Introduction: Navigating the Global Market for brown and sharpe tools

In the competitive landscape of manufacturing, sourcing high-quality Brown and Sharpe tools is a critical challenge for B2B buyers. These precision tools have set industry standards since their inception in the 19th century, making them essential for businesses aiming to enhance productivity and accuracy. This comprehensive guide delves into the various types of Brown and Sharpe tools available, their applications across different sectors, and effective strategies for supplier vetting. Additionally, it provides insights into pricing structures and cost-saving tips tailored for international buyers.

For businesses operating in diverse markets across Africa, South America, the Middle East, and Europe, understanding the nuances of sourcing these tools can significantly impact operational efficiency. This guide empowers B2B buyers by offering actionable insights and best practices that facilitate informed purchasing decisions. By exploring the historical significance, technological advancements, and reliability of Brown and Sharpe tools, buyers can confidently navigate the global market, ensuring they select the right tools that align with their specific manufacturing needs.

Ultimately, this resource serves as a valuable tool for businesses looking to optimize their procurement processes and maintain a competitive edge in their respective industries.

Understanding brown and sharpe tools Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Precision Measuring Tools | High accuracy, durable construction, various types (calipers, micrometers) | Quality control, machining, fabrication | Pros: Exceptional accuracy, long-lasting; Cons: Higher initial investment. |

| Tool Holders | Designed for automatic screw machines, repeatable and durable | CNC machining, automated production | Pros: Reliable performance, versatile; Cons: Specific to machine types. |

| Balance Turning Tools | Features like instant blade setting, designed for precision turning | Turning operations, aerospace, automotive | Pros: Improved efficiency, precise settings; Cons: Requires skilled operators. |

| Adjustable Tool Holders | Versatile for various tool sizes, easy adjustments | Custom machining, prototype development | Pros: Flexibility in applications; Cons: Complexity in setup. |

| Drilling and Chamfering Tools | Specialized for drilling and edge finishing, high-quality materials | Metalworking, construction, assembly | Pros: Enhanced finishing quality; Cons: Limited to specific tasks. |

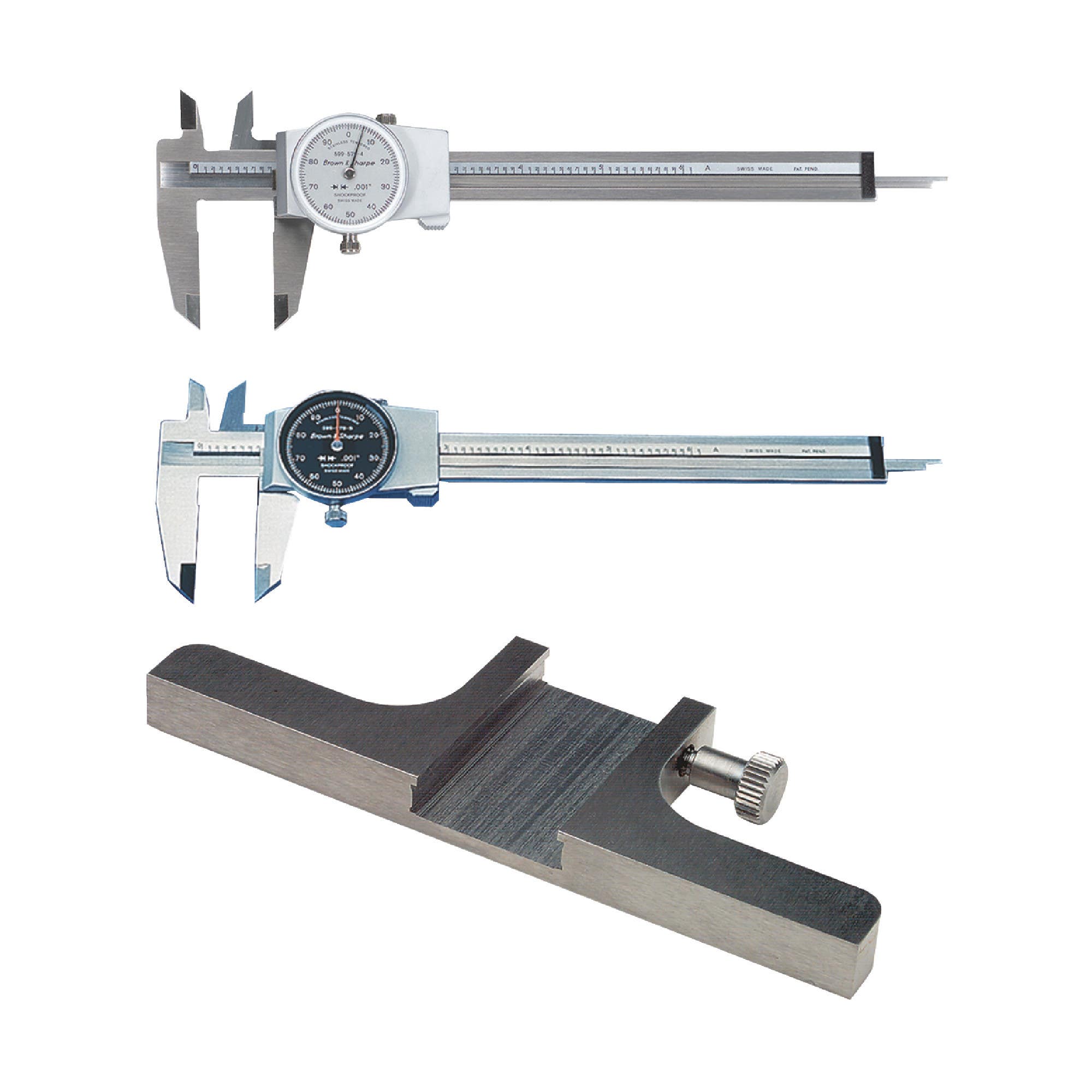

What Are the Key Characteristics of Precision Measuring Tools?

Precision measuring tools from Brown & Sharpe are designed to deliver exceptional accuracy and reliability, making them indispensable in quality control and machining applications. These tools include calipers, micrometers, and height gauges, often constructed with advanced materials to ensure durability. B2B buyers should consider the specific tolerance requirements of their projects, as the investment in high-quality measuring tools can significantly enhance the precision of their operations, ultimately leading to reduced waste and improved product quality.

How Do Tool Holders Enhance Production Efficiency?

Brown & Sharpe tool holders are engineered for automatic screw machines, providing repeatability and durability that are crucial in high-volume production environments. These holders are compatible with a variety of machines, making them a versatile choice for manufacturers. When purchasing, B2B buyers should evaluate the compatibility of tool holders with their existing machinery and consider the long-term benefits of reduced downtime and maintenance costs associated with reliable tool holders.

What Benefits Do Balance Turning Tools Offer?

Balance turning tools are designed for precision turning operations, featuring innovations such as instant blade settings that allow for quick adjustments. These tools are particularly beneficial in industries like aerospace and automotive, where precision is paramount. When considering these tools, B2B buyers should assess their operational efficiency and the skill level required for their workforce, as these tools can significantly improve productivity but may necessitate additional training.

Why Choose Adjustable Tool Holders?

Adjustable tool holders provide B2B buyers with the flexibility to accommodate various tool sizes and types, making them ideal for custom machining and prototype development. Their ease of adjustment can lead to increased productivity by reducing setup times. However, buyers should be aware of the potential complexity in setup and the need for skilled personnel to maximize the benefits of these tools.

What Are the Advantages of Drilling and Chamfering Tools?

Drilling and chamfering tools from Brown & Sharpe are crafted for specific tasks, ensuring high-quality finishes on drilled holes and edges. These tools are essential in metalworking and construction applications where precision and durability are critical. B2B buyers should evaluate the specific applications for which they need these tools, considering the balance between quality and cost to ensure they meet their production needs effectively.

Key Industrial Applications of brown and sharpe tools

| Industry/Sector | Specific Application of brown and sharpe tools | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision measuring tools for component manufacturing | Ensures high accuracy in components, critical for safety and performance | Certification compliance, durability under extreme conditions |

| Automotive | Tool holders and turning tools for part production | Increases efficiency and reduces waste during mass production | Compatibility with existing machinery, quick delivery times |

| Medical Devices | Calipers and micrometers for device calibration | Guarantees precision in life-saving devices | Regulatory compliance, long-term reliability |

| Industrial Manufacturing | Automatic screw machines for high-volume production | Enhances production speed and reduces labor costs | Support for maintenance and training, availability of spare parts |

| Electronics | Measuring tools for PCB and component assembly | Improves quality control and reduces defects | Precision specifications, supplier reliability, and after-sales support |

How Are Brown and Sharpe Tools Used in the Aerospace Industry?

In the aerospace sector, Brown and Sharpe precision measuring tools are essential for manufacturing aircraft components. These tools provide the high accuracy required for safety-critical parts, ensuring compliance with stringent industry standards. Buyers in this sector must consider sourcing tools that meet specific certifications and can withstand extreme environmental conditions, such as temperature fluctuations and vibrations.

What Role Do Brown and Sharpe Tools Play in Automotive Manufacturing?

Automotive manufacturers utilize Brown and Sharpe tool holders and turning tools to enhance the efficiency of part production. These tools are designed for automatic screw machines, significantly increasing throughput while minimizing waste. B2B buyers should prioritize compatibility with existing machinery and ensure quick delivery times to maintain production schedules.

Why Are Brown and Sharpe Tools Critical for Medical Device Calibration?

In the medical device industry, precision is paramount. Brown and Sharpe calipers and micrometers are used to calibrate devices, ensuring they meet the necessary accuracy for life-saving applications. For international buyers, understanding regulatory compliance and seeking tools that offer long-term reliability is crucial to avoid costly recalls or failures.

How Do Brown and Sharpe Tools Enhance Industrial Manufacturing?

Brown and Sharpe automatic screw machines are widely used in industrial manufacturing for high-volume production. These machines streamline operations, leading to significant labor cost reductions and enhanced production speeds. Buyers should consider the availability of maintenance support and spare parts to ensure uninterrupted operations.

What Benefits Do Brown and Sharpe Measuring Tools Offer in Electronics?

In the electronics industry, precision measuring tools from Brown and Sharpe are vital for quality control during PCB and component assembly. These tools help reduce defects and ensure that products meet rigorous quality standards. B2B buyers should focus on precise specifications and the reliability of suppliers, along with after-sales support to maintain their operations effectively.

3 Common User Pain Points for ‘brown and sharpe tools’ & Their Solutions

Scenario 1: Sourcing High-Quality Precision Tools in Emerging Markets

The Problem: B2B buyers in regions such as Africa and South America often struggle to find reliable suppliers of precision measuring tools like those from Brown & Sharpe. With limited access to international shipping and high shipping costs, sourcing these tools can become a logistical nightmare. Additionally, the risk of counterfeit products looms large, leading to concerns about the quality and reliability of tools that are essential for ensuring accurate measurements in manufacturing processes.

The Solution: To mitigate these challenges, buyers should prioritize establishing relationships with authorized distributors of Brown & Sharpe tools. Research local suppliers that have established connections with the brand or its parent company, Hexagon Manufacturing Intelligence. Engage in direct communication with these distributors to confirm their credentials and ask for references from other businesses in your region. Additionally, consider utilizing online marketplaces that verify seller authenticity and offer buyer protection policies. By sourcing from reputable distributors, buyers can ensure they receive genuine products while also minimizing shipping costs and delays.

Scenario 2: Overcoming Calibration and Maintenance Challenges

The Problem: Precision tools require regular calibration and maintenance to ensure they perform at their best. B2B buyers may find themselves overwhelmed by the technical specifications and maintenance requirements of Brown & Sharpe tools, leading to reduced tool lifespan and inaccurate measurements. This situation can result in costly production errors, wasted materials, and delays in project timelines.

The Solution: To address calibration and maintenance issues, businesses should implement a systematic maintenance schedule that includes regular checks and recalibrations of their Brown & Sharpe tools. Investing in training for staff on how to properly maintain and calibrate these tools can significantly improve accuracy and prolong their usability. Additionally, consider partnering with service providers who specialize in precision tool maintenance. These providers can offer on-site calibration services and ensure that tools are always operating within specified tolerances, thus reducing the risk of errors and enhancing overall production efficiency.

Scenario 3: Navigating the Complexity of Tool Selection

The Problem: With a wide array of Brown & Sharpe tools available, B2B buyers often face the challenge of selecting the right tools for their specific applications. Misunderstanding tool specifications or using inappropriate tools can lead to inefficiencies, increased production costs, and subpar product quality. This is particularly critical for companies in competitive markets where precision and efficiency are paramount.

The Solution: To streamline the tool selection process, buyers should begin by conducting a thorough needs assessment that considers the specific applications and materials involved in their operations. Utilize Brown & Sharpe’s extensive catalog and technical resources, which provide detailed specifications and application guidelines for each tool. Additionally, engage with technical support teams or product specialists from Brown & Sharpe or their authorized distributors, who can provide tailored advice based on industry-specific requirements. Participating in industry forums or workshops can also provide insights into best practices for tool selection, helping businesses make informed decisions that enhance productivity and quality.

Strategic Material Selection Guide for brown and sharpe tools

What Are the Key Materials Used in Brown and Sharpe Tools?

When selecting Brown and Sharpe tools, understanding the materials used in their construction is crucial for ensuring optimal performance and longevity. Here, we analyze four common materials: High-Speed Steel (HSS), Carbide, Stainless Steel, and Aluminum. Each material has unique properties, advantages, and limitations that can significantly impact their application in various industrial contexts.

How Does High-Speed Steel (HSS) Benefit Tool Performance?

High-Speed Steel is renowned for its excellent hardness and ability to withstand high temperatures without losing its edge. This material typically has a temperature rating of up to 600°C, making it suitable for high-speed machining applications. HSS tools are also relatively easy to manufacture, which can reduce lead times in production.

Pros: HSS offers good durability and is cost-effective compared to other materials. It is versatile, making it suitable for a wide range of applications, including drilling, milling, and turning.

Cons: While HSS is durable, it is less resistant to wear compared to carbide. Additionally, it may require more frequent sharpening, which can increase maintenance costs.

Impact on Application: HSS is compatible with various media, including metals and plastics, making it a popular choice for general-purpose machining.

Considerations for International Buyers: Buyers from regions like Europe and South America should ensure compliance with ASTM standards for tool materials. HSS tools are widely accepted and have established performance benchmarks globally.

What Advantages Does Carbide Offer for Precision Tools?

Carbide is a composite material that combines carbon and tungsten, known for its exceptional hardness and wear resistance. Carbide tools can withstand temperatures exceeding 1000°C, making them ideal for high-performance applications.

Pros: The primary advantage of carbide is its ability to maintain sharpness longer than HSS, resulting in reduced downtime for tool changes. Carbide tools also provide superior performance in high-speed applications.

Cons: Carbide is more expensive than HSS, and its brittleness can make it prone to chipping under heavy loads. This requires careful handling during manufacturing and use.

Impact on Application: Carbide is particularly effective in machining hard materials, such as stainless steel and titanium, which are prevalent in aerospace and automotive industries.

Considerations for International Buyers: Buyers in Africa and the Middle East should be aware of local standards for carbide tools and their specific applications in industries like oil and gas, where durability is paramount.

How Does Stainless Steel Enhance Tool Durability?

Stainless Steel is known for its corrosion resistance and strength, making it a suitable choice for tools exposed to harsh environments. It typically has a pressure rating suitable for moderate applications and is less prone to rusting compared to carbon steel.

Pros: The corrosion resistance of stainless steel makes it ideal for applications in wet or chemically aggressive environments. It also offers good mechanical properties and is relatively easy to machine.

Cons: While stainless steel is durable, it is generally more expensive than carbon steel and may not perform as well in high-temperature applications compared to HSS or carbide.

Impact on Application: Stainless steel tools are commonly used in food processing and pharmaceutical industries where hygiene is critical.

Considerations for International Buyers: Compliance with local regulations regarding material safety, particularly in Europe (e.g., EU food safety standards), is essential for buyers in these sectors.

Why Is Aluminum a Popular Choice for Tool Holders?

Aluminum is lightweight yet strong, making it an attractive option for tool holders and fixtures. Its thermal conductivity is excellent, allowing for efficient heat dissipation during machining processes.

Pros: The lightweight nature of aluminum reduces the overall weight of tooling systems, improving handling and reducing wear on machine components. It is also cost-effective for large production runs.

Cons: Aluminum is less durable than steel and can deform under high stress, limiting its use in heavy-duty applications.

Impact on Application: Aluminum is frequently used in non-critical applications where weight savings are crucial, such as in the aerospace industry for tool holders.

Considerations for International Buyers: Buyers should consider local manufacturing capabilities and standards (like DIN) when sourcing aluminum tools, especially in regions with stringent material specifications.

Summary Table of Material Selection for Brown and Sharpe Tools

| Material | Typical Use Case for brown and sharpe tools | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High-Speed Steel | General-purpose machining | Cost-effective and versatile | Requires frequent sharpening | Medium |

| Carbide | High-performance machining | Superior wear resistance | Brittle and more expensive | High |

| Stainless Steel | Food processing and pharmaceutical tools | Corrosion-resistant | More expensive than carbon steel | Medium |

| Aluminum | Tool holders and fixtures | Lightweight and cost-effective | Less durable under heavy loads | Low |

This guide provides a comprehensive overview of the materials commonly used in Brown and Sharpe tools, helping international B2B buyers make informed decisions based on their specific needs and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for brown and sharpe tools

What Are the Main Stages in the Manufacturing Process for Brown & Sharpe Tools?

The manufacturing of Brown & Sharpe tools is a meticulous process that ensures precision and quality at every stage. The primary stages include:

Material Preparation

The journey of creating high-quality tools begins with the selection of raw materials. Brown & Sharpe employs premium-grade steel and advanced alloys that provide the necessary durability and hardness for machining. During this stage, materials are inspected for defects, ensuring that only the best materials proceed to the next phase. This initial quality check lays the foundation for the performance and longevity of the tools.

Forming Techniques

Once the materials are prepared, they undergo various forming techniques. This may include processes such as forging, machining, and grinding. For instance, machining involves the use of CNC (Computer Numerical Control) machines that precisely cut and shape materials according to exact specifications. Brown & Sharpe utilizes state-of-the-art technology to enhance accuracy and reduce production time, thus maintaining a competitive edge in the market.

Assembly

After forming, the next phase is assembly. This involves the integration of various components, such as tool holders, cutting edges, and measuring instruments. Skilled technicians meticulously assemble these components, ensuring that they fit together seamlessly. This stage is critical, as improper assembly can lead to tool malfunction or inaccuracies during operation.

Finishing

The final stage of manufacturing is finishing, which includes processes such as coating, polishing, and quality inspection. Tools may receive surface treatments to enhance wear resistance or corrosion protection, ensuring they can withstand harsh working environments. This finishing touch not only improves aesthetics but also significantly boosts the functional lifespan of the tools.

How is Quality Assurance Implemented in the Manufacturing of Brown & Sharpe Tools?

Quality assurance (QA) is integral to the manufacturing process, ensuring that every tool meets stringent performance standards. Brown & Sharpe adheres to several international and industry-specific standards to maintain its reputation for quality.

What International Standards Are Followed for Quality Assurance?

Brown & Sharpe is compliant with ISO 9001, a globally recognized standard that outlines the requirements for a quality management system (QMS). This certification indicates that the company maintains consistent quality in its products and processes. Additionally, tools may also comply with CE marking standards, particularly for the European market, ensuring they meet safety and environmental requirements.

What Are the Key Quality Control Checkpoints?

Brown & Sharpe implements multiple quality control (QC) checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint assesses raw materials before production begins. It ensures that all materials meet predefined specifications and standards.

-

In-Process Quality Control (IPQC): During the manufacturing stages, regular checks are performed to monitor the quality of the tools. This includes dimensional checks and functional testing of components.

-

Final Quality Control (FQC): After assembly, each tool undergoes rigorous testing to verify its performance and accuracy. This may involve calibration against precise measuring instruments.

What Common Testing Methods Are Employed for Quality Assurance?

Brown & Sharpe utilizes a variety of testing methods to ensure the quality of its tools:

-

Calibration Testing: Ensures that measuring tools such as micrometers and calipers provide accurate readings. This is essential for precision applications where even minor discrepancies can lead to significant errors.

-

Durability Testing: Tools undergo stress tests to evaluate their performance under extreme conditions. This helps identify any potential weaknesses before the tools are released to the market.

-

Functional Testing: Each tool is tested for its intended function, ensuring that it performs as expected in real-world applications.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, particularly those operating in international markets such as Africa, South America, the Middle East, and Europe, should consider several strategies to verify the quality control practices of their suppliers:

Conducting Supplier Audits

Regular audits of suppliers can provide insights into their manufacturing processes and quality assurance practices. Buyers should inquire about the frequency and scope of these audits, as well as the methodologies used to assess compliance with quality standards.

Requesting Quality Assurance Reports

Buyers can request detailed quality assurance reports from suppliers, which should outline the results of various tests conducted on the tools. These reports serve as documentation of the supplier’s commitment to quality and can provide reassurance regarding the reliability of the products.

Engaging Third-Party Inspectors

Utilizing third-party inspection services can offer an unbiased assessment of a supplier’s quality control processes. These inspectors can conduct on-site evaluations and testing, ensuring that the tools meet the required specifications before they are shipped.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate additional complexities when it comes to quality control. Understanding the specific regulations and standards required in their respective markets is crucial. For instance:

-

Regional Compliance: Buyers in Europe must ensure that tools comply with CE marking requirements, while those in the Middle East may need to adhere to local certification standards.

-

Cultural Considerations: Different regions may have varying expectations regarding quality and reliability. Buyers should familiarize themselves with these cultural nuances to effectively communicate their quality requirements to suppliers.

-

Logistical Challenges: International shipping can introduce risks to product integrity. Buyers should ensure that suppliers implement adequate packaging and handling procedures to mitigate damage during transit.

In conclusion, understanding the manufacturing processes and quality assurance protocols of Brown & Sharpe tools is vital for B2B buyers seeking reliable and high-quality products. By following the outlined strategies for verifying supplier quality control, buyers can make informed decisions that align with their operational needs and market standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘brown and sharpe tools’

Introduction

This practical sourcing guide is designed to assist B2B buyers in effectively procuring Brown and Sharpe tools, renowned for their precision and durability in machining applications. By following this step-by-step checklist, you can ensure that your procurement process is efficient, cost-effective, and aligned with your operational needs.

Step 1: Define Your Technical Specifications

Clearly outline the specific tools you need based on your operational requirements. This includes identifying the type of Brown and Sharpe tools such as micrometers, calipers, or screw machine tools. Detailed specifications help in communicating your needs to suppliers and ensure you receive the right products for your applications.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in Brown and Sharpe tools. Look for suppliers with a strong reputation and extensive experience in the industry. Utilize online directories, trade shows, and industry forums to gather information and reviews on potential suppliers.

Step 3: Evaluate Supplier Certifications

Before making a decision, verify that potential suppliers hold relevant certifications. This includes ISO certifications, which indicate compliance with international quality standards. Such certifications are essential as they demonstrate a supplier’s commitment to quality and reliability, reducing the risk of subpar products.

Step 4: Request Product Samples

Whenever possible, request samples of the specific Brown and Sharpe tools you intend to purchase. This allows you to assess the quality and performance of the tools firsthand. Pay attention to the materials used, craftsmanship, and any unique features that may enhance usability in your operations.

Step 5: Assess Pricing and Payment Terms

Collect and compare pricing from multiple suppliers to ensure you are getting a competitive deal. Be aware of the total cost of ownership, including shipping and potential import duties. Additionally, inquire about payment terms to understand the financial implications and flexibility offered by each supplier.

Step 6: Check After-Sales Support and Warranty

Evaluate the after-sales support and warranty options provided by suppliers. Reliable customer service is crucial for addressing any issues that may arise post-purchase. Understand the warranty terms, including coverage duration and what it entails, as this can significantly impact your long-term satisfaction with the tools.

Step 7: Finalize Your Order

Once you have conducted your evaluations and are satisfied with a supplier, proceed to finalize your order. Ensure that all terms, including delivery timelines and quantities, are clearly outlined in the purchase agreement. Maintain open communication with the supplier to ensure a smooth transaction and timely delivery of your Brown and Sharpe tools.

By following these steps, you can streamline your procurement process and secure high-quality Brown and Sharpe tools that meet your business needs.

Comprehensive Cost and Pricing Analysis for brown and sharpe tools Sourcing

What Are the Key Cost Components Involved in Sourcing Brown and Sharpe Tools?

When sourcing Brown and Sharpe tools, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: High-quality materials such as high-speed steel and carbide are essential for durability and performance. The cost of these materials can fluctuate based on market demand and availability.

-

Labor: Skilled labor is required for the precision manufacturing of tools. Labor costs can vary significantly based on geographic location and local wage standards.

-

Manufacturing Overhead: This encompasses expenses related to utilities, maintenance of machinery, and facility costs. Manufacturers with advanced machinery may have higher overheads but can produce tools with greater precision.

-

Tooling: The initial investment in tooling can be significant, especially for custom or specialized tools. However, effective tooling can lead to lower per-unit costs in high-volume orders.

-

Quality Control (QC): Given the precision required for Brown and Sharpe tools, investing in rigorous QC processes is critical. This may involve both in-house testing and third-party certifications.

-

Logistics: Shipping costs can be substantial, especially for international transactions. Factors like distance, mode of transport, and customs duties must be considered.

-

Margin: Suppliers will typically add a margin that reflects their operational costs and desired profit levels, which can vary widely between manufacturers.

How Do Price Influencers Affect the Cost of Brown and Sharpe Tools?

Several factors influence the pricing of Brown and Sharpe tools, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for discounts, making it more cost-effective for buyers who can commit to higher volumes.

-

Specifications and Customization: Customized tools that meet specific buyer requirements can incur additional costs. Standard products tend to be more competitively priced.

-

Materials: The choice of materials significantly impacts the price. Premium materials yield better performance but at a higher cost.

-

Quality Certifications: Tools that come with certifications (e.g., ISO standards) may be priced higher due to the assurance of quality and reliability.

-

Supplier Factors: Different suppliers may have varying pricing strategies based on their market positioning and brand reputation. It’s essential to evaluate the supplier’s background and reliability.

-

Incoterms: The agreed-upon Incoterms (International Commercial Terms) can affect pricing. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears shipping costs and risk, influencing the final price.

What Tips Can Buyers Use to Negotiate Better Pricing for Brown and Sharpe Tools?

To enhance cost-efficiency and secure favorable pricing, international B2B buyers can consider the following strategies:

-

Negotiate Volume Discounts: Expressing intent for bulk orders can lead to better pricing. Suppliers are often willing to negotiate on larger quantities.

-

Assess Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, operational costs, and potential downtime. A tool with a higher upfront cost may offer lower TCO due to durability and reliability.

-

Understand Pricing Nuances for International Transactions: Currency fluctuations and international shipping costs can affect pricing. Buyers should factor these elements into their overall budget.

-

Build Long-term Relationships: Establishing a strong relationship with suppliers can lead to better terms and priority in production schedules. Trust and reliability often translate into better pricing.

-

Leverage Market Intelligence: Conduct research on market trends, competitor pricing, and supplier performance. Being well-informed empowers buyers during negotiations.

Final Note on Pricing Indications

While the above insights provide a comprehensive framework for understanding the costs associated with sourcing Brown and Sharpe tools, actual pricing can vary based on the specific context and market conditions. Buyers should seek detailed quotations and consider all influencing factors before making procurement decisions.

Alternatives Analysis: Comparing brown and sharpe tools With Other Solutions

Understanding Alternatives to Brown and Sharpe Tools

In the competitive landscape of precision measuring and machining tools, understanding alternatives to established brands like Brown and Sharpe is crucial for B2B buyers. Companies often seek solutions that not only meet their operational needs but also provide a balance of performance, cost-effectiveness, and ease of use. Below, we compare Brown and Sharpe tools with two viable alternatives: TESA measuring tools and Mitutoyo precision instruments.

| Comparison Aspect | Brown And Sharpe Tools | TESA Measuring Tools | Mitutoyo Precision Instruments |

|---|---|---|---|

| Performance | High precision, industry standards | Advanced technology, precision gages | Renowned for accuracy and reliability |

| Cost | Mid to high range | Generally high due to technology | Competitive, varies by product line |

| Ease of Implementation | User-friendly, requires minimal training | Moderate; some products may need training | Intuitive, with extensive manuals available |

| Maintenance | Low; durable and reliable | Moderate; some calibration needed | Low; robust design with long life expectancy |

| Best Use Case | General machining and manufacturing | High-tech industries, aerospace | Versatile; suitable for various industries |

What Are the Advantages and Disadvantages of TESA Measuring Tools?

TESA measuring tools, particularly their Tesa-Hite height gauges, are known for their advanced technology and precision. They are particularly favored in high-tech industries like aerospace and automotive due to their ability to deliver exact measurements. However, TESA products tend to be on the higher end of the price spectrum, which may not fit every company’s budget. Additionally, while they are user-friendly, some products may require additional training for optimal use, which could delay implementation.

How Do Mitutoyo Precision Instruments Compare?

Mitutoyo is another strong contender in the precision tools market, known for its extensive product range, including calipers, micrometers, and gauges. These instruments are celebrated for their accuracy and reliability, making them suitable for various applications across multiple industries. Mitutoyo products are generally competitively priced, offering value for money without compromising on quality. However, some users may find their extensive manuals and product variety overwhelming, requiring additional time to identify the best tools for their specific needs.

How Can B2B Buyers Choose the Right Solution?

When selecting precision tools, B2B buyers should consider factors such as the specific requirements of their operations, budget constraints, and the level of technical expertise within their teams. Brown and Sharpe tools offer a long-standing reputation for durability and precision, making them a solid choice for traditional machining tasks. TESA tools excel in high-tech environments where advanced features are essential, while Mitutoyo provides a versatile range of instruments at competitive prices. Ultimately, the right choice will depend on the unique needs and priorities of the organization, ensuring that the selected tools align with operational goals and enhance productivity.

Essential Technical Properties and Trade Terminology for brown and sharpe tools

What Are the Key Technical Properties of Brown and Sharpe Tools?

Understanding the technical properties of Brown and Sharpe tools is crucial for B2B buyers seeking reliability and precision in their manufacturing processes. Here are some critical specifications to consider:

-

Material Grade

Brown and Sharpe tools are often made from high-speed steel (HSS) or carbide. HSS offers excellent toughness and wear resistance, making it suitable for high-speed applications, while carbide provides superior hardness and wear resistance, ideal for high-volume production. Selecting the right material impacts tool longevity and performance, directly influencing operational efficiency. -

Tolerance

Tolerance refers to the allowable variation in a tool’s dimensions. Brown and Sharpe tools are renowned for their tight tolerances, often within ±0.001 inches. This precision is vital for ensuring that components fit together correctly, reducing waste and rework, which can significantly lower production costs. -

Durability Rating

The durability of Brown and Sharpe tools is a key selling point. These tools are engineered for repeated use under rigorous conditions, which minimizes downtime and maintenance costs. A higher durability rating means tools can withstand more cycles before needing replacement, enhancing overall productivity. -

Repeatability

Repeatability refers to the tool’s ability to produce the same result multiple times. Brown and Sharpe tools are designed for high repeatability, ensuring consistent quality across production runs. This is particularly important for businesses that rely on mass production, as it leads to uniformity and customer satisfaction. -

Cutting Edge Geometry

The design of the cutting edge affects the tool’s performance, including its ability to cut through various materials. Brown and Sharpe tools feature optimized geometries that enhance chip removal and reduce cutting forces, resulting in smoother finishes and longer tool life. -

Heat Treatment Process

Heat treatment enhances the mechanical properties of the tool materials, improving hardness and resistance to wear. Understanding the heat treatment process used in Brown and Sharpe tools can help buyers assess their suitability for specific applications, especially in high-temperature environments.

What Are Common Trade Terminology and Jargon Related to Brown and Sharpe Tools?

Familiarity with industry terminology can streamline communication and enhance negotiations. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For buyers, understanding whether Brown and Sharpe tools are OEM products can be critical for ensuring compatibility and quality in their machinery. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ for Brown and Sharpe tools helps buyers plan their budgets and inventory levels effectively, especially when dealing with international suppliers. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For buyers, issuing an RFQ for Brown and Sharpe tools can facilitate better pricing and service terms, ensuring they get the best value for their investment. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is essential for B2B buyers to understand shipping costs and risks when importing Brown and Sharpe tools. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. In the context of Brown and Sharpe tools, knowing the lead time helps businesses plan their production schedules and avoid delays in their operations. -

Calibration

Calibration is the process of configuring a measuring instrument to provide accurate measurements. Understanding the calibration requirements for precision tools like those from Brown and Sharpe is crucial for maintaining measurement accuracy and compliance with industry standards.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing Brown and Sharpe tools, ultimately enhancing their manufacturing capabilities.

Navigating Market Dynamics and Sourcing Trends in the brown and sharpe tools Sector

What are the Key Trends Influencing the Brown and Sharpe Tools Market?

The global market for Brown and Sharpe tools is driven by several factors, including technological advancements, increasing demand for precision engineering, and the rise of automation in manufacturing. Emerging technologies such as IoT and AI are reshaping the landscape, enabling real-time monitoring and predictive maintenance, which enhance operational efficiencies for B2B buyers. Additionally, the trend towards Industry 4.0 is pushing manufacturers to adopt smart tools that can be seamlessly integrated into automated production lines.

International buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly focused on sourcing tools that not only meet quality standards but also offer competitive pricing and after-sales support. As global supply chains become more interconnected, the ability to quickly adapt to changes—such as fluctuations in material costs or trade tariffs—has become essential. For example, manufacturers in Germany and Brazil are investing in tools that support lean manufacturing principles, which streamline operations and reduce waste.

Furthermore, the rising importance of digital platforms for sourcing tools cannot be overlooked. Buyers are leveraging e-commerce solutions to compare products, read reviews, and negotiate prices, thus ensuring they make informed purchasing decisions. This shift towards digital sourcing is particularly pronounced in regions like the Middle East, where businesses are rapidly adopting e-commerce to access global suppliers.

How is Sustainability Influencing Sourcing Decisions in the Brown and Sharpe Tools Sector?

Sustainability has become a crucial factor in the sourcing of Brown and Sharpe tools, with an increasing emphasis on minimizing environmental impact. B2B buyers are now prioritizing suppliers that demonstrate a commitment to ethical sourcing practices and environmentally friendly manufacturing processes. This trend is particularly relevant in regions like Europe, where regulatory frameworks are pushing for greater accountability in supply chains.

The importance of ethical supply chains is underscored by the growing consumer demand for transparency. Buyers are keen on understanding the origins of materials used in tool production and the environmental certifications associated with them. Green certifications, such as ISO 14001, are becoming essential for manufacturers seeking to establish credibility in the market. These certifications not only assure buyers of reduced environmental impact but also enhance a company’s reputation.

Moreover, the adoption of eco-friendly materials in tool production is gaining traction. Innovations such as biodegradable lubricants and recyclable packaging are appealing to environmentally conscious buyers. As sustainability becomes a priority, it is clear that the ability to provide tools that align with these values will differentiate suppliers in the competitive landscape.

How Has the Brown and Sharpe Tools Industry Evolved Over Time?

Founded in 1833, Brown and Sharpe has a rich history that reflects the evolution of precision tooling and manufacturing. Initially recognized for pioneering screw machine technology, the company quickly became a leader in producing precision measuring tools, including micrometers and calipers. By the late 19th century, Brown and Sharpe had established itself as a dominant player, responsible for setting many industry standards that remain relevant today.

The company’s innovation continued through the 20th century, especially during World War II, when it supplied the U.S. Armed Forces with high-precision tools. Acquired by Hexagon Manufacturing Intelligence in 2001, Brown and Sharpe has since integrated cutting-edge technology into its product offerings, further solidifying its reputation for quality and reliability.

As the market continues to evolve, international B2B buyers can benefit from this legacy of innovation by sourcing tools that not only meet current manufacturing needs but also anticipate future demands in precision engineering and automation.

Frequently Asked Questions (FAQs) for B2B Buyers of brown and sharpe tools

-

How do I select the right Brown & Sharpe tools for my manufacturing needs?

When choosing Brown & Sharpe tools, assess your specific manufacturing requirements, such as the type of materials you work with and the precision needed for your operations. Consider the range of tools available, including micrometers, calipers, and tool holders, and how they align with your production processes. Additionally, consult with your team or a technical expert to ensure that the selected tools meet industry standards and can enhance your efficiency and accuracy. -

What is the best precision measuring tool for quality control in manufacturing?

For quality control, the Brown & Sharpe micrometers and calipers are highly regarded for their accuracy and reliability. The BesTest® Indicator is another excellent choice, offering a corrosion-resistant design and a constant rotation feature for ease of use. When selecting tools, ensure they are compatible with your existing equipment and can withstand the demands of your production environment to maintain consistent quality standards. -

What are the typical payment terms for purchasing Brown & Sharpe tools internationally?

Payment terms can vary based on the supplier and the region. Common practices include advance payment, letter of credit, or net 30-60 days after delivery. It’s essential to negotiate terms that suit your cash flow while ensuring security for both parties. Always confirm the accepted payment methods and any additional fees associated with international transactions, such as currency conversion or transfer costs. -

How can I verify the reliability of a supplier for Brown & Sharpe tools?

To vet a supplier, check their credentials, years in business, and customer reviews. Look for certifications or partnerships with recognized organizations in the industry, such as ISO certification. Request references from other clients, particularly those in your region, to gauge their experience. Additionally, consider conducting site visits or virtual meetings to discuss their capabilities and quality assurance processes. -

What are the minimum order quantities (MOQ) for Brown & Sharpe tools?

Minimum order quantities can vary significantly based on the specific product and supplier. Some suppliers may have a MOQ of a few units, while others might require larger orders to maintain cost-effectiveness. It’s advisable to communicate directly with suppliers to understand their MOQ policies and discuss your needs, especially if you require customization or specific tool configurations. -

Can I customize Brown & Sharpe tools to meet my specific requirements?

Many suppliers offer customization options for Brown & Sharpe tools, allowing you to tailor products to your manufacturing processes. This may include alterations in size, features, or packaging. Discuss your specific needs with the supplier, and inquire about any additional costs or lead times associated with custom orders to ensure they align with your production schedules. -

What logistics considerations should I keep in mind when importing Brown & Sharpe tools?

When importing tools, consider shipping methods, delivery times, and customs regulations in your country. Evaluate whether you need air or sea freight based on urgency and budget. It’s also crucial to understand the import duties and taxes that may apply, and to ensure that your supplier can provide the necessary documentation for customs clearance. Partnering with a reliable logistics provider can help streamline the process. -

What quality assurance measures should I expect from suppliers of Brown & Sharpe tools?

Reputable suppliers should have robust quality assurance protocols, including regular inspections and testing of tools before shipment. Look for suppliers that adhere to industry standards, such as ISO 9001, which ensures consistent quality management practices. Ask about their warranty policies and after-sales support to address any issues that may arise post-purchase, ensuring that you receive tools that meet your expectations for performance and durability.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Brown And Sharpe Tools Manufacturers & Suppliers List

1. Brown & Sharpe – Tool Holders and Accessories

Domain: brown-sharpe.com

Registered: 2006 (19 years)

Introduction: Brown & Sharpe Screw Machine Tools, a division of Lester Detterbeck Enterprises Ltd, offers a range of tool holders and accessories for automatic screw machines. Key products include: Box Tools with Carbide ‘V’ Rests, Roller Back Box Tools, Balance Turning Tools, Extended Roll Holders, Slide Tools for Turrets, Drilling and Chamfering Tools, Adjustable Tool Holders, Floating Adjusting Reamer Holder…

2. Tesa Brown & Sharpe – Height Gages

Domain: penntoolco.com

Registered: 1997 (28 years)

Introduction: TESA Brown & Sharpe manufactures high-quality precision measuring tools, specializing in height gages under the Tesa-Hite brand. Founded in 1833, Brown & Sharpe is one of the oldest manufacturers of precision measuring tools, known for innovative inventions like the screw machine. The company peaked during World War II, providing tools to the U.S. Armed Forces, and was acquired by Hexagon Metrolog…

3. Brown & Sharpe – Shockproof Stainless Dial Caliper

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Brown & Sharpe products available for sale on eBay include a variety of tools and equipment primarily used in metalworking and inspection. Key items include: 1. Brown & Sharpe 599-579-5 Shockproof Stainless Tempered Swiss Dial Caliper – Pre-Owned, priced at $55.00 with free shipping. 2. Other related searches include Brown and Sharpe Tools, Combination Squares, Calipers, Micrometers, and Indicator…

4. Grainger – Precision Measuring Tools

Domain: grainger.com

Registered: 1994 (31 years)

Introduction: This company, Grainger – Precision Measuring Tools, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Brown & Sharpe – Industrial Tools & Supplies

Domain: allindustrial.com

Registered: 2003 (22 years)

Introduction: Brown & Sharpe Products include a wide range of industrial tools and supplies such as abrasives (brushes, files, belts, discs), deburring tools, dressing tools, grinding wheels, honing and lapping tools, fasteners (bolts, screws, nuts), hydraulic systems, pneumatic tools, hand and power tools, holemaking tools, and various accessories. They offer free shipping on orders over $250 and provide optio…

6. TESA – Portable Quality Control Solutions

Domain: tesatechnology.com

Registered: 2014 (11 years)

Introduction: TESA µ-FINDER: SET 31 AND SET 22 – Combined solution for portable quality control including probe, display unit, and magnetic support. TESA INTRIMIK – Internal micrometer unaffected by temperature variations. TESA TWIN-T10 – Portable display for inductive probes, enabling sub-micron accuracy for CMM checks. New range of TESA dial gauges – Resolutions from 0.1 mm to 0.001 mm, measuring ranges up to…

7. MSC Direct – Test Indicator Contact Point

Domain: mscdirect.com

Registered: 1996 (29 years)

Introduction: This company, MSC Direct – Test Indicator Contact Point, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Brown & Sharpe – Digital Tool Set 00591007

Domain: willrich.com

Registered: 1998 (27 years)

Introduction: {“product_name”: “Brown & Sharpe Digital Tool Set 00591007”, “price”: “$469.00”, “components”: [{“name”: “Micromaster Micrometer”, “range”: “0-1.2\”/0-30mm”, “resolution”: “.00005\”/1μm”, “features”: [“Tungsten carbide anvil and spindle measuring faces”, “Absolute and differential modes”, “Spindle lock”, “Webbed thimble with slip friction drive”]}, {“name”: “Shop-Cal Digital Caliper”, “range”: “0…

Strategic Sourcing Conclusion and Outlook for brown and sharpe tools

How Can International B2B Buyers Leverage Brown and Sharpe Tools for Strategic Sourcing?

In conclusion, Brown and Sharpe tools stand as a hallmark of quality and precision in the manufacturing sector, dating back nearly two centuries. Their extensive range of products, from screw machine tools to precision measuring instruments, offers unparalleled reliability that international B2B buyers can trust. By prioritizing strategic sourcing, companies can optimize their procurement processes, ensuring they benefit from the durability and performance that Brown and Sharpe products are known for.

For buyers in Africa, South America, the Middle East, and Europe, leveraging these tools can lead to enhanced operational efficiencies and improved product quality. The global marketplace is increasingly competitive, and the right tools can be a decisive factor in maintaining an edge. As you consider your sourcing strategy, remember that investing in proven brands like Brown and Sharpe is not just a purchase; it’s a commitment to excellence.

As you move forward, explore partnerships that align with your business objectives. Engage with suppliers who can provide insights into the latest innovations from Brown and Sharpe. By doing so, you can ensure that your operations are equipped with the best tools available, driving your success in the evolving manufacturing landscape.