Introduction: Navigating the Global Market for boron nitride price

Boron nitride pricing presents a significant challenge for international B2B buyers, especially those seeking reliable suppliers across diverse markets such as Africa, South America, the Middle East, and Europe. Understanding the complexities of boron nitride costs—affected by factors like purity levels, particle size, and application requirements—is essential for making informed purchasing decisions. This guide delves into the intricacies of boron nitride pricing, offering insights into various types such as hexagonal and cubic boron nitride, and their applications across industries ranging from automotive to electronics.

In addition to examining price variations from different suppliers, this resource provides actionable strategies for vetting potential vendors to ensure quality and reliability. Buyers will find detailed information on the impact of global supply chains and market trends that influence costs, as well as practical tips for negotiating favorable terms. By equipping B2B buyers with comprehensive knowledge about boron nitride pricing and sourcing, this guide empowers them to navigate the market confidently, ensuring they secure the best value for their investments. Whether you’re based in Brazil or Germany, the insights provided will help streamline your procurement process and enhance your competitive advantage in a rapidly evolving marketplace.

Understanding boron nitride price Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hexagonal Boron Nitride (h-BN) | High purity (≥99%), layered structure, excellent thermal conductivity | Insulating materials, cosmetics, lubricants | Pros: High thermal stability, versatile applications. Cons: Higher cost compared to other forms. |

| Cubic Boron Nitride (c-BN) | Hardest material, high thermal stability, abrasive properties | Cutting tools, abrasives | Pros: Exceptional hardness, long tool life. Cons: Expensive, specialized applications. |

| Boron Nitride Powder | Available in various particle sizes, versatile in formulations | Additives in cosmetics, lubricants | Pros: Cost-effective, customizable. Cons: Performance varies with particle size. |

| Boron Nitride Coatings | Thin films, excellent lubricating properties, chemical inertness | Aerospace, automotive, electronics | Pros: Reduces friction, enhances durability. Cons: Application complexity may increase costs. |

| Boron Nitride Crucibles | High-temperature resistance, non-reactive, stable in vacuum | Semiconductor manufacturing, metallurgy | Pros: Excellent thermal management. Cons: High initial investment for specialized uses. |

What Are the Key Characteristics of Hexagonal Boron Nitride (h-BN)?

Hexagonal Boron Nitride is recognized for its high purity and unique layered structure, which provides exceptional thermal conductivity and chemical inertness. It is commonly used in a variety of industries, including cosmetics as a skin-enhancing additive and in electronics for insulating materials. When considering h-BN, buyers should evaluate the purity level and particle size, as these factors significantly impact performance in specific applications. Despite its advantages, the higher cost may deter some buyers, but its versatility often justifies the investment.

How Does Cubic Boron Nitride (c-BN) Stand Out?

Cubic Boron Nitride is celebrated as the second hardest material known, making it ideal for high-performance cutting tools and abrasives. Its ability to withstand high temperatures without degrading further enhances its appeal in demanding industrial applications. Buyers should consider the specific needs of their machining processes and the potential return on investment due to c-BN’s long tool life. However, the premium pricing and niche applications may limit its widespread adoption.

What Should Buyers Know About Boron Nitride Powder?

Boron Nitride Powder is available in various particle sizes, allowing for customization based on application requirements. It is widely used as an additive in cosmetics and lubricants, enhancing the performance and stability of end products. Buyers should focus on the desired particle size and purity level to ensure compatibility with their formulations. While it is generally cost-effective, the performance can vary, necessitating thorough testing to achieve optimal results.

What Are the Benefits of Boron Nitride Coatings?

Boron Nitride Coatings are known for their ability to reduce friction and enhance the durability of components in high-stress environments, such as aerospace and automotive industries. These coatings are chemically inert, making them suitable for diverse applications, including electronics. Buyers must consider the complexity of application processes and potential long-term savings from reduced wear and tear on machinery. While initial costs may be higher, the benefits often outweigh the investment.

Why Choose Boron Nitride Crucibles?

Boron Nitride Crucibles are designed to withstand extreme temperatures and are non-reactive, making them essential in semiconductor manufacturing and metallurgy. Their ability to manage thermal fluctuations effectively makes them invaluable for precision applications. Buyers should assess the specific thermal requirements and compatibility with their processes. Though the upfront costs can be significant, the long-term performance and reliability often justify the investment in high-quality crucibles.

Key Industrial Applications of boron nitride price

| Industry/Sector | Specific Application of boron nitride price | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Thermal management materials for engine components | Enhanced performance and longevity of critical components | Ensure high purity and specific particle size for reliability. |

| Electronics | Insulating and thermally conductive fillers in electronic devices | Improved device performance and reduced heat generation | Source from reputable suppliers with certifications for purity. |

| Automotive | Lubricants and coatings for high-performance engines | Reduced friction and wear, leading to extended engine life | Consider local regulations and availability of specific grades. |

| Cosmetics | Additive in makeup formulations for improved texture | Enhanced product quality and consumer satisfaction | Verify compliance with regional cosmetic regulations and safety standards. |

| Manufacturing | High-temperature crucibles for material processing | Increased efficiency in high-temperature applications | Evaluate supplier capabilities for custom sizes and shapes. |

How is Boron Nitride Price Utilized in Aerospace Applications?

In the aerospace industry, boron nitride is used primarily in thermal management materials for engine components. Its excellent thermal conductivity and stability at high temperatures help maintain optimal operating conditions, thereby enhancing the performance and longevity of critical aerospace components. International buyers, especially from regions like Europe and the Middle East, must consider the purity and specific particle size of boron nitride to ensure reliability in high-stress environments.

What Role Does Boron Nitride Play in Electronics?

Boron nitride is integral to the electronics sector, particularly as insulating and thermally conductive fillers in electronic devices. It effectively dissipates heat, reducing the risk of overheating and improving overall device performance. B2B buyers in South America and Africa should prioritize sourcing from suppliers that provide high-purity boron nitride with certifications, ensuring that the materials meet stringent industry standards.

How is Boron Nitride Applied in Automotive Lubricants?

In the automotive sector, boron nitride serves as a key ingredient in lubricants and coatings for high-performance engines. Its unique properties reduce friction and wear, which can lead to a longer engine life and improved fuel efficiency. Buyers must be aware of local regulations regarding automotive products and consider the availability of specific grades of boron nitride that meet their operational requirements.

Why is Boron Nitride Important in Cosmetics?

In the cosmetics industry, boron nitride is utilized as an additive in makeup formulations to enhance texture and application. It provides a silky feel and improves the adhesion of products, leading to greater consumer satisfaction. B2B buyers from regions like Brazil and Europe should ensure that the boron nitride sourced complies with regional cosmetic regulations and safety standards, which is crucial for market acceptance.

How is Boron Nitride Used in Manufacturing High-Temperature Crucibles?

Boron nitride is essential in manufacturing high-temperature crucibles used in various material processing applications. Its ability to withstand extreme temperatures and resist chemical corrosion makes it ideal for environments where other materials may fail. Buyers should assess supplier capabilities for custom sizes and shapes to meet specific manufacturing needs, particularly in regions with advanced industrial sectors like Germany and South Africa.

3 Common User Pain Points for ‘boron nitride price’ & Their Solutions

Scenario 1: Navigating Price Fluctuations in Boron Nitride

The Problem: B2B buyers often face significant challenges in managing budget allocations for boron nitride, especially in industries such as automotive and electronics where precise specifications are critical. Prices for boron nitride can fluctuate due to varying market demands, supply chain disruptions, or geopolitical factors. This uncertainty can lead to difficulties in forecasting costs, impacting project timelines and profitability. Buyers may find themselves under pressure to secure competitive pricing while ensuring that quality and specifications are not compromised.

The Solution: To effectively navigate price fluctuations, buyers should establish long-term relationships with multiple suppliers across different regions. This approach not only diversifies risk but also provides leverage in negotiations. Buyers should also stay informed about market trends and forecasts by subscribing to industry reports or joining trade associations. Implementing a strategic sourcing strategy that includes bulk purchasing agreements can help lock in prices for longer periods, mitigating the impact of sudden price increases. Additionally, consider using price monitoring tools that alert you to changes in the boron nitride market, enabling proactive adjustments to your procurement strategies.

Scenario 2: Understanding the Cost-Quality Relationship of Boron Nitride

The Problem: Many B2B buyers struggle to understand how the price of boron nitride correlates with its quality and suitability for specific applications. For example, higher purity levels and specialized forms like hexagonal boron nitride (h-BN) often come at a premium, which can be daunting for companies operating on tight margins. Buyers may hesitate to invest in more expensive options, fearing they may not yield proportional benefits, leading to a mismatch between the product’s performance and the application requirements.

The Solution: To address this concern, it’s essential for buyers to conduct a thorough needs assessment based on their specific applications. Engage with technical experts or suppliers who can provide detailed information on the different grades of boron nitride and their respective applications. This can help clarify the value proposition of higher-priced products. For instance, if your application requires thermal conductivity and electrical insulation, investing in high-purity h-BN might save costs in the long run by enhancing performance and reducing failures. Additionally, consider trialing smaller quantities of various grades to evaluate their performance before committing to larger purchases. This empirical approach can build confidence in your sourcing decisions.

Scenario 3: Managing the Total Cost of Ownership for Boron Nitride

The Problem: B2B buyers often focus solely on the upfront price of boron nitride, neglecting the total cost of ownership (TCO) that includes factors such as storage, handling, and potential waste due to product degradation. Poor management of these aspects can lead to increased overall costs, especially in high-volume production environments where efficiency is paramount. Companies in sectors like manufacturing and electronics may find that what seemed like a low-cost option results in higher expenses over time due to these overlooked factors.

The Solution: To effectively manage TCO, buyers should implement comprehensive procurement strategies that account for all associated costs. This includes evaluating suppliers on their logistics capabilities, including delivery times, packaging, and storage requirements. By selecting suppliers who offer optimal packaging solutions that preserve product integrity, you can minimize waste and reduce handling costs. Additionally, consider investing in training for staff on proper handling and storage techniques for boron nitride products, as this can significantly extend the material’s lifespan and effectiveness. Conducting a lifecycle analysis of your boron nitride usage can also provide insights into how to optimize purchasing and reduce overall costs.

Strategic Material Selection Guide for boron nitride price

What Are the Key Properties of Different Boron Nitride Materials?

Boron nitride (BN) is available in various forms, each with distinct properties that cater to different industrial applications. Understanding these properties is crucial for B2B buyers looking to optimize their material selection based on performance needs and cost considerations.

1. Hexagonal Boron Nitride (h-BN)

Key Properties:

Hexagonal boron nitride is known for its high thermal conductivity, excellent electrical insulation, and chemical inertness. It can withstand temperatures up to 900°C in air and even higher in inert atmospheres. Its layered structure allows for easy lubrication and is often compared to graphite.

Pros & Cons:

The primary advantage of h-BN is its versatility in applications such as lubricants, coatings, and as a filler in plastics and ceramics. However, it can be relatively expensive compared to other fillers, which may deter cost-sensitive projects. Manufacturing complexity is moderate, as it requires careful handling to maintain purity levels.

Impact on Application:

h-BN is particularly suitable for high-temperature applications where electrical insulation is necessary, such as in electronics and aerospace components. Its compatibility with various media makes it a preferred choice in diverse sectors.

Considerations for International Buyers:

International buyers must consider compliance with local regulations regarding chemical safety and environmental impact. Standards like ASTM and DIN are often referenced for quality assurance, particularly in Europe and South America.

2. Cubic Boron Nitride (c-BN)

Key Properties:

Cubic boron nitride is the second hardest material after diamond, making it ideal for cutting and grinding applications. It exhibits excellent thermal stability and is resistant to oxidation.

Pros & Cons:

The key advantage of c-BN is its durability and efficiency in machining hard materials, which can lead to longer tool life and reduced downtime. However, its high cost and manufacturing complexity can be prohibitive for some applications, particularly in regions with budget constraints.

Impact on Application:

C-BN is primarily used in the manufacturing of cutting tools and abrasives. Its ability to withstand high temperatures and pressures makes it suitable for heavy-duty applications in industries like metalworking and mining.

Considerations for International Buyers:

Buyers in Africa and the Middle East should ensure that the suppliers provide certifications that meet local industry standards. The cost of c-BN may vary significantly based on import tariffs and local market conditions.

3. Boron Nitride Nanotubes (BNNTs)

Key Properties:

Boron nitride nanotubes possess exceptional mechanical strength, thermal conductivity, and electrical insulating properties. They can operate effectively at temperatures exceeding 1000°C.

Pros & Cons:

The main advantage of BNNTs is their lightweight and high-strength characteristics, making them ideal for aerospace and automotive applications. However, their production is still relatively costly and complex, which can limit widespread adoption.

Impact on Application:

BNNTs are particularly valuable in applications requiring lightweight yet strong materials, such as in composites and advanced coatings. Their unique properties can enhance the performance of end products significantly.

Considerations for International Buyers:

Buyers should be aware of the evolving regulatory landscape surrounding nanomaterials. Compliance with international safety standards is crucial, especially in Europe, where regulations are stringent.

Summary Table of Boron Nitride Materials

| Material | Typical Use Case for boron nitride price | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Hexagonal Boron Nitride (h-BN) | Lubricants, coatings, fillers | High thermal conductivity and insulation | Higher cost compared to other fillers | High |

| Cubic Boron Nitride (c-BN) | Cutting tools, abrasives | Exceptional durability and efficiency | High cost and manufacturing complexity | High |

| Boron Nitride Nanotubes (BNNTs) | Aerospace, automotive composites | Lightweight and high-strength properties | Costly and complex production | High |

This strategic material selection guide provides international B2B buyers with actionable insights into the properties, advantages, and considerations of different boron nitride materials, facilitating informed purchasing decisions tailored to specific application needs.

In-depth Look: Manufacturing Processes and Quality Assurance for boron nitride price

What Are the Key Stages in the Manufacturing Process of Boron Nitride?

The manufacturing process of boron nitride (BN) involves several critical stages, each requiring specialized techniques and attention to detail. Understanding these stages is essential for B2B buyers to evaluate the quality and reliability of their suppliers.

1. Material Preparation

The first step in manufacturing boron nitride is the preparation of raw materials. This typically involves sourcing high-purity boron and nitrogen sources, which may include boron oxide and ammonia gas. The quality of these raw materials is paramount, as impurities can significantly affect the final product’s performance. Buyers should inquire about suppliers’ sourcing practices and the purity levels of the materials used.

2. Forming Techniques

After material preparation, the next stage is forming. Several techniques are employed depending on the desired final product:

- Sintering: This process involves compacting the BN powder and heating it to a temperature below its melting point, allowing particles to bond. This is commonly used for producing bulk BN materials.

- Hot Pressing: This method combines heat and pressure to densify BN powders, resulting in stronger, more durable materials suitable for high-performance applications.

- Chemical Vapor Deposition (CVD): CVD is used for creating thin films of boron nitride. This technique is especially important in electronics and semiconductor applications.

Understanding these forming techniques helps buyers assess which products are best suited for their specific applications.

3. Assembly and Finishing Processes

Once the boron nitride material is formed, it undergoes assembly (if required) and finishing processes. This may include:

- Machining: For precision components, machining may be required to achieve specific dimensions and tolerances.

- Coating and Surface Treatment: Some applications necessitate additional surface treatments to enhance properties like corrosion resistance or thermal conductivity.

Buyers should consider the finishing capabilities of potential suppliers, as this can impact the final product’s performance in its intended application.

How is Quality Control Implemented in Boron Nitride Manufacturing?

Quality control (QC) is a vital aspect of boron nitride manufacturing, ensuring that the final products meet industry standards and customer specifications. Understanding the QC measures in place can help B2B buyers make informed decisions.

Relevant International Standards for Boron Nitride Quality Assurance

Manufacturers of boron nitride often adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards signifies a commitment to quality and continuous improvement.

In addition, industry-specific certifications may apply, such as:

- CE Marking: This indicates compliance with European health, safety, and environmental protection standards.

- API Certification: Relevant for applications in the oil and gas sector, ensuring that materials meet specific performance and safety criteria.

Buyers should verify that their suppliers hold these certifications, as they provide assurance of quality and reliability.

What Are the Key QC Checkpoints in Boron Nitride Production?

Quality control checkpoints are strategically integrated throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This initial stage involves testing raw materials for purity and compliance with specifications before they enter production.

- In-Process Quality Control (IPQC): During the manufacturing process, regular checks are performed to monitor critical parameters such as temperature, pressure, and material density.

- Final Quality Control (FQC): After production, the finished boron nitride products undergo rigorous testing to ensure they meet all specifications and standards.

B2B buyers should inquire about the specific QC processes utilized by suppliers to understand how they ensure product integrity.

What Testing Methods Are Commonly Used for Quality Assurance?

Various testing methods are employed to verify the quality and performance of boron nitride products. Common methods include:

- X-Ray Diffraction (XRD): Used to determine the crystallinity and phase composition of boron nitride.

- Scanning Electron Microscopy (SEM): Provides detailed images of the surface morphology and particle size distribution.

- Thermal Conductivity Testing: Measures the material’s ability to conduct heat, a critical property for many applications.

Buyers can request documentation of these tests to validate the quality of the products they are considering.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control practices of their suppliers. Here are some strategies:

- Supplier Audits: Conducting regular audits allows buyers to assess the supplier’s manufacturing processes and QC measures in real-time.

- Requesting Quality Reports: Suppliers should provide detailed quality reports, including results from IQC, IPQC, and FQC stages.

- Third-Party Inspections: Engaging independent third-party organizations to inspect and certify the quality of products adds an extra layer of assurance.

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding these verification methods is crucial for ensuring product quality in diverse markets.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers must navigate various regulatory environments and certification requirements. For instance, products exported to the European Union may require CE marking, while those entering the United States may need to comply with FDA regulations, depending on their application.

Additionally, cultural and logistical factors can influence the QC process. Buyers should be aware of potential language barriers and time zone differences when coordinating audits or inspections. Establishing clear communication channels with suppliers can help mitigate these challenges.

By understanding the manufacturing processes and quality assurance measures associated with boron nitride, B2B buyers can make informed purchasing decisions that align with their quality and performance requirements. This comprehensive knowledge empowers buyers to select suppliers that not only meet their product needs but also adhere to the highest industry standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘boron nitride price’

This practical sourcing guide is designed to assist B2B buyers in effectively procuring boron nitride, ensuring that they make informed decisions based on price, quality, and supplier reliability. By following this step-by-step checklist, buyers can navigate the complexities of sourcing boron nitride for various applications, from industrial uses to specialized products.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements for boron nitride. Consider factors such as purity, particle size, and form (powder, solid, etc.). This clarity will help you communicate effectively with suppliers and ensure that you receive products that meet your specific needs.

Step 2: Research Market Prices

Conduct thorough research on the current market prices for boron nitride. Prices can vary significantly based on purity, form, and supplier. Use reputable online platforms and industry reports to gather pricing information, and create a comparative analysis to identify reasonable price ranges.

Step 3: Evaluate Potential Suppliers

It’s essential to vet potential suppliers to ensure reliability and product quality. Request company profiles, case studies, and references from other buyers in your industry. Look for suppliers that have established reputations, certifications, and a track record of delivering quality products consistently.

- Sub-bullet: Check for industry-specific certifications (ISO, etc.) that can indicate compliance with quality standards.

Step 4: Request Samples for Testing

Before placing large orders, request samples of boron nitride from shortlisted suppliers. Testing samples allows you to evaluate the product’s quality and suitability for your applications. This step is critical to avoid costly mistakes that could arise from substandard materials.

Step 5: Negotiate Terms and Conditions

Once you have identified a suitable supplier, engage in negotiations to establish favorable terms and conditions. Discuss pricing, payment terms, delivery timelines, and any bulk order discounts. Clear agreements at this stage can prevent misunderstandings and ensure a smoother procurement process.

Step 6: Verify Compliance with Regulations

Ensure that the boron nitride products you are sourcing comply with local and international regulations. This includes understanding any import/export restrictions, safety data sheet (SDS) requirements, and environmental regulations. Compliance not only protects your company from legal issues but also supports sustainability efforts.

Step 7: Establish a Reliable Supply Chain

After finalizing your supplier, focus on building a reliable supply chain. Develop a good relationship with your supplier to facilitate timely deliveries and support. Consider establishing a long-term partnership that can provide you with consistent supply and possibly better pricing in the future.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing boron nitride, ensuring that they procure high-quality materials at competitive prices while minimizing risks.

Comprehensive Cost and Pricing Analysis for boron nitride price Sourcing

What Are the Key Cost Components in Boron Nitride Pricing?

Understanding the cost structure for boron nitride is crucial for international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe. The primary components contributing to the overall cost include:

-

Materials: The base cost of boron nitride is influenced by the purity and form (hexagonal or cubic). Higher purity levels, such as ≥99% purity, command premium prices, reflecting their application in specialized industries like electronics and cosmetics.

-

Labor: Labor costs encompass the expenses related to manufacturing, including skilled workers who handle complex processes. These costs can vary significantly based on the manufacturing location and the labor market conditions in a specific region.

-

Manufacturing Overhead: This includes costs associated with facilities, utilities, and equipment maintenance. Efficient manufacturing processes can help minimize these overheads, affecting the final price.

-

Tooling and QC: The tooling costs for producing boron nitride products and the expenses related to quality control testing to ensure compliance with industry standards are integral to pricing. Suppliers often invest heavily in QC to maintain high-quality outputs.

-

Logistics: Transportation costs play a significant role, particularly for international shipments. Factors such as distance, shipping methods, and customs duties can inflate prices.

-

Margin: Suppliers typically apply a markup on their costs to ensure profitability. This margin can vary widely depending on market conditions and competition.

How Do Price Influencers Affect Boron Nitride Costs?

Several factors influence the pricing of boron nitride, making it essential for buyers to understand these dynamics:

-

Volume/MOQ (Minimum Order Quantity): Pricing often decreases with higher order volumes. Suppliers may offer better rates to buyers who can commit to larger quantities, helping them optimize production runs.

-

Specifications and Customization: Custom formulations or specific particle sizes can lead to increased costs. Buyers should clarify their requirements upfront to avoid unexpected price changes.

-

Material Quality and Certifications: Products with higher quality and certifications (e.g., ISO standards) may be priced higher due to the added assurance of reliability and performance. Buyers should consider the total cost of ownership when evaluating these options.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their track record, while new entrants might offer competitive pricing to penetrate the market.

-

Incoterms: The terms of shipping and delivery can significantly impact total costs. Understanding the implications of Incoterms (like FOB, CIF) is vital for buyers to calculate the final landed cost accurately.

What Buyer Tips Can Help Optimize Boron Nitride Procurement?

Navigating the complexities of boron nitride pricing can be challenging for international buyers. Here are some actionable tips:

-

Negotiate Effectively: Leverage bulk purchasing and establish long-term relationships with suppliers to negotiate better terms and prices. Building rapport can lead to preferential treatment and pricing adjustments.

-

Focus on Cost Efficiency: Evaluate the total cost of ownership rather than just the upfront price. Consider factors such as performance, longevity, and maintenance costs associated with different boron nitride products.

-

Understand Pricing Nuances for International Buyers: Be aware that international shipping can introduce variables such as tariffs, customs duties, and exchange rate fluctuations. Buyers should factor these into their budget to avoid surprises.

-

Seek Transparent Pricing Models: Request detailed breakdowns of costs from suppliers to understand what you are paying for. Transparency in pricing can help in making informed procurement decisions.

-

Monitor Market Trends: Staying informed about market dynamics, such as changes in raw material costs and supply chain disruptions, can help buyers anticipate price fluctuations and adapt their sourcing strategies accordingly.

Disclaimer on Indicative Prices

Prices for boron nitride products can vary widely based on numerous factors, including supplier, region, and market conditions. The prices mentioned in various sources serve as indicative figures and may not reflect current market rates. Buyers should request quotes from multiple suppliers to ensure competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing boron nitride price With Other Solutions

In the world of materials science and industrial applications, the selection of a suitable solution often hinges on cost-effectiveness, performance, and ease of use. For businesses considering boron nitride, it’s essential to evaluate alternative materials that can meet similar needs. This analysis will compare boron nitride pricing against two alternative solutions: graphite and molybdenum disulfide (MoS₂), both of which are widely utilized in various industries.

| Comparison Aspect | Boron Nitride Price | Graphite Price | Molybdenum Disulfide Price |

|---|---|---|---|

| Performance | Excellent thermal conductivity, chemical inertness, and high dielectric strength | Good thermal and electrical conductivity, but lower thermal stability | Superior lubrication properties, good thermal conductivity |

| Cost | $3.50 to $1,056.57 per lb | $2.50 to $10 per lb | $30 to $100 per lb |

| Ease of Implementation | Moderate complexity; requires specific handling | Easy to implement; widely available | Requires careful handling and sometimes specialized equipment |

| Maintenance | Low maintenance; stable under high temperatures | Requires periodic replacement depending on application | Moderate maintenance; may require more frequent replenishment |

| Best Use Case | High-performance insulation and thermal management | General lubrication and conductive applications | High-load lubrication and extreme pressure environments |

What Are the Pros and Cons of Graphite Compared to Boron Nitride?

Graphite is a popular alternative due to its relatively low cost and ease of availability. It performs well in thermal and electrical applications, making it suitable for a variety of industries including automotive and electronics. However, graphite has limitations in terms of thermal stability and chemical reactivity, particularly in high-temperature environments where boron nitride excels. Additionally, graphite can oxidize when exposed to air at elevated temperatures, which could lead to performance degradation.

How Does Molybdenum Disulfide Stand Against Boron Nitride?

Molybdenum disulfide (MoS₂) is renowned for its outstanding lubrication properties, particularly under high-load conditions. It is ideal for applications requiring extreme pressure and has a superior performance in lubrication compared to boron nitride. However, the cost of MoS₂ can be higher, and it may require more careful handling and specialized equipment for application. Its performance can also be compromised in environments with high temperatures or reactive chemicals, where boron nitride offers significant advantages.

How Should B2B Buyers Choose Between These Materials?

When selecting the right material for specific applications, B2B buyers must consider several factors, including performance requirements, budget constraints, and the operational environment. If thermal stability and chemical inertness are paramount, boron nitride may be the best choice despite its higher price range. Conversely, if cost is a primary concern and the application does not demand the extreme properties of boron nitride, graphite could provide a sufficient solution. For applications needing exceptional lubrication under high pressure, molybdenum disulfide may be the optimal choice, albeit at a potentially higher cost.

Ultimately, the decision should align with the operational requirements and long-term goals of the business, ensuring that the chosen material supports both performance and budgetary objectives effectively.

Essential Technical Properties and Trade Terminology for boron nitride price

Understanding the technical properties and trade terminology associated with boron nitride (BN) is crucial for international B2B buyers seeking to navigate pricing and procurement effectively. This section outlines essential specifications and commonly used terms, providing valuable insights for decision-makers.

What Are the Key Technical Properties of Boron Nitride That Affect Pricing?

-

Material Grade: Boron nitride is available in various grades, such as hexagonal (h-BN) and cubic (c-BN). The grade influences its properties, including thermal and electrical conductivity, chemical stability, and mechanical strength. Higher-grade materials often command higher prices due to their enhanced performance in specialized applications, such as high-temperature insulation and advanced lubricants.

-

Purity Level: The purity of boron nitride is a critical factor affecting its cost. Products with a purity level of 99% or higher are typically more expensive due to the rigorous processing and quality control measures required to achieve such standards. In B2B transactions, specifying purity is vital as it directly correlates with performance in applications like electronics and cosmetics.

-

Particle Size Distribution: Particle size can significantly impact the effectiveness of boron nitride in applications. Finer powders (e.g., 1-2 microns) are often preferred for uses in coatings and lubricants, as they provide better dispersion and enhanced performance. Understanding the specific requirements for particle size is essential for buyers to ensure compatibility with their manufacturing processes.

-

Thermal Conductivity: Boron nitride is known for its excellent thermal conductivity, making it suitable for applications requiring heat dissipation, such as semiconductor packaging. The thermal conductivity rating can affect pricing, with higher performance materials typically priced at a premium. Buyers must assess their thermal management needs to select the appropriate grade.

-

Density: The density of boron nitride affects its application in various industries. For instance, higher density materials are beneficial in applications requiring durability and resistance to wear. Buyers should consider density specifications when evaluating cost versus performance to ensure they receive the best value.

What Are the Common Trade Terms Related to Boron Nitride Pricing?

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In boron nitride transactions, OEMs often seek bulk purchases for use in their products. Understanding OEM relationships is important for pricing negotiations.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. For boron nitride, MOQs can vary based on the grade and application. Buyers should be aware of MOQs when planning their procurement strategies to avoid over-purchasing or missing out on favorable pricing.

-

RFQ (Request for Quote): An RFQ is a document issued by a buyer to solicit pricing and terms from suppliers. In the context of boron nitride, issuing an RFQ helps buyers compare offers, ensuring they secure the best price and conditions for their required specifications.

-

Incoterms (International Commercial Terms): These are a set of predefined commercial terms published by the International Chamber of Commerce, which define the responsibilities of buyers and sellers. Understanding Incoterms is crucial for B2B transactions involving boron nitride, as they dictate who bears shipping costs, insurance, and risk during transit.

-

TDS (Technical Data Sheet): A TDS provides detailed information about a product’s properties, applications, and handling instructions. For boron nitride, TDS is critical for buyers to evaluate the suitability of the material for their specific needs and to ensure compliance with industry standards.

-

SDS (Safety Data Sheet): An SDS outlines the hazards associated with a chemical product and provides safety information. It is essential for buyers to review SDS when procuring boron nitride to ensure proper handling and compliance with safety regulations.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions regarding boron nitride purchases, ultimately optimizing their procurement processes and ensuring they achieve the best value for their investments.

Navigating Market Dynamics and Sourcing Trends in the boron nitride price Sector

What Are the Key Market Dynamics Influencing Boron Nitride Prices?

The global boron nitride market is experiencing significant shifts driven by various factors, including technological advancements, increasing demand across multiple industries, and geopolitical influences. As the material finds applications in sectors such as automotive, aerospace, electronics, and cosmetics, its versatility is becoming increasingly recognized. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, staying abreast of these trends is crucial.

Emerging sourcing trends include a growing preference for high-purity hexagonal boron nitride (h-BN) due to its superior thermal and electrical properties, making it an essential component in advanced materials. The market is also witnessing a rise in the use of boron nitride as a lubricant and additive in cosmetic formulations, which is contributing to the demand surge. Buyers should consider the implications of fluctuating raw material costs and supply chain disruptions caused by geopolitical tensions or environmental regulations, as these factors can significantly impact pricing.

Moreover, the trend towards digital procurement platforms is making it easier for buyers to source boron nitride products globally. These platforms provide valuable insights into pricing trends and supplier reliability, allowing businesses to make informed purchasing decisions.

How Does Sustainability Influence Boron Nitride Sourcing?

Sustainability is becoming a central theme in the sourcing of boron nitride, with increasing emphasis on minimizing environmental impacts and ethical supply chains. B2B buyers are now more aware of the environmental consequences of their sourcing decisions, leading to a demand for ‘green’ certifications and sustainable materials.

For manufacturers, adopting sustainable practices not only helps in reducing their carbon footprint but also enhances their marketability. Buyers should seek suppliers who demonstrate responsible sourcing practices, such as using recycled materials or eco-friendly production processes. Furthermore, transparency in the supply chain is critical; buyers should inquire about the sourcing of raw materials and the overall lifecycle impact of boron nitride products.

The shift towards sustainability is also prompting innovations in product formulations. For instance, suppliers are exploring eco-friendly additives that can replace traditional boron nitride applications, particularly in cosmetics. This trend not only meets regulatory requirements but also resonates with environmentally conscious consumers, ultimately influencing purchasing decisions.

How Has the Boron Nitride Market Evolved Over Time?

The history of boron nitride is marked by its discovery in the early 20th century and its gradual acceptance as a high-performance material in various industrial applications. Initially used in niche applications, its unique properties—such as high thermal conductivity, electrical insulation, and chemical stability—have led to broader adoption across multiple sectors.

In recent years, advancements in manufacturing techniques have allowed for the production of high-purity boron nitride at competitive prices. This evolution has made it more accessible to industries looking for reliable performance materials. As international trade expands, especially among emerging markets in Africa and South America, the demand for boron nitride is expected to grow, driven by its critical role in innovative technologies and applications.

Understanding the evolution of this material can provide B2B buyers with insights into future trends and potential opportunities in the boron nitride market. By recognizing historical patterns, buyers can better anticipate market shifts and align their sourcing strategies accordingly.

Frequently Asked Questions (FAQs) for B2B Buyers of boron nitride price

-

How do I determine the right boron nitride product for my application?

When selecting a boron nitride product, consider factors such as purity, particle size, and specific application requirements. For instance, hexagonal boron nitride is often favored for its thermal conductivity and electrical insulation properties. Review technical data sheets provided by suppliers to ensure compatibility with your intended use, whether it’s in lubricants, coatings, or advanced ceramics. Engaging with your supplier for samples can also help assess performance in your specific application. -

What is the average price range for boron nitride products?

The price of boron nitride can vary significantly based on factors like purity, form (powder, coating, or bulk), and supplier. Generally, prices may range from $3.50 for small samples to over $1,000 for high-purity formulations. To get the best deal, it’s advisable to request quotes from multiple suppliers, factoring in shipping and potential bulk discounts to ensure you are getting a competitive price. -

What factors affect the pricing of boron nitride in international markets?

Several factors influence boron nitride pricing, including raw material costs, production methods, and market demand. Additionally, international trade tariffs, shipping costs, and local regulations can impact prices for buyers in regions like Africa, South America, and Europe. Staying informed about these variables can help you negotiate better pricing and terms with your suppliers. -

How can I vet suppliers of boron nitride products?

Vetting suppliers is crucial for ensuring product quality and reliability. Start by researching their reputation through customer reviews and industry references. Verify certifications and compliance with international standards, such as ISO. It’s also beneficial to request samples and assess their responsiveness and customer service. Establishing a trial order can further help gauge their reliability and product performance. -

What are the minimum order quantities (MOQs) for boron nitride products?

Minimum order quantities for boron nitride can vary widely among suppliers. Some may offer small sample sizes for testing, while others may require larger MOQs, especially for custom formulations or bulk orders. It’s essential to clarify these terms before placing an order, as this can significantly affect your procurement strategy and cost management. -

What payment terms should I expect when sourcing boron nitride?

Payment terms can differ between suppliers, but common practices include upfront payment, partial payment upon order confirmation, and balance upon delivery. For large orders, you might negotiate terms such as net 30 or net 60 days. Always ensure that payment terms are clearly defined in the contract to avoid misunderstandings and protect your interests. -

How do I ensure quality assurance for boron nitride products?

To ensure quality assurance, request certificates of analysis (CoA) from your supplier, which confirm the product’s specifications and purity levels. Regular audits and inspections of the manufacturing process can also help maintain quality standards. Additionally, consider establishing a quality control process on your end to evaluate incoming products against your specifications. -

What logistics considerations should I keep in mind when sourcing boron nitride internationally?

Logistics play a vital role in international sourcing. Factors such as shipping methods, customs clearance, and delivery timelines are crucial to consider. Ensure that your supplier can provide reliable shipping options and understand the import regulations in your country. Establishing a clear communication channel with your logistics partner will also help streamline the process and avoid delays.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Boron Nitride Price Manufacturers & Suppliers List

1. MSE Supplies – MSE PRO Hexagonal Boron Nitride Powder

Domain: msesupplies.com

Registered: 2014 (11 years)

Introduction: {“Product Name”: “MSE PRO Hexagonal Boron Nitride (h-BN) Powder”, “Purity”: “99%”, “Particle Size”: “1~2 um”, “SKU”: “PO6001 (250g), PO6002 (500g), PO6003 (1kg)”, “CAS Number”: “10043-11-5”, “Formula”: “BN”, “Crystal Structure”: “Hexagonal”, “Molecular Weight”: “24.82 g/mol”, “Density”: “2.29 g/cm³ at 25°C”, “Color”: “White”, “Applications”: [“Insulating and thermally conductive fillers”, “Deep ul…

2. Asbury – Boron Nitride Products

Domain: asbury.com

Registered: 1996 (29 years)

Introduction: Boron Nitride products available for purchase include:

– Boron Nitride 5003: $67.94

– Boron Nitride 5006: $69.39

– Boron Nitride 5009: $1,056.57

– Boron Nitride 5018: $79.58

– Boron Nitride 5035: $86.38

Applications include automotive, aluminum, bakery, conductive polymers, gaskets, general lubricants, graphene, maintenance, PTFE, railroad, thermo plastics, and friction.

3. Sigma-Aldrich – Boron Nitride Suspension

Domain: sigmaaldrich.com

Registered: 1998 (27 years)

Introduction: This company, Sigma-Aldrich – Boron Nitride Suspension, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Lower Friction – Hexagonal Boron Nitride Powder

Domain: lowerfriction.com

Registered: 2005 (20 years)

Introduction: {“Product Name”: “Hexagonal Boron Nitride Powder, 5 micron”, “SKU”: “MK-hBN-500”, “Purity”: “98% Pure”, “Average Particle Size”: “5.0 micron”, “Price”: “$54.00”, “Availability”: “Usually ships in 1-2 business days”, “Shipping”: “Non-Hazardous shipping options only”, “Weight Options”: [“1 lb.”, “10 lbs.”], “SDS”: “View/Download SDS-English-Hexagonal Boron Nitride (hBN)”, “Brochure”: “View/Download …

5. Precise Ceramic – Boron Nitride Solutions

Domain: preciseceramic.com

Registered: 2017 (8 years)

Introduction: Boron Nitride (BN) is an advanced synthetic ceramic material available in solid and powder forms, including Hexagonal Boron Nitride (h-BN) and Pyrolytic Boron Nitride (PBN). It features excellent thermal conductivity, corrosion resistance, electrical resistance, and high heat capacity. The solid form exhibits a hexagonal platy crystal structure, likened to “white graphene” or “inorganic graphite,”…

6. Thermo Fisher – Boron Nitride

Domain: thermofisher.com

Registered: 2006 (19 years)

Introduction: Product Code: 040608.04

Product Name: Boron nitride

Availability: Not orderable at the moment. Please contact Technical Support for possible alternatives.

7. Combat® – Boron Nitride HP Sheet

Domain: professionalplastics.com

Registered: 1997 (28 years)

Introduction: {“Product Code”: “SBORHP.625X16.000X18.500”, “Material”: “Boron Nitride HP Sheet”, “Dimensions”: “0.625 X 16.000 X 18.500”, “Unit”: “Each”, “Brand”: “Combat®”, “Manufacturer”: “Professional Plastics”}

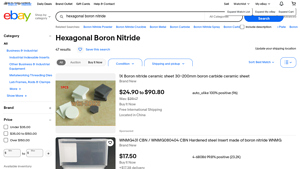

8. eBay – Hexagonal Boron Nitride Products

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Hexagonal Boron Nitride products available on eBay include various forms such as powders, ceramic sheets, and inserts. Key offerings include:

– Boron Nitride High Temperature Resistant Coating, Paste, and Emulsion (50gr) priced at $50.00.

– 1 oz MICROLUBROL Hexagonal Boron Nitride hBN Powder Ultra FINE (0.5 µ Micron) priced at $23.95.

– 2 oz MICROLUBROL Hexagonal Boron Nitride hBN Lubricant Powder…

9. ChemicalBook – Boron Nitride

Domain: chemicalbook.com

Registered: 2006 (19 years)

Introduction: {“Product Name”: “Boron nitride”, “CAS No”: “10043-11-5”, “Molecular Formula”: “BN”, “Molecular Weight”: “24.82”, “EINECS”: “233-136-6”, “MDL Number”: “MFCD00011317”, “Price Range”: “$42.65 – $1816”, “Synonyms”: [“Boron nitride sputtering target, 25.4mm (1.0in) dia x 3.18mm (0.125in) thick, 99.99% (metals basis)”, “Boron nitride, Aerosol Refractory Paint, 97+% (balance B2O3)”, “Boron Nitride (Meta…

Strategic Sourcing Conclusion and Outlook for boron nitride price

In the current landscape of boron nitride pricing, strategic sourcing emerges as a critical component for international B2B buyers. Understanding the diverse applications and price variations—from the economical options available in smaller quantities to premium products catering to specialized needs—enables buyers to make informed decisions that align with their operational requirements. For instance, while hexagonal boron nitride powders may have higher upfront costs, their unique properties can lead to significant long-term savings in efficiency and performance.

Furthermore, the demand for boron nitride across industries such as automotive, electronics, and cosmetics emphasizes the importance of establishing reliable supplier relationships. Engaging with suppliers who offer transparency in pricing and consistent product quality can enhance supply chain resilience, especially in markets across Africa, South America, the Middle East, and Europe.

As we look to the future, it is essential for buyers to stay abreast of market trends and price fluctuations. Adopting a proactive approach to sourcing, such as considering bulk purchases or long-term contracts, could mitigate risks associated with price volatility. By prioritizing strategic sourcing, businesses can not only optimize costs but also ensure the availability of high-quality boron nitride essential for their applications.