Introduction: Navigating the Global Market for brass mechanical properties

In the rapidly evolving global market, sourcing high-quality brass mechanical properties can present significant challenges for international B2B buyers. Whether you’re in Africa, South America, the Middle East, or Europe, understanding the diverse characteristics of brass—such as tensile strength, corrosion resistance, and machinability—is crucial for making informed purchasing decisions. This guide serves as a comprehensive resource, covering various types of brass, their mechanical and thermal properties, and their applications across industries.

From plumbing components to precision machinery parts, the versatility of brass makes it a preferred choice in numerous sectors. However, the complexities of supplier vetting, cost considerations, and regulatory compliance can complicate the sourcing process. This guide empowers buyers by providing actionable insights into the key properties of brass alloys, including detailed comparisons and specifications that aid in supplier selection.

By navigating the nuances of brass materials, buyers can enhance their procurement strategies, ensuring that they secure the best quality products tailored to their specific needs. With this knowledge, B2B buyers can confidently engage with suppliers, optimize their material choices, and ultimately drive success in their projects.

Understanding brass mechanical properties Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Free-Cutting Brass | High machinability, good corrosion resistance | Fasteners, plumbing components, electrical parts | Pros: Excellent for precision machining; Cons: Lower strength compared to other brasses. |

| Architectural Brass | Aesthetic appeal, good corrosion resistance | Decorative elements, fixtures, and fittings | Pros: Attractive finish; Cons: May require more maintenance to retain appearance. |

| Leaded Brass | Enhanced machinability due to lead content | Valves, gears, and intricate components | Pros: Superior machining capabilities; Cons: Lead content raises health concerns. |

| Naval Brass | High corrosion resistance, especially in marine environments | Marine hardware, fittings, and fasteners | Pros: Excellent durability in harsh conditions; Cons: Higher cost than standard brass. |

| High-Strength Brass | Increased tensile strength and hardness | Structural components, heavy-duty applications | Pros: Suitable for demanding applications; Cons: Reduced ductility may limit forming capabilities. |

What Are the Characteristics of Free-Cutting Brass?

Free-cutting brass, typically UNS C36000, is renowned for its exceptional machinability, making it a preferred choice in industries requiring precision components. Comprising around 60-63% copper and 35.5% zinc, it also features lead to enhance cutting performance. This alloy is particularly suitable for manufacturing fasteners and plumbing components where intricate designs are common. When purchasing, consider the trade-off between its ease of machining and lower overall strength, which may not be suitable for high-stress applications.

Why Choose Architectural Brass for Aesthetic Applications?

Architectural brass is often selected for its visual appeal and corrosion resistance, making it ideal for decorative elements in buildings. This type of brass can be polished to a high sheen, enhancing its aesthetic value in fixtures and fittings. However, while it provides an attractive finish, buyers must consider the potential for tarnishing and maintenance requirements to keep its appearance intact. Understanding the environmental conditions where the brass will be installed can inform purchasing decisions.

What Advantages Does Leaded Brass Offer for Machining?

Leaded brass, characterized by its lead content, significantly improves machinability, allowing for faster and more efficient production of complex components such as valves and gears. This alloy is particularly advantageous in industries where precision is critical. However, buyers should be aware of the health concerns associated with lead, which may necessitate additional safety measures during manufacturing. Evaluating the balance between machinability and safety is crucial for B2B buyers in this sector.

How Does Naval Brass Stand Out in Marine Applications?

Naval brass is specifically formulated for high resistance to corrosion, especially in saltwater environments, making it an essential choice for marine hardware and fittings. With a composition that includes copper, zinc, and small amounts of tin, this alloy excels in durability and performance under challenging conditions. While the benefits are clear, the higher cost associated with naval brass may be a consideration for budget-conscious buyers. It is vital to assess the long-term value and performance against initial investment.

What Makes High-Strength Brass Suitable for Structural Applications?

High-strength brass is engineered to provide increased tensile strength and hardness, making it suitable for structural components in demanding applications. This type of brass is often used in heavy-duty machinery and equipment where reliability is paramount. However, buyers should consider the potential trade-off in ductility, as higher strength may limit the material’s ability to be formed into complex shapes. Understanding the specific requirements of the application will guide buyers in selecting the right brass type.

Key Industrial Applications of brass mechanical properties

| Industry/Sector | Specific Application of brass mechanical properties | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Plumbing | Manufacturing of plumbing fittings and fixtures | High corrosion resistance ensures durability and longevity of products. | Consider local regulations on lead content and corrosion resistance standards. |

| Automotive | Production of electrical connectors and components | Excellent conductivity and machinability enhance performance and reliability. | Ensure compliance with international automotive standards and specifications. |

| Electronics | Fabrication of circuit board relays and connectors | High thermal and electrical conductivity improves efficiency and performance. | Look for suppliers who offer quality certifications and precise machining capabilities. |

| Aerospace | Creation of valve components and fasteners | Lightweight yet strong, brass components reduce overall weight without compromising safety. | Evaluate suppliers based on their experience with aerospace-grade materials and quality assurance processes. |

| General Manufacturing | Production of gears, nuts, and bolts | High machinability reduces production time and costs, enhancing operational efficiency. | Assess the supplier’s ability to meet custom specifications and delivery timelines. |

In the plumbing sector, brass is extensively used for manufacturing fittings and fixtures due to its excellent corrosion resistance. This property ensures that plumbing systems remain functional over long periods, reducing maintenance costs. Buyers should consider local regulations regarding lead content, as certain brass alloys may not meet health standards in various regions.

In the automotive industry, brass components, particularly electrical connectors, benefit from the alloy’s high conductivity and machinability. These properties are crucial for ensuring reliable electrical connections in vehicles, which is paramount for safety and performance. International buyers must verify that suppliers adhere to automotive standards to ensure product reliability.

The electronics sector utilizes brass in circuit board relays and connectors, where high thermal and electrical conductivity is essential for efficient performance. The unique mechanical properties of brass allow for precise machining, which is critical for the miniaturization of electronic components. Buyers should prioritize suppliers with quality certifications to guarantee component reliability.

Aerospace applications leverage brass for valve components and fasteners, where the material’s lightweight yet robust nature contributes to overall aircraft efficiency. The stringent safety standards in the aerospace industry necessitate that buyers assess suppliers based on their expertise with aerospace-grade materials and compliance with quality assurance processes.

In general manufacturing, brass is favored for producing gears, nuts, and bolts due to its exceptional machinability. This property allows for quicker production times and cost savings, making brass an efficient choice for various applications. Buyers should evaluate suppliers for their ability to meet custom specifications and ensure timely delivery to maintain production schedules.

3 Common User Pain Points for ‘brass mechanical properties’ & Their Solutions

Scenario 1: Inconsistent Quality Across Suppliers

The Problem: A B2B buyer in the manufacturing sector discovers that the brass components received from different suppliers vary significantly in mechanical properties, such as tensile strength and elongation at break. This inconsistency leads to production delays and quality control issues, ultimately affecting the buyer’s ability to meet client specifications and deadlines. The lack of standardized testing and reporting practices among suppliers complicates the buyer’s decision-making process, as they struggle to determine which supplier can provide reliable material properties.

The Solution: To mitigate this issue, buyers should establish clear communication and quality assurance protocols with their suppliers. First, they should request detailed material certifications that include mechanical properties for each batch supplied. This documentation should adhere to industry standards, such as ASTM or ISO, to ensure uniformity in testing methods. Additionally, buyers can implement a supplier scorecard system that evaluates consistency in quality, delivery time, and adherence to specifications. By fostering strong relationships with a select group of suppliers and conducting periodic audits, buyers can ensure they receive high-quality brass that meets their specific mechanical property requirements.

Scenario 2: Challenges in Machinability and Fabrication

The Problem: A company specializing in precision machining faces difficulties when working with brass materials, particularly in machining operations that require high precision. The variability in machinability ratings among different brass alloys creates challenges during production, leading to increased tool wear, longer machining times, and higher costs. Buyers often find themselves in a bind, trying to balance the desired mechanical properties of brass with the practical aspects of machinability.

The Solution: To overcome these challenges, buyers should focus on selecting the right brass alloy for their specific machining needs. For instance, opting for free-cutting brass (like UNS C36000) can significantly improve machinability, as it has a machinability rating of 100%. Buyers should also consider investing in advanced tooling and machine settings tailored for brass materials, which can reduce tool wear and enhance production efficiency. Collaborating with suppliers who understand the machining process and can provide alloy recommendations based on specific applications can further streamline operations. Regular training for machinists on best practices when working with brass can also lead to improved outcomes.

Scenario 3: Corrosion Resistance and Environmental Factors

The Problem: A B2B buyer in the plumbing industry encounters issues with brass components corroding prematurely in certain environments, leading to product failures and increased warranty claims. This problem is exacerbated in regions with high humidity or exposure to aggressive chemicals, which can significantly impact the longevity and reliability of brass fittings and fixtures. The buyer is left grappling with how to select the right brass alloy that can withstand these challenging conditions without compromising on performance.

The Solution: To address corrosion resistance concerns, buyers should conduct thorough research on the specific environmental factors that their products will face. Selecting a brass alloy with higher copper content, such as naval brass or specialized corrosion-resistant alloys, can enhance durability in harsh environments. Additionally, buyers should consider applying protective coatings or platings to brass components, which can further increase resistance to corrosion. It is also advisable to consult with materials engineers or metallurgists who can provide insights into the best practices for selecting and treating brass materials based on the intended application. Regular field testing and monitoring of installed components can help identify potential corrosion issues before they lead to significant failures.

Strategic Material Selection Guide for brass mechanical properties

What Are the Key Mechanical Properties of Common Brass Alloys?

Brass alloys are widely utilized in various industries due to their favorable mechanical properties. Here, we analyze four common brass materials, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Free-Cutting Brass (UNS C36000)

Key Properties: Free-cutting brass is known for its excellent machinability, with a machinability rating of 100%. It typically contains 61.5% copper, 35.5% zinc, and 3% lead. Its tensile strength ranges from 49,000 to 68,000 psi, making it suitable for high-stress applications. The melting point is between 1,630°F and 1,650°F.

Pros & Cons: The primary advantage of free-cutting brass is its exceptional machinability, which reduces manufacturing complexity and costs. However, the presence of lead raises concerns regarding environmental compliance, especially in regions with strict regulations on lead content.

Impact on Application: This alloy is ideal for precision components like valves, fittings, and fasteners, where high durability and ease of machining are critical.

Considerations for International Buyers: Compliance with international standards such as ASTM and EN is essential. Buyers from regions like Europe may encounter stricter regulations regarding lead content, necessitating careful supplier selection.

2. Architectural Brass (C26800)

Key Properties: Architectural brass typically comprises 60% copper, 39% zinc, and minor amounts of other elements. It exhibits good corrosion resistance and moderate strength, with an ultimate tensile strength of approximately 50,000 psi. Its melting point ranges from 1,650°F to 1,750°F.

Pros & Cons: Architectural brass is aesthetically pleasing, making it suitable for decorative applications. However, its lower strength compared to other brass types may limit its use in high-stress environments.

Impact on Application: This material is often used in architectural applications such as railings, fixtures, and decorative elements, where appearance is as crucial as performance.

Considerations for International Buyers: Buyers should verify compliance with local building codes and standards, which can vary significantly across regions, particularly in Europe and the Middle East.

3. Naval Brass (C46400)

Key Properties: Naval brass, with a composition of 60% copper, 39% zinc, and 1% tin, is designed for marine applications. It offers excellent corrosion resistance in seawater and has a tensile strength of around 60,000 psi. Its melting point is approximately 1,600°F.

Pros & Cons: The primary advantage of naval brass is its superior resistance to corrosion, making it ideal for marine environments. However, its higher cost compared to standard brass alloys may be a limiting factor for some applications.

Impact on Application: Naval brass is commonly used in ship fittings, propellers, and other marine hardware, where exposure to harsh conditions is expected.

Considerations for International Buyers: Buyers should ensure that the brass meets maritime standards and certifications, which can differ by region, especially in Europe and the Middle East.

4. Cartridge Brass (C26000)

Key Properties: Cartridge brass contains approximately 70% copper and 30% zinc, providing a good balance of strength and ductility. It has a tensile strength of around 60,000 psi and is known for its excellent cold working properties.

Pros & Cons: The main advantage of cartridge brass is its versatility, making it suitable for a wide range of applications from plumbing to electrical components. However, its susceptibility to dezincification in certain environments can be a drawback.

Impact on Application: This alloy is widely used in the manufacturing of ammunition casings, plumbing fixtures, and electrical connectors, where both strength and workability are essential.

Considerations for International Buyers: Buyers should be aware of local regulations regarding the use of copper alloys and ensure that their suppliers adhere to relevant quality standards.

Summary Table of Brass Mechanical Properties

| Material | Typical Use Case for brass mechanical properties | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Free-Cutting Brass (C36000) | Precision components, valves, fittings | Exceptional machinability | Environmental compliance issues | Medium |

| Architectural Brass (C26800) | Decorative fixtures, railings | Aesthetic appeal | Lower strength | Medium |

| Naval Brass (C46400) | Marine hardware, ship fittings | Superior corrosion resistance | Higher cost | High |

| Cartridge Brass (C26000) | Plumbing fixtures, electrical components | Versatility and good workability | Susceptibility to dezincification | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for brass mechanical properties

What Are the Key Stages in the Manufacturing Process of Brass?

The manufacturing of brass involves several crucial stages that ensure the production of high-quality components with the desired mechanical properties. Understanding these stages can help B2B buyers make informed decisions when sourcing brass products.

1. Material Preparation: What Materials Are Used and How Are They Processed?

The first step in brass manufacturing is material preparation, which typically involves sourcing high-purity copper and zinc, as well as any additional alloying elements like lead, depending on the specific brass grade. The copper and zinc are melted together in a furnace, usually at temperatures between 885°C and 900°C (1630°F to 1650°F).

Once melted, the alloy is poured into molds to form ingots. These ingots are then cooled and subjected to further processing. It’s crucial for suppliers to adhere to stringent quality standards to ensure the materials meet the required specifications for mechanical properties.

2. Forming: What Techniques Are Employed in Shaping Brass?

After the ingots are produced, the next stage is forming. This can be achieved through various methods such as extrusion, forging, or casting. Each method is chosen based on the desired shape, volume, and mechanical properties of the final product.

-

Extrusion: This technique is widely used for producing long shapes like bars and tubes. The brass is heated and pushed through a die, creating uniform cross-sectional profiles.

-

Forging: Used for components requiring higher strength, forging involves shaping the brass by applying compressive forces. This method enhances the material’s grain structure, thereby improving mechanical properties.

-

Casting: For complex shapes, brass can be cast using sand casting or die casting. This process allows for intricate designs but may require additional finishing steps to achieve desired tolerances.

How Is Quality Control Implemented in Brass Manufacturing?

Quality assurance is vital in brass manufacturing to ensure that the mechanical properties meet the specified standards. Various international and industry-specific standards guide these processes, helping to maintain consistency and reliability.

What International Standards Are Relevant for Brass Manufacturing?

ISO 9001 is a widely recognized quality management standard applicable across industries, including brass manufacturing. Compliance with ISO 9001 ensures that manufacturers implement systematic processes for quality control throughout the production cycle.

In addition to ISO standards, industry-specific certifications such as CE marking (for products sold in the European Economic Area) and API standards (for oil and gas components) may also be relevant, depending on the intended application of the brass products.

What Are the Key Quality Control Checkpoints?

Quality control in brass manufacturing typically consists of several checkpoints:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials for compliance with specifications before they enter the manufacturing process.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, operators perform checks to ensure processes are correctly executed and that the product is on track to meet the required standards.

-

Final Quality Control (FQC): After production, the final products undergo rigorous testing to verify their mechanical properties, dimensions, and overall quality.

What Testing Methods Are Commonly Used in Brass Quality Assurance?

Various testing methods are employed to verify the mechanical properties of brass. These include:

-

Tensile Testing: Measures the ultimate tensile strength, yield strength, and elongation at break, providing insights into how the material will behave under stress.

-

Hardness Testing: Commonly performed using the Rockwell or Brinell methods, this testing assesses the material’s resistance to deformation.

-

Metallographic Analysis: This involves examining the microstructure of the brass to ensure uniformity and identify any defects that could affect performance.

-

Chemical Composition Analysis: Conducted using spectrometry, this test ensures that the alloying elements are within specified limits, which is crucial for achieving desired mechanical properties.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers must ensure that their suppliers maintain robust quality control measures. Here are several actionable steps:

-

Supplier Audits: Conducting regular audits of suppliers can provide insight into their quality control processes and adherence to international standards.

-

Requesting Quality Reports: Suppliers should provide detailed quality assurance documentation, including test results and compliance certificates, to validate their claims.

-

Third-Party Inspections: Engaging independent inspectors to evaluate the manufacturing processes and final products can add an extra layer of assurance regarding quality.

What Nuances Should International Buyers Consider in Quality Control?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control in brass manufacturing is crucial. Factors such as shipping logistics, cultural differences in business practices, and varying regulatory standards can impact the procurement process.

Establishing clear communication with suppliers regarding quality expectations and certifications can help mitigate risks. Additionally, buyers should familiarize themselves with the specific regulatory requirements in their own markets to ensure compliance.

By understanding the manufacturing processes and quality assurance practices in brass production, B2B buyers can make informed decisions that align with their quality requirements and business objectives. This comprehensive approach not only ensures product reliability but also fosters long-term partnerships with suppliers committed to excellence.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘brass mechanical properties’

Introduction

Navigating the procurement of brass, particularly its mechanical properties, is crucial for international B2B buyers. This guide provides a structured checklist to ensure you select the right brass material that meets your specific application requirements. By following these steps, you can make informed decisions that will enhance your product quality and operational efficiency.

Step 1: Define Your Technical Specifications

Before sourcing brass, clearly outline your technical requirements. This includes specifying the desired mechanical properties such as tensile strength, yield strength, elongation, and machinability. Understanding these parameters ensures that the brass you procure will perform adequately in its intended application, whether it’s for plumbing components, fasteners, or electrical parts.

- Key Properties to Consider:

- Tensile Strength: Ensure it meets your application demands.

- Machinability Rating: Affects production efficiency and cost.

Step 2: Research Material Grades and Types

Brass comes in various grades, each with unique properties and applications. Familiarize yourself with common types such as C36000, known for its excellent machinability, or C26000, which offers good corrosion resistance. This knowledge will help you identify which brass type aligns best with your project needs.

- Common Grades:

- C36000: Free-cutting brass with high machinability.

- C26000: General-purpose brass with good corrosion resistance.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request company profiles, product samples, and case studies to assess their capabilities. It’s also beneficial to seek references from other businesses in your industry or region to verify their reliability and quality.

- Key Evaluation Criteria:

- Certifications: Check for ISO or other relevant quality certifications.

- Experience: Look for suppliers with a proven track record in your industry.

Step 4: Request Material Certifications and Test Reports

Ensure that your selected suppliers can provide material certifications and mechanical test reports. These documents validate the properties of the brass, confirming that it meets your specified requirements. This step mitigates risks associated with material failure in your applications.

- Important Documents:

- Mill Test Reports (MTRs): Verify chemical and mechanical properties.

- Compliance Certifications: Ensure materials meet local and international standards.

Step 5: Consider Logistics and Delivery Times

Evaluate the logistics capabilities of your suppliers, including shipping times and delivery reliability. Understanding lead times is essential for maintaining your production schedule and minimizing downtime. It’s advisable to discuss these factors upfront to set clear expectations.

- Logistical Considerations:

- Shipping Options: Air freight may be quicker but more expensive than sea freight.

- Local Regulations: Be aware of any import/export restrictions in your region.

Step 6: Negotiate Pricing and Terms

Once you have identified a suitable supplier, negotiate pricing and payment terms. Consider not just the upfront cost but also the long-term value, including quality and service. A transparent discussion on terms can lead to a mutually beneficial agreement that supports your procurement goals.

- Key Negotiation Points:

- Bulk Discounts: Inquire about pricing tiers for larger orders.

- Payment Terms: Establish favorable terms that align with your cash flow needs.

Step 7: Plan for Quality Assurance

After procurement, implement a quality assurance plan to monitor the performance of the brass materials in your operations. Regularly assess the material against your specifications and document any deviations to address potential issues promptly.

- Quality Control Measures:

- Routine Testing: Conduct periodic checks on material properties.

- Feedback Loop: Establish a communication channel with your supplier for ongoing quality discussions.

By following this checklist, you can navigate the complexities of sourcing brass with confidence, ensuring that you select materials that meet your operational requirements and quality standards.

Comprehensive Cost and Pricing Analysis for brass mechanical properties Sourcing

What Are the Key Cost Components in Sourcing Brass Mechanical Properties?

When evaluating the cost structure for sourcing brass mechanical properties, several key components come into play. The primary cost elements include:

-

Materials: The cost of raw materials, specifically the copper and zinc used to produce brass, significantly influences pricing. Fluctuations in the global copper market can lead to price volatility. For instance, the cost of high-quality brass, such as UNS C36000, may be higher due to its superior mechanical properties and machinability.

-

Labor: Skilled labor is essential for the machining and fabrication of brass components. Labor costs can vary significantly depending on the region and the complexity of the production process. In regions with lower labor costs, such as parts of South America or Africa, overall sourcing costs may be reduced.

-

Manufacturing Overhead: This encompasses costs associated with production facilities, utilities, and administrative expenses. Efficient manufacturing processes can reduce overhead, directly impacting pricing for buyers.

-

Tooling: The initial investment in tooling is a significant cost, particularly for custom brass components. High-quality tooling can enhance production efficiency but requires upfront capital. This cost is often amortized over the production run.

-

Quality Control (QC): Ensuring that brass components meet specified mechanical properties and certifications can incur additional costs. Quality control measures are crucial for international compliance, which may necessitate more rigorous testing and inspection processes.

-

Logistics: Transportation and handling of brass materials and finished products can add to the overall cost. Factors such as distance, shipping method, and customs duties should be carefully considered. Incoterms can also influence logistics costs, especially for international buyers.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. Understanding the market dynamics and supplier relationships can help buyers negotiate better pricing.

How Do Price Influencers Impact Brass Mechanical Properties Pricing?

Several factors can influence the pricing of brass mechanical properties:

-

Volume/MOQ: Larger orders often qualify for bulk pricing, reducing the per-unit cost. Buyers should assess their needs and negotiate minimum order quantities (MOQ) to optimize their purchasing strategy.

-

Specifications and Customization: Customized brass components that meet specific mechanical properties may incur higher costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Brass with higher purity levels or specific certifications (e.g., ISO standards) generally commands a premium. Buyers should evaluate whether the additional cost aligns with their application needs.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers with a track record of quality may charge more, but the assurance of consistent supply and quality may justify the higher cost.

-

Incoterms: Understanding the terms of delivery is essential for calculating total costs. Different Incoterms can shift the responsibility for logistics and customs duties, impacting the final price.

What Are Some Effective Buyer Tips for Cost-Efficiency in Brass Sourcing?

For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, here are some actionable tips for cost-effective sourcing of brass mechanical properties:

-

Negotiate with Suppliers: Always engage in negotiations to secure better pricing. Building long-term relationships with suppliers can also lead to preferential pricing and terms.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Evaluate the long-term costs associated with maintenance, durability, and potential failures to determine the most cost-effective option.

-

Stay Informed on Market Trends: Keep abreast of fluctuations in raw material prices and market demands. This awareness can provide leverage during negotiations and help in timing purchases effectively.

-

Leverage Local Resources: When sourcing brass, consider local suppliers who may offer lower logistics costs and faster delivery times. This can be particularly beneficial for buyers in regions with developing industrial bases.

-

Understand Pricing Nuances: Different regions may have varying pricing structures based on local demand, labor costs, and material availability. Conduct thorough market research to understand these nuances before making purchasing decisions.

Disclaimer on Indicative Prices

Prices for brass mechanical properties can fluctuate based on market conditions, supplier pricing strategies, and other external factors. It is advisable for buyers to obtain quotes from multiple suppliers and conduct thorough due diligence to ensure they are receiving competitive pricing.

Alternatives Analysis: Comparing brass mechanical properties With Other Solutions

Exploring Viable Alternatives to Brass Mechanical Properties

In various industrial applications, brass is a commonly favored material due to its impressive mechanical properties, including high corrosion resistance and excellent machinability. However, it is essential for B2B buyers to evaluate alternative materials that may offer comparable or superior properties based on specific needs, regional availability, and cost considerations. Below, we compare brass with two viable alternatives: aluminum and stainless steel.

| Comparison Aspect | Brass Mechanical Properties | Aluminum Alloy | Stainless Steel |

|---|---|---|---|

| Performance | High tensile strength (up to 68,000 psi), excellent corrosion resistance, 100% machinability | Good strength-to-weight ratio, corrosion-resistant, lower tensile strength (up to 60,000 psi) | Very high tensile strength (up to 150,000 psi), excellent corrosion resistance but less machinable |

| Cost | Moderate cost per pound, varies with copper prices | Generally lower cost, especially for high-volume production | Higher cost due to alloying elements and processing |

| Ease of Implementation | Easy to machine, widely available | Easy to fabricate, lightweight, requires specialized tooling for complex shapes | More complex to machine; often requires specialized tools |

| Maintenance | Low maintenance, good long-term durability | Requires protective coating in harsh environments | Very low maintenance, excellent durability |

| Best Use Case | Plumbing fixtures, fasteners, electrical components | Aerospace, automotive parts, lightweight applications | Heavy-duty applications, medical instruments, architectural components |

Detailed Breakdown of Alternatives

1. Aluminum Alloy

Aluminum alloys are known for their lightweight nature and good corrosion resistance. They are often used in aerospace and automotive applications where weight reduction is crucial. While they offer a favorable strength-to-weight ratio, aluminum alloys typically have lower tensile strength compared to brass, which may limit their use in high-stress applications. Additionally, aluminum is generally less expensive, making it an attractive option for large-scale manufacturing. However, specialized tooling may be required for complex designs, which could impact initial setup costs.

2. Stainless Steel

Stainless steel is renowned for its exceptional strength and corrosion resistance. It is often the material of choice for heavy-duty applications such as medical instruments and architectural components. While it can withstand higher tensile loads than brass, stainless steel is less machinable, which can lead to increased production costs and longer lead times. Additionally, stainless steel tends to be more expensive than both brass and aluminum, making it less appealing for cost-sensitive projects. However, its durability and low maintenance requirements can justify the investment in long-term applications.

Conclusion: Choosing the Right Solution for Your Needs

When selecting between brass and its alternatives, B2B buyers should carefully assess their specific application requirements. Factors such as mechanical performance, cost efficiency, and ease of implementation play crucial roles in this decision-making process. Brass remains a strong contender for applications that prioritize machinability and moderate cost. However, if weight reduction or extreme strength is critical, aluminum or stainless steel may provide better solutions. Conducting a thorough analysis of these alternatives will help ensure that you choose the most suitable material for your project needs, ultimately enhancing efficiency and productivity in your operations.

Essential Technical Properties and Trade Terminology for brass mechanical properties

What Are the Key Technical Properties of Brass That B2B Buyers Should Know?

Understanding brass mechanical properties is crucial for B2B buyers to make informed decisions regarding materials for manufacturing and production. Here are some essential technical specifications that impact performance, durability, and application suitability:

-

Material Grade

The material grade of brass, such as UNS C36000 or C26000, indicates its specific composition and properties. Each grade has unique characteristics, such as machinability, corrosion resistance, and strength. For instance, C36000 (free-cutting brass) is known for its excellent machinability, making it ideal for precision components. Selecting the right grade is vital for ensuring the material meets the specific requirements of your application. -

Tensile Strength

Measured in megapascals (MPa) or pounds per square inch (psi), tensile strength refers to the maximum stress a material can withstand while being stretched or pulled before failing. For example, C36000 brass typically has a tensile strength ranging from 338 to 469 MPa (49,000 to 68,000 psi). This property is particularly important for applications subjected to high stress, as it helps determine the material’s durability and longevity. -

Elongation at Break

This property, expressed as a percentage, indicates how much a material can stretch before breaking. Brass typically exhibits high elongation rates (up to 65% for some grades), signifying its ductility. This characteristic is essential for applications requiring bending or forming, as it allows for flexibility without fracturing. -

Machinability Rating

The machinability of brass is quantified on a scale, with C36000 brass receiving a 100% rating, making it the most machinable of copper alloys. A high machinability rating means less tool wear and faster production times, which are critical factors for manufacturers looking to optimize costs and efficiency. -

Thermal Conductivity

Brass has excellent thermal conductivity, typically around 115 W/m-K, making it suitable for applications requiring efficient heat dissipation, such as heat exchangers and automotive parts. Understanding thermal properties helps B2B buyers select materials that can withstand specific thermal environments. -

Corrosion Resistance

Brass is known for its fair to excellent corrosion resistance due to its copper and zinc content. This property is vital for components exposed to harsh environments, such as plumbing fixtures and marine applications, ensuring longevity and reducing maintenance costs.

What Are Common Trade Terms Related to Brass Mechanical Properties?

Familiarity with industry jargon is essential for effective communication in B2B transactions. Here are several key terms that buyers should understand:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products used in another company’s end product. Understanding OEM specifications ensures that the brass components meet the required quality and performance standards for integration into larger systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers manage inventory levels and understand pricing strategies, as larger orders often result in lower per-unit costs. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific materials or products. Submitting an RFQ allows buyers to compare offers and negotiate better deals, ensuring they obtain the best value for their investments. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps buyers clarify shipping costs, risk transfer, and delivery obligations, which are crucial for effective logistics planning. -

Lead Time

This term refers to the time it takes from placing an order until it is delivered. Knowing lead times is vital for production scheduling and inventory management, allowing buyers to align their supply chain needs with manufacturing timelines. -

Certification

Certification indicates that a material meets specific industry standards or regulations. For brass products, certifications may relate to quality assurance, environmental compliance, or safety regulations. Buyers should inquire about certifications to ensure their materials meet applicable standards.

By grasping these essential properties and terms, B2B buyers can make informed decisions that enhance their procurement processes and ensure successful project outcomes.

Navigating Market Dynamics and Sourcing Trends in the brass mechanical properties Sector

What Are the Key Market Trends Influencing Brass Mechanical Properties?

The brass mechanical properties market is experiencing significant growth driven by increasing demand from various sectors, including construction, automotive, and electronics. The global market is largely influenced by the rising need for corrosion-resistant materials, particularly in humid and coastal regions of Africa, South America, the Middle East, and Europe. Countries such as Saudi Arabia and Vietnam are ramping up infrastructure projects, which in turn boosts the demand for high-quality brass components, such as fasteners and plumbing fixtures.

Emerging technologies are reshaping sourcing practices within the brass industry. Digital platforms for procurement and supply chain management are gaining traction, allowing international buyers to access a broader range of suppliers, compare prices, and evaluate material properties more efficiently. Furthermore, advancements in manufacturing technologies, such as precision machining and 3D printing, are enhancing the quality and customization of brass products, making them more attractive to B2B buyers looking for tailored solutions.

Additionally, the market is witnessing a shift towards sustainable sourcing, with buyers increasingly prioritizing suppliers who demonstrate environmental responsibility. This trend is particularly pertinent in regions where regulatory frameworks around sustainability are tightening, pushing companies to rethink their sourcing strategies.

How Is Sustainability Impacting Brass Sourcing and Supply Chains?

Sustainability is a pivotal concern in the brass mechanical properties sector, with environmental impacts driving changes in sourcing practices. The extraction and processing of metals can lead to significant ecological degradation if not managed properly. As international buyers become more aware of these issues, there is a growing emphasis on ethical sourcing and sustainable practices across supply chains.

Buyers are increasingly seeking suppliers who can provide certifications that demonstrate compliance with environmental standards. For instance, sourcing brass materials that are recycled or contain a high percentage of recycled content is becoming more common. These ‘green’ materials not only minimize environmental impact but also cater to the rising consumer demand for sustainable products.

Moreover, companies are adopting circular economy principles, focusing on reducing waste and reusing materials. B2B buyers from regions like Europe and South America are particularly vigilant about ensuring that their suppliers adhere to sustainability practices, as this can significantly impact their own brand reputation and market competitiveness.

What Is the Historical Context of Brass Mechanical Properties in B2B Markets?

The use of brass dates back thousands of years, with its popularity stemming from its favorable mechanical properties, including corrosion resistance, machinability, and strength. Initially utilized in decorative applications and coins, brass found its way into industrial uses during the Industrial Revolution when the demand for durable materials surged.

Over the decades, advancements in metallurgy and alloy composition have led to the development of various brass grades, each tailored for specific applications. The introduction of free-cutting brass, which enhances machinability, revolutionized manufacturing processes and made brass a staple in precision engineering and fastener production.

As global markets expanded, particularly in the latter half of the 20th century, international trade in brass products grew, paving the way for a more interconnected supply chain. Today, the brass mechanical properties sector stands at the intersection of tradition and innovation, with ongoing research aimed at improving its environmental footprint while meeting the evolving needs of B2B buyers worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of brass mechanical properties

-

How do I solve issues with brass corrosion in my application?

To mitigate corrosion issues in brass applications, consider using alloys with higher copper content, as they offer better corrosion resistance. Ensure proper surface treatments or coatings are applied to protect the brass from environmental factors. Additionally, maintaining a controlled environment where moisture and corrosive agents are minimized can significantly enhance the longevity of brass components. Regular inspections and maintenance can also help identify early signs of corrosion, allowing for timely intervention. -

What is the best brass alloy for high-stress applications?

For high-stress applications, UNS C36000 (free-cutting brass) is often recommended due to its excellent tensile strength, which ranges from 49,000 to 68,000 psi. Its high machinability rating (100%) makes it suitable for precision components. If corrosion resistance is a priority, consider alloys with higher zinc content, such as C28000, which also provides good strength and ductility. Always assess the specific mechanical requirements of your application when selecting an alloy. -

How can I verify the quality of brass from international suppliers?

To ensure the quality of brass from international suppliers, request material certifications that detail mechanical and chemical properties. Conduct supplier audits or assessments to verify their manufacturing processes and quality control measures. Additionally, consider third-party testing for critical applications. Building a relationship with suppliers who have a proven track record in your industry can also enhance trust in the quality of their products. -

What are the typical minimum order quantities (MOQs) for brass products?

Minimum order quantities for brass products can vary significantly by supplier and product type. Generally, MOQs can range from 100 kg to several tons for standard products. Custom orders may have higher MOQs due to the complexities involved in production. It is advisable to discuss your specific needs with suppliers to negotiate favorable terms that align with your purchasing strategy. -

What payment terms should I expect when sourcing brass internationally?

Payment terms for international brass sourcing often include options such as advance payment, letters of credit, or payment upon delivery. Common practices involve a 30% deposit with the order and the remaining 70% upon shipment. However, terms can vary based on supplier policies and the buyer’s creditworthiness. Always clarify payment conditions upfront to avoid misunderstandings and ensure a smooth transaction. -

How does logistics impact the sourcing of brass materials?

Logistics plays a crucial role in sourcing brass materials, affecting lead times, costs, and product availability. Factors such as shipping methods, customs regulations, and freight costs can significantly impact overall procurement expenses. To mitigate potential delays, work with suppliers who have reliable logistics partners and experience in international shipping. Additionally, consider incorporating buffer times in your project timelines to accommodate unforeseen logistics challenges. -

Can I customize brass components to meet specific requirements?

Yes, many suppliers offer customization options for brass components, allowing you to specify dimensions, finishes, and alloy compositions tailored to your needs. When considering customization, provide detailed specifications and drawings to ensure accurate production. Be aware that custom orders may involve longer lead times and higher costs, so it’s essential to discuss these aspects with your supplier early in the process. -

What quality assurance practices should I look for in brass suppliers?

When evaluating brass suppliers, look for those that adhere to international quality standards such as ISO 9001. Ensure they have robust quality assurance processes, including material testing, in-process inspections, and final product evaluations. A supplier’s willingness to provide documentation of their quality control measures and certifications can be an indicator of their commitment to delivering high-quality brass products.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Brass Mechanical Properties Manufacturers & Suppliers List

1. Ezlok – Free-Cutting Brass C36000

Domain: ezlok.com

Registered: 1997 (28 years)

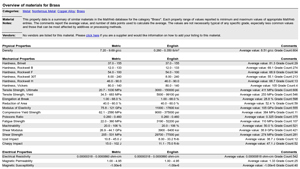

Introduction: {‘material’: ‘Free-Cutting Brass’, ‘uns’: ‘C36000’, ‘composition’: {‘Cu’: ’60 – 63%’, ‘Fe’: ‘Max 0.35%’, ‘Other’: ‘Max 0.5%’, ‘Pb’: ‘2.5 – 3.7%’, ‘Zn’: ‘35.5%’}, ‘physical_properties’: {‘density’: {‘metric’: ‘8.49 g/cc’, ‘english’: ‘0.307 lb/in³’, ‘temperature’: ’20°C (68°F)’}}, ‘mechanical_properties’: {‘tensile_strength_ultimate’: {‘metric’: ‘338 – 469 MPa’, ‘english’: ‘49000 – 68000 psi’}, ‘ten…

2. AZOM – Brass UNS C28000

Domain: azom.com

Registered: 1999 (26 years)

Introduction: Brass UNS C28000 is a copper-zinc alloy known for its electrical and thermal conductivity, strength, hardness, wear-resistance, ductility, and corrosion-resistance. It has a chemical composition of 59-63% Copper (Cu), 0.070% Iron (Fe), 0.30% Lead (Pb), and 40% Zinc (Zn). The physical properties include a melting point of 904°C (liquidus) and 899°C (solidus), and a density of 8.39 gm/cm³. Mechanica…

3. MatWeb – Brass Overview

Domain: matweb.com

Registered: 1997 (28 years)

Introduction: {“Overview”:”Brass is a copper alloy categorized under nonferrous metals.”,”Physical_Properties”:{“Density”:{“Metric”:”7.20 – 9.69 g/cc”,”English”:”0.260 – 0.350 lb/in³”,”Average”:”8.51 g/cc”},”Hardness_Brinell”:{“Metric”:”37.0 – 155″,”English”:”37.0 – 155″,”Average”:”81.3″},”Hardness_Rockwell_B”:{“Metric”:”12.0 – 133″,”English”:”12.0 – 133″,”Average”:”69.1″},”Tensile_Strength_Ultimate”:{“Metric”:…

4. CCT Precision – Brass 260

Domain: cctprecision.com

Registered: 2016 (9 years)

Introduction: Brass is a non-ferrous alloy of Copper with fair to excellent corrosion resistance, excellent cold workability, and good hot formability. Applications include radiator cores and tanks, fasteners, locks, ammunition components, plumbing accessories, pins, and rivets.

Brass 260:

– Density: 8.53 g/cc

– Tensile Strength, Ultimate: 315 MPa

– Tensile Strength, Yield: 95.0 MPa

– Elongation at Break: 65%…

5. Vegas Fastener – Medium-Leaded Brass C34000

Domain: vegasfastener.com

Registered: 2001 (24 years)

Introduction: {“Material”:”Brass”,”Type”:”Medium-leaded brass”,”UNS”:”C34000″,”Temper”:”OSO25″,”Subcategory”:[“Brass”,”Copper Alloy”,”Metal”,”Nonferrous Metal”],”Keywords”:[“340 brass”,”CZ118″,”ISO CuZn35Pb1″,”CEN CW600N”],”Component Composition”:{“Cu”:”62.5 – 66.5 %”,”Fe”:”Max 0.1 %”,”Other”:”Max 0.5 %”,”Pb”:”0.8 – 1.4 %”,”Zn”:”34 %”},”Corrosion Resistance”:”Fair to excellent”,”Fabrication Methods”:[“blanking”…

6. MakeItFrom – Annealed (OS050) C26000 Brass

Domain: makeitfrom.com

Registered: 2009 (16 years)

Introduction: {‘name’: ‘Annealed (OS050) C26000 Brass’, ‘ductility’: ‘Second highest compared to other variants of C26000 brass’, ‘mechanical_properties’: {‘Elastic_Modulus’: ‘110 GPa’, ‘Elongation_at_Break’: ‘62%’, ‘Fatigue_Strength’: ’90 MPa’, “Poisson’s_Ratio”: ‘0.31’, ‘Rockwell_Hardness’: ’64’, ‘Shear_Modulus’: ’41 GPa’, ‘Shear_Strength’: ‘230 MPa’, ‘Tensile_Strength_UTS’: ‘330 MPa’, ‘Tensile_Strength_Yield…

7. MDPI – Brass Properties

Domain: mdpi.com

Registered: 2003 (22 years)

Introduction: This company, MDPI – Brass Properties, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Sequoia Brass – Industrial Alloys

Domain: sequoia-brass-copper.com

Registered: 1998 (27 years)

Introduction: Brass is an industrial alloy primarily made of zinc and copper, with varying compositions that can include aluminum, phosphorus, lead, manganese, or silicon. Key properties of brass include:

– Corrosion Resistance: Certain alloys can withstand seawater.

– Workability: Malleable and can be cold worked, brazed, and welded.

– Germicidal Properties: Some alloys have antimicrobial effects.

– Aesthetic …

Strategic Sourcing Conclusion and Outlook for brass mechanical properties

In summary, understanding the mechanical properties of brass, such as tensile strength, elongation, and machinability, is crucial for B2B buyers across various industries. Brass alloys, particularly C36000, offer exceptional strength and corrosion resistance, making them ideal for applications ranging from plumbing fixtures to intricate fasteners. By strategically sourcing high-quality brass materials, businesses can enhance their product durability and performance, ultimately leading to greater customer satisfaction and reduced operational costs.

For international buyers in regions like Africa, South America, the Middle East, and Europe, leveraging local suppliers who understand the unique demands of your market can provide a competitive edge. Engaging with suppliers that offer customization options and reliable delivery timelines ensures that your business remains agile and responsive to market changes.

As we look to the future, the demand for innovative brass solutions will continue to grow. It’s essential to stay informed about advancements in brass technology and to foster relationships with trusted suppliers. Take action today—evaluate your sourcing strategies and explore partnerships that can elevate your product offerings in an increasingly competitive global marketplace.