humid environments. They also maintain their appearance over time.

Cons: The cost of stainless steel is generally higher than carbon steel and may not be necessary for all applications. It can also be more difficult to machine due to its toughness.

Impact on Application: Stainless steel is ideal for applications where hygiene and corrosion resistance are critical, such as in food processing or medical equipment.

Considerations for International Buyers: Compliance with health and safety regulations is essential, especially in the food and medical industries, where buyers must ensure that stainless steel tools meet local standards.

Summary Table of Material Selection for Brown & Sharpe Tooling

| Material | Typical Use Case for brown & sharpe tooling | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High-Speed Steel | General machining, cutting tools | Excellent toughness and wear resistance | Less hard than carbide | Medium |

| Carbide | High-speed machining, precision cutting | Superior cutting performance and longevity | Brittle, can chip under shock | High |

| Tool Steel | Dies, molds, heavy-duty machining | Excellent toughness, heat-treatable | Susceptible to corrosion | Medium |

| Stainless Steel | Precision measuring tools, hygiene-critical applications | Corrosion resistant, durable | Higher cost, difficult to machine | High |

This comprehensive analysis of materials used in Brown & Sharpe tooling provides valuable insights for B2B buyers, enabling informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for brown & sharpe tooling

What Are the Main Stages of Manufacturing Brown & Sharpe Tooling?

The manufacturing process for Brown & Sharpe tooling is meticulously structured to ensure precision and reliability. It typically comprises four main stages: material preparation, forming, assembly, and finishing.

How Is Material Prepared for Brown & Sharpe Tooling?

Material preparation begins with the selection of high-quality raw materials, such as high-speed steel and carbide, chosen for their durability and performance. These materials undergo rigorous inspections for chemical composition and physical properties, ensuring they meet the stringent requirements of the tooling industry.

Once the materials are validated, they are cut into manageable sizes and treated to enhance their mechanical properties. This may include processes such as annealing or hardening to improve strength and wear resistance, which are critical for the longevity of tooling.

What Forming Techniques Are Used in Brown & Sharpe Tooling?

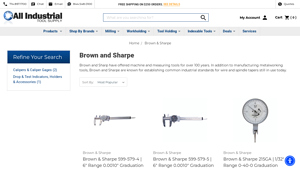

The forming stage involves various machining processes, including turning, milling, and grinding. Brown & Sharpe utilizes advanced CNC (Computer Numerical Control) machines to achieve high precision in shaping the tooling components.

In this phase, tools are crafted to exact specifications, with tolerances that often fall within microns. Techniques such as electrical discharge machining (EDM) may also be employed for intricate designs, ensuring that even the most complex geometries are produced with accuracy.

How Is the Assembly of Brown & Sharpe Tooling Conducted?

Following the forming stage, components are assembled. This process involves aligning and fitting various parts with precision to ensure functionality. Assembly may include the integration of precision measuring instruments, such as calipers and micrometers, which are essential for maintaining quality during production.

Highly trained technicians oversee the assembly process, employing specialized tools and fixtures to ensure that components are assembled correctly. This attention to detail is vital, as it directly impacts the tool’s performance and reliability.

What Finishing Processes Are Applied to Brown & Sharpe Tooling?

The finishing stage is crucial for enhancing the performance characteristics of the tooling. It often involves surface treatments such as polishing, coating, or plating to reduce friction and improve corrosion resistance. These processes not only extend the lifespan of the tooling but also enhance its aesthetic appeal.

Quality checks during this phase ensure that the surface finish meets industry standards. Techniques such as surface roughness testing may be used to evaluate the effectiveness of the finishing processes.

What Quality Assurance Practices Are Implemented in Brown & Sharpe Tooling?

Quality assurance (QA) is an integral aspect of the manufacturing process for Brown & Sharpe tooling, designed to meet both international and industry-specific standards.

Which International Standards Are Relevant for Quality Assurance?

Brown & Sharpe adheres to international quality standards such as ISO 9001, which outlines criteria for an effective quality management system. This certification ensures that the manufacturing processes are continuously monitored and improved, aligning with global best practices.

Additionally, specific industry standards such as CE marking for safety compliance in Europe and API standards for oil and gas applications further enhance the credibility of Brown & Sharpe tooling products in the global market.

What Are the Key Quality Control Checkpoints?

The quality control (QC) process incorporates several checkpoints, including Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

- IQC involves inspecting raw materials and components upon arrival to ensure they meet specified requirements.

- IPQC is conducted during the manufacturing process, where operators perform checks at various stages to identify any discrepancies early.

- FQC occurs after production, where finished products undergo rigorous testing for accuracy, functionality, and appearance before shipment.

What Common Testing Methods Are Used for Quality Assurance?

Common testing methods employed in the QC process include dimensional inspections using coordinate measuring machines (CMM), hardness testing, and functionality tests. These methods ensure that the tools meet precise specifications and are capable of performing under expected operating conditions.

For precision measuring tools, tests often include calibration against certified standards to ensure accuracy. This is critical for industries that require high precision, such as aerospace and automotive.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential. Here are several strategies to ensure quality:

What Are the Best Practices for Supplier Audits?

Conducting supplier audits is one of the most effective ways to assess a manufacturer’s quality control practices. Buyers should establish a checklist based on relevant standards (ISO, CE, API) and perform on-site evaluations of the manufacturing processes, QC checkpoints, and overall compliance with industry standards.

How Can Buyers Access Quality Reports and Certifications?

Buyers should request quality assurance reports and certifications from suppliers. These documents provide insights into the manufacturing processes, testing methods, and compliance with international standards.

Additionally, third-party inspection reports can offer an unbiased assessment of the supplier’s quality control practices and product reliability.

What Are the Nuances of QC and Certification for International Buyers?

International buyers should be aware of the nuances in QC and certification processes that may differ from local standards. Understanding the specific regulations and requirements in their respective regions is crucial. For example, while CE marking is important in Europe, other regions may have different compliance requirements.

Engaging with suppliers who are experienced in international trade and certifications can help facilitate smoother transactions and ensure compliance with local regulations.

Conclusion

Understanding the manufacturing processes and quality assurance practices of Brown & Sharpe tooling is vital for international B2B buyers. By being informed about the stages of manufacturing, quality control checkpoints, and verification methods, buyers can make educated decisions when sourcing tooling products. This knowledge ultimately leads to better partnerships and superior product outcomes in diverse markets across Africa, South America, the Middle East, and Europe.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘brown & sharpe tooling’

Introduction

Sourcing Brown & Sharpe tooling requires a strategic approach to ensure you acquire high-quality, reliable equipment that meets your production needs. This checklist serves as a practical guide for B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, helping you navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical specifications of the tooling you require. Understanding your production processes, including the types of materials you will be working with and the precision required, will guide you in selecting the appropriate tools. This step is critical, as it helps avoid costly mistakes and ensures the tooling aligns with your operational capabilities.

Step 2: Research Available Products

Conduct thorough research on the range of Brown & Sharpe tooling products available. Investigate their product catalog to identify specific tools that meet your defined specifications. Pay attention to features such as durability, compatibility with existing machinery, and the availability of replacement parts, as these factors will influence the long-term viability of your purchase.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers. Request detailed company profiles, case studies, and references from other buyers, especially those in your industry or region. Assess their reputation in the market, focusing on their reliability and customer service, as these are crucial for ongoing support and maintenance.

- Key Considerations:

- Look for suppliers with a proven track record in your industry.

- Verify customer reviews and feedback on product performance.

Step 4: Verify Supplier Certifications

Ensure that the suppliers you are considering have the necessary certifications and quality assurance processes in place. Certifications such as ISO 9001 can indicate a commitment to quality management systems, which is essential for ensuring the tools meet industry standards. This step mitigates risks associated with subpar products that may lead to operational disruptions.

Step 5: Request Samples or Demonstrations

Whenever possible, request samples or arrange for demonstrations of the tooling you are interested in. This hands-on approach allows you to assess the tool’s performance, ergonomics, and suitability for your specific applications. Evaluating the tools in action can provide invaluable insights into their functionality and ease of use.

Step 6: Discuss Terms and Conditions

Engage in detailed discussions regarding pricing, delivery timelines, warranties, and post-purchase support. Clear communication about terms and conditions is vital to avoid misunderstandings that could affect your supply chain. Ensure that the supplier is transparent about any additional costs, such as shipping fees or customs duties, especially for international transactions.

Step 7: Finalize Your Purchase

Once you have completed your evaluations and are satisfied with your supplier choice, proceed to finalize the purchase. Ensure all agreements are documented and that you have a clear understanding of the payment process. After the purchase, maintain open lines of communication with your supplier for any future needs or concerns.

By following this structured checklist, B2B buyers can navigate the procurement of Brown & Sharpe tooling with confidence, ensuring they make informed decisions that will enhance their operational efficiency and productivity.

Comprehensive Cost and Pricing Analysis for brown & sharpe tooling Sourcing

What Are the Key Cost Components in Brown & Sharpe Tooling?

When sourcing Brown & Sharpe tooling, understanding the cost structure is vital for effective budgeting and procurement strategies. The primary cost components include:

-

Materials: High-quality materials such as carbide, high-speed steel, and other specialized alloys are essential for producing durable tooling. The choice of material directly impacts performance, longevity, and cost.

-

Labor: Skilled labor is required for both manufacturing and quality control processes. The labor cost varies significantly by region, with markets in Europe typically facing higher wage rates compared to some regions in Africa and South America.

-

Manufacturing Overhead: This includes utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can help minimize overhead, thereby reducing overall costs.

-

Tooling: The initial investment in tooling is significant, especially for custom designs. Reusable and standardized tooling can mitigate costs over time.

-

Quality Control (QC): Rigorous QC measures are essential to ensure that products meet the high standards associated with the Brown & Sharpe brand. This includes inspections, testing, and certifications, which add to the overall cost.

-

Logistics: Transportation and shipping costs can vary widely depending on the destination and the chosen Incoterms. International shipping involves customs duties, tariffs, and insurance, which must be factored into the total cost.

-

Margin: Suppliers will include a profit margin in their pricing, which can fluctuate based on market demand, competition, and the supplier’s operational costs.

How Do Pricing Influencers Affect Brown & Sharpe Tooling Costs?

Several factors influence the pricing of Brown & Sharpe tooling, including:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases typically lead to discounted pricing. Buyers should negotiate MOQs to achieve favorable pricing terms.

-

Specifications and Customization: Custom tooling or specific specifications can significantly increase costs. Buyers should assess whether standard products meet their needs before opting for customized solutions.

-

Materials and Quality Certifications: Higher-grade materials and certified products often come at a premium. Understanding the trade-off between price and quality is crucial for long-term performance.

-

Supplier Factors: The reputation, reliability, and location of suppliers can affect pricing. Established suppliers may command higher prices due to their track record of quality and service.

-

Incoterms: Different Incoterms can impact the total landed cost of products. Understanding the implications of terms like CIF (Cost, Insurance, and Freight) versus FOB (Free on Board) is essential for accurate cost assessment.

What Are the Best Practices for Negotiating Brown & Sharpe Tooling Prices?

To optimize costs and ensure favorable pricing when sourcing Brown & Sharpe tooling, consider the following tips:

-

Leverage Volume Discounts: When possible, consolidate orders to meet minimum quantities for discounts.

-

Evaluate Total Cost of Ownership (TCO): Look beyond initial purchase prices. Consider factors like maintenance, durability, and performance to assess the long-term value of tooling.

-

Engage in Strategic Negotiation: Develop relationships with suppliers to facilitate negotiations. Understanding market conditions and competitor pricing can provide leverage.

-

Consider Local Suppliers: For buyers in regions like Africa and South America, exploring local suppliers may reduce logistics costs and lead times.

-

Stay Informed on Pricing Trends: Monitor industry trends and fluctuations in raw material prices to better understand when to buy and negotiate effectively.

Disclaimer on Pricing

Prices for Brown & Sharpe tooling can vary widely based on the factors discussed above. The information provided is indicative and should not be considered as fixed pricing. Buyers are encouraged to conduct thorough market research and engage directly with suppliers for accurate quotes tailored to their specific needs.

Alternatives Analysis: Comparing brown & sharpe tooling With Other Solutions

Understanding Alternatives to Brown & Sharpe Tooling

When considering tooling solutions for precision machining and manufacturing, it’s essential to evaluate various options available in the market. Brown & Sharpe tooling has a long-standing reputation for quality and precision, but there are alternative solutions that may better meet specific needs based on performance, cost, and other factors. This analysis compares Brown & Sharpe tooling with two viable alternatives: TESA measuring tools and Mitutoyo precision instruments.

Comparison Table

| Comparison Aspect | Brown & Sharpe Tooling | TESA Measuring Tools | Mitutoyo Precision Instruments |

|---|---|---|---|

| Performance | High precision, industry standards established | Advanced measuring capabilities, reliable | Exceptional accuracy, wide range of tools |

| Cost | Moderate to high investment | Generally lower cost than Brown & Sharpe | Premium pricing, reflects quality and brand |

| Ease of Implementation | Familiarity with existing systems required | User-friendly, minimal training needed | Requires some training for best use |

| Maintenance | Durable, low maintenance | Regular calibration needed | Regular calibration and maintenance required |

| Best Use Case | Ideal for high-volume, precision machining | Best for general measuring tasks | Versatile, suitable for various applications |

Detailed Breakdown of Alternatives

TESA Measuring Tools

TESA, based in Switzerland, offers a range of measuring tools that are known for their technological advancements. Their products, such as height gages and micrometers, are designed for high accuracy and ease of use. While they generally come at a lower cost compared to Brown & Sharpe, they may require regular calibration to maintain their precision. TESA tools are best suited for businesses that need reliable measuring instruments without the extensive investment associated with some traditional brands.

Mitutoyo Precision Instruments

Mitutoyo is recognized globally for its extensive range of precision measuring tools, including calipers, micrometers, and gauges. Known for their exceptional accuracy, Mitutoyo products are a staple in many manufacturing environments. However, they often come with a premium price tag, which may not be justifiable for all businesses. Mitutoyo tools may require a bit of training to maximize their capabilities, making them ideal for organizations that prioritize precision and have the resources for investment and training.

Conclusion: How to Choose the Right Tooling Solution

Selecting the right tooling solution involves assessing your specific operational needs, budget constraints, and the skill level of your workforce. Brown & Sharpe tooling is an excellent choice for companies that demand high precision and have established machining processes. However, for businesses looking for cost-effective alternatives or those that require specialized measuring capabilities, TESA and Mitutoyo offer valuable options. It is crucial to weigh the pros and cons of each alternative against your operational goals to ensure that you invest in the tooling that best supports your manufacturing objectives.

Essential Technical Properties and Trade Terminology for brown & sharpe tooling

What Are the Key Technical Properties of Brown & Sharpe Tooling?

When evaluating Brown & Sharpe tooling, understanding its technical properties is crucial for making informed purchasing decisions. Here are some essential specifications to consider:

-

Material Grade

The material grade of tooling significantly affects durability and performance. Brown & Sharpe tools are typically made from high-speed steel (HSS) or carbide, which provide high wear resistance and longer tool life. For B2B buyers, selecting the appropriate material grade is vital, as it directly correlates with the expected lifespan and operational efficiency of the tools. -

Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension. Brown & Sharpe tooling is known for its precision, often achieving tolerances within ±0.0001 inches. This level of accuracy is essential for industries that require exact specifications, such as aerospace and automotive manufacturing. A tight tolerance ensures that parts fit together properly, reducing waste and rework. -

Surface Finish

The surface finish of a tool impacts its performance and the quality of the machined parts. Brown & Sharpe tools generally feature a high-quality finish that minimizes friction and wear during operation. A smooth surface finish can enhance the tool’s effectiveness and extend its operational life, making it a significant factor for manufacturers looking to optimize production efficiency. -

Hardness

Hardness is a measure of a material’s resistance to deformation and wear. Tools from Brown & Sharpe often exhibit high hardness levels, which are critical for maintaining sharp cutting edges. For B2B buyers, selecting tools with the right hardness is important to ensure they can withstand the demands of their specific applications without excessive degradation. -

Repeatability

Repeatability is the ability of a tool to produce the same results under unchanged conditions. Brown & Sharpe tooling is designed for high repeatability, which is crucial in automated manufacturing processes. This characteristic minimizes variability in production, leading to consistent product quality and reduced operational costs.

What Are Common Trade Terms Associated with Brown & Sharpe Tooling?

Understanding industry jargon can facilitate smoother transactions and clearer communication between buyers and suppliers. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of Brown & Sharpe tooling, buyers often seek OEM products for reliability and compatibility with existing machinery. Recognizing OEM status can help ensure the quality and performance of the tooling. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, understanding MOQ is essential for budgeting and inventory management. Brown & Sharpe tooling may have specific MOQs that buyers need to meet in order to place an order, impacting purchasing decisions. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for a specific quantity of products. When seeking Brown & Sharpe tooling, submitting an RFQ can help buyers gather competitive pricing and terms from multiple suppliers, aiding in informed decision-making. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Familiarity with these terms is crucial for B2B buyers importing Brown & Sharpe tooling, as they dictate the risk and cost responsibilities during transportation. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. Understanding lead time is vital for production planning. For Brown & Sharpe tooling, knowing the lead time can help buyers manage their supply chain effectively and avoid production delays. -

Calibration

Calibration is the process of adjusting and verifying the accuracy of measuring tools. For precision tools like those from Brown & Sharpe, regular calibration is necessary to maintain accuracy. Buyers should consider calibration requirements to ensure their tools meet industry standards and specifications.

By grasping these technical properties and trade terms, B2B buyers can make strategic decisions that enhance their operations and improve their bottom line.

Navigating Market Dynamics and Sourcing Trends in the brown & sharpe tooling Sector

What Are the Key Trends Shaping the Brown & Sharpe Tooling Market?

The Brown & Sharpe tooling sector is currently experiencing significant transformations driven by various global factors. One primary driver is the ongoing digitalization of manufacturing processes, which enhances efficiency and precision. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are increasingly seeking advanced tooling solutions that integrate with smart manufacturing technologies. This shift is fostering the adoption of Industry 4.0 principles, where data analytics and IoT-enabled machines lead to improved operational insights and productivity.

Emerging trends in B2B sourcing also emphasize the importance of supplier transparency and collaboration. Buyers are now looking for partners who can provide not just quality products but also detailed information on production processes, lead times, and logistics. This trend is particularly relevant for buyers in developing markets, where understanding supply chain dynamics can significantly impact operational success. Additionally, sustainability is becoming a pivotal consideration; buyers are increasingly inclined to source from companies that prioritize eco-friendly practices and materials, aligning with global movements toward sustainable manufacturing.

Furthermore, the rise of e-commerce platforms tailored for B2B transactions is reshaping how buyers discover and procure Brown & Sharpe tooling products. These platforms facilitate easier access to product catalogs, user reviews, and competitive pricing, empowering buyers to make informed decisions quickly.

How Is Sustainability Influencing B2B Sourcing in the Brown & Sharpe Tooling Sector?

Sustainability and ethical sourcing are becoming critical focal points for international B2B buyers in the Brown & Sharpe tooling market. The environmental impact of manufacturing processes has prompted companies to reassess their supply chains and sourcing strategies. Buyers are increasingly demanding suppliers who adhere to sustainable practices, such as reducing waste, conserving energy, and utilizing renewable materials.

Certifications like ISO 14001 (Environmental Management) and adherence to industry-specific standards are crucial for suppliers aiming to establish credibility in the marketplace. Additionally, the use of ‘green’ materials in tooling production not only meets regulatory requirements but also appeals to a growing segment of environmentally conscious buyers.

Ethical sourcing practices are also vital, particularly in regions where supply chain transparency can be a concern. Buyers are looking for suppliers who can demonstrate fair labor practices and responsible sourcing of raw materials. This commitment not only enhances a company’s reputation but also ensures long-term viability in a market increasingly scrutinized for its ethical implications.

What Is the Historical Context Behind Brown & Sharpe Tooling’s Market Presence?

Brown & Sharpe has a storied history that dates back to 1833, making it one of the oldest manufacturers of precision tooling. Originally founded in Providence, Rhode Island, the company quickly established itself as a pioneer in the screw machine and precision measuring tool sectors. By the late 19th century, it had become synonymous with quality and innovation, leading to widespread adoption of its products across various industries.

The company’s commitment to precision and quality was particularly notable during World War II, when it played a crucial role in supplying the U.S. Armed Forces with essential tools. This legacy of excellence continues today, as Brown & Sharpe remains a trusted name in the tooling industry, adapting to modern technological advancements while maintaining the high standards that have defined its history. For B2B buyers, this heritage not only signifies reliability but also a wealth of expertise that informs product development and customer service.

Frequently Asked Questions (FAQs) for B2B Buyers of brown & sharpe tooling

-

How do I ensure the quality of Brown & Sharpe tooling before purchase?

To ensure the quality of Brown & Sharpe tooling, start by sourcing from authorized distributors or manufacturers with a proven track record. Request product samples or detailed specifications to assess materials and workmanship. Additionally, inquire about certifications and compliance with international quality standards, such as ISO. Establish clear communication regarding your quality expectations, and consider visiting the supplier’s facility if feasible, to see their production processes firsthand. -

What is the best Brown & Sharpe tooling for precision machining?

The best Brown & Sharpe tooling for precision machining typically includes their micrometers, calipers, and height gauges. These tools are renowned for their accuracy and reliability, essential for high-precision tasks. Depending on your specific needs, you might also consider their adjustable tool holders and specialized cutting tools, which can enhance productivity and precision in machining operations. Always evaluate your specific applications to select the most suitable tools. -

How can I verify the credentials of a Brown & Sharpe tooling supplier?

To verify the credentials of a Brown & Sharpe tooling supplier, conduct thorough research on their business history, customer reviews, and industry reputation. Check for certifications, such as ISO 9001, which indicate adherence to quality management standards. Additionally, consider requesting references from past clients, particularly those in your region. Engaging in direct communication with the supplier can also provide insights into their customer service and responsiveness. -

What are the typical payment terms for international orders of Brown & Sharpe tooling?

Payment terms for international orders of Brown & Sharpe tooling can vary by supplier but typically include options such as advance payment, letters of credit, or payment upon delivery. It’s essential to discuss and agree on payment terms before finalizing the order. Additionally, be aware of potential currency exchange rates and transaction fees. Ensure that the payment terms align with your cash flow capabilities to avoid disruptions in procurement. -

What is the minimum order quantity (MOQ) for Brown & Sharpe tooling?

Minimum order quantities (MOQ) for Brown & Sharpe tooling can vary widely depending on the supplier and specific product lines. Generally, MOQs may range from a few pieces for standard items to larger quantities for specialized or custom tooling. Discussing your requirements with the supplier can often lead to flexibility on MOQs, especially if you are a repeat customer or if you are ordering a range of products that can be grouped together. -

How can I arrange logistics for shipping Brown & Sharpe tooling internationally?

Arranging logistics for shipping Brown & Sharpe tooling internationally involves selecting a reliable freight forwarder experienced in handling industrial tools. Discuss shipping options that best suit your timeline and budget, such as air freight for speed or sea freight for cost-effectiveness. Ensure that all customs documentation is prepared in advance to avoid delays. Consider insurance for high-value shipments to mitigate potential risks during transit. -

Can Brown & Sharpe tooling be customized to meet specific needs?

Yes, many Brown & Sharpe tooling products can be customized to meet specific operational requirements. Customization options may include alterations to tool dimensions, materials used, or specific features tailored to your machining processes. It’s advisable to discuss your needs with the supplier during the inquiry phase, providing detailed specifications to ensure that the final product meets your expectations. -

What quality assurance processes should I expect when sourcing Brown & Sharpe tooling?

When sourcing Brown & Sharpe tooling, you should expect comprehensive quality assurance processes that include rigorous testing and inspection protocols. These may involve checks for dimensional accuracy, material integrity, and performance reliability. Suppliers should provide documentation of quality checks, including compliance certifications. Engaging with suppliers about their QA processes can give you confidence in the tooling’s reliability and performance in your applications.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Brown & Sharpe Tooling Manufacturers & Suppliers List

1. Brown & Sharpe – Tool Holders and Accessories

Domain: brown-sharpe.com

Registered: 2006 (19 years)

Introduction: Brown & Sharpe Screw Machine Tools, a division of Lester Detterbeck Enterprises Ltd, offers a variety of tool holders and accessories for automatic screw machines. Key products include: Box Tools with Carbide ‘V’ Rests, Roller Back Box Tools, Balance Turning Tools, Extended Roll Holders, Slide Tools for Turrets, Drilling and Chamfering Tools, Adjustable Tool Holders, Floating Adjusting Reamer Hold…

2. Tesa Brown & Sharpe – Height Gages

Domain: penntoolco.com

Registered: 1997 (28 years)

Introduction: TESA Brown & Sharpe manufactures high-quality precision measuring tools, specializing in height gages under the trade name Tesa-Hite. Founded in 1833, Brown & Sharpe became a leading manufacturer of precision measuring tools and machine tools, known for calipers and micrometers with exceptional tolerance. They were acquired by Hexagon Metrology in 2001 and continue to produce superior hand tools. …

3. Brown & Sharpe – Industrial Tools and Supplies

Domain: allindustrial.com

Registered: 2003 (22 years)

Introduction: Brown & Sharpe Products available at All Industrial Tool Supply include a wide range of tools and supplies such as abrasives (brushes, files, belts, discs), deburring tools, dressing tools, grinding wheels, honing and lapping tools, fasteners, electrical equipment, hand and power tools, pneumatic tools, holemaking tools, and various accessories. They offer free shipping on orders over $250 and pro…

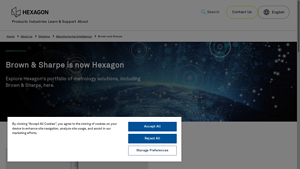

4. Brown and Sharpe – Automated Measurement & CAD/CAM Solutions

Domain: hexagon.com

Registered: 1993 (32 years)

Introduction: Brown and Sharpe offers a range of products including: 1. Automated measurement systems for future automated inspection. 2. CAD/CAM & production software for generating, managing, and optimizing CNC machining toolpaths. 3. CAE software for simulating product and process performance. 4. Coordinate measuring machines (CMMs) available in various accuracy levels. 5. Laser scanning technology for non-c…

5. Brown & Sharpe – Precision Tools and Measuring Instruments

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Brown & Sharpe products available for sale on eBay include a variety of precision tools and measuring instruments such as micrometers, calipers, indicators, squares, and gage sets. Notable items include the Brown & Sharpe No. 840 Joint Caliper/Divider Set, No. 736 Lathe Test Indicator Gauge, 599-579-5 Shockproof Stainless Dial Caliper, and various micrometer sets. Prices range from $2.99 for stick…

6. National Distribution – Brown & Sharpe Repair Parts

Domain: nationaldistribution.com

Registered: 1997 (28 years)

Introduction: Brown & Sharpe Repair Parts and Tooling offered by National Distribution, Inc. includes a complete line of tools, tool holders, work holding products, pumps, chains, and rebuild services. Key products include: Box Tool, Adjustable Tool, Drill & Reamer, Cut-off, Knurl, Tap, Collets, Pushers, and Masters Pads. Most parts can ship within 24 hours and come with a 100-percent Satisfaction Guarantee. Re…

7. Grainger – Precision Measuring Tools

Domain: grainger.com

Registered: 1994 (31 years)

Introduction: This company, Grainger – Precision Measuring Tools, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Brown & Sharpe – Precision Measurement Solutions

Domain: toolandgagehouse.com

Registered: 1999 (26 years)

Introduction: Brown & Sharpe brand has been synonymous with quality for over 150 years. It is a flagship brand of the Hexagon Metrology group. The product offerings include Coordinate Measuring Machines (CMMs), optical measuring systems, 1D, 2D, and 3D benchtop measuring machines, and precision hand tools. Key CMM series include the Global and ONE CMM series, manufactured in North Kingstown, Rhode Island, and Q…

9. Hobby Machinist – Brown & Sharpe Tooling

Domain: hobby-machinist.com

Registered: 2010 (15 years)

Introduction: Brown & Sharpe #10 arbor; BS#9 and BS#7 tooling; Endmills with rear threads for drawbar and flat Morse style tang; 7/8″ arbor bar; BS#10 to BS#7 adapter priced around $74; BS#10 reamer priced around $180; Availability of BS#9 and BS#7 collets from Little Machine Shop; Mention of tapered adapter modification for draw-bar threading.

Strategic Sourcing Conclusion and Outlook for brown & sharpe tooling

In conclusion, the strategic sourcing of Brown & Sharpe tooling offers unparalleled advantages for businesses seeking to enhance their manufacturing capabilities. With a legacy dating back to 1833, Brown & Sharpe has consistently set industry standards in quality and precision. Their diverse range of tooling solutions, from screw machine tools to precision measuring instruments, ensures that international buyers can find reliable products that meet specific operational requirements.

Investing in Brown & Sharpe tooling not only guarantees durability and repeatability but also aligns with the increasing demand for high-performance machinery in emerging markets across Africa, South America, the Middle East, and Europe. As companies navigate global supply chains, strategic sourcing becomes vital for optimizing production processes and reducing operational costs.

Looking ahead, international B2B buyers are encouraged to explore partnerships with Brown & Sharpe to leverage their innovative solutions and maintain a competitive edge. By prioritizing quality sourcing, businesses can enhance their operational efficiency and drive growth in an ever-evolving marketplace. Engage with Brown & Sharpe today to discover how their tooling solutions can elevate your production capabilities to new heights.