Contents Manufacturing Insight: Cnc Wood Working Machine Technical Capabilities From CAD to Part: The Process Start Your Project Manufacturing Insight: Cnc Wood Working Machine Precision Wood Machining Capabilities at Honyo Prototype Honyo Prototype delivers advanced CNC machining services engineered for complex wood components, transforming intricate designs into high-fidelity prototypes and low-volume production parts. Our specialized […]

Contents Manufacturing Insight: Cnc Machine G Codes List Technical Capabilities From CAD to Part: The Process Start Your Project Manufacturing Insight: Cnc Machine G Codes List Understanding CNC Machine G Codes for Precision Manufacturing G codes form the universal programming language that drives CNC machining operations, translating complex geometries into precise tool paths for milling, […]

Contents Manufacturing Insight: Cnc Plasma Systems Technical Capabilities From CAD to Part: The Process Start Your Project Manufacturing Insight: Cnc Plasma Systems Precision CNC Plasma Fabrication Solutions from Honyo Prototype CNC plasma cutting systems represent a cornerstone of modern industrial fabrication, delivering exceptional speed and accuracy for complex metal part production across aerospace, automotive, and […]

Contents Manufacturing Insight: Cnc Stone Engraving Machine Technical Capabilities From CAD to Part: The Process Start Your Project Manufacturing Insight: Cnc Stone Engraving Machine Honyo Prototype delivers precision CNC stone engraving solutions for demanding industrial and architectural applications where durability and exacting detail are non-negotiable. Our specialized CNC stone engraving machines, operated by experienced manufacturing […]

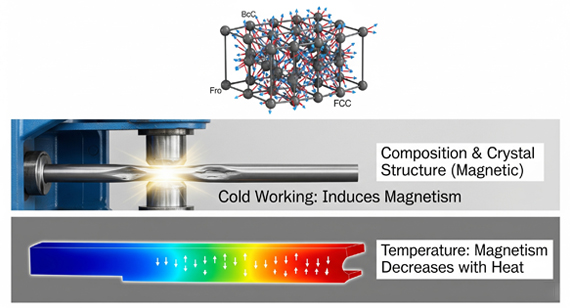

Contents Manufacturing Insight: Is Steel Magnetic Material Technical Capabilities From CAD to Part: The Process Start Your Project Manufacturing Insight: Is Steel Magnetic Material Understanding Steel Magnetism in Precision Manufacturing Steel’s magnetic properties are a critical consideration in engineering design and manufacturing, varying significantly based on alloy composition and microstructure. While ferritic and martensitic stainless […]

Contents Manufacturing Insight: Steel Alloy Metals Technical Capabilities From CAD to Part: The Process Start Your Project Manufacturing Insight: Steel Alloy Metals Precision Steel Alloy Fabrication for Demanding Industrial Applications Steel alloys remain the backbone of robust industrial manufacturing, offering an unmatched balance of strength, durability, and versatility across aerospace, medical, and heavy machinery sectors. […]

Contents Manufacturing Insight: Normalization Of Steel Technical Capabilities From CAD to Part: The Process Start Your Project Manufacturing Insight: Normalization Of Steel As Senior Manufacturing Engineer at Honyo Prototype, I emphasize that effective steel normalization is a critical prerequisite for achieving optimal results in precision CNC machining operations. This controlled heat treatment process—where steel is […]

Contents Manufacturing Insight: Ztl Machining Technical Capabilities From CAD to Part: The Process Start Your Project Manufacturing Insight: Ztl Machining Precision CNC Machining Services at Honyo Prototype At Honyo Prototype, we specialize in high-precision CNC machining, delivering complex, tight-tolerance components for industries demanding uncompromising quality and repeatability. Our advanced 3-, 4-, and 5-axis milling and […]

Contents Manufacturing Insight: Chrome Alloy Steel Technical Capabilities From CAD to Part: The Process Start Your Project Manufacturing Insight: Chrome Alloy Steel Precision Machining Excellence for Chrome Alloy Steel Components Chrome alloy steels represent a critical material class for high-strength, wear-resistant applications across aerospace, automotive, and industrial machinery sectors. Characterized by chromium content enhancing hardenability, […]

Contents Manufacturing Insight: Steel Alloys & Services Technical Capabilities From CAD to Part: The Process Start Your Project Manufacturing Insight: Steel Alloys & Services Steel Alloys & Precision CNC Machining Services Honyo Prototype delivers engineered solutions for demanding steel alloy applications, leveraging advanced CNC machining capabilities to transform complex designs into high-integrity components. Our expertise […]

Contents Manufacturing Insight: Cnc Mill Coolant Technical Capabilities From CAD to Part: The Process Start Your Project Manufacturing Insight: Cnc Mill Coolant Optimizing Precision and Productivity in CNC Milling Through Advanced Coolant Management At Honyo Prototype, we recognize that effective coolant application is not merely a maintenance consideration but a critical determinant of machining precision, […]

Contents Manufacturing Insight: Aluminium Casting Projects Technical Capabilities From CAD to Part: The Process Start Your Project Manufacturing Insight: Aluminium Casting Projects Precision Aluminium Casting Solutions Enhanced by Honyo Prototype CNC Machining Expertise Aluminium casting delivers exceptional design flexibility and material efficiency for complex geometries, yet achieving final part specifications often requires precise secondary operations. […]

Contents Manufacturing Insight: Stainless Steel Fasteners In Aluminum Technical Capabilities From CAD to Part: The Process Start Your Project Manufacturing Insight: Stainless Steel Fasteners In Aluminum Galvanic corrosion presents a significant engineering challenge when integrating stainless steel fasteners with aluminum components, particularly in demanding aerospace, marine, and industrial applications. The electrochemical potential difference between these […]

Contents Manufacturing Insight: Aluminum Alloy Metal Technical Capabilities From CAD to Part: The Process Start Your Project Manufacturing Insight: Aluminum Alloy Metal Precision Aluminum Alloy Fabrication: Engineering Excellence from Honyo Prototype Aluminum alloys represent a cornerstone material in advanced manufacturing, prized for their exceptional strength-to-weight ratio, inherent corrosion resistance, thermal conductivity, and ease of fabrication. […]

Contents Manufacturing Insight: Peek Extrusion Technical Capabilities From CAD to Part: The Process Start Your Project Manufacturing Insight: Peek Extrusion Precision PEEK Component Manufacturing: Where Extruded Stock Meets CNC Excellence PEEK (Polyether Ether Ketone) remains the material of choice for mission-critical applications in aerospace, medical implants, and semiconductor manufacturing due to its exceptional thermal stability, […]