Introduction: Navigating the Global Market for brass cnc machining

In an increasingly interconnected world, international B2B buyers face the challenge of sourcing high-quality brass CNC machining components that meet specific industry standards. This guide is designed to navigate the complexities of the global market for brass CNC machining, addressing key concerns such as material selection, supplier vetting, and cost considerations. Brass, known for its excellent machinability and corrosion resistance, is widely used in various applications, from automotive components to plumbing fixtures.

This comprehensive resource delves into the various types of brass alloys, highlighting their unique properties and suitability for different machining applications. Buyers will gain insights into the most commonly used brass grades, such as C260 and C360, and discover how these options can optimize production efficiency and product performance. Additionally, the guide offers practical advice on evaluating suppliers, ensuring that partners uphold rigorous quality standards and timely delivery.

By empowering B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe—such as Nigeria and Germany—this guide equips them with the knowledge needed to make informed purchasing decisions. Understanding the nuances of brass CNC machining will not only enhance product quality but also streamline operations and improve competitiveness in the global market.

Understanding brass cnc machining Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cartridge Brass (C260) | Contains 70% copper, high ductility, versatile | Rivets, hinges, automotive parts | Pros: Excellent machinability; Cons: Lower corrosion resistance compared to other brass types. |

| Free Machining Brass (C360) | High lead content for superior machinability | High-volume production, fittings, valves | Pros: Best for mass production; Cons: Lead content raises health concerns. |

| Naval Brass (C464) | High corrosion resistance, contains aluminum | Marine applications, plumbing fixtures | Pros: Durable in marine environments; Cons: Higher cost due to alloying elements. |

| Architectural Brass | Aesthetic appeal with various finishes | Decorative elements, fixtures, jewelry | Pros: Attractive appearance; Cons: May require additional surface finishing. |

| Leaded Brass | Enhanced machinability with lead content | Precision parts, screws, and fasteners | Pros: Ideal for complex shapes; Cons: Environmental regulations on lead. |

What is Cartridge Brass (C260) and Its B2B Significance?

Cartridge Brass, also known as C260, is a widely used brass alloy composed of 70% copper and 30% zinc. Its high ductility makes it suitable for forming complex shapes, making it a preferred choice for various applications such as rivets, automotive parts, and hinges. B2B buyers should consider its excellent machinability, which allows for high feed rates and minimal coolant needs during production. However, its corrosion resistance is relatively lower than other brass types, which could be a drawback in specific environments.

Why Choose Free Machining Brass (C360) for High-Volume Production?

C360, or Free Machining Brass, is recognized for its high lead content, which significantly enhances its machinability. This alloy is the industry standard for high-volume production due to its ability to maintain precision during machining processes. Common applications include fittings, valves, and other components requiring mass production. B2B buyers should weigh the benefits of efficient manufacturing against the potential health concerns associated with lead content, which may necessitate compliance with specific regulations.

How Does Naval Brass (C464) Stand Out in Corrosion Resistance?

Naval Brass, specifically C464, is engineered with aluminum to provide exceptional corrosion resistance, making it ideal for marine applications and plumbing fixtures. Its durability in harsh environments is a significant advantage for B2B buyers in industries dealing with water exposure. While its performance is commendable, the increased cost due to alloying elements may impact budget considerations for large-scale projects.

What Are the Benefits of Architectural Brass for Decorative Applications?

Architectural Brass is favored for its aesthetic appeal, available in various finishes that enhance its visual impact. This type of brass is commonly used in decorative elements, fixtures, and jewelry. B2B buyers should appreciate its attractive appearance, which can elevate product offerings. However, depending on the application, additional surface finishing may be required, potentially increasing production time and costs.

Why Consider Leaded Brass for Precision Parts?

Leaded Brass is characterized by its enhanced machinability due to the inclusion of lead, making it ideal for producing precision parts, screws, and fasteners. Its ability to be machined into complex shapes quickly and efficiently is a key advantage for B2B manufacturers. However, buyers must navigate environmental regulations concerning lead, which could influence sourcing decisions and production processes.

Key Industrial Applications of brass cnc machining

| Industry/Sector | Specific Application of Brass CNC Machining | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Electrical Terminals and Connectors | High conductivity and corrosion resistance ensure reliable electrical connections. | Assess the quality of brass grades and certifications for automotive standards. |

| Plumbing | Valves and Fittings | Durability and resistance to corrosion enhance the lifespan of plumbing components. | Verify compatibility with local plumbing standards and regulations. |

| Electronics | Heat Sinks and Connectors | Excellent thermal and electrical conductivity improves device performance. | Ensure compliance with international electrical standards and specifications. |

| Marine | Marine Hardware and Components | Corrosion resistance in saltwater environments prolongs equipment life. | Evaluate the specific alloy compositions for marine-grade applications. |

| Musical Instruments | Instrument Parts (e.g., Trumpets, Saxophones) | Aesthetic appeal and acoustic properties enhance product quality and marketability. | Consider customization options and lead times for specialized components. |

How is Brass CNC Machining Applied in the Automotive Industry?

In the automotive sector, brass CNC machining is crucial for manufacturing electrical terminals and connectors. These components require high conductivity and resistance to corrosion to ensure reliable electrical connections, especially in vehicles exposed to various environmental conditions. International buyers, particularly from regions like Africa and Europe, should prioritize sourcing brass grades that meet stringent automotive standards to ensure durability and performance.

What Role Does Brass CNC Machining Play in Plumbing Applications?

Brass CNC machining is widely used to produce valves and fittings in plumbing systems. The inherent durability and corrosion resistance of brass make it an ideal choice for components that must withstand high pressure and moisture. For B2B buyers in South America and the Middle East, it’s essential to verify that the brass parts comply with local plumbing regulations and standards to avoid costly compliance issues.

Why is Brass CNC Machining Important for the Electronics Sector?

In electronics, brass CNC machining is utilized for manufacturing heat sinks and connectors, which require excellent thermal and electrical conductivity. These properties enhance the performance of electronic devices, making them more efficient and reliable. Buyers, especially from Europe, should ensure that sourced components adhere to international electrical standards to facilitate seamless integration into their products.

How Does Brass CNC Machining Benefit the Marine Industry?

The marine industry benefits significantly from brass CNC machining, particularly in the production of marine hardware and components. Brass’s resistance to corrosion in saltwater environments is a vital asset, extending the lifespan of critical equipment. B2B buyers from regions like Africa and the Middle East should evaluate the specific alloy compositions to ensure they are suitable for marine-grade applications, as this can impact both performance and safety.

What Advantages Does Brass CNC Machining Offer for Musical Instruments?

Brass CNC machining is essential in crafting parts for musical instruments such as trumpets and saxophones. The aesthetic appeal of brass, combined with its acoustic properties, enhances the quality and marketability of these instruments. Buyers looking to source custom components should consider the availability of specialized machining options and lead times to meet production schedules effectively.

3 Common User Pain Points for ‘brass cnc machining’ & Their Solutions

Scenario 1: Difficulty Sourcing Quality Brass Components

The Problem: Many B2B buyers face challenges in sourcing high-quality brass components that meet their precise specifications. In industries like automotive or medical manufacturing, the tolerances for machined parts can be incredibly tight. Discrepancies in material quality or machining precision can lead to production delays, increased costs, and even compromised product integrity. Buyers often struggle with inconsistent quality from different suppliers, making it hard to maintain standards across their supply chain.

The Solution: To overcome this challenge, B2B buyers should adopt a rigorous vendor evaluation process that emphasizes quality assurance. Start by identifying reputable brass CNC machining suppliers with a proven track record in your specific industry. Request samples of their work and assess their adherence to industry standards such as ISO certifications. Additionally, consider suppliers that provide comprehensive documentation, including material certificates and inspection reports. Establishing long-term relationships with a select few suppliers can also facilitate better communication and consistency in quality, ensuring that your components are not only reliable but also compliant with regulatory requirements.

Scenario 2: Challenges with Machining Brass Alloys

The Problem: Brass alloys come in various grades, each with unique properties that can significantly affect the machining process. For instance, while C360 brass is renowned for its machinability, other alloys might present challenges such as increased wear on tools or unexpected machining behavior. B2B buyers often find themselves overwhelmed by the technical specifications and may inadvertently select the wrong brass grade, leading to inefficiencies in production and higher costs due to increased tool wear or defective parts.

The Solution: To mitigate these challenges, buyers should invest time in understanding the specific properties of different brass alloys and their suitability for various applications. Collaborate closely with your CNC machining partner to discuss your intended application and seek their expertise in material selection. Utilize resources such as technical datasheets and industry guidelines to make informed decisions. Additionally, consider leveraging simulation software that can help predict machining outcomes based on the selected brass grade, allowing for adjustments before actual production begins. This proactive approach can save time and resources, ensuring that the chosen brass alloy aligns perfectly with your machining capabilities and end-use requirements.

Scenario 3: Managing Costs in Brass CNC Machining

The Problem: Cost management is a significant concern for B2B buyers in brass CNC machining. Fluctuating brass prices, coupled with the expenses associated with high-precision machining, can strain budgets. Buyers often face the dilemma of balancing quality with cost-effectiveness, leading to decisions that may compromise the integrity of the final product or result in unexpected financial burdens.

The Solution: To control costs without sacrificing quality, B2B buyers should focus on optimizing their production processes. Begin by conducting a thorough cost analysis that examines every aspect of the machining process, from material procurement to labor and overhead. Engage in value engineering discussions with your suppliers to explore alternative materials or machining methods that could yield cost savings. For instance, consider bulk purchasing agreements for brass to lock in lower prices and ensure a consistent supply. Additionally, implementing lean manufacturing principles can help identify waste and inefficiencies in your production workflow, ultimately reducing costs while maintaining the high standards required for brass components. Regularly reviewing and refining your supply chain strategy will also allow you to adapt to market changes, ensuring a more stable cost structure in the long term.

Strategic Material Selection Guide for brass cnc machining

Brass CNC machining is a popular choice for various industries due to its favorable properties and versatility. When selecting the right brass material for CNC machining, it is essential to consider the specific grades available, their mechanical properties, and how they align with application requirements. Below is an analysis of four common brass materials used in CNC machining, focusing on their key properties, advantages and disadvantages, impact on applications, and considerations for international B2B buyers.

What are the Key Properties of C260 Brass for CNC Machining?

C260 brass, also known as cartridge brass, is composed of approximately 70% copper and 30% zinc. This alloy exhibits excellent ductility, making it suitable for various applications requiring intricate designs. It has a melting point of around 885-890 °C and offers good corrosion resistance, particularly in environments with moisture.

Pros & Cons: The high machinability of C260 brass allows for faster production rates, reducing manufacturing costs. However, its lower strength compared to other brass grades may limit its use in high-stress applications.

Impact on Application: C260 brass is ideal for components like rivets, hinges, and plumbing fittings, where moderate strength and corrosion resistance are essential.

Considerations for International Buyers: Buyers in regions like Nigeria and Germany should ensure compliance with ASTM standards for quality assurance and consider local sourcing to mitigate shipping costs.

How Does C360 Brass Compare for High-Volume Production?

C360 brass is often regarded as the industry standard for CNC machining due to its exceptional machinability. This alloy typically contains around 61% copper and 39% zinc, with a small percentage of lead, which enhances its machining properties.

Pros & Cons: The primary advantage of C360 brass is its ability to be machined at high speeds with minimal tool wear, making it ideal for high-volume production. However, the presence of lead can raise health and environmental concerns, leading to stricter regulations in some regions.

Impact on Application: C360 brass is commonly used in automotive components, electrical connectors, and precision instruments, where high production rates and dimensional accuracy are critical.

Considerations for International Buyers: Buyers should be aware of local regulations regarding lead content and ensure that their suppliers meet any applicable safety standards.

What Makes C464 Brass a Good Option for Marine Applications?

C464 brass, also known as naval brass, is composed of copper, zinc, and a small percentage of tin. This alloy is specifically designed for applications in marine environments due to its superior corrosion resistance, particularly against saltwater.

Pros & Cons: The corrosion resistance of C464 brass enhances the longevity of components used in harsh environments. However, its higher cost compared to other brass grades may be a barrier for some applications.

Impact on Application: C464 brass is ideal for marine fittings, valves, and hardware, where exposure to seawater can lead to rapid degradation of lesser alloys.

Considerations for International Buyers: Buyers in coastal regions should prioritize sourcing C464 brass to ensure compliance with marine industry standards and regulations.

Why is C385 Brass Considered a Versatile Choice?

C385 brass is a free-machining alloy that contains a balanced composition of copper and zinc, along with small amounts of lead. It is known for its excellent machinability and is often used in applications requiring complex shapes.

Pros & Cons: C385 brass offers a good balance of strength and machinability, making it suitable for various applications. However, it may not provide the same level of corrosion resistance as other brass alloys, limiting its use in specific environments.

Impact on Application: This alloy is commonly used in the production of screws, fasteners, and decorative items, where ease of machining and aesthetic appeal are important.

Considerations for International Buyers: Buyers should evaluate the environmental regulations in their region regarding lead content and ensure that their suppliers adhere to international standards.

Summary Table of Brass Materials for CNC Machining

| Material | Typical Use Case for brass cnc machining | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| C260 Brass | Rivets, hinges, plumbing fittings | Excellent ductility and machinability | Lower strength | Medium |

| C360 Brass | Automotive components, electrical connectors | High-speed machining capabilities | Lead content concerns | Medium |

| C464 Brass | Marine fittings, valves, hardware | Superior corrosion resistance | Higher cost | High |

| C385 Brass | Screws, fasteners, decorative items | Good balance of strength and machinability | Limited corrosion resistance | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions when sourcing brass materials for CNC machining.

In-depth Look: Manufacturing Processes and Quality Assurance for brass cnc machining

What Are the Main Stages in the Brass CNC Machining Manufacturing Process?

The brass CNC machining manufacturing process consists of several key stages, each critical for ensuring the production of high-quality components. These stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Brass CNC Machining?

Material preparation begins with the selection of high-grade brass alloys, such as C260 and C360, which are known for their excellent machinability and mechanical properties. The selected material is then cut into manageable sizes or blanks. This initial step often involves using saws or shears to create pieces that are suitable for machining.

Once the brass is cut, it undergoes inspection to ensure it meets predefined specifications. This includes checking for dimensional accuracy, surface defects, and chemical composition. In many cases, suppliers will provide material certificates that detail the properties of the brass, allowing B2B buyers to verify that they are receiving the correct grade and quality.

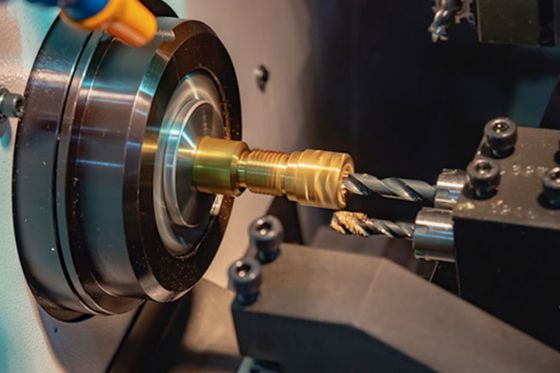

What Techniques Are Used in the Forming Stage?

The forming stage involves the use of CNC machines equipped with various cutting tools to shape the brass blanks into the desired components. Common techniques include milling, turning, and drilling.

Milling is used to remove material from the surface of the blank, allowing for intricate designs and features to be created. Turning, often employed for cylindrical components, rotates the brass blank against a cutting tool to achieve precise dimensions. Drilling is utilized to create holes or cavities in the components, which may be required for assembly or functionality.

Throughout this stage, machine operators monitor the process closely, adjusting parameters such as feed rate and spindle speed to optimize efficiency and maintain quality.

How Is Assembly Managed in Brass CNC Machining?

In some cases, the machined components may require assembly with other parts. This could involve inserting fasteners, welding, or soldering, depending on the design specifications. The assembly process is typically carried out in a controlled environment to minimize contamination and ensure component integrity.

Quality control measures are also implemented during assembly. Operators verify that all components fit together correctly and function as intended. This may involve testing the assembled parts under simulated operational conditions.

What Finishing Techniques Are Commonly Used?

Finishing is a crucial stage in brass CNC machining, as it directly impacts both the aesthetics and functionality of the final product. Common finishing techniques include polishing, plating, and anodizing.

Polishing enhances the surface finish, giving the brass components an attractive appearance while also reducing friction and wear. Plating can be applied to improve corrosion resistance, especially for components that will be used in harsh environments. Anodizing is less common with brass but can be used to enhance surface properties in specific applications.

Each finishing technique requires careful selection based on the intended use of the component. For B2B buyers, understanding these options can help in selecting the right processes to meet their requirements.

What Quality Assurance Practices Are Critical in Brass CNC Machining?

Quality assurance is paramount in brass CNC machining to ensure that components meet international and industry-specific standards. This involves implementing a series of quality control checkpoints and testing methods.

Which International Standards Should Buyers Be Aware Of?

B2B buyers should be familiar with relevant international standards, such as ISO 9001, which outlines criteria for a quality management system. Compliance with ISO 9001 ensures that suppliers consistently provide products that meet customer and regulatory requirements.

Additionally, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant, depending on the application of the brass components. These certifications signify that the products comply with safety and performance standards specific to their industries.

What Are the Key Quality Control Checkpoints?

Quality control in brass CNC machining typically includes several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon receipt to ensure they meet the required specifications before processing begins.

-

In-Process Quality Control (IPQC): During machining, operators conduct regular checks to monitor dimensions, tolerances, and surface finishes. This proactive approach helps identify and rectify issues before they escalate.

-

Final Quality Control (FQC): After machining and finishing, a final inspection is performed to verify that the finished components meet all specifications and quality standards.

What Common Testing Methods Are Employed?

Various testing methods are utilized to validate the quality of machined brass components. These may include:

-

Dimensional Inspection: Using tools such as calipers and micrometers to measure the dimensions of the components.

-

Material Testing: Conducting tensile tests and hardness tests to ensure that the brass meets the necessary mechanical properties.

-

Surface Finish Evaluation: Assessing the surface quality through visual inspections or specialized equipment to ensure it meets aesthetic and functional requirements.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control measures employed by their suppliers. This can include:

-

Audits: Conducting regular audits of the supplier’s manufacturing processes and quality control systems can provide insight into their practices and adherence to standards.

-

Quality Reports: Requesting detailed quality control reports, including test results and compliance certifications, helps buyers assess the reliability of the supplier.

-

Third-Party Inspections: Engaging third-party inspection services can provide an independent assessment of the supplier’s quality control processes and product quality.

What Are the Quality Control Nuances for International Buyers?

International B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, may encounter unique challenges regarding quality control. Factors such as varying regulatory standards, communication barriers, and logistical issues can impact quality assurance.

To navigate these challenges, buyers should establish clear communication channels with suppliers, ensuring that expectations regarding quality standards are well understood. Additionally, they should be aware of local regulations and standards that may affect product compliance.

By implementing these strategies, international buyers can enhance their confidence in the quality of brass CNC machined components and foster long-term, reliable partnerships with suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘brass cnc machining’

In today’s competitive manufacturing landscape, sourcing high-quality brass CNC machining services requires a strategic approach. This guide provides a practical checklist to assist international B2B buyers in making informed decisions, ensuring the procurement of reliable and efficient brass machining services.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for successful sourcing. Outline the dimensions, tolerances, and surface finishes required for your brass components. This clarity helps potential suppliers understand your needs and enables them to provide accurate quotes.

- Considerations:

- Specify the brass grade (e.g., C260, C360) based on mechanical properties and intended application.

- Include any certifications or industry standards that the parts must comply with.

Step 2: Identify Potential Suppliers

Conduct thorough research to identify suppliers specializing in brass CNC machining. Utilize online platforms, industry directories, and trade shows to compile a list of potential candidates.

- What to Look For:

- Supplier experience in your specific industry (e.g., automotive, plumbing).

- Their ability to handle both small and large production runs.

Step 3: Evaluate Supplier Capabilities

Before committing, assess the capabilities of each potential supplier. This includes evaluating their machinery, technology, and workforce expertise.

- Key Aspects:

- Verify if they utilize advanced CNC technology for precision machining.

- Check if they have a quality assurance process in place to maintain production standards.

Step 4: Request Samples and Prototypes

Once you shortlist suppliers, request samples or prototypes of their work. This step is essential to evaluate the quality of their brass components before placing a larger order.

- Why It Matters:

- Samples allow you to assess the machining accuracy, surface finish, and overall craftsmanship.

- It gives you the opportunity to identify any potential issues before committing to a full production run.

Step 5: Verify Supplier Certifications

Ensure that your chosen suppliers hold relevant certifications that demonstrate their commitment to quality and compliance with industry standards.

- Important Certifications to Check:

- ISO 9001 for quality management systems.

- Any specific certifications relevant to your industry (e.g., AS9100 for aerospace components).

Step 6: Discuss Lead Times and Pricing

Engage in discussions regarding lead times and pricing structures with your selected suppliers. Understanding these factors is vital for planning and budgeting your production schedule.

- Negotiation Tips:

- Inquire about bulk order discounts and payment terms.

- Clarify the expected turnaround time for both prototypes and full orders.

Step 7: Establish a Communication Plan

Finally, develop a clear communication plan with your supplier to ensure smooth collaboration throughout the production process. Effective communication minimizes misunderstandings and enhances project management.

- What to Include:

- Designate primary contacts on both sides.

- Set regular update intervals to monitor progress and address any issues promptly.

By following this checklist, B2B buyers can streamline their sourcing process for brass CNC machining, ensuring they partner with reliable suppliers capable of meeting their specific needs.

Comprehensive Cost and Pricing Analysis for brass cnc machining Sourcing

What Are the Key Cost Components in Brass CNC Machining?

Understanding the cost structure of brass CNC machining is essential for international B2B buyers looking to optimize their sourcing strategies. The primary cost components include:

-

Materials: The price of brass can fluctuate based on market conditions, alloy composition, and global demand. Common brass grades like C260 and C360 exhibit varying costs due to differences in copper and zinc content. Buyers should consider not only the base material cost but also the potential need for specialized alloys that may incur higher expenses.

-

Labor: Labor costs are influenced by the skill level required for CNC machining. Regions with a higher labor cost, such as parts of Europe, may result in increased machining prices. Conversely, regions with lower labor costs, like certain countries in Africa and South America, may offer more competitive pricing.

-

Manufacturing Overhead: This encompasses the costs associated with running a machining facility, including utilities, rent, and equipment maintenance. A well-established supplier with efficient operations may pass on lower overhead costs, benefiting buyers.

-

Tooling: Tooling costs can be significant, especially for custom projects requiring specialized tools or fixtures. Buyers should inquire about tooling costs upfront, as these can dramatically affect the overall pricing.

-

Quality Control (QC): Implementing strict quality control measures is crucial, particularly for high-stakes applications. The cost of QC can vary based on the complexity of the parts and the certification requirements (e.g., ISO standards).

-

Logistics: Shipping and handling costs can add to the total expenditure, especially for international buyers. Factors like distance, shipping method, and customs duties must be considered when evaluating logistics.

-

Margin: Suppliers will include their profit margins in the final pricing. Understanding the typical margin range in the industry can help buyers negotiate better deals.

How Do Volume and Customization Affect Brass Machining Prices?

Price influencers play a crucial role in determining the cost of brass CNC machining. One of the most significant factors is the volume of the order. Higher volumes typically lead to lower per-unit costs due to economies of scale. Buyers should establish minimum order quantities (MOQs) with suppliers to leverage better pricing.

Customization also impacts pricing. Unique specifications or designs can lead to increased tooling and setup costs. Buyers seeking custom solutions should clearly communicate their requirements to avoid unexpected charges.

What Supplier Factors Should Buyers Consider for Brass CNC Machining?

When sourcing brass CNC machining services, the reputation and capabilities of the supplier are vital. Factors such as the supplier’s experience, certifications, and technological capabilities can influence pricing. Suppliers with advanced machining technology may offer better precision and efficiency, potentially lowering the total cost of ownership.

What Are the Best Negotiation Strategies for International Buyers?

Negotiation is a critical skill for international buyers, particularly when sourcing from regions with different pricing structures. Here are several strategies:

-

Understand Total Cost of Ownership (TCO): Evaluate not just the initial price but also the long-term implications of sourcing decisions, including maintenance, replacement, and potential production downtime.

-

Leverage Incoterms: Familiarize yourself with Incoterms to clarify responsibilities for shipping, insurance, and tariffs. Choosing the right Incoterm can significantly affect the overall cost.

-

Establish Long-term Relationships: Building a strong relationship with suppliers can lead to better pricing and service levels. Consider signing long-term contracts or agreements that can lock in favorable rates.

What Pricing Nuances Should Buyers from Africa, South America, the Middle East, and Europe Be Aware Of?

International buyers must navigate various pricing nuances. Currency fluctuations can impact costs, so it’s advisable to negotiate prices in a stable currency. Additionally, buyers should be aware of import duties and tariffs specific to their regions, as these can add to the overall cost.

In conclusion, understanding the comprehensive cost structure and pricing dynamics of brass CNC machining is essential for international B2B buyers. By considering the various cost components, price influencers, and negotiation strategies, buyers can make informed decisions that optimize their sourcing efforts. Always seek multiple quotes and engage in thorough discussions with suppliers to ensure the best value for your investment.

Alternatives Analysis: Comparing brass cnc machining With Other Solutions

Exploring Alternative Solutions to Brass CNC Machining

In today’s manufacturing landscape, businesses often seek the best method for producing components that meet their specific needs. While brass CNC machining is a popular choice due to its excellent machinability and corrosion resistance, there are alternative solutions worth considering. This section provides a comparative analysis of brass CNC machining against other viable methods, including aluminum CNC machining and 3D printing with metal materials.

| Comparison Aspect | Brass CNC Machining | Aluminum CNC Machining | 3D Printing with Metal |

|---|---|---|---|

| Performance | High precision and durability; excellent for intricate designs | Good strength-to-weight ratio; suitable for high-volume production | Versatile; allows for complex geometries and rapid prototyping |

| Cost | Moderate; tooling and material costs can be higher | Generally lower; abundant material and efficient production | Can be high; initial setup and materials may be expensive |

| Ease of Implementation | Requires skilled operators and CNC machines | Easier to implement with automated systems | Requires specialized equipment and expertise |

| Maintenance | Low maintenance; brass parts are durable | Moderate; aluminum parts can wear but are generally resilient | Varies; printers require regular maintenance and calibration |

| Best Use Case | Electrical, plumbing, and decorative components | Aerospace, automotive, and general engineering | Prototyping, custom parts, and low-volume production |

Understanding Aluminum CNC Machining

Aluminum CNC machining is a robust alternative that offers a favorable strength-to-weight ratio, making it ideal for industries like aerospace and automotive. Aluminum is easier to machine than brass, often resulting in lower costs and faster production times. However, while aluminum components are lightweight and resistant to corrosion, they may not provide the same level of aesthetic appeal or mechanical properties as brass. Additionally, aluminum’s lower density can lead to reduced strength in some applications, making it less suitable for high-stress environments.

Evaluating 3D Printing with Metal Materials

3D printing with metal materials, such as stainless steel or titanium, is an innovative solution that allows for the creation of complex geometries and rapid prototyping. This method is particularly beneficial for producing custom parts or low-volume production runs where traditional machining methods may be less economical. However, the initial investment in 3D printing technology can be significant, and the materials used can also drive costs higher. While 3D printing enables unparalleled design freedom, the mechanical properties of printed parts may not always match those produced through traditional CNC machining methods.

Making the Right Choice for Your Manufacturing Needs

When selecting the appropriate manufacturing method, B2B buyers should consider their specific requirements, including performance, cost, and application. Brass CNC machining is ideal for applications demanding high durability and precision, particularly in electrical and plumbing components. In contrast, aluminum machining may be more suitable for industries prioritizing weight and cost efficiency. Meanwhile, 3D printing emerges as a compelling option for businesses focused on customization and rapid prototyping.

Ultimately, the choice between brass CNC machining and its alternatives will depend on factors such as project scope, budget, and desired material properties. By understanding the strengths and limitations of each method, businesses can make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for brass cnc machining

Understanding the technical properties and trade terminology associated with brass CNC machining is crucial for B2B buyers seeking to make informed purchasing decisions. This section outlines essential specifications and common industry terms that can aid in navigating the procurement process effectively.

What Are the Key Technical Properties of Brass CNC Machining?

1. Material Grade

Brass alloys are categorized into various grades, each defined by its composition and mechanical properties. Common grades include C260 (Cartridge Brass) and C360 (Free Machining Brass). The grade selected affects the machinability, strength, and application suitability. For instance, C360 is preferred for high-volume production due to its excellent machinability, making it a go-to choice for components such as fittings and valves.

2. Tolerance

Tolerance refers to the allowable deviation from a specified dimension. In CNC machining, tight tolerances (e.g., ±0.005 inches) are often required to ensure parts fit precisely within assemblies. Understanding tolerance levels is critical for buyers because it impacts the functionality and performance of the final product. High precision can also reduce the need for costly rework.

3. Surface Finish

The surface finish of machined brass can significantly impact its performance and aesthetics. Common finishes include machined, polished, or anodized. A smoother finish may be necessary for components that experience friction or require a decorative appearance. Buyers should specify surface finish requirements based on the intended application, as this can affect both cost and functionality.

4. Mechanical Properties

Key mechanical properties of brass include tensile strength, hardness, and ductility. For instance, C360 brass has a tensile strength of about 58 ksi and a hardness of 78 HRB. These properties are essential for determining how the material will perform under stress and wear conditions. Buyers must assess these specifications to ensure the selected material can withstand operational demands.

5. Machinability

Machinability is a critical factor in the production efficiency of brass components. Brass is known for its high machinability, primarily due to its lead content. This attribute allows for faster feed rates and reduced tooling wear, leading to lower production costs. Buyers should evaluate the machinability of the brass grade in relation to their production volume and complexity of parts.

What Common Trade Terms Should B2B Buyers Know?

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that manufactures products that are sold under another company’s brand name. In the context of brass CNC machining, buyers often work with OEMs to produce custom components that meet specific design and quality requirements.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to plan their inventory and budget effectively. For custom brass components, MOQs can vary significantly based on complexity and tooling requirements.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products or services. This process is critical for comparing suppliers and ensuring competitive pricing for brass CNC machining projects.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is vital for buyers importing brass components, as they dictate who is responsible for shipping, insurance, and tariffs.

5. Lead Time

Lead time refers to the time taken from the placement of an order until its delivery. Understanding lead times is crucial for buyers to align their production schedules and meet project deadlines. Longer lead times can impact inventory management and project timelines.

By grasping these technical properties and industry terms, B2B buyers can enhance their decision-making process, ensuring that they procure the right brass components for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the brass cnc machining Sector

What Are the Key Market Dynamics and Trends Influencing Brass CNC Machining?

The brass CNC machining market is experiencing significant growth, driven by the increasing demand for precision-engineered components across various industries such as automotive, electronics, and plumbing. Global buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are seeking high-quality brass components due to the material’s excellent machinability, corrosion resistance, and aesthetic appeal. The rise of advanced manufacturing technologies, including automation and digitalization, is reshaping sourcing strategies. Buyers are leveraging data analytics and real-time monitoring to optimize supply chains, ensuring timely delivery and quality assurance.

Emerging trends, such as the shift towards customization and rapid prototyping, are also noteworthy. Companies are increasingly adopting CNC machining for short-run production and tailored solutions, enabling them to meet specific client requirements more effectively. Additionally, the focus on sustainability is influencing material sourcing, with buyers prioritizing suppliers that utilize eco-friendly practices and materials. The ongoing economic shifts and geopolitical factors, particularly in regions like Europe and the Middle East, necessitate agile sourcing strategies to mitigate risks and maintain supply chain resilience.

How Is Sustainability and Ethical Sourcing Shaping Brass CNC Machining?

Sustainability has become a cornerstone of business strategies in the brass CNC machining sector, reflecting a growing awareness of environmental impact among international buyers. The production of brass components can involve significant energy consumption and waste generation, making it imperative for companies to adopt sustainable practices. Buyers are increasingly favoring suppliers who demonstrate commitment to minimizing their carbon footprint and employing eco-friendly processes.

Ethical sourcing is equally critical, as businesses strive to ensure that their supply chains are transparent and responsible. Certifications such as ISO 14001 (Environmental Management) and adherence to the Responsible Business Alliance standards are becoming prerequisites for many buyers. Furthermore, the use of recycled brass and sustainable materials is gaining traction, allowing manufacturers to produce high-quality components while reducing resource depletion. By prioritizing sustainability and ethical sourcing, companies can enhance their brand reputation and appeal to environmentally conscious consumers and partners.

What Is the Historical Context of Brass CNC Machining and Its B2B Relevance?

Brass has been utilized in manufacturing for centuries, with its properties making it a preferred material for various applications. The evolution of brass CNC machining began in the mid-20th century with the advent of computer numerical control (CNC) technology, which revolutionized the precision and efficiency of machining processes. Early adopters of CNC technology quickly recognized brass’s machinability and versatility, leading to its widespread use in high-precision components.

As industries progressed, the demand for customized and high-quality brass parts surged, propelling advancements in machining techniques and tooling. The historical context of brass CNC machining emphasizes the material’s adaptability and reliability, making it a staple for B2B buyers seeking durable solutions. Today, the legacy of brass continues, as its applications expand in modern industries, further reinforcing its significance in the global manufacturing landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of brass cnc machining

-

How do I choose the right brass grade for CNC machining?

Choosing the right brass grade depends on the specific application requirements. Common grades include C260 (cartridge brass) for general-purpose applications due to its excellent ductility and C360, known for its superior machinability and suitability for high-volume production. Evaluate factors such as mechanical properties, corrosion resistance, and the intended use of the machined parts. Additionally, consider the presence of other alloying elements, as they can significantly affect the material’s performance and suitability for your project. -

What are the typical lead times for brass CNC machining orders?

Lead times for brass CNC machining can vary based on factors like order complexity, volume, and supplier capabilities. Generally, standard orders may take 2-4 weeks, while custom or large volume projects could extend to 6-8 weeks or more. It’s crucial to discuss timelines with your supplier upfront and factor in potential delays in sourcing materials or logistics. Establishing clear communication regarding your project timeline can help ensure timely delivery and avoid disruptions in your supply chain. -

What is the minimum order quantity (MOQ) for brass CNC machining?

Minimum order quantities (MOQ) for brass CNC machining can differ significantly among suppliers. Some may have no MOQ for prototyping or small runs, while others might require a minimum of several hundred pieces for cost-effectiveness. When sourcing, clarify MOQ policies with potential suppliers to ensure they align with your project needs. If you’re a smaller business, consider working with suppliers that specialize in low-volume production to maintain flexibility in your orders. -

How can I ensure quality assurance in my brass CNC machining parts?

To ensure quality assurance in brass CNC machining, it’s essential to work with reputable suppliers who adhere to international quality standards such as ISO 9001. Request detailed information on their quality control processes, including inspections and testing methodologies. Additionally, consider asking for samples before placing large orders to verify the quality of the machined parts. Establishing a clear quality agreement with your supplier can also help mitigate risks and ensure that the final products meet your specifications. -

What payment terms should I expect when sourcing brass CNC machining services?

Payment terms for brass CNC machining can vary widely based on the supplier and your negotiation. Common arrangements include upfront payments, net 30, or net 60 days after delivery. Some suppliers may also offer discounts for early payment or extended credit terms for repeat customers. It’s advisable to discuss payment terms early in the negotiation process to avoid misunderstandings and ensure that the terms align with your cash flow and budgeting strategies. -

How do I vet suppliers for brass CNC machining?

Vetting suppliers for brass CNC machining involves several steps. Start by researching their industry experience, customer reviews, and certifications. Request case studies or references from previous clients to assess their reliability and quality. Additionally, consider visiting their facilities or arranging virtual tours to evaluate their equipment and processes. Engaging in direct communication can also provide insights into their responsiveness and customer service, which are crucial for a successful partnership. -

What logistics considerations should I be aware of when importing brass CNC machined parts?

When importing brass CNC machined parts, consider shipping methods, customs regulations, and potential tariffs. Choose a reliable logistics partner familiar with international trade to navigate these complexities. Ensure that your supplier provides necessary documentation, such as invoices and certificates of origin, to streamline customs clearance. Also, factor in shipping times, as they can impact your overall project timeline. Planning for these logistics in advance can help avoid delays and additional costs. -

Can I customize my brass CNC machined components?

Yes, customization is a significant advantage of brass CNC machining. Most suppliers offer tailored solutions, allowing you to specify dimensions, tolerances, and surface finishes according to your project requirements. When discussing customization, provide detailed drawings or specifications to ensure clarity. Additionally, inquire about any limitations in customization options, such as minimum order quantities or additional costs associated with unique designs. Collaborating closely with your supplier during the design phase can lead to better outcomes and satisfaction with the final product.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Brass Cnc Machining Manufacturers & Suppliers List

1. AT Machining – Brass Alloys

Domain: at-machining.com

Registered: 2014 (11 years)

Introduction: Brass is a metal alloy of copper and zinc, used across various industries such as electrical, plumbing, and medical. Key properties include:

– Excellent mechanical properties: corrosion resistance, low friction point, high machinability, good ductility, flexibility, and high feed rate.

– Melting point: 885 to 890 ℃

– Density: 8.5 g/cm³

– Modulus of Elasticity: 97 GPa

– Thermal Conductivity: 115 W/…

2. Protolabs – Brass CNC Machining

Domain: protolabs.com

Registered: 2006 (19 years)

Introduction: Brass CNC Machining for Custom Parts: Cost-efficient machined parts at any quantity. Brass is an alloy of copper and zinc, known for its weather- and corrosion-resistance, and has tensile strength similar to mild steel. It is easy to machine with high feedrates and minimal coolant needs. Types of Brass for CNC Machining include Brass C260 (70% copper, 30% zinc, high ductility, general purpose) and…

3. Grovtec – Brass Machining Services

Domain: grovtecmachining.com

Registered: 2014 (11 years)

Introduction: Brass machining services; used in plumbing, oil and gas, medical and dental industries; excellent machining qualities; cost efficient and durable; commonly used in electronics and high tech industries; made from copper and zinc; improved properties with lead addition; versatile machining material; serving industries including Aerospace, Military & Defense, Electronics, Medical, Oil and Gas, Firear…

4. PCBWay – CNC Machining in Brass

Domain: pcbway.com

Registered: 2012 (13 years)

Introduction: CNC Machining in Brass – Material Type: Brass C360; Characteristics: Highly machinable, good tensile strength, natural corrosion resistance, ideal for low friction parts; Service Processes: CNC Milling, CNC Turning; Properties: Corrosion resistant, non-magnetic.

5. DW Products – Brass CNC Machining Components

Domain: dwproducts.com

Registered: 2005 (20 years)

Introduction: Brass CNC Parts Machining at DW Products includes manufacturing capabilities for various brass components using CNC machining techniques. Key features include: exceptional workability, superior corrosion resistance, high conductivity, and the ability to withstand variable temperatures. Brass is ideal for applications in industries such as plumbing, automotive, and filtration. Benefits of custom ma…

6. Wayken – Brass CNC Machining

Domain: waykenrm.com

Registered: 2013 (12 years)

Introduction: Brass CNC Machining: A Complete Guide for Custom Brass Parts. Brass is an alloy primarily composed of copper and zinc, with possible additional metals like magnesium, iron, and lead. Key properties of brass include: 1. Highly Machinable – due to lead content, allowing high feed rates and good ductility. 2. Corrosion Resistance – suitable for liquid environments, longevity of tools. 3. Malleability…

7. CNC Masters – Entry-Level Desktop Milling Machine

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Looking for an entry-level desktop CNC milling machine for brass, copper, and aluminum. Preference for purchasing on Amazon. Interested in learning Fusion 360 CAM. Considering costs vs benefits of full CNC mill vs two-axis “engraver” or laser cutter, noting that simpler machines may only produce two-dimensional parts.

8. Unbranded – Custom High Precision Brass CNC Machining Service

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“item_title”:”Custom High Precision Brass CNC Machining Service”,”item_condition”:”New”,”item_price”:”$4.79″,”quantity_available”:3,”brand”:”Unbranded”,”functions”:[“Milling”,”Drilling”],”shipping_info”:{“estimated_delivery”:”Sat, Jul 26 – Fri, Aug 15″,”shipping_origin”:”Shenzhen, China”,”returns_policy”:”Accepted within 30 days, buyer pays return shipping”},”seller_info”:{“seller_username”:”b bo…

Strategic Sourcing Conclusion and Outlook for brass cnc machining

In summary, strategic sourcing for brass CNC machining offers significant advantages for international buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The unique properties of brass, such as excellent machinability, corrosion resistance, and aesthetic appeal, make it an ideal choice for various applications, from plumbing components to intricate electronic parts. Understanding the specific grades of brass, such as C260 and C360, empowers buyers to select the most suitable material for their projects, ensuring optimal performance and durability.

As global markets continue to evolve, the demand for high-quality, cost-effective brass components will only increase. Companies that prioritize strategic sourcing can leverage competitive pricing, reliable supply chains, and advanced manufacturing techniques to enhance their product offerings.

Looking ahead, B2B buyers are encouraged to engage with reputable CNC machining suppliers who can provide tailored solutions and innovative designs. By investing in strategic partnerships and staying informed about industry trends, businesses can position themselves for success in the dynamic landscape of brass CNC machining. Now is the time to explore these opportunities and elevate your manufacturing capabilities.