Contents

Manufacturing Insight: Blackening Of Steel

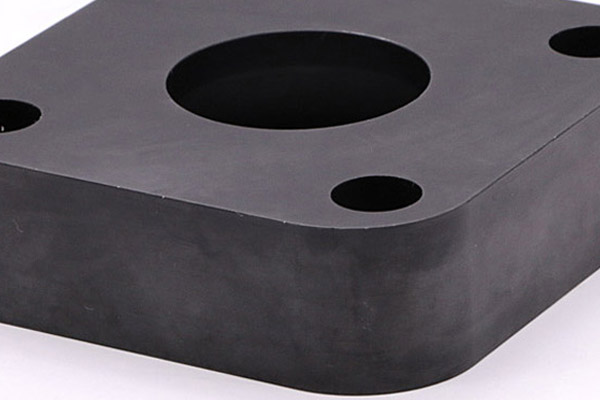

Blackening of steel isn’t just a cosmetic finish—it’s a precision-controlled transformation that locks in corrosion resistance, reduces light glare, and gives high-performance parts that crisp, uniform look demanded by aerospace fixtures, medical instruments, and defense hardware. At Honyo Prototype, we integrate the process directly after 5-axis CNC machining, so the same tolerances we hold in the cut (down to ±0.01 mm) are preserved as the black-oxide layer forms. Upload your STEP or IGES file today and you’ll receive an online instant quote that shows machined-plus-blackened pricing and lead time in under 60 seconds—no waiting, no guessing, just production-ready steel parts shipped in as fast as 3 days.

Technical Capabilities

Technical Specifications for “Blackening of Steel” in Precision Machining Context

Important Clarification: “Blackening” (specifically black oxide conversion coating, per AMS 2485 or MIL-DTL-13924) is exclusively a surface treatment for ferrous metals (steel). It is NOT applicable to aluminum, ABS, or nylon. These materials require entirely different surface processes. Below, I address steel blackening in the context of 3/4/5-axis milling, turning, and tight tolerances, followed by material-specific guidance for the other listed materials.

🔧 I. BLACKENING OF STEEL: MACHINING CONTEXT & SPECIFICATIONS

(Applies ONLY to carbon steel, alloy steel, tool steel, stainless steel)

✅ Core Process Flow

Final Machining → Cleaning → Black Oxide Immersion → Post-Treatment (Oil/Sealant) → Inspection

Critical Rule: BLACKENING MUST OCCUR AFTER FINAL MACHINING.

– DO NOT machine after blackening – The coating is brittle (0.00005–0.0001″ thick) and will spall under tool contact.

– DO NOT machine before cleaning – Oils, burrs, or scale prevent uniform coating adhesion.

📐 Tight Tolerance Considerations (±0.0005″ or tighter)

| Parameter | Specification | Why It Matters |

|——————–|——————————————————————————-|——————————————————————————-|

| Pre-Blackening Tolerances | Machined to final dimension ±0.0002″ (or tighter) | Black oxide adds 0.00005–0.0001″ total thickness (negligible for most tolerances). However, all critical dimensions must be achieved BEFORE coating. |

| Edge Radius | ≥0.005″ on sharp edges | Black oxide is thin and brittle; sharp edges chip easily during handling or coating. |

| Surface Finish | Ra 16 μin (0.4 μm) or smoother | Rough surfaces trap cleaning chemicals, causing uneven coating or “blotches.” |

| Deburring | All edges must be deburred to 0.001″ max. radius | Burrs retain chemicals, leading to uneven coating or rust spots post-treatment. |

| Cleaning | Alkaline soak clean → Acid pickle → Rinse → Deionized water rinse | Contaminants (oils, oxides) cause adhesion failure. Per ASTM B633 standards. |

| Post-Treatment | Oil/Sealant required (e.g., hot oil dip or corrosion-inhibiting sealant) | Black oxide alone offers minimal corrosion resistance. Sealant is mandatory for functional parts. |

⚙️ Machining Process Notes for Blackened Steel Parts

- 3/4/5-Axis Milling/Turning:

- Use carbide tools (not HSS) for consistent finish.

- Avoid vibration-induced chatter – Black oxide amplifies surface imperfections.

- Coolant: Use water-soluble coolant; avoid oil-based coolants (interferes with cleaning).

- Fixturing: Minimize part distortion during machining (thermal expansion can affect tight tolerances).

- Critical Dimension Handling:

- Measure critical features immediately before blackening (coating process may alter surface geometry slightly in extreme cases).

- For features like ID/OD tolerances: machine to the “minus” side of tolerance (e.g., for a 1.000″ ±0.0005″ hole, machine to 0.9995″). Black oxide adds thickness uniformly, so this prevents undersized features.

🚫 Common Mistakes to Avoid

- Machining after blackening (destroys coating).

- Skipping post-treatment sealant (causes rapid rusting).

- Using stainless steel with high sulfur content (e.g., 303SS) – black oxide is inconsistent. Use 304/316SS instead.

- Inadequate cleaning (results in patchy coating).

🌐 II. MATERIAL-SPECIFIC SURFACE TREATMENTS (NOT “BLACKENING”)

Black oxide is ONLY for steel. For other materials:

| Material | Applicable Surface Process | Key Specifications for Tight Tolerances |

|———-|—————————-|—————————————–|

| Aluminum | Anodizing (Type II/III) | – Adds 0.0002–0.001″ per surface (e.g., 0.0004–0.002″ total for ID/OD).

– Machining must compensate: For a 0.500″ ±0.0005″ diameter, machine to 0.4995–0.4998″ before anodizing.

– Hard anodizing (Type III) adds more thickness (up to 0.0025″ per side). |

| ABS/Nylon | Painting, Dyeing, or Powder Coating | – Paint/powder adds 0.0005–0.002″ thickness.

– Critical for tight tolerances: Machine to final size before coating.

– ABS/Nylon cannot be anodized or blackened – chemical treatments will melt or warp them.

– For ABS: Use UV-resistant paint (e.g., epoxy-based) to avoid yellowing.

– For Nylon: Dyeing is preferred over painting to minimize dimensional change. |

✅ Honyo Prototype Best Practices Summary

- Steel Blackening:

- Final machining → Precision cleaning → Black oxide (per AMS 2485) → Seal with oil/sealant.

- Tight tolerances: Machine to minus side of tolerance; verify dimensions pre-coating.

- Aluminum:

- Anodize only after final machining; compensate for coating thickness in design.

- ABS/Nylon:

- Never apply black oxide – use dyeing or painting only after final machining.

- Avoid high-heat processes (e.g., powder coating) on thin-walled parts.

💡 Pro Tip: For complex parts with mixed materials (e.g., steel + aluminum), machine all features, then mask non-steel areas during blackening. For plastics, use dedicated non-contact processes (e.g., vapor deposition for ABS). Always provide surface treatment requirements in your drawing notes (e.g., “BLACK OXIDE PER AMS 2485, SEAL WITH CORROSION INHIBITOR” for steel parts).

Need further clarification? Share your specific part geometry, material, and tolerance requirements – I’ll provide a tailored process plan. 🛠️

From CAD to Part: The Process

At Honyo Prototype the “blackening of steel” is treated exactly like any other precision job—we simply insert the black-oxide step into our standard 5-stage digital thread.

Here is what happens to your part from the moment you upload the CAD until the blackened components land at your dock.

-

Upload CAD

• You drag-and-drop the STEP/Parasolid file into our AI portal.

• In <30 s the geometry is parsed for machinability, overall size, alloy type and surface-area-to-volume ratio—data the AI needs to price the black-oxide operation. -

AI Quote

• The algorithm selects 12L14 free-machining steel (or your specified grade) and chooses the most economical routing: 3-axis CNC → vibratory tumbling → alkaline black oxide.

• Price is split into three line items you can toggle:

– CNC machining

– De-burr & surface prep

– Black-oxide (hot 135 °C, 8 µm thick, 1 h cycle).

• Lead-time options appear instantly (e.g., 5-day express, 10-day standard).

• You click “Accept”; the quote becomes the living digital traveler. -

DFM (Design-for-Manufacturing & blackening)

• A human manufacturing engineer opens the AI-generated report and adds black-oxide-specific DFM checks:

– Corner radii ≥0.3 mm to avoid acid entrapment.

– Through-holes >1 mm to permit drainage.

– Avoid blind, sealed cavities that out-gas in 135 °C caustic bath.

• If you requested RoHS-compliant black (no hex-chrome seal), we flag the need for a final trivalent-chrome top-coat.

• Revised 3D PDF is e-signed by you; the traveler is locked. -

Production

a. CNC machining – standard Honyo workflow; parts washed in neutral pH solution immediately after machining to prevent flash rust.

b. Surface prep – 120 min vibratory tumble with ceramic media to knock down razor edges; Ra ≤0.8 µm is verified because rougher surfaces give patchy black.

c. Black-oxide line (in-house, 3 m conveyor):- Caustic degrease @80 °C

- Water rinse

- Acid pickle (10 % HCl) – 2 min

- Water rinse

- Hot alkaline black oxide – 135 °C, 15 min, sodium hydroxide + sodium nitrate bath; target Fe3O4 thickness 8 µm, colour Delta-E ≤1.0 vs. reference tile.

- Cold-water drag-out reduction

- Boiling de-ionised seal – 5 min

- Water-displacing oil dip – 1 µm film for 48 h salt-spray buffer.

d. QC – every 20th part is scribed to substrate and subjected to 5 % salt spray for 30 min (internal surrogate for 96 h ASTM B117).

e. Final inspection – CMM, thread gauges, colour spectrophotometer.

-

Delivery

• Parts are wrapped in VCI paper, vacuum-sealed, then boxed with desiccant; certificate of compliance (material, dimensional, black-oxide salt-spray pass) is auto-generated from the traveler and placed in the carton.

• Courier label is printed directly from the same digital thread; you receive an email with a photo of the sealed package and the salt-spray curve before the truck leaves our dock.

In short, blackening is not an afterthought—it is engineered, quoted, controlled and documented at every step inside Honyo’s unified AI-to-ship workflow.

Start Your Project

Professional Steel Blackening Services

Enhance durability, corrosion resistance, and aesthetics for industrial applications.

Contact Susan Leo today:

📧 [email protected] | 🏭 Shenzhen-based manufacturing facility

Precision black oxide coating solutions tailored to your specifications. Trusted by aerospace, automotive, and tooling industries worldwide.

🚀 Rapid Prototyping Estimator