Introduction: Navigating the Global Market for brass replacement piece

In the dynamic world of global commerce, sourcing high-quality brass replacement pieces can present significant challenges for B2B buyers. As industries increasingly rely on precision-engineered components to enhance product durability and functionality, the demand for reliable brass parts has surged. However, navigating the complexities of international supply chains, fluctuating costs, and varying quality standards can be daunting. This guide serves as a comprehensive resource for international B2B buyers from Africa, South America, the Middle East, and Europe—including regions like Vietnam and Brazil—looking to streamline their procurement processes.

Within these pages, you will find an in-depth exploration of brass replacement pieces, covering a wide array of types and applications. From musical instruments to lighting fixtures, the versatility of brass parts is unmatched. We delve into the nuances of supplier vetting, ensuring you can identify reputable manufacturers who meet your specific needs. Additionally, we provide insights into cost factors, helping you make informed purchasing decisions that align with your budgetary constraints.

By equipping yourself with the knowledge contained in this guide, you will be empowered to overcome common sourcing hurdles, optimize your supply chain, and ultimately enhance your product offerings. Whether you are looking to maintain a competitive edge or ensure compliance with international standards, this resource is designed to support your strategic goals in the brass replacement market.

Understanding brass replacement piece Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Brass Instrument Components | Specialized parts for various brass instruments | Music education, instrument manufacturing | Pros: High durability; Cons: Replacement may require professional installation. |

| Brass Lamp Parts | Includes sockets, rods, and decorative elements | Lighting manufacturers, home decor | Pros: Aesthetic appeal; Cons: Can be costly depending on design complexity. |

| Brass Plumbing Fixtures | Valves, fittings, and connectors | Construction, plumbing services | Pros: Corrosion resistance; Cons: Heavier than alternatives, potentially increasing shipping costs. |

| Brass Hardware Accessories | Hinges, locks, and decorative fasteners | Furniture manufacturers, cabinetry | Pros: Enhances product value; Cons: Limited to specific design styles. |

| Brass Automotive Parts | Engine components, fittings, and connectors | Automotive manufacturing and repair | Pros: High strength; Cons: Price volatility due to metal market fluctuations. |

What Are the Key Characteristics of Brass Instrument Components?

Brass instrument components encompass a wide range of specialized parts designed for instruments like trumpets, trombones, and French horns. These parts include tuning slides, valve caps, and mouthpieces, each crafted to enhance the functionality and sound quality of the instrument. B2B buyers in the music education and instrument manufacturing sectors should consider the compatibility of these components with specific instrument brands and models, as well as the potential need for professional installation during repairs or upgrades.

How Do Brass Lamp Parts Differ in Application?

Brass lamp parts, such as sockets, rods, and decorative elements, are essential for lighting manufacturers and home decor businesses. These components not only serve functional purposes but also contribute to the aesthetic appeal of lighting fixtures. When purchasing brass lamp parts, B2B buyers should evaluate the design complexity and potential customization options, as these factors can influence both the cost and the final product’s marketability.

What Advantages Do Brass Plumbing Fixtures Offer?

Brass plumbing fixtures, including valves, fittings, and connectors, are widely used in construction and plumbing services due to their excellent corrosion resistance and durability. These fixtures are ideal for both residential and commercial applications, ensuring long-lasting performance under varying environmental conditions. Buyers should consider the weight of brass fixtures, as this can impact shipping costs and installation requirements, particularly in large-scale projects.

Why Choose Brass Hardware Accessories for Furniture?

Brass hardware accessories, such as hinges, locks, and decorative fasteners, enhance the value and functionality of furniture products. These components are favored by furniture manufacturers and cabinetry businesses for their durability and classic appearance. When selecting brass hardware, B2B buyers should assess how the design aligns with their product offerings and the market demand for specific styles, which can affect overall sales potential.

What Are the Considerations for Brass Automotive Parts?

Brass automotive parts, including engine components and fittings, are known for their strength and reliability in various automotive applications. These parts are crucial for automotive manufacturers and repair services that prioritize quality and performance. Buyers should be aware of the price volatility associated with brass due to fluctuations in the metal market, which can influence procurement strategies and budget planning.

Key Industrial Applications of brass replacement piece

| Industry/Sector | Specific Application of brass replacement piece | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Musical Instruments | Replacement parts for brass instruments (e.g., trumpets, horns) | Ensures optimal performance and sound quality for musicians. | Quality standards, compatibility with existing instruments, bulk pricing. |

| Lighting Fixtures | Brass components for lamps and light fixtures | Enhances aesthetic appeal and durability of lighting products. | Corrosion resistance, design specifications, and electrical safety compliance. |

| Plumbing and HVAC | Brass fittings and valves in plumbing systems | Provides reliable sealing and flow control in fluid systems. | Pressure ratings, size compatibility, and international standards compliance. |

| Electronics | Brass connectors and terminals for electronic devices | Improves conductivity and reliability in electronic applications. | Electrical specifications, sourcing from certified manufacturers, and cost efficiency. |

| Antique Restoration | Replacement parts for antique brass items | Preserves historical value and functionality of vintage items. | Authenticity, compatibility with original materials, and craftsmanship quality. |

How Are Brass Replacement Pieces Used in Musical Instruments?

In the musical instruments sector, brass replacement pieces are crucial for maintaining the functionality of brass instruments such as trumpets and trombones. Key components like valve caps and tuning slides often require replacement due to wear and tear. By sourcing high-quality brass parts, manufacturers ensure that musicians can achieve optimal sound quality and performance. International buyers should consider compatibility with existing instruments and the reputation of suppliers to avoid frequent replacements.

What Role Do Brass Components Play in Lighting Fixtures?

Brass replacement pieces are integral to the production of lighting fixtures, where they serve as connectors, bases, and decorative elements. Their natural resistance to corrosion and tarnishing enhances the longevity and aesthetic appeal of lamps and chandeliers. Businesses in this sector should prioritize sourcing from manufacturers that offer a range of designs and comply with electrical safety standards. This ensures that the final products not only look good but are also safe and reliable for consumers.

Why Are Brass Fittings Essential in Plumbing and HVAC Systems?

In plumbing and HVAC applications, brass fittings and valves are essential for creating reliable connections that withstand high pressure and prevent leaks. These components are favored for their durability and corrosion resistance, making them ideal for long-term installations. B2B buyers in this sector must focus on sourcing parts that meet international standards, especially when dealing with varying regional regulations across Africa, South America, the Middle East, and Europe.

How Do Brass Connectors Enhance Electronics?

Brass replacement pieces, particularly connectors and terminals, are vital in the electronics industry for ensuring efficient electrical conductivity. Their ability to handle high currents makes them suitable for various applications, from consumer electronics to industrial machinery. Buyers should evaluate the electrical specifications and certifications of the sourcing partners to ensure the reliability and safety of their electronic products, particularly in regions with diverse regulatory requirements.

What Is the Importance of Brass in Antique Restoration?

In the field of antique restoration, brass replacement parts are crucial for maintaining the integrity and functionality of vintage items. Whether restoring a classic lamp or a historical piece of furniture, sourcing authentic brass components is essential to preserving the original charm and value. Buyers must ensure that suppliers can provide high-quality craftsmanship and compatibility with original materials to avoid diminishing the historical significance of the items being restored.

3 Common User Pain Points for ‘brass replacement piece’ & Their Solutions

Scenario 1: Difficulty Sourcing Quality Brass Replacement Parts

The Problem: B2B buyers often struggle to find high-quality brass replacement parts that meet the specific requirements of their instruments or machinery. This challenge can stem from a lack of reliable suppliers, especially in regions where access to quality parts is limited. For instance, buyers in emerging markets may encounter low-quality imports that lead to premature failure or incompatibility, creating additional costs in terms of repairs and downtime.

The Solution: To overcome this sourcing challenge, buyers should prioritize establishing relationships with reputable suppliers who specialize in brass replacement parts. Conduct thorough research and seek suppliers with strong industry reputations and positive reviews. Additionally, consider attending trade shows or industry-specific events to connect directly with manufacturers. It’s also beneficial to request samples or certifications to ensure that the quality meets your specifications. Collaborating with suppliers who offer customized solutions can further help in sourcing parts that are tailored to your specific needs, ensuring better performance and longevity.

Scenario 2: Ensuring Compatibility of Brass Replacement Components

The Problem: Compatibility issues often arise when purchasing brass replacement parts, especially when dealing with vintage or specialized instruments and machinery. Many buyers find that parts do not fit as expected, leading to frustration and the need for additional modifications or returns. This is particularly concerning for businesses that rely on timely repairs to maintain operational efficiency.

The Solution: To ensure compatibility, buyers should thoroughly document the specifications of the existing brass components, including dimensions, threading types, and material grades. Before making a purchase, it’s crucial to cross-reference these specifications with the product details provided by suppliers. Engaging with technical support teams from manufacturers can also clarify compatibility concerns and provide insights on alternative options if needed. Additionally, investing in a universal measurement tool or a digital caliper can facilitate accurate assessments of parts, ensuring that the right replacements are sourced the first time.

Scenario 3: Managing Long Lead Times for Brass Replacement Parts

The Problem: Long lead times for brass replacement parts can severely impact production schedules and service delivery. Buyers often face delays due to supply chain disruptions, especially when sourcing from international suppliers. Such delays can lead to operational bottlenecks and affect customer satisfaction, ultimately harming the business’s reputation.

The Solution: To mitigate the risk of long lead times, B2B buyers should implement a proactive inventory management strategy that includes maintaining a buffer stock of critical brass replacement parts. Collaborating with multiple suppliers can also provide alternative options if lead times become extended. Additionally, establishing clear communication channels with suppliers regarding expected delivery times and potential delays can enhance planning and reduce the impact of unforeseen disruptions. Using demand forecasting tools can further assist in anticipating needs and adjusting orders accordingly, ensuring that essential parts are always available when required.

Strategic Material Selection Guide for brass replacement piece

What Are the Key Properties of Common Materials for Brass Replacement Pieces?

When selecting materials for brass replacement pieces, understanding the properties and suitability of each option is crucial. Here we analyze four common materials: brass, stainless steel, aluminum, and plastic. Each material has unique characteristics that influence performance, durability, and application compatibility.

Brass: The Traditional Choice

Brass is a copper-zinc alloy known for its excellent machinability and acoustic properties, making it a popular choice for musical instruments and fittings. It exhibits good corrosion resistance, especially in non-chlorinated environments, and can withstand moderate temperatures and pressures.

Pros: Brass is durable, has a pleasing aesthetic finish, and is relatively easy to work with. Its acoustic properties make it ideal for musical applications.

Cons: Brass can be susceptible to dezincification, which may weaken the material in certain environments. It is also more expensive than some alternatives, which can impact overall project costs.

Impact on Application: Brass is well-suited for applications involving air and water, but caution should be exercised in chlorinated environments.

Considerations for International Buyers: Compliance with standards such as ASTM B36 for brass products is essential. Buyers in regions like Africa and South America may prefer locally sourced brass to minimize costs and ensure availability.

Stainless Steel: The Corrosion-Resistant Alternative

Stainless steel is an alloy primarily composed of iron, chromium, and nickel. It is renowned for its exceptional corrosion resistance and strength, making it suitable for harsh environments.

Pros: Stainless steel is highly durable and can withstand extreme temperatures and pressures. Its corrosion resistance makes it ideal for applications exposed to moisture or chemicals.

Cons: The cost of stainless steel can be significantly higher than brass, and its machining can be more complex, leading to increased manufacturing costs.

Impact on Application: Stainless steel is particularly effective in applications involving aggressive media, such as chemicals and saline solutions.

Considerations for International Buyers: Compliance with international standards like ASTM A240 is critical. Buyers in the Middle East, where humidity levels are high, often prefer stainless steel for its longevity.

Aluminum: The Lightweight Option

Aluminum is a lightweight, corrosion-resistant metal that is often used in applications where weight is a critical factor. It is easy to machine and can be anodized for additional surface protection.

Pros: Aluminum is cost-effective and offers excellent corrosion resistance. Its lightweight nature makes it suitable for portable applications.

Cons: While aluminum is durable, it is not as strong as brass or stainless steel, which may limit its use in high-stress applications.

Impact on Application: Aluminum is ideal for applications where weight savings are essential, such as in transport and aerospace industries.

Considerations for International Buyers: Compliance with standards such as ASTM B221 is important. Buyers in Europe may prefer aluminum for its lightweight properties, particularly in automotive applications.

Plastic: The Versatile and Cost-Effective Material

Plastic, particularly engineering plastics like polycarbonate and nylon, offers a versatile alternative for brass replacement pieces. These materials can be molded into complex shapes and are resistant to corrosion and chemicals.

Pros: Plastics are lightweight, cost-effective, and can be produced in various colors and finishes. They also provide excellent insulation properties.

Cons: Plastics may not withstand high temperatures or mechanical stresses as well as metals, which can limit their application scope.

Impact on Application: Plastic is suitable for low-pressure applications and environments where corrosion is a concern.

Considerations for International Buyers: Compliance with standards like ASTM D638 for plastics is necessary. In regions like South America, where cost is a significant factor, plastic may be favored for non-critical applications.

Summary of Material Selection for Brass Replacement Pieces

| Material | Typical Use Case for brass replacement piece | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Musical instruments, fittings | Excellent machinability and aesthetics | Susceptible to dezincification | Medium |

| Stainless Steel | Harsh environments, chemical applications | Exceptional corrosion resistance | Higher cost and machining complexity | High |

| Aluminum | Aerospace, transport applications | Lightweight and cost-effective | Lower strength compared to metals | Low |

| Plastic | Low-pressure applications, insulation | Versatile and cost-effective | Limited temperature and stress tolerance | Low |

This guide provides a comprehensive overview of material options for brass replacement pieces, enabling international B2B buyers to make informed decisions based on their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for brass replacement piece

What Are the Main Stages in the Manufacturing Process of Brass Replacement Pieces?

Manufacturing brass replacement pieces involves several critical stages, each designed to ensure that the final product meets high standards of quality and functionality. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of high-quality brass alloys, typically consisting of copper and zinc. Suppliers often conduct thorough inspections of the raw materials to ensure they meet specified chemical compositions and mechanical properties. This step may involve cutting the brass sheets or rods to the required dimensions and preheating them if necessary to facilitate subsequent processing.

-

Forming Techniques: Various forming techniques are employed depending on the complexity of the replacement part. Common methods include:

– Casting: Molten brass is poured into molds to create intricate shapes.

– Machining: Using CNC (Computer Numerical Control) machines, manufacturers precisely cut and shape the brass components.

– Stamping: This technique involves pressing brass sheets into specific shapes using dies, which is efficient for producing large volumes of uniform parts.

– Forging: This process involves shaping brass through compressive forces, enhancing the material’s strength. -

Assembly: For components that require multiple parts, assembly is a crucial step. This may involve soldering, welding, or using screws and fasteners to join different brass elements. The assembly process must ensure that all parts fit correctly and function as intended.

-

Finishing: The finishing stage enhances the aesthetic appeal and durability of brass components. Techniques such as polishing, plating, and applying protective coatings are common. These processes not only improve the appearance but also help resist corrosion and wear, which is essential for longevity in various applications.

How Is Quality Assurance Implemented in Brass Replacement Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that every brass replacement piece meets or exceeds industry standards. B2B buyers should be aware of the following QA protocols and certifications:

-

International Standards: Many manufacturers comply with international quality standards such as ISO 9001. This certification ensures that companies maintain a systematic approach to quality management, focusing on continuous improvement and customer satisfaction.

-

Industry-Specific Certifications: Depending on the application of the brass replacement parts, additional certifications may be relevant. For example:

– CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

– API Standards: Important for components used in the oil and gas industries, ensuring that products meet specific performance criteria.

What Are the Key Quality Control Checkpoints in Brass Replacement Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process to catch defects early and ensure product reliability:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials and components before they enter the production process. Materials are tested for compliance with specifications, including chemical composition and mechanical properties.

-

In-Process Quality Control (IPQC): During manufacturing, various tests are conducted to monitor the process’s consistency and quality. This may include measuring dimensions, checking tolerances, and verifying that machinery is functioning correctly.

-

Final Quality Control (FQC): Once the manufacturing process is complete, the finished brass replacement pieces undergo rigorous testing. This can involve visual inspections, functional tests, and dimensional checks to ensure they meet the required specifications.

What Testing Methods Are Commonly Used in Brass Replacement Manufacturing?

Testing methods are essential for validating the quality and performance of brass replacement pieces. Common testing methods include:

- Dimensional Inspection: Utilizing calipers and gauges to measure the dimensions of the parts to ensure they meet specified tolerances.

- Mechanical Testing: Assessing properties such as tensile strength, hardness, and ductility to ensure the material can withstand its intended application.

- Corrosion Testing: Exposing the brass components to various environments to evaluate their resistance to corrosion and wear.

- Functional Testing: Ensuring that the parts operate correctly in their intended applications, especially in complex assemblies.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to verify the quality control practices of potential suppliers. Here are some effective strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the supplier’s manufacturing processes, quality control measures, and overall compliance with international standards. This firsthand observation can provide valuable insights into the supplier’s capabilities.

-

Quality Reports: Requesting detailed quality reports, including inspection records and test results, can help buyers understand the supplier’s commitment to quality. These documents should outline the testing methods used and the results obtained.

-

Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased evaluation of the supplier’s quality practices. These inspections can occur at various stages of production, offering additional assurance of quality.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential:

-

Cultural and Regulatory Differences: Buyers must be aware of the varying quality standards and regulations that exist across different regions. This understanding can help in selecting suppliers who comply with both local and international standards.

-

Language Barriers: Communication can be challenging when dealing with suppliers from different countries. Ensuring that documentation is clear and available in multiple languages can facilitate smoother transactions.

-

Logistics and Shipping Considerations: Buyers should consider the implications of shipping and logistics on quality control. This includes ensuring that the products are adequately packaged to prevent damage during transit.

By understanding these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing brass replacement pieces, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘brass replacement piece’

In the competitive landscape of sourcing brass replacement pieces, a systematic approach is essential for B2B buyers aiming to secure high-quality components at favorable prices. This checklist serves as a practical guide to streamline your procurement process, ensuring that you select the right suppliers and products that meet your business needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clarify the technical requirements of the brass replacement pieces you need. This includes dimensions, material specifications, and any industry standards that must be adhered to. A well-defined specification will facilitate communication with suppliers and help avoid costly misunderstandings later in the procurement process.

- Key Considerations:

- Material grade (e.g., brass alloy type).

- Tolerances and finish requirements.

Step 2: Conduct Market Research

Investigate the current market landscape to identify potential suppliers and understand pricing trends. Research can reveal insights into the most reliable manufacturers and distributors, as well as emerging competitors. This knowledge can help you negotiate better terms and recognize value propositions.

- Key Actions:

- Utilize online directories and B2B platforms.

- Analyze competitor sourcing strategies for similar parts.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they meet your company’s quality standards and reliability. Request company profiles, certifications, and references from other businesses in your industry. This step is vital to mitigate risks associated with poor-quality products and unreliable delivery timelines.

- Important Factors:

- ISO certifications or industry-specific quality standards.

- Testimonials and case studies from previous clients.

Step 4: Request Samples

Before placing a bulk order, request samples of the brass replacement pieces. Testing samples allows you to evaluate the quality, fit, and finish of the components firsthand. This step can prevent costly returns and disruptions in your production line.

- Sample Assessment Criteria:

- Dimensional accuracy.

- Surface finish and corrosion resistance.

Step 5: Verify Supplier Certifications

Ensure that your selected suppliers have the necessary certifications to comply with international standards. Compliance with standards like ISO 9001 or relevant local certifications is crucial for maintaining quality and safety in your products. This verification can also enhance your company’s credibility in the marketplace.

- What to Check:

- Validity of certifications and scope of compliance.

- Any recent audits or inspections conducted.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier, engage in negotiations to finalize terms of sale. Discuss pricing, payment terms, delivery schedules, and warranty conditions. Effective negotiation can lead to better pricing and favorable terms that enhance your procurement strategy.

- Key Negotiation Points:

- Discounts for bulk orders.

- Terms for returns and defective parts.

Step 7: Establish a Communication Plan

Post-order, maintain open lines of communication with your supplier. Clear communication regarding order status, shipment tracking, and potential issues can foster a stronger relationship and ensure timely delivery of your brass replacement pieces.

- Communication Tips:

- Set regular check-ins for updates.

- Utilize project management tools for transparency.

By following this checklist, B2B buyers can streamline their sourcing process for brass replacement pieces, ensuring they make informed decisions that align with their business objectives.

Comprehensive Cost and Pricing Analysis for brass replacement piece Sourcing

What Are the Key Cost Components in Brass Replacement Piece Sourcing?

When sourcing brass replacement parts, understanding the various cost components is essential for effective budgeting and financial planning. The primary cost elements include:

- Materials: The type of brass used significantly affects the cost. High-quality brass alloys may incur higher costs but offer better durability and performance.

- Labor: Skilled labor is required for manufacturing and assembly. Labor costs can vary widely depending on the region and the complexity of the part.

- Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help mitigate these costs.

- Tooling: Initial tooling costs can be substantial, especially for custom parts. Investing in high-quality tooling is crucial for precision and longevity.

- Quality Control (QC): Ensuring parts meet specific standards may require additional QC measures, adding to the overall cost.

- Logistics: Shipping and handling costs must be considered, particularly for international transactions. Factors such as distance, shipping method, and customs duties play a significant role.

- Margin: Suppliers typically include a profit margin in their pricing. Understanding the markup can aid in negotiation and sourcing strategies.

How Do Price Influencers Affect Brass Replacement Part Sourcing?

Several factors can influence the pricing of brass replacement parts, particularly in the B2B context:

- Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to discounts. Negotiating favorable MOQs can significantly reduce per-unit costs.

- Specifications and Customization: Customized parts tailored to specific needs may incur higher costs due to additional design and manufacturing requirements.

- Material Quality and Certifications: Higher-quality materials and certifications (like ISO or ASTM) can elevate costs. Buyers should weigh the benefits of certified products against their budget constraints.

- Supplier Factors: The reliability and reputation of the supplier can influence pricing. Established suppliers may charge more but offer consistent quality and service.

- Incoterms: The chosen Incoterms can impact total costs. For instance, DDP (Delivered Duty Paid) may offer convenience but can be more expensive than EXW (Ex Works).

What Are the Best Negotiation Tips for International B2B Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should consider the following strategies:

- Research Market Prices: Understanding standard pricing for similar parts can empower buyers during negotiations.

- Build Relationships: Establishing a rapport with suppliers can lead to better pricing and terms. Long-term partnerships often yield more favorable conditions.

- Discuss Total Cost of Ownership (TCO): Emphasizing TCO, which includes maintenance, logistics, and potential downtime, can justify higher upfront costs for quality parts.

- Leverage Multiple Quotes: Obtaining quotes from various suppliers can create competitive tension, leading to better pricing.

- Be Aware of Pricing Nuances: Different regions may have unique pricing structures due to local market conditions, tariffs, and regulations. Understanding these nuances can aid in making informed decisions.

What Should Buyers Consider Regarding Pricing for Brass Replacement Parts?

While indicative prices can guide initial budgeting, buyers should remain cautious. Prices can fluctuate based on market demand, availability of raw materials, and geopolitical factors. It is advisable to factor in potential price increases and include contingencies in budget forecasts.

By comprehensively analyzing costs, understanding pricing influencers, and employing effective negotiation strategies, international B2B buyers can enhance their sourcing outcomes for brass replacement parts, ensuring they obtain quality components that meet their operational needs.

Alternatives Analysis: Comparing brass replacement piece With Other Solutions

Exploring Alternatives to Brass Replacement Pieces: A Comprehensive Comparison

In the realm of manufacturing and maintenance, the choice of materials and components can significantly impact performance, longevity, and cost-effectiveness. While brass replacement pieces are widely used for their durability and aesthetic appeal, various alternative solutions exist. This analysis will compare brass replacement pieces against two notable alternatives: stainless steel components and plastic fittings. Understanding these options can help B2B buyers make informed decisions tailored to their specific needs.

| Comparison Aspect | Brass Replacement Piece | Stainless Steel Components | Plastic Fittings |

|---|---|---|---|

| Performance | Excellent durability; good corrosion resistance | High strength; superior corrosion resistance | Adequate for low-stress applications; limited lifespan |

| Cost | Moderate to high | Higher initial investment | Low cost |

| Ease of Implementation | Generally easy | Requires specialized tools for installation | Very easy; often involves simple assembly |

| Maintenance | Requires periodic maintenance to prevent tarnishing | Low maintenance; resistant to rust | Minimal maintenance; can degrade over time |

| Best Use Case | High-end applications where aesthetics matter | Industrial settings with high corrosion exposure | Low-pressure applications or temporary solutions |

What Are the Advantages and Disadvantages of Stainless Steel Components?

Stainless steel components are renowned for their strength and corrosion resistance, making them ideal for demanding environments such as chemical processing plants or marine applications. Their ability to withstand extreme conditions ensures a longer lifespan compared to brass. However, the initial cost of stainless steel can be significantly higher, which may deter budget-conscious buyers. Additionally, installation may require specialized tools, adding to overall project costs.

How Do Plastic Fittings Compare in Terms of Cost and Application?

Plastic fittings offer a budget-friendly alternative to both brass and stainless steel. They are lightweight and resistant to corrosion, making them suitable for a wide range of applications, especially in plumbing and HVAC systems. However, plastic may not hold up well under high temperatures or pressures, limiting its use in more demanding settings. While installation is straightforward, the longevity of plastic fittings is often less than that of metal counterparts, necessitating more frequent replacements.

Making the Right Choice: Which Solution Is Best for Your Needs?

When selecting the right replacement piece for your application, consider the specific requirements of your project. For high-end applications where aesthetics and durability are critical, brass replacement pieces may be the best option. If your project is in an industrial environment with exposure to harsh chemicals, stainless steel components could offer the durability and corrosion resistance needed. Conversely, for low-pressure applications or if budget constraints are a primary concern, plastic fittings might be the most pragmatic choice.

In conclusion, understanding the comparative advantages and limitations of brass replacement pieces, stainless steel components, and plastic fittings empowers B2B buyers to make well-informed decisions. Each alternative serves distinct needs, and the right choice will depend on performance requirements, budget constraints, and the specific context of use. By evaluating these factors, businesses can ensure they select the most suitable solution for their operational demands.

Essential Technical Properties and Trade Terminology for brass replacement piece

What Are the Key Technical Properties of Brass Replacement Pieces?

Brass replacement pieces are essential components in various industries, including music, lighting, and plumbing. Understanding their technical properties ensures buyers select the right parts for their needs.

-

Material Grade: Brass is categorized into different grades based on its composition, typically including copper and zinc. Common grades include C260 (yellow brass) and C280 (commercial brass). The material grade affects durability, corrosion resistance, and machinability. Selecting the appropriate grade ensures longevity and performance in applications, which is critical for minimizing downtime and replacement costs.

-

Tolerance: Tolerance refers to the allowable deviation from specified dimensions. Precision in tolerances is vital for components that must fit together perfectly, such as valves in brass instruments or lighting fixtures. Tighter tolerances can lead to higher manufacturing costs but are often necessary for high-performance applications. Ensuring the correct tolerances can prevent operational issues and enhance product reliability.

-

Finish: The surface finish of brass components can vary from polished to brushed or matte. The finish not only affects aesthetic appeal but also influences corrosion resistance and wear characteristics. For instance, a polished finish may provide better protection against oxidation, which is particularly important in humid environments. Buyers should consider the finish that best suits their operational environment and aesthetic requirements.

-

Weight: The weight of brass components can impact their application, especially in musical instruments where balance is crucial for playability. Heavier parts might offer a richer sound quality but can also affect the instrument’s ease of use. Understanding the weight specifications helps buyers make informed decisions that align with performance expectations.

-

Compatibility: Many brass replacement pieces are designed for specific brands or models. Compatibility ensures that parts fit and function correctly, which is essential for maintaining equipment performance. Buyers must verify that replacement parts match the specifications of existing equipment to avoid costly mismatches.

What Are Common Trade Terms Related to Brass Replacement Pieces?

Familiarizing oneself with industry jargon can streamline procurement processes and improve communication with suppliers.

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts that are used in the manufacturing of a final product. In the context of brass replacement parts, sourcing OEM components ensures that the replacements meet the original specifications and quality standards, which is crucial for performance and warranty considerations.

-

MOQ (Minimum Order Quantity): MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ helps buyers plan their inventory and budget effectively. For brass components, purchasing in bulk may lead to cost savings, but it also requires careful forecasting of needs to avoid overstocking.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting pricing and terms for specific products. This process is essential for comparing offers and negotiating terms. When requesting RFQs for brass replacement pieces, including detailed specifications helps ensure accurate quotes.

-

Incoterms: These are international commercial terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is critical for managing shipping costs, delivery timelines, and risk. For brass parts, knowing the agreed terms can help in planning logistics and understanding liability during transit.

-

Lead Time: This term indicates the time taken from placing an order to delivery. For businesses reliant on brass replacement parts, understanding lead times is vital for inventory management and operational continuity. Longer lead times may necessitate advance planning to avoid production delays.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions that enhance operational efficiency and product reliability in their respective industries.

Navigating Market Dynamics and Sourcing Trends in the brass replacement piece Sector

What Are the Key Trends Shaping the Global Brass Replacement Piece Market?

The brass replacement piece sector is influenced by various global drivers, including technological advancements, evolving customer preferences, and increased demand for high-quality components. The rise of digital platforms has transformed the sourcing landscape, enabling international B2B buyers from regions such as Africa, South America, the Middle East, and Europe to connect with suppliers more efficiently. Emerging technologies, such as 3D printing and automation, are paving the way for customized and rapid production of brass components, allowing businesses to meet specific needs with greater agility.

Furthermore, sustainability is becoming a pivotal factor in purchasing decisions. Many buyers are now prioritizing suppliers who demonstrate a commitment to ethical sourcing and environmental stewardship. The integration of smart inventory management systems and data analytics is enhancing supply chain efficiency, offering real-time insights into stock levels and demand forecasting. This trend is particularly important for businesses operating in diverse markets, where understanding local demand can significantly impact competitiveness.

Lastly, the market is witnessing a shift towards modularity and interchangeability of parts, which simplifies repairs and maintenance for end-users. This trend not only reduces operational costs but also extends the lifecycle of brass instruments and components, making them a more sustainable choice in the long run.

How Are Sustainability and Ethical Sourcing Impacting Brass Replacement Piece Procurement?

Sustainability and ethical sourcing are increasingly influencing the brass replacement piece market. The environmental impact of brass manufacturing, including resource extraction and waste generation, has prompted buyers to seek out suppliers who prioritize eco-friendly practices. This includes the use of recycled materials and energy-efficient production processes that minimize carbon footprints.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers are becoming more discerning, looking for suppliers who adhere to fair labor practices and provide transparency throughout their operations. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as indicators of a supplier’s commitment to sustainability.

The shift towards green materials is also gaining traction. Suppliers that offer brass components made from sustainable sources or that employ environmentally friendly coatings are likely to appeal more to B2B buyers who are prioritizing sustainability in their procurement processes. This trend not only aligns with global sustainability goals but also enhances brand reputation, making it a strategic advantage in the competitive market landscape.

How Has the Brass Replacement Piece Market Evolved Over Time?

The evolution of the brass replacement piece market can be traced back to the early days of brass instrument manufacturing, where craftsmanship was paramount. Initially, replacement parts were often custom-made, limiting accessibility and affordability. However, as industrialization progressed, mass production techniques emerged, making brass components more widely available and affordable for both musicians and manufacturers.

In recent decades, the market has experienced significant changes due to technological advancements and the globalization of supply chains. The introduction of precision engineering and computer-aided design (CAD) has improved the quality and consistency of brass replacement parts. Today, buyers can easily access a wide array of components, ranging from basic repairs to specialized parts for high-end instruments.

Moreover, the rise of e-commerce has revolutionized the way businesses source brass components. B2B platforms now offer extensive catalogs and the ability to compare prices and specifications, facilitating smarter purchasing decisions for international buyers. As the market continues to evolve, the focus on sustainability and ethical sourcing is expected to shape future trends, ensuring that the brass replacement piece sector remains responsive to global demands and environmental considerations.

Frequently Asked Questions (FAQs) for B2B Buyers of brass replacement piece

-

How do I solve compatibility issues with brass replacement parts?

To address compatibility issues, first, ensure that you have the exact specifications of the brass components you need, such as dimensions, thread types, and material grades. Consult with your supplier for detailed product catalogs and cross-reference with your existing parts. If possible, request samples or prototypes to verify compatibility before placing a bulk order. Establishing clear communication with your supplier can also help mitigate any potential issues by confirming part specifications. -

What is the best way to source high-quality brass replacement parts?

When sourcing high-quality brass replacement parts, prioritize suppliers with established reputations and positive customer reviews. Look for manufacturers that adhere to international quality standards, such as ISO certifications. Additionally, consider suppliers that provide detailed product specifications and material certifications. Engaging in direct communication with potential suppliers can also help you assess their commitment to quality and customer service. -

What are the typical minimum order quantities (MOQs) for brass replacement parts?

Minimum order quantities (MOQs) for brass replacement parts can vary widely based on the supplier and the specific components. Generally, MOQs can range from as low as 50 units to several thousand. It’s important to clarify MOQs during the negotiation phase to ensure they align with your purchasing needs. Some suppliers may offer flexibility for first-time buyers or for specific product lines, so don’t hesitate to discuss your requirements. -

How can I ensure the quality of brass replacement parts before purchasing?

To ensure the quality of brass replacement parts, request samples from suppliers before committing to larger orders. Conduct thorough inspections to check for defects, material consistency, and adherence to specifications. Additionally, inquire about the supplier’s quality assurance processes and certifications. Establishing a quality control checklist can help standardize your evaluations and ensure that all parts meet your operational requirements. -

What payment terms are commonly accepted by suppliers of brass replacement parts?

Payment terms for brass replacement parts can vary, but common options include advance payment, net 30/60 days, and letters of credit. It’s advisable to negotiate terms that provide you with sufficient time to inspect the goods upon receipt. Additionally, consider the risks associated with each payment method and choose one that balances security and cash flow. Always document agreed-upon terms in a formal contract to avoid misunderstandings. -

How do I vet suppliers for brass replacement parts in international markets?

Vetting suppliers in international markets involves several steps. Start by researching their business history, customer reviews, and industry reputation. Request references and reach out to previous clients to gather feedback on their experiences. It’s also beneficial to verify the supplier’s certifications and compliance with international quality standards. Finally, consider visiting the supplier’s facilities if possible, or utilize third-party inspection services to assess their operations. -

What logistics considerations should I keep in mind when importing brass replacement parts?

When importing brass replacement parts, consider logistics factors such as shipping methods, lead times, and customs regulations. Choose a reliable freight forwarder familiar with international shipping to ensure timely delivery. Understand the import duties and taxes applicable in your country, as these can significantly affect overall costs. Additionally, establish clear communication with your supplier regarding shipping schedules and tracking options to avoid delays. -

Can brass replacement parts be customized to meet specific needs?

Yes, many suppliers offer customization options for brass replacement parts. Customization can include specific dimensions, finishes, or even the addition of unique features based on your requirements. Be prepared to provide detailed specifications and, if necessary, collaborate with the supplier’s engineering team during the design phase. Keep in mind that custom orders may have longer lead times and higher costs, so factor these into your planning.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Brass Replacement Piece Manufacturers & Suppliers List

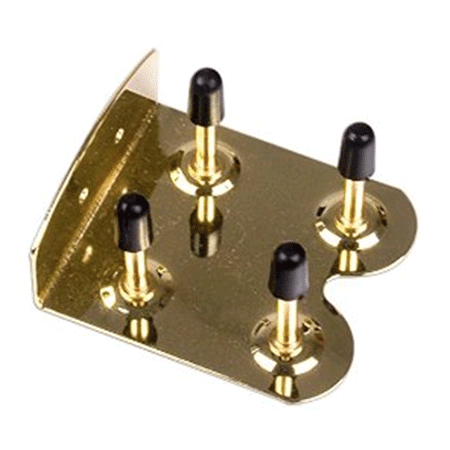

1. Bach – Stradivarius Trumpet Gold Trim Kit

Domain: musicarts.com

Registered: 1996 (29 years)

Introduction: [{‘name’: ‘Bach Stradivarius Trumpet Gold Trim Kit’, ‘price’: ‘519.99’}, {‘name’: ‘Bach Trumpet Water Key Corks’, ‘price’: ‘10.99’}, {‘name’: ‘Bach Trumpet Valve Stem Felt Washers’, ‘price’: ‘17.99’}, {‘name’: ‘Bach Trumpet Finger Button’, ‘price’: ‘19.99’}, {‘name’: ‘Yamaha French Horn String’, ‘price’: ‘4.99’}, {‘name’: ‘Conn Sousaphone Neck for Conn and King Sousaphones’, ‘price’: ‘189.99’}, {‘…

2. Grand Brass – Lamp and Chandelier Parts

Domain: grandbrass.com

Registered: 1997 (28 years)

Introduction: Grand Brass Lamp Parts, LLC offers a wide range of lamp and chandelier parts including:

1. Armbacks – Various styles including cast, decorative, disk, geometric, and straight.

2. Lamp and Chandelier Arms – Options include bent, angle, J shape, pinup, bridge, S shape, cast, and crystal arms.

3. Back Plates – Available in cast and stamped designs for sconces.

4. Canopies – Includes escutcheons and …

3. Mouthpiece Express – Brass Instrument Parts

Domain: mouthpieceexpress.com

Registered: 1999 (26 years)

Introduction: Brass: Instrument Parts, Mouthpiece Express offers a variety of products including: Aftermarket 4 7/8″ 124MM Bb Trumpet Bells, Bach Parts, Benge Parts, Blessing Parts, Bundy Parts, C.G.Conn Parts, Eastman Parts, Finger Buttons, Getzen Parts, Hans Hoyer Parts, Holton Parts, Jupiter Parts, King Parts, Olds Parts, Schilke Parts, Yamaha Parts. The site features Genuine Original Manufacturer Parts (OEM…

4. Apex – Brass Fitting Spare Parts

Domain: apexinst.com

Registered: 1995 (30 years)

Introduction: {“product_name”: “Brass Fitting Spare Parts”, “price_range”: “$0.90 – $2.90”, “fitting_tube_sizes”: [“1/4 in Tube”, “3/8 in Tube”, “1/2 in Tube”, “5/8 in Tube”], “part_types”: [“Front Ferrule”, “Back Ferrule”, “Ferrule Set”, “Nut”, “Cap”, “Plug”], “weight”: “0.25 lbs”, “dimensions”: “2 × 1 × 1 in”, “sku”: “Brass Fitting Spare Parts”, “category”: “Fittings and Adapters”}

5. TOPE Band Supply – Universal Valve Springs

Domain: topebandsupplyco.com

Registered: 2021 (4 years)

Introduction: Brass Instrument Spare Parts & Replacement Parts available at TOPE Band Supply. Key products include:

– Universal Valve Springs (Regular price: $12.99)

– Amado Water Key Repair Parts (From $12.99 to $19.99)

– Universal Valve Stem, Finger Button (Regular price: $8.99)

– French Horn & Tuba Rotary (From $8.99)

– Universal Cork Washers, Standard Valve (From $9.99)

– Valve Stem & Finger Button (From $…

6. My Lamp Parts – Brass and Steel Components

Domain: mylampparts.com

Registered: 2006 (19 years)

Introduction: Brass and Steel Parts include various components such as:

– 3-Way Brass Leviton Rotary Switch with Non-Removable Knob (SL19320-NRK): Rated 3A-125V-T, 1A-250V, 3/8″ Shank, U.L Listed, Price: $3.28

– Flat Steel Waste Nut (SL21154): 1/4″ F (1/2″ diameter hole), Overall length 2-7/16″, Overall width 1-1/4″, Price: $1.62

– 3/4″ Knurled Brass Locknut – Tapped 1/8 IPS (SL02244): Unfinished, 3/4″ Diameter…

7. Quality Float Works – Brass Adapters

Domain: qualityfloatworks.com

Registered: 2003 (22 years)

Introduction: Quality Float Works offers a range of replacement parts including brass adapters. These adapters are designed for durability and compatibility with various float systems. They are essential for ensuring proper function and reliability in float applications.

8. Arrowhead Brass – Select-A-Length Anti-Siphon Stem

Domain: arrowheadbrass.com

Registered: 2000 (25 years)

Introduction: This company, Arrowhead Brass – Select-A-Length Anti-Siphon Stem, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for brass replacement piece

In today’s competitive landscape, strategic sourcing of brass replacement parts is essential for international B2B buyers seeking quality, reliability, and value. By carefully selecting suppliers and understanding market trends, businesses can ensure they are equipped with the right components to maintain operational efficiency. The diverse range of brass replacement pieces available—from instrument parts to industrial components—highlights the importance of sourcing from reputable manufacturers who prioritize durability and performance.

Moreover, leveraging relationships with suppliers can lead to better pricing, improved lead times, and enhanced product support. For buyers in regions such as Africa, South America, the Middle East, and Europe, tapping into local and global networks can unlock opportunities for cost savings and innovation.

As you move forward, consider evaluating your current sourcing strategies and exploring new partnerships that align with your business goals. The future of sourcing brass replacement parts is promising, and proactive engagement will position your organization to thrive in a dynamic market. Embrace the potential for growth and efficiency by investing in quality sourcing practices today.