Introduction: Navigating the Global Market for blue chrome powder coat

In the dynamic world of industrial coatings, sourcing high-quality blue chrome powder coat can be a significant challenge for B2B buyers operating in diverse markets, including Africa, South America, the Middle East, and Europe. As businesses strive to enhance product aesthetics while ensuring durability and compliance with environmental standards, understanding the nuances of blue chrome powder coat becomes essential. This guide offers a comprehensive overview, covering various types of blue chrome powder coats, their applications across industries, and critical insights into supplier vetting processes.

Navigating this global market requires an informed approach to purchasing decisions. This guide empowers international buyers by providing detailed information on pricing structures, performance characteristics, and application techniques. By highlighting the unique qualities of different blue chrome powder coats—such as gloss levels, color depth, and compatibility with various substrates—buyers can make strategic choices that align with their specific needs. Additionally, the guide addresses the importance of sourcing from reputable suppliers to mitigate risks and ensure product consistency.

With a focus on actionable insights, this resource aims to equip B2B buyers with the knowledge necessary to navigate the complexities of the blue chrome powder coat market effectively. Whether you are in Germany, Nigeria, or elsewhere, this guide is designed to support you in making informed purchasing decisions that drive value for your business.

Understanding blue chrome powder coat Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Chrome Blue | Teal blue with faint silver metallic; glossy finish; polyester-based. | Automotive parts, decorative items, and furniture. | Pros: High gloss, aesthetic appeal. Cons: Requires careful application to avoid defects. |

| Transparent Candy Blue | Requires a chrome or silver base coat for reflective finish; varies with thickness. | Custom automotive finishes, premium furniture. | Pros: Unique depth of color, versatile application. Cons: Higher cost due to base coat requirements. |

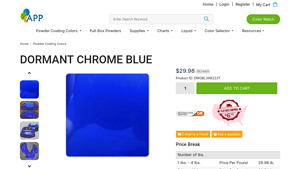

| Dormant Chrome Blue | Reflective true blue without metallic sparkle; requires a clear coat. | Architectural components, consumer goods. | Pros: Smooth finish, excellent color retention. Cons: Additional step needed for clear coat application. |

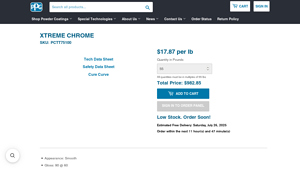

| Xtreme Chrome | Ultra-durable with excellent chemical and UV resistance; smooth finish. | Industrial equipment, outdoor furniture, automotive. | Pros: Long-lasting protection, high-quality finish. Cons: Potentially higher price point for premium durability. |

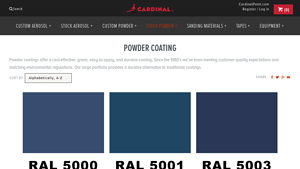

| RAL 5000 Violet Blue | Deep blue color; often used in industrial applications; matches RAL color standards. | Manufacturing, construction, and automotive industries. | Pros: Standardized color matching, high visibility. Cons: Limited aesthetic appeal compared to more vibrant options. |

What Are the Characteristics of Chrome Blue Powder Coat?

Chrome Blue powder coat is distinguished by its sleek teal blue hue with a subtle silver metallic sheen. This polyester-based coating offers a glossy finish, making it ideal for applications in automotive parts, decorative items, and furniture. B2B buyers should consider the need for precise application techniques to avoid defects, as any imperfections may detract from its visual appeal. Its aesthetic qualities make it a popular choice for manufacturers looking to enhance product designs.

How Does Transparent Candy Blue Differ from Other Variants?

Transparent Candy Blue is a unique powder coat that requires a chrome or metallic silver base coat for optimal reflectivity. This candy top coat is highly sought after for custom automotive finishes and premium furniture. Its color depth can vary based on application thickness, offering versatility in design. However, buyers should be aware of the added costs associated with the necessary base coat, which can impact overall project budgets.

Why Choose Dormant Chrome Blue for Your Projects?

Dormant Chrome Blue is characterized by its reflective true blue appearance without metallic sparkles, creating a distinct look. It requires a clear coat to achieve the final color, shifting from silver to blue upon curing. This powder coat is suitable for architectural components and consumer goods, appealing to manufacturers seeking a smooth finish with excellent color retention. Buyers must factor in the additional step of applying a clear coat, which can extend production timelines.

What Makes Xtreme Chrome a Preferred Choice in Industrial Applications?

Xtreme Chrome powder coat is designed for durability, offering excellent resistance to chemicals, UV rays, and corrosion. Its smooth finish and ultra-durable characteristics make it suitable for industrial equipment, outdoor furniture, and automotive applications. While it may come at a higher price point, the long-lasting protection and high-quality finish can result in cost savings over time, making it a worthwhile investment for B2B buyers focused on quality and durability.

How Does RAL 5000 Violet Blue Stand Out in the Market?

RAL 5000 Violet Blue is a deep blue powder coat that adheres to standardized RAL color matching systems, making it a reliable choice for manufacturing and construction industries. Its high visibility and consistent color quality make it suitable for various applications, including automotive parts and industrial equipment. However, its aesthetic appeal may be limited compared to more vibrant options, which should be considered by buyers focusing on design elements.

Key Industrial Applications of blue chrome powder coat

| Industry/Sector | Specific Application of blue chrome powder coat | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Custom vehicle parts and accessories | Enhances aesthetic appeal and corrosion resistance | Ensure compatibility with various substrates and curing times. |

| Architectural & Design | Decorative fixtures and hardware | Provides a unique finish that elevates design value | Verify color consistency and UV resistance for longevity. |

| Industrial Equipment | Manufacturing machinery and tools | Increases durability and reduces maintenance costs | Assess the powder’s chemical resistance for specific environments. |

| Electronics | Enclosures and casings for electronic devices | Improves product lifespan and visual appeal | Consider thermal conductivity and coating thickness for functionality. |

| Consumer Goods | Home appliances and furniture | Boosts consumer attraction and product differentiation | Evaluate gloss levels and application methods for quality assurance. |

How is blue chrome powder coat applied in the automotive industry?

In the automotive sector, blue chrome powder coat is widely used for custom vehicle parts and accessories, such as wheels, trim, and body panels. This coating not only enhances the aesthetic appeal of vehicles but also provides significant corrosion resistance, crucial for longevity in various climates. B2B buyers in this industry must ensure that the powder is compatible with different substrates and meets specific curing times to achieve optimal results.

What role does blue chrome powder coat play in architectural design?

In architectural and design applications, blue chrome powder coat is applied to decorative fixtures, hardware, and structural elements. The vibrant finish elevates the design value, making it an attractive option for both modern and traditional settings. For international buyers, particularly in Europe and the Middle East, it is essential to verify color consistency and UV resistance to ensure the coating maintains its visual appeal over time.

How does blue chrome powder coat benefit industrial equipment manufacturers?

Manufacturers of industrial equipment utilize blue chrome powder coat to enhance the durability of machinery and tools. The coating significantly reduces maintenance costs by providing a tough, resilient layer that withstands harsh working conditions. Buyers in this sector should assess the powder’s chemical resistance to ensure it can endure specific industrial environments, particularly in regions like Africa and South America where conditions can be extreme.

In what ways is blue chrome powder coat utilized in electronics?

For the electronics industry, blue chrome powder coat is applied to enclosures and casings for devices, improving both visual appeal and product lifespan. The coating protects against environmental factors while allowing for customization in design. B2B buyers need to consider the thermal conductivity of the powder and the required coating thickness, ensuring that the final product meets functional and aesthetic demands.

How is blue chrome powder coat advantageous for consumer goods?

In the consumer goods sector, blue chrome powder coat is often used on home appliances and furniture, providing a unique finish that attracts consumers. This coating not only enhances visual appeal but also contributes to product differentiation in a competitive market. Buyers should evaluate gloss levels and application methods to ensure that the final finish meets quality assurance standards, particularly when sourcing from diverse international markets.

3 Common User Pain Points for ‘blue chrome powder coat’ & Their Solutions

Scenario 1: Navigating Color Consistency in Production

The Problem: A common challenge for B2B buyers of blue chrome powder coat is achieving consistent color across large production runs. Variability can occur due to differences in batch production or application techniques. For manufacturers in sectors such as automotive or consumer goods, inconsistencies can lead to product rejections, increased costs, and potential damage to brand reputation. This issue can be particularly pronounced when working with international suppliers, where communication and quality control measures may differ.

The Solution: To ensure color consistency, buyers should establish a rigorous color matching process. This begins with obtaining sample swatches from suppliers before placing bulk orders. Utilizing a spectrophotometer can help accurately measure and compare colors across batches. Additionally, implementing strict quality control protocols during application—such as temperature and humidity monitoring—can minimize color variation. It’s advisable to work closely with suppliers who offer color matching services and can provide technical data sheets outlining specific application parameters.

Scenario 2: Understanding Application Limitations of Blue Chrome Powder Coat

The Problem: Buyers often encounter limitations regarding the application of blue chrome powder coat, particularly when it comes to substrate compatibility and surface preparation. Many users are unaware that certain coatings, like candy blue, require a chrome base coat to achieve the desired finish. Failing to understand these prerequisites can lead to poor adhesion and subpar aesthetic results, resulting in wasted materials and time.

The Solution: To avoid application pitfalls, B2B buyers should conduct thorough research on the specific blue chrome powder coat being used. It’s essential to understand the substrate requirements and recommended base coats. Buyers should consult technical data sheets for each product and consider conducting a test application on a sample piece. Furthermore, investing in training for applicators on proper surface preparation techniques—such as cleaning, sandblasting, or priming—can significantly enhance the adhesion and overall finish of the coating. Collaborating with experienced applicators or coating consultants can provide valuable insights and best practices tailored to specific projects.

Scenario 3: Overcoming Environmental and Regulatory Compliance Challenges

The Problem: Buyers in regions like Africa, South America, and the Middle East may face stringent environmental regulations regarding the use of certain powder coatings, including blue chrome options that may contain harmful chemicals. This can create uncertainty about compliance and increase the risk of legal repercussions, leading to potential disruptions in production or additional costs for compliance measures.

The Solution: To navigate these regulatory landscapes, it’s vital for B2B buyers to familiarize themselves with local environmental laws and standards. Engaging with suppliers who prioritize eco-friendly formulations, such as TGIC-free or low-VOC options, can alleviate some compliance concerns. Buyers should also request safety data sheets (SDS) and technical data sheets (TDS) for each product to understand the materials’ chemical compositions and potential hazards. Establishing a proactive compliance strategy, including regular audits and staff training on environmental standards, can ensure ongoing adherence to regulations while maintaining production efficiency. Additionally, joining industry associations can provide valuable resources and updates on regulatory changes, helping businesses stay ahead of compliance issues.

Strategic Material Selection Guide for blue chrome powder coat

What Are the Key Materials for Blue Chrome Powder Coat Applications?

When selecting materials for blue chrome powder coating, it is essential to consider the substrate compatibility, performance characteristics, and regional standards applicable to various international markets. Below are four common materials used in conjunction with blue chrome powder coat, along with their properties, advantages, disadvantages, and considerations for international buyers.

1. Steel

Steel is one of the most commonly used substrates for blue chrome powder coating due to its strength and versatility.

- Key Properties: Steel offers excellent tensile strength and can withstand high temperatures, making it suitable for various applications. Its corrosion resistance can be enhanced through proper surface preparation and pre-treatment.

- Pros & Cons: Steel is durable and cost-effective, but it may require additional treatments to prevent rust, especially in humid climates. Manufacturing complexity can increase if intricate designs are needed.

- Impact on Application: Steel is compatible with most powder coatings, including blue chrome, but requires proper surface preparation to ensure adhesion.

- International Considerations: Compliance with standards such as ASTM A123 for hot-dip galvanizing is crucial, particularly in regions like Europe and the Middle East where corrosion resistance is paramount.

2. Aluminum

Aluminum is favored for its lightweight properties and resistance to corrosion, making it an excellent choice for blue chrome powder coating.

- Key Properties: Aluminum has a lower density than steel and exhibits good thermal conductivity. It is naturally resistant to corrosion due to the formation of an oxide layer.

- Pros & Cons: The lightweight nature of aluminum is advantageous for applications requiring mobility. However, its cost is generally higher than steel, and it may require specific pre-treatment processes to enhance powder adhesion.

- Impact on Application: Aluminum surfaces can be coated directly with blue chrome powder, but they often benefit from a primer to improve adhesion.

- International Considerations: Buyers should be aware of regional standards, such as DIN 17615 for aluminum coatings in Europe, to ensure compliance and quality.

3. Zinc-Coated Steel

Zinc-coated steel combines the strength of steel with enhanced corrosion resistance, making it suitable for outdoor applications.

- Key Properties: The zinc coating provides a sacrificial layer that protects the underlying steel from rust and corrosion.

- Pros & Cons: This material is ideal for environments with high moisture exposure. However, the preparation process for powder coating can be more complex due to the need to remove zinc from the areas to be coated.

- Impact on Application: Blue chrome powder coat adheres well to zinc-coated surfaces, provided that proper surface preparation is followed.

- International Considerations: Compliance with standards like ASTM A653 for galvanized steel is important for ensuring the longevity of the coating, especially in regions like Africa and South America where environmental conditions can vary significantly.

4. Plastic Composites

Plastic composites are increasingly used in various industries due to their lightweight and corrosion-resistant properties.

- Key Properties: Composites can be engineered to provide specific performance characteristics, such as UV resistance and impact strength.

- Pros & Cons: They are generally easier to mold into complex shapes and are resistant to corrosion. However, their compatibility with powder coating can be limited, requiring specific formulations.

- Impact on Application: Blue chrome powder coat can be applied to certain composites, but it is crucial to select a powder specifically designed for non-metal substrates.

- International Considerations: Buyers should consider compliance with local regulations regarding plastic materials, especially in Europe where stringent environmental standards apply.

Summary Table of Material Selection for Blue Chrome Powder Coat

| Material | Typical Use Case for blue chrome powder coat | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Automotive parts, furniture | High strength and durability | Requires rust prevention treatments | Medium |

| Aluminum | Aerospace components, decorative items | Lightweight and corrosion-resistant | Higher cost and specific pre-treatment | High |

| Zinc-Coated Steel | Outdoor structures, automotive applications | Excellent corrosion resistance | Complex preparation required | Medium |

| Plastic Composites | Consumer goods, automotive interiors | Lightweight and moldable | Limited compatibility with coatings | Medium |

This strategic material selection guide provides a comprehensive overview for B2B buyers, enabling informed decisions that align with their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for blue chrome powder coat

What Are the Main Stages in the Manufacturing Process of Blue Chrome Powder Coat?

The manufacturing process of blue chrome powder coat involves several key stages, each critical to ensuring high-quality outcomes.

-

Material Preparation: The process begins with selecting high-quality raw materials, typically polyester resins combined with pigments and additives. These materials are carefully weighed and mixed to achieve the desired color and properties. For blue chrome powder coats, achieving the right shade is essential, often requiring precise formulations to ensure consistent color across batches.

-

Forming: The mixed materials are then extruded through a die to create a continuous strand of powder. This process involves heating the mixture to a specific temperature, allowing the ingredients to melt and blend uniformly. Once cooled, the strands are broken into granules, which are then classified by size to ensure uniform particle distribution.

-

Assembly: While not a traditional assembly process like in other manufacturing, this stage may involve blending different powders or adding special effects, such as metallic finishes, to achieve the desired appearance. This is particularly relevant for blue chrome finishes, where a glossy and reflective surface is crucial.

-

Finishing: The final stage involves packaging the powder coat into appropriate containers for distribution. Quality checks are performed to ensure that the powder meets specified criteria such as particle size, color consistency, and flow characteristics. Proper labeling is also essential, especially for international shipments, to comply with various regulations.

How Is Quality Assurance Implemented in Blue Chrome Powder Coating?

Quality assurance (QA) in the manufacturing of blue chrome powder coat is paramount to meet industry standards and customer expectations.

-

International Standards Compliance: Manufacturers typically adhere to ISO 9001 standards, which outline requirements for a quality management system. This ensures that processes are standardized, documented, and continuously improved. Compliance with other industry-specific standards, such as CE marking in Europe or API specifications for certain applications, may also be required.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival. Suppliers must provide certificates of analysis to confirm that materials meet required specifications.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, various checkpoints are established to monitor parameters such as temperature, mixing time, and particle size. This ensures that deviations are caught early before they affect the final product.

– Final Quality Control (FQC): Once the powder coat is produced, samples are taken for final testing. This may include visual inspections, gloss measurements, and tests for adhesion, durability, and resistance to environmental factors such as UV exposure and salt spray. -

Common Testing Methods: Various testing methods are employed to evaluate the performance of blue chrome powder coatings. These include:

– Adhesion Tests: To ensure the coating bonds properly to the substrate.

– Gloss Measurement: To verify that the finish meets aesthetic requirements.

– Durability Tests: Such as salt spray tests to assess corrosion resistance.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers play a crucial role in ensuring the quality of the products they procure. Here are ways to effectively verify a supplier’s quality control practices:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their quality control processes. This may involve on-site inspections of manufacturing facilities to assess compliance with international standards and internal protocols.

-

Reviewing Quality Reports: Requesting detailed quality reports, including results from IQC, IPQC, and FQC stages, can help buyers understand a supplier’s commitment to quality. These reports should outline any issues encountered and how they were addressed.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control measures. These agencies can conduct random inspections and tests to verify compliance with specified standards.

What Are the Quality Control Nuances for International B2B Buyers?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, there are specific nuances to consider:

-

Understanding Local Regulations: Different countries have varying regulations regarding powder coatings, including safety and environmental standards. Buyers should familiarize themselves with these regulations to ensure compliance when importing products.

-

Shipping and Handling Considerations: Quality can be affected during shipping, especially if powders are exposed to moisture or temperature fluctuations. Buyers should verify that suppliers use appropriate packaging and shipping methods to mitigate these risks.

-

Cultural and Communication Factors: Language barriers and cultural differences can affect the clarity of quality expectations. Establishing clear communication channels and expectations upfront is essential to avoid misunderstandings.

-

Building Long-term Relationships: Establishing long-term relationships with suppliers can facilitate better quality assurance practices. Regular communication and feedback loops can help ensure that suppliers remain aligned with the buyer’s quality standards over time.

Conclusion

In summary, the manufacturing processes and quality assurance practices for blue chrome powder coat are integral to ensuring high-quality products that meet international standards. By understanding these processes and actively engaging in quality verification, B2B buyers can make informed decisions and foster successful partnerships with their suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘blue chrome powder coat’

To help B2B buyers navigate the procurement of blue chrome powder coat effectively, this guide provides a structured checklist of critical steps. Each step is designed to ensure that your sourcing process is thorough, minimizing risks and maximizing the quality of your final product.

Step 1: Define Your Technical Specifications

Before you begin sourcing, it’s essential to outline the specific requirements for the blue chrome powder coat you need. Consider factors such as color shade, gloss level, and application method (e.g., electrostatic spray). This step helps in narrowing down suppliers who can meet your exact needs.

- Gloss Level: High gloss (around 90-100) is often preferred for aesthetic appeal.

- Application Requirements: Ensure you understand if a base coat or clear coat is needed.

Step 2: Research Suppliers Thoroughly

Identifying potential suppliers is crucial, but thorough research is equally important. Look for suppliers who specialize in powder coatings and have a solid reputation in the market.

- Certifications: Check for industry certifications that indicate quality standards.

- Customer Reviews: Read testimonials and case studies to gauge supplier reliability.

Step 3: Evaluate Product Specifications

Once you’ve identified potential suppliers, request detailed product specifications for their blue chrome powder coat. This includes the chemical composition, cure times, and performance metrics.

- Cure Temperature: Ensure it aligns with your production process (e.g., typically around 400°F).

- Durability Metrics: Look for salt spray resistance and theoretical coverage per pound.

Step 4: Request Samples for Testing

Before making a large order, request samples of the blue chrome powder coat. Testing these samples in your production environment will help determine suitability and performance.

- Application Testing: Evaluate how the powder adheres and cures on your substrates.

- Color Matching: Ensure the sample matches your specified shade under various lighting conditions.

Step 5: Verify Supplier Certifications

Confirm that your chosen suppliers have relevant certifications, such as ISO 9001, to ensure their adherence to quality management standards. This step is vital for maintaining product consistency and reliability.

- Environmental Compliance: Check if they meet local regulations regarding VOCs and waste management.

- Safety Data Sheets (SDS): Review SDS for handling and safety requirements.

Step 6: Negotiate Terms and Pricing

Once you’ve selected a supplier, it’s time to discuss terms. Negotiate pricing based on order volume and delivery schedules to secure the best deal.

- Volume Discounts: Inquire about pricing tiers based on quantity.

- Lead Times: Ensure the supplier can meet your production timelines.

Step 7: Establish a Quality Assurance Process

Implement a quality assurance process to monitor the quality of the blue chrome powder coat upon delivery. This will help catch any discrepancies early on.

- Inspection Protocols: Develop protocols for inspecting the coating for consistency in color and texture.

- Feedback Loop: Create a system for providing feedback to suppliers based on your findings.

By following this structured checklist, B2B buyers can ensure a smooth and efficient procurement process for blue chrome powder coat, leading to enhanced product quality and customer satisfaction.

Comprehensive Cost and Pricing Analysis for blue chrome powder coat Sourcing

What Are the Key Cost Components for Blue Chrome Powder Coat Sourcing?

When evaluating the cost structure for blue chrome powder coat, several components must be considered:

-

Materials: The primary raw materials include polyester resins and pigments, which significantly influence pricing. High-quality pigments that provide vibrant colors and durability can command a premium. For instance, a standard blue chrome powder coat may range from $17.55 to $29.98 per pound, depending on the quality and supplier.

-

Labor: Labor costs include not only the workforce engaged in mixing and processing the powder but also skilled technicians who ensure proper application and adherence to safety protocols. These costs can vary significantly based on the region and the specific labor market conditions.

-

Manufacturing Overhead: This encompasses the costs associated with running manufacturing facilities, including utilities, equipment maintenance, and factory rent. Efficient production processes can help mitigate overhead costs.

-

Tooling: For custom formulations or specific application methods, tooling costs can arise. These include molds or specialized machinery that may be required to produce unique powder coatings.

-

Quality Control (QC): Ensuring the powder meets industry standards involves extensive testing and quality assurance processes. These costs are critical, particularly for international buyers who must adhere to stringent quality certifications.

-

Logistics: Transportation and storage of powder coatings can affect overall pricing. International shipping can incur additional costs due to tariffs, import duties, and freight charges, which must be factored into the total cost.

-

Margin: Suppliers will typically include a margin on the cost of production, which can vary widely based on the supplier’s pricing strategy and market conditions.

What Influences Pricing for Blue Chrome Powder Coats?

Numerous factors influence the pricing of blue chrome powder coats:

-

Volume/MOQ: Larger orders often attract discounts. Suppliers may offer tiered pricing based on minimum order quantities (MOQs), which can substantially reduce per-pound costs.

-

Specifications and Customization: Custom formulations or specific gloss levels can lead to higher prices. Buyers should clearly communicate their requirements to avoid unexpected costs.

-

Materials and Quality Certifications: The choice of raw materials directly impacts cost. Powders that meet specific environmental standards or certifications (e.g., VOC compliance) may have a higher price point.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with a proven track record may charge more due to their quality assurance processes and customer service.

-

Incoterms: Understanding the terms of trade is crucial for international transactions. Incoterms dictate the responsibilities of buyers and sellers concerning shipping costs and risks, which can influence the overall cost structure.

What Are the Best Buyer Tips for Cost-Efficient Sourcing?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies for cost-effective sourcing:

-

Negotiation: Always negotiate pricing, especially for large orders. Suppliers may be willing to offer discounts or better terms, particularly if they are keen to secure a long-term relationship.

-

Focus on Total Cost of Ownership (TCO): Evaluate the overall cost, including logistics, potential waste, and quality issues. A lower upfront price may lead to higher long-term costs if the product does not meet performance standards.

-

Understand Pricing Nuances: Be aware that prices can vary based on regional market conditions and economic factors. Establishing relationships with multiple suppliers can provide leverage in negotiations.

-

Consider Local Suppliers: Sourcing from local suppliers can reduce shipping costs and lead times, enhancing your supply chain efficiency.

-

Stay Informed: Keep abreast of market trends and material costs, as fluctuations can impact pricing. Regularly review supplier performance and market conditions to make informed purchasing decisions.

Disclaimer for Indicative Prices

Prices mentioned in this analysis are indicative and may vary based on market conditions, supplier pricing strategies, and specific buyer requirements. Always request quotes directly from suppliers to obtain the most accurate and current pricing.

Alternatives Analysis: Comparing blue chrome powder coat With Other Solutions

Introduction to Alternatives in Powder Coating Solutions

When it comes to powder coating, especially in striking colors like blue chrome, businesses have several options. Understanding these alternatives is crucial for B2B buyers looking to optimize their product finishes while considering factors such as performance, cost, and application methods. This analysis compares blue chrome powder coat with two viable alternatives: transparent candy blue powder coat and dormant chrome blue powder coat. Each solution offers unique attributes that cater to different applications and preferences.

Comparison Table

| Comparison Aspect | Blue Chrome Powder Coat | Transparent Candy Blue Powder Coat | Dormant Chrome Blue Powder Coat |

|---|---|---|---|

| Performance | High gloss, excellent durability | Requires chrome base for best results | Reflective finish when applied over chrome |

| Cost | $17.55 – $19.50 per lb | $21.99 per lb | $26.79 – $29.98 per lb |

| Ease of Implementation | Easy to apply with standard powder coating equipment | Requires a chrome base coat; slightly complex | Requires clear coat application after initial curing |

| Maintenance | Minimal; resistant to corrosion and UV | Moderate; base coat can affect durability | Low; high resistance to wear once cured |

| Best Use Case | Automotive, architectural finishes | Automotive, decorative items needing depth | High-end automotive, appliances for aesthetic appeal |

Pros and Cons of Each Alternative

Transparent Candy Blue Powder Coat

The transparent candy blue powder coat is a vibrant option that can produce a rich depth of color when applied over a chrome base. Its appeal lies in the glossy finish and the way it enhances the underlying chrome, making it an excellent choice for high-end automotive finishes. However, it requires meticulous application, as the base coat significantly influences the final appearance. The cost is slightly higher, which may be a consideration for budget-conscious buyers.

Dormant Chrome Blue Powder Coat

Dormant chrome blue powder coat offers a unique reflective quality that mimics a candy finish when layered over a chrome base. Its high gloss and smooth surface make it ideal for applications requiring an upscale appearance. However, it necessitates a clear coat after curing, adding an extra step to the process, which might complicate implementation for some manufacturers. The price point is also higher than standard blue chrome options, which could be a deterrent for bulk purchases.

Conclusion: Choosing the Right Powder Coating Solution

Selecting the appropriate powder coating solution depends on various factors, including desired aesthetic, application method, and budget constraints. For B2B buyers, blue chrome powder coat presents a balanced choice with excellent durability and ease of application, making it suitable for a wide range of industries. However, if a deeper color finish is desired, exploring alternatives like transparent candy blue or dormant chrome blue may provide the desired visual impact, albeit with additional application considerations and costs. Ultimately, understanding the specific needs of the project will guide buyers in making an informed decision that aligns with their operational goals.

Essential Technical Properties and Trade Terminology for blue chrome powder coat

What Are the Key Technical Properties of Blue Chrome Powder Coat?

When considering blue chrome powder coat for your projects, understanding its essential technical properties is crucial for making informed purchasing decisions. Here are some key specifications that significantly influence performance and suitability for various applications:

-

Material Composition: Blue chrome powder coat is typically composed of polyester or TGIC (Triglycidyl Isocyanurate). Polyester is known for its excellent outdoor durability and resistance to UV light, while TGIC provides enhanced chemical resistance. This distinction is vital for B2B buyers seeking coatings that can withstand environmental factors, especially in regions with intense sunlight or humidity.

-

Gloss Level: The gloss level, measured in gloss units, indicates the sheen of the finish. A higher gloss level (e.g., 90-100 units) results in a reflective and visually striking surface, enhancing aesthetic appeal. For businesses in industries like automotive or retail, a high gloss finish can improve product visibility and attractiveness, driving sales.

-

Cure Temperature and Time: Blue chrome powder coatings generally require a cure temperature of around 400°F (204°C) for 10 minutes at part metal temperature. This specification is essential for ensuring that the coating adheres properly and achieves its intended performance characteristics. Understanding the curing process helps in planning production schedules and ensuring quality control.

-

Theoretical Coverage: This metric indicates how much area a pound of powder can cover, typically expressed in square feet per pound at a certain mil thickness. For instance, a theoretical coverage of 51.5 sq. ft/lb means that one pound of powder will cover this area at a thickness of 2 mils. This information is critical for procurement managers to estimate material needs and reduce waste.

-

Salt Spray Resistance: Measured in hours, this property indicates the powder coat’s ability to withstand corrosion in saline environments. A rating of over 1,000 hours is often desirable, especially for products intended for marine or coastal applications. This characteristic is particularly relevant for companies operating in regions with high humidity or salt exposure.

-

Specific Gravity: This property, typically ranging from 1.2 to 1.8 for blue chrome powder coats, affects the powder’s application characteristics and coverage. A higher specific gravity may indicate a denser powder, which can influence the application process and the final finish quality.

Which Trade Terms Should B2B Buyers Know About Blue Chrome Powder Coat?

Navigating the procurement of blue chrome powder coat also requires familiarity with industry jargon. Here are some common terms that B2B buyers should understand:

-

OEM (Original Equipment Manufacturer): This term refers to companies that manufacture products that are sold under another brand’s name. For buyers, knowing if a supplier is an OEM can assure them of the quality and compatibility of the powder coat with existing products.

-

MOQ (Minimum Order Quantity): This is the smallest quantity a supplier is willing to sell. Understanding MOQ helps buyers assess whether a supplier can meet their needs without incurring excess costs or inventory.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers asking for price quotes on specific products. This process is crucial for buyers looking to compare prices and terms from multiple vendors before making a purchase decision.

-

Incoterms (International Commercial Terms): These are standardized international trade terms that define the responsibilities of buyers and sellers in shipping agreements. Familiarity with Incoterms helps buyers understand shipping costs, risk, and insurance, which is essential when sourcing products from international suppliers.

-

Cure Schedule: This refers to the specific temperature and time required to properly cure the powder coating. Knowing the cure schedule is vital for ensuring that the coating achieves its desired properties and longevity.

-

Color Match: This term refers to the process of ensuring that the powder coat color meets the buyer’s specific requirements. For projects requiring precise color specifications, understanding color matching is essential for maintaining brand consistency and aesthetic appeal.

Understanding these technical properties and trade terminology will empower B2B buyers to make informed decisions when sourcing blue chrome powder coat, ultimately leading to successful project outcomes.

Navigating Market Dynamics and Sourcing Trends in the blue chrome powder coat Sector

What Are the Current Market Dynamics and Key Trends in the Blue Chrome Powder Coat Sector?

The global powder coating market, particularly the blue chrome variant, is experiencing robust growth driven by several factors. The increasing demand for aesthetic finishes in various industries such as automotive, architecture, and consumer goods is a significant driver. Blue chrome powder coats are particularly sought after for their unique visual appeal and durability. Emerging trends include the integration of advanced application technologies such as electrostatic spray and fluidized bed coating, which enhance efficiency and reduce waste. Furthermore, the rise of e-commerce platforms is transforming the sourcing landscape, allowing B2B buyers from regions like Africa, South America, the Middle East, and Europe to access a broader range of products and suppliers.

International buyers are also witnessing a shift towards customization in powder coatings. As businesses strive to differentiate their products, the ability to offer tailored colors and finishes becomes a competitive advantage. This trend is particularly relevant in markets like Germany and Nigeria, where consumer preferences are evolving rapidly. Additionally, the COVID-19 pandemic has underscored the importance of resilient supply chains, prompting companies to seek reliable sourcing partners who can deliver quality materials consistently.

How Is Sustainability and Ethical Sourcing Reshaping the Blue Chrome Powder Coat Industry?

Sustainability is becoming a crucial consideration in the sourcing of blue chrome powder coats. Environmental regulations are tightening globally, and companies are increasingly held accountable for their ecological footprint. As a result, many suppliers are adopting environmentally friendly practices, such as using low-VOC formulations and recyclable packaging. B2B buyers are encouraged to seek out suppliers that provide transparency in their sourcing processes and demonstrate commitment to sustainable practices.

Ethical sourcing is equally important, as companies face pressure from consumers and regulatory bodies to ensure their supply chains are free from exploitative practices. Certifications such as ISO 14001 for environmental management and Green Seal for sustainable products are gaining prominence. Buyers should prioritize suppliers who have achieved these certifications, as they indicate adherence to rigorous environmental and ethical standards. By investing in sustainable and ethically sourced blue chrome powder coats, companies not only enhance their brand reputation but also contribute positively to the planet.

What Is the Historical Context of Blue Chrome Powder Coatings in the B2B Landscape?

The blue chrome powder coat has evolved significantly since its inception in the 1960s. Initially developed for industrial applications, advancements in technology have broadened its use across various sectors. The introduction of polyester and TGIC-free formulations has improved durability and performance, making blue chrome finishes popular in automotive and architectural applications.

In the past two decades, the increasing focus on aesthetics has propelled blue chrome powder coats into the spotlight, as businesses seek to captivate customers with vibrant and glossy finishes. The growth of digital manufacturing techniques has also made it easier for companies to experiment with color combinations and finishes, leading to a richer variety of blue chrome products available in the market today. This evolution reflects a broader trend towards customization and quality in B2B transactions, catering to the diverse needs of global buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of blue chrome powder coat

-

How do I choose the right blue chrome powder coat for my application?

Selecting the appropriate blue chrome powder coat involves considering factors such as the desired finish, application method, and substrate material. For automotive applications, look for powders that offer high gloss and durability, like Xtreme Chrome or Dormant Chrome Blue. If you require a candy effect, ensure you have a suitable base coat, such as chrome or metallic silver, to enhance the visual appeal. Additionally, review technical data sheets for specific curing requirements and performance characteristics to ensure compatibility with your production process. -

What is the best application method for blue chrome powder coat?

The optimal application method for blue chrome powder coat typically involves electrostatic spray technology, which provides an even and consistent coating. Ensure that the substrate is properly prepped and cleaned to remove any contaminants. Follow the manufacturer’s guidelines for curing, usually requiring a metal temperature of around 400°F for approximately 10 minutes. For achieving the best finish, consider using a professional powder coating setup that allows for precise control over the application process. -

What minimum order quantities (MOQ) should I expect when sourcing blue chrome powder coat?

Minimum order quantities can vary significantly between suppliers, often depending on the product type and the manufacturer’s policies. Generally, for blue chrome powder coat, you might encounter MOQs ranging from 50 to 200 pounds. It’s advisable to discuss your specific needs with potential suppliers to negotiate favorable terms, especially if you are looking to test different colors or require custom formulations. Establishing a good relationship with suppliers can sometimes lead to more flexible MOQ arrangements. -

What payment terms should I consider when purchasing blue chrome powder coat internationally?

When engaging in international transactions for blue chrome powder coat, payment terms can vary based on the supplier and the buyer’s creditworthiness. Common terms include advance payment, letters of credit, or net 30/60 days after delivery. It’s crucial to clearly define payment terms in your purchase agreement to avoid misunderstandings. Additionally, consider using secure payment methods to protect your investment and ensure compliance with international trade regulations. -

How can I ensure the quality of the blue chrome powder coat I am sourcing?

To ensure quality, request samples before placing a bulk order. Review the supplier’s certifications and compliance with international standards such as ISO 9001. Conduct thorough supplier vetting, including checking references and customer reviews. Additionally, consider implementing quality assurance measures, such as inspecting the product upon arrival and conducting performance tests (e.g., salt spray tests) to confirm that the powder coat meets your specifications and durability requirements. -

What logistics considerations should I keep in mind when importing blue chrome powder coat?

When importing blue chrome powder coat, consider factors such as shipping methods, customs duties, and lead times. Ensure that the supplier provides accurate documentation, including safety data sheets and compliance certificates, to facilitate smooth customs clearance. Work with a reliable freight forwarder experienced in handling powder coatings to navigate potential challenges. Additionally, assess the impact of shipping on the product’s shelf life and storage conditions to maintain quality upon arrival. -

Can I customize the color or finish of blue chrome powder coat?

Many suppliers offer customization options for blue chrome powder coats, allowing you to specify unique shades or finishes. Discuss your requirements with potential suppliers, as some may provide color-matching services or custom formulations. Be prepared to share color samples or detailed specifications to achieve the desired result. Keep in mind that custom orders may have longer lead times and higher costs, so factor this into your planning and budget. -

What industries commonly use blue chrome powder coat, and for what applications?

Blue chrome powder coat is widely used across various industries, including automotive, aerospace, furniture, and architectural applications. In the automotive sector, it provides an attractive finish for rims, trim, and body parts, while in furniture design, it adds aesthetic appeal to metal frames and components. Its durability and resistance to corrosion make it suitable for outdoor applications as well. Understanding the specific needs of your industry can guide your selection process and help you identify suitable suppliers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Blue Chrome Powder Coat Manufacturers & Suppliers List

1. The Powder Coat Store – Candy Blue Powder Coat

2. Eastwood – Durable Blue Powder Coating

Domain: eastwood.com

Registered: 1995 (30 years)

Introduction: This company, Eastwood – Durable Blue Powder Coating, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. All Powder Paints – Dormant Chrome Blue

Domain: allpowderpaints.com

Registered: 2011 (14 years)

Introduction: {“product_name”: “Dormant Chrome Blue”, “price_per_lb”: {“1_to_4_lbs”: 29.98, “5_to_10_lbs”: 29.54, “11_to_19_lbs”: 29.03, “20_to_29_lbs”: 28.49, “30_to_39_lbs”: 27.69, “40_to_200_lbs”: 26.79}, “product_id”: “DMGBL398223T”, “description”: “This is a reflective true blue, with no metallic sparkle, and will look like a candy over a chrome base coat when finished. A clear coat must be applied over al…

4. Columbia Coatings – All In One Chrome

Domain: columbiacoatings.com

Registered: 2001 (24 years)

Introduction: {“product_name”: “All In One Chrome”, “item_number”: “M2692012”, “price_per_pound”: {“1-9”: “$21.45”, “10-24”: “$20.63”, “25-43”: “$18.56”, “44-87”: “$17.91”, “88+”: “$17.19”}, “description”: “This is a single-stage chrome powder. The chrome and clear are bonded for single stage application. Works great as a base coat for translucent colors. A clear coat is recommended for outdoor use.”, “availabi…

5. PPG – PCTT75100 Xtreme Chrome

Domain: powdercoatings.ppg.com

Registered: 1990 (35 years)

Introduction: {“product_name”: “PCTT75100 Xtreme Chrome”, “product_type”: “Powder Coating”, “features”: [“High gloss finish”, “Excellent durability”, “Corrosion resistance”, “Chemical resistance”], “applications”: [“Automotive”, “Aerospace”, “Industrial”, “Architectural”], “color”: “Chrome”, “packaging”: “Available in various sizes”, “cure_time”: “Varies based on application”, “temperature_range”: “High tempera…

6. Cardinal Paint – RAL5000 Violet Blue Powder

Domain: shop.cardinalpaint.com

Registered: 1996 (29 years)

Introduction: [{‘name’: ‘RAL5000 Violet Blue Powder’, ‘price’: 156.25}, {‘name’: ‘RAL5001 Green Blue Powder’, ‘price’: 186.25}, {‘name’: ‘RAL5003 Sapphire Blue Powder’, ‘price’: 190.0}, {‘name’: ‘RAL5005 Signal Blue Powder’, ‘price’: 181.25}, {‘name’: ‘RAL5010 Gentian Blue Powder’, ‘price’: 186.25}, {‘name’: ‘RAL5011 Steel Blue Powder’, ‘price’: 182.5}, {‘name’: ‘RAL5015 Sky Blue Powder’, ‘price’: 190.0}]

7. TIGER – Powder Coating Colors

Domain: tiger-coatings.com

Registered: 2000 (25 years)

Introduction: Shop Powder Coating Colors Online | Over 1,000+ Finishes, TIGER Drylac® applications, Metallics & Special Effects, TIGER Trend Colors & Finishes 2025, BattleCoats by TIGER & HyperShock, TIGER Drylac® metallics, 3D Metallics, Pearl, Antique/Vein, Dusk, Horizon, Arctic Steel, Aqua Marine Metallic, Amber, Ruby, Flame, Tangerine, Yellow, TIGITAL Inks, Tattoo, Revolutionary 3D Powder Coating Visualizat…

8. The Powder Coat Store – Transparent Candy Blue Powder Coating Paint

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Transparent Candy Blue Powder Coating Paint”, “Weight”: “1 LB”, “Brand”: “The Powder Coat Store”, “Condition”: “New”, “Color”: “Blue”, “Type”: “Powder Coat”, “Sheen”: “Gloss”, “Suitable For”: “Aluminum, Metal”, “Country/Region of Manufacture”: “United States”, “Price”: “US $31.99”, “Shipping”: “May not ship to Hong Kong”, “Returns”: “30 days returns, buyer pays for return shippin…

Strategic Sourcing Conclusion and Outlook for blue chrome powder coat

The strategic sourcing of blue chrome powder coat offers a unique opportunity for international buyers to enhance their product offerings with a visually striking finish while ensuring durability and environmental compliance. The versatility of blue chrome powder coats, available in various formulations such as metallic, candy, and dormant finishes, allows businesses to cater to diverse industries, from automotive to architectural applications.

Leveraging strategic sourcing can significantly reduce costs, improve supply chain efficiency, and enhance product quality. By collaborating with reliable suppliers and understanding regional market trends, buyers from Africa, South America, the Middle East, and Europe can make informed decisions that align with their business goals.

As market demands evolve and sustainability becomes a priority, investing in high-quality blue chrome powder coats not only elevates product aesthetics but also positions businesses competitively in the marketplace. It is crucial for B2B buyers to engage with suppliers who prioritize innovation and quality in their offerings.

Looking ahead, now is the time for international buyers to explore the potential of blue chrome powder coats to differentiate their products and drive growth. Establishing strong partnerships with reputable suppliers will ensure access to the latest advancements in powder coating technology, setting the stage for future success.