Contents

Manufacturing Insight: Blackening Of Steel

Integrating Precision Steel Blackening with CNC Machining Excellence

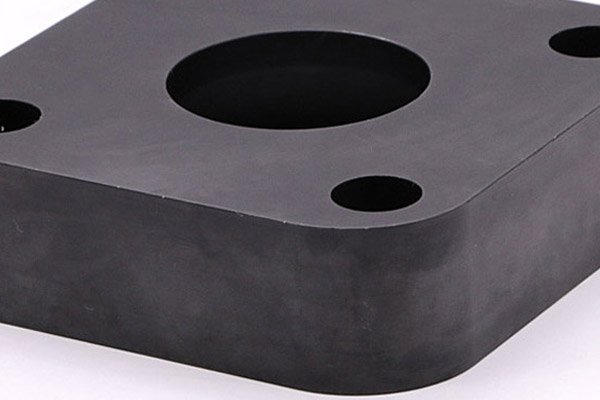

Steel blackening, or black oxide conversion coating, serves as a critical secondary operation for functional and aesthetic enhancement of machined components. This chemical process forms a magnetite layer on ferrous surfaces, delivering uniform matte-black finishes while providing mild corrosion resistance, reduced light glare, and improved lubricity for moving parts. For industries demanding tight tolerances and seamless integration—such as aerospace, medical devices, and precision instrumentation—the transition from CNC machining to surface treatment must preserve dimensional integrity without introducing delays.

At Honyo Prototype, we engineer this synergy intrinsically. Our end-to-end CNC machining capabilities span milling, turning, and multi-axis fabrication, followed by in-house blackening performed under rigorously controlled parameters. Unlike outsourced finishing that risks tolerance drift or extended lead times, our integrated workflow ensures parts move directly from machining centers to treatment baths within a single facility. This eliminates handling variables, maintains geometric accuracy per ISO 2768-mK standards, and accelerates time-to-shipment by up to 40% compared to fragmented supply chains.

Our technical team collaborates with clients during design for manufacturability (DFM) reviews to optimize part geometry for both machining efficiency and blackening efficacy. Whether producing low-volume prototypes or high-mix production runs, we adhere to ASTM D6679 specifications for coating thickness (0.5–1.5 µm) and corrosion resistance (4–24 hours neutral salt spray per ASTM B117).

Accelerate your project timeline with Honyo’s Online Instant Quote platform. Upload CAD files to receive geometry-aware pricing, lead time estimates, and material recommendations within minutes—valid for both CNC machining and value-added blackening services. This digital workflow ensures transparency from RFQ to delivery, empowering engineering teams to make data-driven sourcing decisions without procurement bottlenecks.

| Service Integration Advantage | Traditional Outsourced Approach |

|---|---|

| Single-point quality control | Multiple handoffs, risk of tolerance stack-up |

| Lead time reduction (20–40%) | Extended logistics between vendors |

| DFM-aligned process planning | Reactive problem-solving post-machining |

| Real-time coating parameter validation | Batch testing with delayed feedback |

Partner with Honyo Prototype to transform precision-machined steel components into finished, application-ready solutions—where CNC excellence meets flawless surface engineering. Initiate your quote today to experience seamless manufacturing continuity.

Technical Capabilities

Blackening of steel, also known as black oxide coating or black conversion coating, is a chemical surface treatment primarily applied to ferrous materials to enhance corrosion resistance, minimize light reflection, and improve aesthetic appearance. While blackening is not a machining process itself, it is often specified as a post-machining finish for components produced via 3/4/5-axis milling and turning operations—especially those requiring tight tolerances. The process involves converting the surface layer of steel into magnetite (Fe₃O₄) through a hot alkaline oxide bath (typically 135–150°C), although cold and mid-temperature variants exist.

The blackening process has minimal impact on dimensional tolerances—typically adding less than 0.0001” (2.5 µm) per surface—making it well-suited for tight-tolerance applications where post-machining dimensional stability is critical. However, it is essential to note that blackening is only effective on ferrous materials such as carbon and alloy steels; it does not adhere to non-ferrous metals or plastics.

For components machined from aluminum, ABS, or nylon, alternative surface treatments (such as anodizing, painting, or dyeing) are required to achieve a black finish. These materials are incompatible with the chemical reaction needed for black oxide formation.

Below is a summary of technical considerations for blackening in the context of precision machining operations:

| Parameter | Specification / Detail |

|---|---|

| Compatible Materials | Carbon steel, alloy steel (ferrous metals only) |

| Incompatible Materials | Aluminum, stainless steel (without catalyst), ABS, Nylon, other non-ferrous materials |

| Process Type | Chemical conversion coating (hot, mid-temperature, or cold) |

| Typical Coating Thickness | 0.00001″ – 0.0001″ (0.25 – 2.5 µm) per surface |

| Dimensional Impact | Negligible; suitable for tight-tolerance parts (±0.0002″ or better) |

| Corrosion Resistance | Moderate; improved with oil or wax post-treatment (e.g., rust preventative oil) |

| Common Applications | Precision mechanical components, tooling, aerospace parts, firearm components |

| Machining Compatibility | Ideal post-process for 3/4/5-axis milling and turning due to minimal part distortion |

| Surface Appearance | Matte black finish, uniform coloration |

| Temperature Range (Hot Process) | 135–150°C (275–300°F) |

| Post-Processing Requirement | Sealing with oil or wax to enhance corrosion resistance |

| Alternative for Non-Ferrous | Anodizing (Aluminum), Painting or Dyeing (ABS, Nylon) |

When designing precision parts requiring a black finish, material selection must align with the intended surface treatment. For aluminum components produced via multi-axis milling, Type II or Type III anodizing with dye is typically specified. For ABS and nylon parts—common in prototyping and low-friction applications—painting or immersion dyeing provides the desired aesthetic without compromising machined tolerances.

In high-precision environments, the blackening process is scheduled after final machining and inspection to ensure that critical dimensions remain unaffected and that the coating is uniformly applied without masking key datums or features.

From CAD to Part: The Process

Honyo Prototype integrates steel blackening as a critical surface treatment within our end-to-end manufacturing workflow, not as a standalone phase. Our process ensures technical rigor and seamless execution from design to delivery, with blackening specifically addressed during production planning and execution. Below is the precise sequence aligned with your query, detailing where blackening is technically managed.

Upload CAD

Clients submit CAD files specifying blackening requirements (e.g., ASTM A967 Type 2 for oxide finish). Our system validates file integrity and extracts critical parameters like material grade (e.g., 1018, 4140), geometry complexity, and tolerance zones. For blackening, we immediately flag features prone to issues—such as blind holes causing solution entrapment or sharp edges leading to uneven coating—which directly informs downstream DFM analysis.

AI Quote

Our AI engine cross-references the CAD data with real-time process databases to generate a technical quote. For blackening, it calculates:

Material compatibility (e.g., low-carbon steels vs. stainless)

Secondary operation sequencing (e.g., blackening after machining but before welding assembly)

Environmental compliance costs (e.g., waste treatment for alkaline oxidizing solutions)

The quote explicitly states blackening method options (e.g., hot alkaline oxide vs. room-temperature selenium-based) based on steel alloy and functional requirements, with lead time impacts quantified.

DFM (Design for Manufacturing)

This phase is where blackening feasibility is rigorously validated. Our engineers conduct:

Geometry review: Identifying recesses requiring solution agitation to prevent staining

Material verification: Confirming steel composition (e.g., phosphorus content in 1215 free-machining steel affecting oxide adhesion)

Tolerance analysis: Accounting for minimal dimensional change (typically 0.00002–0.00003″ per surface)

Hydrogen embrittlement risk assessment for high-strength steels (e.g., ASTM F1941 bake requirements post-plating if applicable)

A formal DFM report documents blackening-specific recommendations, such as adding drainage holes or adjusting surface roughness specs to ensure coating uniformity.

Production

Blackening occurs exclusively within our controlled production cell after all machining and pre-treatment steps. Key technical controls include:

| Process Stage | Critical Parameters for Steel Blackening | Honyo Control Method |

|---|---|---|

| Pre-treatment | Oil/grease removal, acid activation | Ultrasonic cleaning + pH-monitored acid dip (10-15 sec) |

| Blackening | Solution temp (285-290°F), immersion time (15-20 min) | NIST-traceable thermocouples, automated timer systems |

| Post-treatment | Sealing oil viscosity, corrosion resistance | ASTM B117 salt spray testing (minimum 48 hrs), IR spectrometry for oil thickness |

All blackening baths undergo hourly specific gravity checks, and every batch receives adhesion testing per ASTM D3359. High-strength steels (>180 ksi UTS) undergo mandatory stress relief baking within 4 hours post-blackening.

Delivery

Final inspection certifies blackening quality against client-specified standards. We provide:

Dimensional reports confirming no distortion from thermal exposure

Salt spray test results (e.g., 96 hours per ASTM B117 for military specs)

Material traceability documentation linking heat numbers to process parameters

Packaging using vapor corrosion inhibitors (VCI) to prevent flash rust during shipment

Honyo treats blackening not as a discrete step but as an engineered surface solution integrated into our production physics. This approach eliminates common failures like peeling coatings or hydrogen-induced cracking by enforcing material-science-driven protocols from the initial CAD review through final validation. Clients receive certified, functionally reliable components with documented process traceability for critical applications.

Start Your Project

Interested in high-quality blackening of steel services for your precision components? Honyo Prototype offers professional surface treatment solutions with fast turnaround times. Our black oxide finish provides excellent corrosion resistance, minimizes light reflection, and enhances the appearance of steel parts—all performed at our Shenzhen manufacturing facility.

For quotes and technical inquiries, contact Susan Leo at [email protected]. Trust Honyo Prototype for reliable, industrial-grade metal finishing tailored to your engineering requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.