Introduction: Navigating the Global Market for bronze vs copper price

Navigating the complexities of sourcing bronze versus copper prices can be a daunting task for international B2B buyers. Fluctuating market conditions, varying compositions, and diverse applications create a landscape where informed purchasing decisions are essential. This comprehensive guide aims to demystify the pricing dynamics of these two critical metals, offering insights into their distinct properties, applications, and the nuances of supplier vetting.

Throughout this guide, we will explore the fundamental differences between bronze and copper, including their alloy compositions and the implications for cost. Buyers will gain a deeper understanding of how factors such as raw material costs, supply and demand dynamics, and manufacturing expenses affect pricing. Additionally, we will delve into the specific applications of bronze and copper across various industries, from construction to electronics, highlighting how these metals serve different needs.

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Brazil and Germany—this guide serves as an essential resource. By equipping you with actionable insights and strategies, we empower you to make informed decisions that align with your business goals. Understanding the intricacies of bronze and copper pricing not only enhances your purchasing strategy but also positions your business for success in an increasingly competitive global market.

Understanding bronze vs copper price Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Copper | Pure metal; excellent electrical and thermal conductivity | Electrical components, architecture | Pros: High conductivity; widely available. Cons: Prone to oxidation; higher cost compared to some alloys. |

| Tin Bronze | Alloy of copper and tin; good corrosion resistance | Marine applications, musical instruments | Pros: Durable; corrosion-resistant. Cons: Higher cost due to tin content; limited to specific applications. |

| Aluminum Bronze | Contains aluminum; strong and wear-resistant | Aerospace, marine hardware | Pros: High strength; excellent corrosion resistance. Cons: More expensive; requires specialized machining. |

| Silicon Bronze | Contains silicon; good weldability and formability | Welding applications, art, and sculptures | Pros: Good for welding; excellent corrosion resistance. Cons: Lower conductivity than pure copper; may be pricier. |

| Commercial Bronze | High copper content with zinc; versatile | Architectural fittings, plumbing | Pros: Cost-effective; versatile applications. Cons: Lower strength than some other alloys; may not be suitable for high-stress environments. |

What are the Key Characteristics of Copper for B2B Buyers?

Copper is a pure metal known for its exceptional electrical and thermal conductivity, making it essential in electrical components and architectural elements. Its availability is a significant advantage for buyers, as it is widely sourced globally. However, copper is susceptible to oxidation, which can affect its performance in specific applications. Buyers should consider the balance between cost and the necessary properties for their projects, particularly in industries where conductivity is paramount.

Why Choose Tin Bronze for Specific Applications?

Tin bronze is an alloy primarily composed of copper and tin, recognized for its durability and excellent corrosion resistance. This alloy is particularly suited for marine applications and musical instruments, where exposure to harsh environments is common. While the higher cost of tin can be a drawback, the longevity and reliability of tin bronze in demanding conditions often justify the investment. B2B buyers should evaluate the long-term benefits of using tin bronze against initial material costs.

What Makes Aluminum Bronze a Preferred Choice?

Aluminum bronze is characterized by its high strength and wear resistance, making it ideal for applications in aerospace and marine hardware. Its corrosion resistance is superior, particularly in seawater environments, which is critical for industries operating in such conditions. However, the processing of aluminum bronze can be more complex and costly than other materials. B2B buyers must assess the specific requirements of their applications to determine if the benefits outweigh the additional costs.

How Does Silicon Bronze Stand Out in Welding Applications?

Silicon bronze is known for its good weldability and formability, making it a popular choice in welding applications and artistic endeavors. It offers excellent corrosion resistance, which is beneficial for structures exposed to the elements. While it may be less conductive than pure copper, its welding properties and resistance to corrosion make it a valuable material for specific projects. Buyers should consider the welding characteristics and environmental factors when selecting silicon bronze for their applications.

Why is Commercial Bronze a Versatile Option?

Commercial bronze features a high copper content with zinc, providing a balance of strength and versatility for various applications, including architectural fittings and plumbing. This alloy is often more cost-effective than other bronze types, making it appealing for large-scale projects. However, it may not withstand high-stress environments as well as other specialized alloys. B2B buyers should evaluate their application needs and budget constraints when opting for commercial bronze.

Key Industrial Applications of bronze vs copper price

| Industry/Sector | Specific Application of bronze vs copper price | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electrical Manufacturing | Use of copper in wiring and electrical components | High conductivity reduces energy loss, enhancing efficiency | Assess global copper prices and availability; consider lead times for production and shipping. |

| Marine Engineering | Bronze components for ship propellers and fittings | Corrosion resistance extends lifespan and reduces maintenance | Evaluate bronze alloy grades for specific marine applications; prioritize suppliers with marine certifications. |

| Construction | Copper for roofing and plumbing systems | Durability and aesthetic appeal lead to long-term savings | Monitor fluctuations in copper prices; ensure compliance with local building codes and standards. |

| Art and Sculpture | Bronze for sculptures and decorative items | High value in artistic markets; enhances cultural significance | Source from reputable foundries; consider the impact of raw material prices on final artwork costs. |

| Renewable Energy | Copper in solar panel connections and energy systems | Essential for efficient energy transfer and system reliability | Focus on sustainable sourcing practices; assess the impact of copper price volatility on project budgets. |

How is ‘bronze vs copper price’ used in Electrical Manufacturing?

In the electrical manufacturing sector, copper is the preferred material for wiring and components due to its unmatched electrical conductivity. As energy efficiency becomes a priority, businesses rely on copper to minimize energy loss. However, international B2B buyers must stay informed about fluctuating copper prices, as these can significantly affect production costs. Suppliers should ensure timely delivery and quality assurance to maintain operational continuity.

What role does ‘bronze vs copper price’ play in Marine Engineering?

Marine engineering heavily utilizes bronze for components like ship propellers and fittings, primarily due to its superior corrosion resistance in saltwater environments. This characteristic extends the lifespan of marine equipment, reducing maintenance costs and downtime for businesses. B2B buyers should evaluate the specific bronze alloy grades suited for marine applications and prioritize suppliers with certifications that guarantee compliance with maritime standards.

Why is ‘bronze vs copper price’ critical in Construction?

In construction, copper is widely used for roofing and plumbing systems, valued for its durability and aesthetic appeal. The long lifespan of copper installations translates to cost savings over time. However, B2B buyers must monitor copper price fluctuations and ensure compliance with local building codes. Sourcing from reliable suppliers who can provide consistent quality and timely delivery is essential for project success.

How does ‘bronze vs copper price’ impact Art and Sculpture?

In the art and sculpture sector, bronze is favored for its aesthetic qualities and cultural significance. The price of bronze can directly affect the affordability of sculptures and decorative items, making it crucial for artists and galleries to understand the market dynamics. When sourcing bronze, buyers should work with reputable foundries to ensure quality and consider the impact of raw material prices on the final artwork costs.

What is the significance of ‘bronze vs copper price’ in Renewable Energy?

Copper plays a vital role in renewable energy systems, particularly in solar panel connections, due to its efficiency in energy transfer. As the demand for renewable energy grows, businesses must navigate the complexities of copper pricing, which can impact project budgets. B2B buyers should focus on sustainable sourcing practices and assess how fluctuations in copper prices could affect their overall project costs and timelines.

3 Common User Pain Points for ‘bronze vs copper price’ & Their Solutions

Scenario 1: Navigating Price Volatility in Copper and Bronze Markets

The Problem: B2B buyers, especially those in industries like construction and electronics, often face challenges stemming from the volatility of copper and bronze prices. Fluctuations in global markets, influenced by factors such as geopolitical tensions, mining strikes, and supply chain disruptions, can lead to sudden increases in costs. This unpredictability makes it difficult for buyers to budget and forecast expenses, potentially impacting project timelines and profitability.

The Solution: To mitigate the effects of price volatility, buyers should consider establishing long-term contracts with suppliers that include fixed pricing or pricing caps. This strategy can provide stability in budgeting and protect against unforeseen spikes in material costs. Additionally, buyers should actively monitor market trends and global economic indicators that may signal price changes. Utilizing tools such as price alerts from commodity exchanges or engaging in industry forums can offer insights into upcoming shifts, allowing for proactive purchasing decisions. Finally, diversifying sourcing strategies by incorporating recycled bronze materials when possible can also help stabilize costs while promoting sustainability.

Scenario 2: Understanding the Cost Implications of Alloy Composition

The Problem: Many buyers struggle to comprehend how the composition of bronze and copper alloys affects pricing, leading to confusion when selecting the appropriate material for their applications. For instance, buyers may mistakenly choose a lower-cost alloy without recognizing that it may lack the necessary properties for their intended use, resulting in increased costs over time due to failures or replacements.

The Solution: To address this issue, buyers should invest time in understanding the specific alloy grades and their respective properties. Collaborating with metallurgical experts can provide valuable insights into the implications of different compositions. Buyers should also leverage detailed specifications and application guidelines from suppliers to make informed decisions. Implementing a rigorous evaluation process for materials based on performance requirements rather than solely price will ensure that the selected alloys meet operational needs, ultimately leading to cost savings and enhanced product longevity.

Scenario 3: The Challenge of Supply Chain Disruptions Affecting Availability and Pricing

The Problem: International B2B buyers often encounter supply chain disruptions that lead to shortages of copper and bronze. Events such as natural disasters, trade disputes, or transportation issues can create significant delays and lead to inflated prices. This can halt production lines and jeopardize project deadlines, resulting in lost revenue and damaged client relationships.

The Solution: To combat supply chain vulnerabilities, buyers should develop a more resilient sourcing strategy. This includes identifying multiple suppliers across different geographical locations to reduce dependency on a single source. Establishing strong relationships with suppliers can also facilitate better communication regarding potential disruptions. Additionally, maintaining a strategic inventory of critical materials can buffer against short-term supply issues. Lastly, incorporating just-in-time inventory practices can optimize cash flow while ensuring that materials are available when needed. This proactive approach not only minimizes risk but also enhances overall operational efficiency.

Strategic Material Selection Guide for bronze vs copper price

What Are the Key Properties of Bronze and Copper for International B2B Buyers?

When assessing bronze and copper for B2B applications, understanding their key properties is essential. Bronze, primarily an alloy of copper and tin, exhibits superior corrosion resistance, making it ideal for marine and industrial applications. Its hardness, typically rated between 40-42 on the Brinell hardness scale, enhances its durability in demanding environments. Conversely, copper, with its unmatched electrical conductivity (100% standard), is preferred for electrical applications. However, it is less hard (35 on the Brinell scale) and more susceptible to corrosion, particularly in chlorinated environments.

What Are the Pros and Cons of Using Bronze and Copper in Manufacturing?

Bronze offers several advantages, including excellent wear resistance and a lower melting point than copper, which simplifies manufacturing processes. Its versatility allows for applications ranging from musical instruments to marine hardware. However, the complexity of alloying elements can lead to higher costs and manufacturing challenges.

Copper’s primary advantage lies in its superior electrical and thermal conductivity, making it the standard choice for electrical wiring and components. It is also more malleable, allowing for easier shaping and forming. Nevertheless, copper’s susceptibility to corrosion and higher price point compared to bronze can be significant drawbacks for certain applications.

How Do Bronze and Copper Impact Specific Applications?

In applications requiring high corrosion resistance, such as marine environments, bronze is often the material of choice. Its ability to withstand harsh conditions makes it suitable for components like propellers and bearings. Conversely, copper is favored in electrical applications due to its high conductivity, making it ideal for wiring and electronic components.

International B2B buyers should consider the specific media compatibility of these materials. For instance, bronze is not suitable for chlorine-rich environments, while copper can develop a protective patina that enhances its corrosion resistance in many situations.

What Should International B2B Buyers Consider When Choosing Between Bronze and Copper?

For international buyers, compliance with regional standards such as ASTM (American Society for Testing and Materials), DIN (Deutsches Institut für Normung), and JIS (Japanese Industrial Standards) is crucial. Buyers from Africa, South America, the Middle East, and Europe should also be aware of local preferences and availability of materials. For example, the European market may have stringent regulations regarding the use of certain alloys, while buyers in South America might prioritize cost-effectiveness due to budget constraints.

Additionally, fluctuations in raw material prices can significantly impact overall costs. Buyers should stay informed about market trends and consider sourcing strategies that include recycled materials, which can help stabilize prices.

| Material | Typical Use Case for bronze vs copper price | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Bronze | Marine hardware, musical instruments, industrial components | High corrosion resistance and durability | More complex alloying can lead to higher costs | Medium |

| Copper | Electrical wiring, electronic components, thermal applications | Superior electrical and thermal conductivity | Susceptible to corrosion in certain environments | High |

| Aluminum Bronze | Marine applications, aerospace components | Excellent corrosion resistance and strength | Higher cost compared to standard bronze | High |

| Leaded Bronze | Industrial machinery, bearings, bushings | Good machinability and wear resistance | Limited applications due to lead content restrictions | Medium |

This strategic material selection guide equips international B2B buyers with the insights needed to make informed decisions regarding bronze and copper pricing, ensuring they choose the right material for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for bronze vs copper price

What Are the Key Manufacturing Processes for Bronze and Copper?

Manufacturing bronze and copper involves several critical stages, each integral to ensuring the quality and performance of the final products. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Bronze and Copper Production?

The first step in the manufacturing process is material preparation, which involves sourcing high-quality raw materials. For bronze, this typically includes copper and tin, with potential additions of other alloying elements like aluminum or nickel depending on the desired properties. Copper, on the other hand, may be sourced in various grades, such as electrolytic or oxygen-free copper.

Once the materials are sourced, they undergo rigorous testing to ensure they meet the required specifications. This may include chemical composition analysis and mechanical property assessments to verify that the materials can achieve the desired performance in their intended applications.

What Forming Techniques Are Commonly Used in Bronze and Copper Manufacturing?

The next stage involves forming the prepared materials into desired shapes. Common techniques include:

-

Casting: Both bronze and copper can be cast into molds to create complex shapes. Bronze casting is particularly popular in artistic applications, such as sculptures, while copper casting is often used in industrial components.

-

Forging: This technique is often employed for copper, where the material is heated and shaped using compressive forces. Forging enhances the mechanical properties of copper, making it ideal for high-stress applications.

-

Extrusion: In this process, bronze and copper are forced through a die to create long shapes, such as rods or tubes. This method is efficient for producing consistent cross-sectional shapes and allows for precise control over dimensions.

-

Rolling: For both metals, rolling is a common technique that involves passing the material through rollers to produce sheets or strips. This method is particularly important in applications where thin, flat materials are required.

How Is Assembly Conducted in Bronze and Copper Production?

Assembly refers to the joining of various components to form a final product. For bronze, this may involve soldering or welding, particularly in applications like plumbing fixtures or marine hardware. Copper components are often assembled using similar methods but may also utilize mechanical fasteners due to their excellent ductility.

Quality assurance during the assembly stage is critical. Manufacturers often employ visual inspections and dimensional checks to ensure that components fit together correctly and meet design specifications.

What Finishing Techniques Are Applied to Bronze and Copper Products?

Finishing processes enhance the aesthetic and functional properties of the final products. Common finishing techniques include:

-

Polishing: This is crucial for applications where appearance matters, such as in decorative items or architectural features. Polishing removes surface imperfections and provides a high-gloss finish.

-

Coating: Applying protective coatings helps enhance corrosion resistance, especially for bronze products used in marine environments. Coatings can also improve the appearance and durability of copper products.

-

Heat Treatment: This process can be applied to both metals to improve mechanical properties like strength and hardness. Heat treatment involves heating the material to a specific temperature and then cooling it in a controlled manner.

What Quality Control Measures Are Essential for Bronze and Copper Manufacturing?

Quality control (QC) is paramount in ensuring that bronze and copper products meet international standards and customer expectations. The following outlines the key QC measures in the manufacturing process.

Which International Standards Are Relevant for Quality Assurance in Metal Manufacturing?

Compliance with international standards is crucial for manufacturers targeting global markets. ISO 9001 is a widely recognized quality management standard that helps organizations ensure consistent quality in their products and services. Additionally, industry-specific standards such as CE marking for products sold in Europe and API standards for oil and gas applications may also be relevant.

What Are the Key QC Checkpoints in the Manufacturing Process?

QC checkpoints are established at various stages of the manufacturing process to monitor quality effectively:

-

Incoming Quality Control (IQC): This initial phase involves inspecting raw materials upon receipt to verify they meet specifications. Any non-conforming materials are rejected or returned to the supplier.

-

In-Process Quality Control (IPQC): During the manufacturing stages, regular inspections are conducted to ensure that processes are followed correctly. This includes monitoring temperature, pressure, and other critical parameters during casting, forging, or extrusion.

-

Final Quality Control (FQC): Once the product is complete, a final inspection is performed. This includes dimensional checks, visual inspections, and functional tests to ensure the product meets all specifications before shipping.

What Common Testing Methods Are Used to Ensure Product Quality?

Manufacturers employ various testing methods to validate the quality of bronze and copper products:

-

Chemical Analysis: This determines the material composition to ensure compliance with specifications. Techniques such as spectroscopy are commonly used.

-

Mechanical Testing: Hardness tests, tensile tests, and impact tests assess the mechanical properties of the materials and finished products.

-

Non-Destructive Testing (NDT): Methods like ultrasonic testing or radiography are employed to detect internal defects without damaging the product.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control practices of suppliers is essential to ensure they receive high-quality products. Here are several strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and overall operational standards of their suppliers.

-

Reviewing Quality Reports: Requesting and reviewing quality control reports from suppliers can provide insights into their QC practices and any issues encountered during production.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s processes and products, ensuring they meet specified standards.

-

Certifications and Accreditations: Buyers should verify that suppliers hold relevant certifications, such as ISO 9001 or industry-specific certifications, which indicate a commitment to quality management.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing bronze and copper products internationally, buyers should be aware of potential quality control nuances. Cultural differences in manufacturing practices, varying standards of quality, and logistical challenges can affect the final product. Therefore, establishing clear communication channels and setting explicit quality expectations upfront is vital to mitigate risks and ensure satisfaction.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing bronze and copper products, ensuring they receive high-quality materials that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bronze vs copper price’

Introduction

Navigating the procurement of bronze and copper can be complex due to fluctuating prices and varying applications. This practical sourcing guide serves as a step-by-step checklist to help international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, make informed decisions when sourcing these metals. By following these steps, you can effectively evaluate prices, suppliers, and market conditions to secure the best deal for your needs.

Step 1: Define Your Technical Specifications

Clearly outline your requirements for bronze or copper, including alloy grades and intended applications. Specifications such as tensile strength, conductivity, and corrosion resistance will determine the appropriate grade for your project. Understanding these technical details will guide your sourcing process and ensure you select the right material for your specific needs.

Step 2: Research Current Market Prices

Stay updated on current market prices for both bronze and copper. Utilize reputable financial news sources, industry reports, and commodity exchanges to track price trends. Knowing the average costs will empower you to negotiate better deals and identify when prices are favorable for procurement.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your specifications and delivery timelines. Request company profiles, certifications, and references from previous clients in similar industries. A reliable supplier should have a proven track record and be able to provide quality assurance documentation.

- Consider certifications: Look for ISO certifications or industry-specific credentials that demonstrate compliance with international standards.

- Assess geographical advantages: Suppliers located closer to your operation may reduce shipping costs and lead times.

Step 4: Assess Supply Chain Reliability

Investigate the reliability of the supplier’s supply chain, especially considering potential disruptions. Factors such as geopolitical stability, mining operations, and transportation logistics can impact availability. Understanding these dynamics will help you mitigate risks associated with sourcing.

Step 5: Negotiate Pricing and Payment Terms

Engage in negotiations to secure favorable pricing and payment terms. Discuss bulk purchasing discounts, payment schedules, and potential for long-term contracts. Clear communication during this phase can lead to significant cost savings and better cash flow management.

Step 6: Consider Recycling Options

Evaluate the availability of recycled bronze and copper as a cost-effective and environmentally friendly alternative. The recycling market can offer competitive pricing and reduce reliance on newly mined materials. Ensure that recycled materials meet the same quality standards as newly produced metals.

- Inspect quality assurance: Verify that recycled materials come with certifications that confirm their quality and suitability for your applications.

Step 7: Monitor Industry Trends and Developments

Stay informed about industry trends that may influence the prices of bronze and copper. Factors such as technological advancements, changes in regulations, and global economic shifts can affect demand and pricing structures. Regularly reviewing these trends will help you adapt your procurement strategy as necessary.

By following this checklist, you will enhance your ability to make informed decisions when sourcing bronze and copper, ultimately leading to more effective procurement strategies for your business.

Comprehensive Cost and Pricing Analysis for bronze vs copper price Sourcing

When considering the cost structure and pricing analysis for sourcing bronze versus copper, several key components and influential factors come into play. Understanding these can aid international B2B buyers in making informed decisions that maximize value while minimizing costs.

What Are the Key Cost Components for Bronze and Copper?

-

Materials: The most significant cost driver for both bronze and copper is the raw material itself. Copper prices generally fluctuate due to global supply-demand dynamics, mining output, and geopolitical factors. Bronze, being an alloy primarily of copper and tin, inherits copper’s pricing volatility. The exact composition of the bronze alloy also influences its cost—higher tin content typically raises the price.

-

Labor and Manufacturing Overhead: Labor costs can vary based on geographic location, skill levels, and the complexity of the manufacturing processes involved. For both metals, labor-intensive operations such as smelting and alloying contribute significantly to overall costs. Manufacturing overhead, including utilities and equipment maintenance, is also a critical factor that impacts pricing.

-

Tooling and Quality Control (QC): Tooling costs are particularly relevant for custom bronze and copper products, where specialized molds or dies may be required. Quality control processes, essential for ensuring product specifications and compliance with industry standards, can also add to the cost structure. Certifications for quality assurance can further influence the pricing, especially in sectors where regulatory compliance is paramount.

-

Logistics: The logistics of transporting raw materials and finished products play a vital role in the overall cost. Factors such as distance, transportation modes, and associated tariffs or duties can significantly affect pricing, particularly for international transactions. Incoterms will dictate responsibilities for shipping, insurance, and customs, further impacting total costs.

-

Margin: Supplier margins vary widely based on market conditions, competition, and the uniqueness of the product offering. Buyers should be aware of these margins when negotiating prices, as they can represent a significant percentage of the total cost.

How Do Price Influencers Affect Bronze and Copper Costs?

-

Volume and Minimum Order Quantity (MOQ): Pricing often scales with order volume; larger orders typically benefit from lower per-unit costs. Understanding the MOQ set by suppliers can help buyers negotiate better terms.

-

Specifications and Customization: Customized products generally incur higher costs due to the additional resources required for design and manufacturing. Buyers should evaluate whether standard products could meet their needs to avoid unnecessary expenses.

-

Material Quality and Certifications: The quality of raw materials, along with any certifications (such as ISO standards), can significantly affect pricing. Higher quality often equates to higher costs, but it can also lead to better performance and lower Total Cost of Ownership (TCO).

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with proven track records may charge a premium, but they can offer benefits such as consistent quality and reliable delivery schedules.

What Are the Buyer Tips for Navigating Bronze and Copper Pricing?

-

Effective Negotiation Strategies: Engage in thorough research to understand market prices and trends before negotiating with suppliers. Leverage volume commitments or long-term contracts to secure better pricing.

-

Focus on Cost-Efficiency: Analyze the Total Cost of Ownership by considering not just the purchase price but also the lifecycle costs associated with maintenance, durability, and performance. This approach can reveal opportunities for savings that may not be immediately apparent.

-

Understand Pricing Nuances for International Buyers: For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, it’s essential to consider currency fluctuations, import tariffs, and local market conditions. These factors can dramatically influence the total cost of sourcing bronze or copper.

-

Stay Informed About Market Trends: Regularly monitor market trends for copper and bronze prices, as fluctuations can create opportunities for cost savings or necessitate strategic purchasing decisions.

In conclusion, sourcing bronze versus copper involves a complex interplay of costs and pricing influencers. By understanding these dynamics and employing strategic purchasing practices, international B2B buyers can optimize their sourcing decisions and enhance their competitive edge in the marketplace.

Disclaimer: Prices are indicative and subject to fluctuations based on market conditions, supplier negotiations, and geopolitical factors.

Alternatives Analysis: Comparing bronze vs copper price With Other Solutions

Introduction: Exploring Alternatives to Bronze and Copper Pricing

In the realm of industrial materials, the choice between bronze and copper often hinges on specific application requirements, cost considerations, and performance characteristics. However, various alternative materials and technologies can provide similar benefits while potentially offering different pricing structures. Understanding these alternatives is crucial for B2B buyers looking to optimize their procurement strategies in diverse industries.

Comparison Table

| Comparison Aspect | Bronze Vs Copper Price | Aluminum Alloys | Stainless Steel |

|---|---|---|---|

| Performance | High corrosion resistance; good mechanical properties | Lightweight; good strength-to-weight ratio | Excellent corrosion resistance; high strength |

| Cost | Generally more expensive due to copper content | Lower cost, typically more affordable | Moderate to high cost depending on grade |

| Ease of Implementation | Requires specific fabrication techniques | Easy to work with; widely used | Requires specialized welding techniques |

| Maintenance | Low maintenance; resistant to wear | Moderate; can corrode in certain environments | Low; resistant to rust and stains |

| Best Use Case | Marine applications, artistic sculptures, electrical components | Aerospace, automotive, packaging | Medical devices, food processing, construction |

Detailed Breakdown of Alternatives

1. Aluminum Alloys

Aluminum alloys are becoming increasingly popular due to their lightweight properties and cost-effectiveness. With a high strength-to-weight ratio, they are ideal for applications in the aerospace and automotive industries. While they do not offer the same level of corrosion resistance as bronze, their lower cost and ease of fabrication make them a viable alternative for many projects. However, aluminum’s lower melting point and susceptibility to certain environmental conditions can be a downside for specific applications.

2. Stainless Steel

Stainless steel presents a robust alternative to both bronze and copper, especially in environments where corrosion resistance is paramount. Its high strength makes it suitable for structural applications, such as in medical devices and food processing equipment. Although the cost can vary significantly depending on the grade, stainless steel tends to be a moderate to high-cost option. Additionally, it requires specialized welding techniques, which could complicate implementation compared to bronze or copper.

Conclusion: How to Choose the Right Solution for Your Needs

When evaluating the choice between bronze, copper, and their alternatives, B2B buyers should consider the specific requirements of their projects, including performance criteria, budget constraints, and implementation capabilities. While bronze and copper offer unique properties, alternatives like aluminum alloys and stainless steel can provide competitive benefits depending on the application. By assessing the pros and cons of each material, businesses can make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for bronze vs copper price

What Are the Key Technical Properties of Bronze and Copper Relevant to Pricing?

Understanding the technical properties of bronze and copper is essential for B2B buyers, especially when considering pricing and sourcing. Here are several critical specifications that influence pricing and application decisions.

1. Material Grade

Material grade refers to the specific composition and purity of the metal. For bronze, grades like Alloy 932 and Alloy 954 indicate varying percentages of copper, tin, and other alloying elements. In copper, grades such as Alloy 101 (oxygen-free) and Alloy 110 (electrolytic) denote high electrical conductivity. Knowing the material grade helps buyers select the right alloy for their specific applications, ultimately influencing the cost and performance of the final product.

2. Tolerance

Tolerance defines the permissible limit of variation in a physical dimension of the metal product. For example, a tighter tolerance might be required for components in electrical applications where precision is critical. In contrast, broader tolerances may suffice for more general applications. Understanding tolerance specifications is crucial for ensuring compatibility with manufacturing processes and minimizing waste, which can affect overall pricing.

3. Hardness

Hardness is a measure of a material’s resistance to deformation, typically assessed using the Brinell hardness test. Bronze generally exhibits higher hardness (40-42) compared to copper (35), making it suitable for applications requiring durability, such as in marine hardware or construction tools. Buyers should consider hardness when determining the longevity and performance of the materials, as this can impact the total cost of ownership.

4. Electrical Conductivity

Electrical conductivity quantifies a material’s ability to conduct electric current. Copper is known for its exceptional conductivity (100%), while bronze offers significantly lower conductivity (about 15%). This property is particularly important for industries focused on electrical components, where using the right material can lead to significant cost savings and efficiency gains.

5. Thermal Conductivity

Thermal conductivity measures a material’s ability to conduct heat. Copper has a thermal conductivity of 223 BTU/hr-ft²-°F, while bronze varies between 229 to 1440 BTU/hr-ft²-°F depending on the alloy. This property influences applications in heat exchangers and electronic devices. Buyers should evaluate thermal conductivity to ensure optimal performance and energy efficiency in their applications.

What Are Common Trade Terms Relevant to Bronze and Copper Pricing?

Familiarity with industry jargon is vital for effective communication and negotiation in B2B transactions. Here are several key terms that buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable suppliers for bronze and copper components, ensuring they meet required specifications and quality standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory management, as it can influence total costs, especially for smaller businesses or projects.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers use to solicit price quotes from suppliers. Including detailed specifications for bronze or copper components in an RFQ can lead to more accurate pricing and better supplier responses, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can help buyers navigate shipping and delivery costs effectively, impacting overall pricing strategies.

5. Scrap Value

Scrap value refers to the residual value of materials after they have been used. Understanding scrap value is crucial for industries that recycle bronze and copper, as fluctuations in scrap prices can influence the cost of sourcing new materials and overall profitability.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, enhance negotiation strategies, and ultimately optimize their investments in bronze and copper materials.

Navigating Market Dynamics and Sourcing Trends in the bronze vs copper price Sector

What Are the Current Market Dynamics Affecting Bronze and Copper Prices?

The market for bronze and copper is significantly influenced by a variety of global drivers, including economic shifts, geopolitical tensions, and supply chain disruptions. Notably, the price of copper, which constitutes a major component of bronze, is subject to fluctuations driven by demand in key sectors such as construction, electronics, and renewable energy. For instance, as infrastructure projects ramp up in regions like Africa and South America, the demand for both metals is expected to rise, exerting upward pressure on prices.

Emerging B2B technologies, such as blockchain for supply chain transparency and AI for predictive analytics, are playing an increasingly vital role in sourcing strategies. Companies are leveraging these tools to enhance their procurement processes and mitigate risks associated with price volatility. Additionally, the rising trend of circular economy practices is influencing sourcing trends, with a greater emphasis on the recycling of scrap metal, particularly bronze, which can stabilize market prices.

International B2B buyers should also pay attention to local market conditions. For example, in Europe, regulatory frameworks surrounding the use of sustainable materials are shaping purchasing decisions. Buyers in regions like Brazil and Germany are increasingly prioritizing suppliers who can provide real-time pricing data and demonstrate robust supply chain management capabilities. Understanding these dynamics is crucial for making informed sourcing decisions.

How Can Sustainability and Ethical Sourcing Impact B2B Decisions in the Bronze and Copper Market?

Sustainability and ethical sourcing are becoming critical considerations in the procurement of bronze and copper. The environmental impact of mining activities, including habitat destruction and pollution, has led to heightened scrutiny from consumers and regulatory bodies alike. B2B buyers are increasingly seeking suppliers who adhere to sustainable practices, such as responsible mining and low-carbon manufacturing processes.

Moreover, the importance of ethical supply chains cannot be overstated. Companies that prioritize ethical sourcing are likely to enhance their brand reputation and attract environmentally conscious customers. Certifications such as the Responsible Minerals Initiative (RMI) and ISO 14001 for environmental management systems are becoming essential benchmarks for buyers assessing supplier practices. These certifications not only ensure compliance with environmental standards but also signal a commitment to sustainable business practices.

As the demand for ‘green’ materials rises, the market for recycled bronze, which has a lower carbon footprint than newly mined metals, is expected to grow. B2B buyers should actively seek suppliers who can demonstrate a commitment to sustainability and offer transparent sourcing practices, as this can lead to cost savings and improved market positioning in an increasingly eco-conscious marketplace.

What Is the Historical Context of Bronze and Copper in B2B Markets?

The historical context of bronze and copper usage can provide valuable insights for B2B buyers today. Bronze, an alloy primarily composed of copper and tin, has been utilized since around 3500 BC, initially for tools and weapons. Its discovery marked a significant technological advancement, leading to the Bronze Age, where civilizations flourished due to improved material properties.

Copper, on the other hand, has been used in its pure form for even longer, dating back to 5000 BC. Its natural abundance and excellent conductivity made it a staple in early electrical applications and artistic endeavors. Over the centuries, both metals have evolved in terms of their applications, adapting to the demands of various industries—from construction to electronics and marine engineering.

Understanding the evolution of these metals helps B2B buyers appreciate their value in contemporary markets. By recognizing how historical trends influence current applications and pricing dynamics, buyers can make more informed sourcing decisions that align with both industry standards and consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of bronze vs copper price

-

How do I determine the current market price of bronze and copper?

To determine the current market price of bronze and copper, consider subscribing to commodity price tracking services or financial news platforms that specialize in metals. Websites like the London Metal Exchange (LME) provide real-time pricing updates. Additionally, engaging with local suppliers or brokers can offer insights into regional price fluctuations influenced by local demand and supply dynamics. Be aware that prices can vary significantly based on the alloy’s composition and market conditions, so continuous monitoring is crucial for making informed purchasing decisions. -

What factors influence the pricing of bronze compared to copper?

The pricing of bronze and copper is influenced by several factors, including raw material costs, supply and demand dynamics, and manufacturing expenses. Since bronze is primarily an alloy of copper and tin, fluctuations in the prices of these base metals directly affect bronze pricing. Additionally, geopolitical events, mining operations, and global economic trends can create volatility. Understanding these factors helps buyers anticipate market changes and make strategic sourcing decisions, especially in regions with varying economic conditions like Africa and South America. -

What is the best alloy of bronze for industrial applications?

The best alloy of bronze for industrial applications depends on the specific requirements of your project. For example, Alloy 954, which consists of 83% copper and 10-11.5% aluminum, is ideal for industrial and mounting equipment due to its strength and corrosion resistance. Conversely, if electrical conductivity is a priority, consider using copper alloys like Alloy 101, which is oxygen-free and offers high ductility. Always evaluate the alloy’s properties against your application needs to ensure optimal performance. -

How can I vet suppliers for bronze and copper?

Vetting suppliers for bronze and copper involves several steps. Start by researching their industry reputation through online reviews and ratings. Request references from other B2B clients to assess reliability and quality. Additionally, evaluate their certifications and compliance with international standards to ensure product quality. A site visit can also provide insights into their operational capabilities and quality control processes. Finally, discussing payment terms and logistics upfront can help establish a transparent and trustworthy relationship. -

What are the typical minimum order quantities (MOQ) for bronze and copper?

Minimum order quantities (MOQ) for bronze and copper can vary widely depending on the supplier and the specific alloy. Generally, MOQs can range from 100 kg to several tons, particularly for custom or specialized alloys. It is advisable to communicate your needs directly with potential suppliers to negotiate MOQs that align with your purchasing capacity. Some suppliers may offer flexibility for initial orders or provide bulk pricing discounts, which can be beneficial for larger projects. -

What are common payment terms for international purchases of bronze and copper?

Common payment terms for international purchases of bronze and copper typically include options like Letters of Credit (LC), advance payments, or net 30/60/90 days after delivery. Terms may vary based on the supplier’s policies and your business relationship. Establishing clear payment terms is essential to mitigate risks associated with currency fluctuations and potential supply chain disruptions. Always ensure that the terms are documented in the contract to avoid misunderstandings. -

What quality assurance measures should I expect from suppliers?

When sourcing bronze and copper, expect suppliers to implement rigorous quality assurance measures, including material certifications, compliance with international standards (such as ASTM or ISO), and regular testing of alloy compositions. Reputable suppliers should provide documentation like Certificates of Analysis (CoA) to verify the properties and specifications of the metals. Inquire about their quality control processes, including any third-party inspections, to ensure that the products meet your industry standards. -

How does logistics impact the cost of sourcing bronze and copper?

Logistics can significantly impact the overall cost of sourcing bronze and copper. Factors such as shipping distance, transportation modes, and customs duties can add to the final price. For international transactions, consider the costs associated with freight forwarding and insurance. Efficient logistics planning, such as consolidating shipments or using local suppliers, can help minimize these costs. Be proactive in discussing logistics with suppliers to explore options that can reduce lead times and expenses.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Bronze Vs Copper Price Manufacturers & Suppliers List

1. KDM Fab – Bronze and Copper Comparison

Domain: kdmfab.com

Registered: 2022 (3 years)

Introduction: Bronze and Copper Comparison:

1. **What is Bronze?**

– Composition: Primarily copper (about 88%) and tin (about 12%), with possible alloying elements like nickel, zinc, lead, arsenic, and phosphorus.

– Historical Use: Discovered around 3500 BC.

2. **What is Copper?**

– Composition: Freely exists in nature, with artifacts dating back to around 5000 BC.

– Chemical Symbol: Cu.

3….

2. Reliable Recycling Center – Scrap Metal Pricing

Domain: reliablerecyclingcenter.com

Registered: 2004 (21 years)

Introduction: This company, Reliable Recycling Center – Scrap Metal Pricing, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Okon Recycling – Bronze Price Insights

Domain: okonrecycling.com

Registered: 2022 (3 years)

Introduction: Understanding the Price of Bronze Per Pound: A Guide

– Bronze is an alloy primarily composed of copper (88-92%) and tin.

– The price of bronze per pound is influenced by:

1. Raw Material Costs: Changes in copper and tin prices due to global supply and demand, mining costs, and geopolitical factors.

2. Supply and Demand Dynamics: Industrial demand from sectors like construction, shipbuilding, …

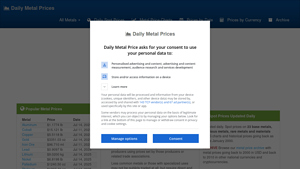

4. Daily Metal Prices – Key Metal Rates

Domain: dailymetalprice.com

Registered: 2016 (9 years)

Introduction: Daily Metal Prices: Aluminum, Cobalt, Copper, Gallium, Gold, Indium, Iridium, Iron Ore, Lead, Lithium, Molybdenum, Neodymium, Nickel, Palladium, Platinum, Rhodium, Ruthenium, Silver, Steel Rebar, Tellurium, Tin, Uranium, Zinc. Prices (as of July 14, 2025): Aluminum $1.1774 lb, Cobalt $15.121 lb, Copper $5.5118 lb, Gold $3351.03 oz, Iron Ore $96.710 mt, Lead $0.9097 lb, Lithium $9.0200 kg, Nickel $…

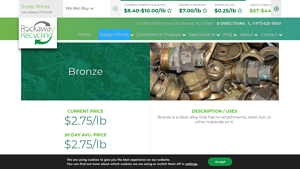

5. Rockaway Recycling – Bronze Scrap Metal

Domain: rockawayrecycling.com

Registered: 2007 (18 years)

Introduction: {“current_price”:”$2.75/lb”,”30_day_avg_price”:”$2.75/lb”,”description”:”Bronze is a clean alloy that has no attachments, steel, iron, or other materials on it. It is darker orange/red compared to brass, but more yellow than copper. Bronze generally consists of 90% copper and 10% zinc. For bronze to be priced differently than brass, it must contain 80-90% copper. It is important that bronze is com…

6. ScrapWorks – Current Scrap Metal Prices in Texas

Domain: scrapworks.com

Registered: 2002 (23 years)

Introduction: Current Scrap Metal Prices in Texas, Ferrous Scrap Metal, Stainless Steel Scrap, Copper Scrap, Yellow Brass Scrap, Aluminum Cans Scrap

7. Currie Warner – Brass Alloys

Domain: curriewarner.com

Registered: 1999 (26 years)

Introduction: Brass is an alloy primarily made of copper and zinc, with various types influencing its price based on composition. Key types include: 1. Alpha Brass (5%-20% zinc) – Soft, used in plumbing fittings and musical instruments, generally less expensive. 2. Alpha-Beta Brass (20%-45% zinc) – Stronger and harder, slightly more expensive than alpha brass. 3. Cartridge Brass (70% copper, 30% zinc) – Good st…

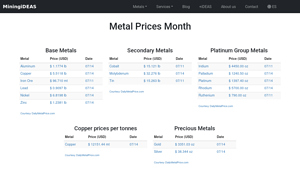

8. Mining Ideas – Base Metals Pricing

Domain: miningideas.com

Registered: 2015 (10 years)

Introduction: This company, Mining Ideas – Base Metals Pricing, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for bronze vs copper price

In the intricate landscape of metal pricing, understanding the dynamics between bronze and copper is crucial for strategic sourcing. The comparative analysis reveals that while copper typically commands a higher price due to its purity and electrical conductivity, bronze offers significant advantages in applications requiring enhanced corrosion resistance and mechanical properties. For B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, leveraging market intelligence on these metals can lead to cost-effective procurement strategies.

Key takeaways include the importance of monitoring raw material costs, as fluctuations in copper and tin prices directly influence bronze pricing. Additionally, awareness of supply and demand trends, alongside geopolitical factors, can empower buyers to make informed purchasing decisions. As industries increasingly prioritize sustainability, the recycling of bronze also presents opportunities for cost stabilization.

Looking ahead, international buyers should remain proactive in their sourcing strategies, aligning with suppliers who demonstrate efficiency and adaptability in production. By embracing a forward-thinking approach, businesses can not only navigate the complexities of metal pricing but also enhance their competitive edge in the global market. Engaging with reliable suppliers and investing in market insights will be paramount for successful sourcing in the coming years.