Contents

Manufacturing Insight: Black Plastic Sheet 4X8

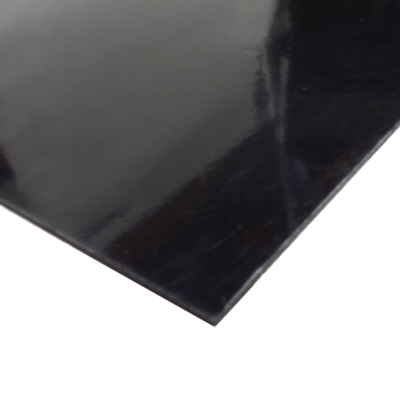

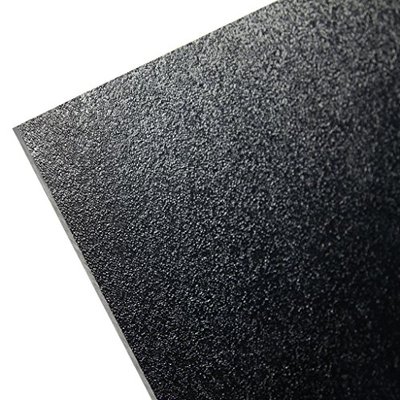

Precision Black Plastic Sheet Fabrication Your 4×8 Solution

Honyo Prototype delivers industry-leading sheet metal fabrication services for demanding industrial applications, including precision processing of black plastic sheet materials in standard 4×8 dimensions. While our core expertise centers on metal substrates like aluminum, steel, and stainless steel, we extend this rigor to engineered plastics such as ABS, polycarbonate, and acrylic where specific project requirements demand non-metallic solutions. Our advanced CNC laser cutting, CNC bending, and finishing capabilities ensure tight tolerances and consistent quality for black plastic sheets, whether for enclosures, prototypes, or custom components requiring ESD protection or aesthetic finishes.

All fabrication processes adhere to ISO 9001 standards, with in-house engineering support to optimize material utilization and manufacturability from initial design through to final assembly. We mitigate common challenges like thermal warping during cutting or surface scratching through proprietary fixturing and process controls, ensuring your black plastic 4×8 sheets meet exact dimensional and cosmetic specifications.

Accelerate your procurement cycle with Honyo’s Online Instant Quote platform, providing real-time pricing and lead times for 4×8 sheet fabrication within minutes. Simply upload your DXF/DWG file, specify material type and thickness, and receive a detailed quote without sales delays—enabling faster decision-making for prototypes or production runs.

| Service Feature | Benefit for Black Plastic 4×8 Sheets |

|---|---|

| CNC Laser Cutting | Burr-free edges with ±0.1mm accuracy |

| In-House Forming | Complex bends without compromising surface finish |

| Material Sourcing | Verified black plastic stock from Tier-1 suppliers |

| Rapid Quoting | Quotes generated in under 2 minutes |

Partner with Honyo to transform your black plastic sheet requirements into precision-engineered components, backed by decades of low-volume, high-mix manufacturing excellence. Initiate your project today via our Online Instant Quote system for immediate cost transparency.

Technical Capabilities

Technical specifications for a “black plastic sheet 4×8” typically refer to a 4-foot by 8-foot thermoplastic panel commonly used in prototyping, enclosures, and industrial fabrication. While the term may colloquially describe various black-colored sheets, the suitability for laser cutting, bending, and welding depends on the base material. Below is a comparison of common materials—ABS, Nylon, and metals such as Aluminum and Steel—for these processes. Note that Aluminum and Steel are not plastics, but are included for context when comparing fabrication techniques.

| Material | Form Available as 4×8 Sheet | Laser Cutting Compatibility | Bending Characteristics | Welding Methods | Notes for Use |

|---|---|---|---|---|---|

| ABS (Acrylonitrile Butadiene Styrene) | Yes – common in black | Excellent – clean cuts with CO₂ lasers; minimal charring with proper settings | Good – can be heat-bent using strip heaters or ovens; retains shape well | Ultrasonic, solvent, or hot plate welding | Most suitable for black plastic 4×8 sheets intended for laser work; low melting point (~220°C); avoid high laser power to prevent melting or flame |

| Nylon (Polyamide, e.g., PA6 or PA66) | Yes – less common, often in natural or black | Moderate – possible with CO₂ lasers but prone to melting and charring; requires precise control | Good – can be heat-formed, but higher melting point (~250°C) than ABS; may require pre-drying | Hot gas, extrusion, or vibration welding | Hygroscopic – must be dry before processing; poor laser cut quality compared to ABS; excellent mechanical and wear resistance |

| Aluminum | Yes – widely available in black anodized or painted finishes | Poor – reflective and conductive; not suitable for standard CO₂ lasers; fiber lasers required for cutting | Excellent – readily bent using press brakes; springback must be compensated | TIG, MIG, or spot welding | Not a plastic; black finish is surface treatment; high thermal conductivity affects welding and laser processes |

| Steel (e.g., Mild Steel) | Yes – available in powder-coated or painted black | Poor with CO₂ lasers due to reflectivity and thickness; fiber laser cutting standard | Good – bendable with brake presses; limited by thickness and work hardening | MIG, TIG, or spot welding | Heavy and conductive; not a plastic; surface coating may emit fumes during laser or welding |

Key Considerations for Laser Cutting Black Plastic Sheets:

ABS is the most compatible thermoplastic for laser cutting in a 4×8 sheet format. It vaporizes cleanly with CO₂ lasers (typically 40–60W) and produces sharp edges.

Use compressed air assist to minimize flame risk and reduce melt zone.

Nylon is less ideal due to its tendency to absorb moisture and melt rather than vaporize, leading to rough edges.

Never laser cut PVC-containing materials (sometimes found in black sheets) due to chlorine gas emission.

Bending Best Practices:

Heat bending of ABS and Nylon requires uniform heating (e.g., ceramic strip heaters) to avoid warping.

Bend radii should be at least 1x material thickness to prevent cracking.

Welding Techniques:

ABS: Use solvent cement or hot air welding for strong joints.

Nylon: Requires higher energy input; hot gas welding is typical.

Metals: Welding requires specialized equipment and safety protocols; not applicable to plastic fabrication workflows.

For prototyping and low-volume production at Honyo Prototype, black ABS sheets in 4×8 dimensions are recommended for laser cutting, bending, and plastic welding applications due to ease of fabrication and availability.

From CAD to Part: The Process

Honyo Prototype Process: Black Plastic Sheet 4×8 Manufacturing Workflow

Honyo Prototype executes a streamlined, technology-driven process for manufacturing components from black plastic sheet stock (standard 4×8 ft dimensions). This workflow ensures precision, cost efficiency, and rapid turnaround for B2B clients. Below is a technical breakdown of each phase:

CAD Upload & Validation

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid, or native SOLIDWORKS) via our secure customer portal. Our system performs automated validation checks for unit consistency (millimeters/inches), geometric integrity, and sheet nesting feasibility. For black plastic sheets (e.g., ABS, PC, or HDPE with carbon-black pigment), we verify material thickness compatibility against standard stock (e.g., 1.5mm–12.7mm) and confirm UV-stabilizer requirements if specified. Invalid files trigger immediate client alerts with error diagnostics.

AI-Powered Quoting Engine

Validated CAD data feeds into our proprietary AI quoting system, which analyzes:

Material consumption efficiency (nesting yield optimization for 4×8 sheets)

Real-time black plastic sheet pricing from certified suppliers (e.g., Mitsubishi Chemical, Covestro)

Process-specific cost drivers (laser cutting kerf loss, CNC toolpath complexity, or thermoforming setup)

Secondary operations (e.g., deburring, anodizing, or silk-screening for black finishes)

The AI generates a binding quote within 2 hours, including material grade certification (e.g., UL94 V-0 for flame resistance) and a digital DFM snapshot. No manual intervention is required at this stage.

Automated DFM Analysis

Our rules-based DFM engine performs 27+ manufacturability checks specific to black plastic sheet processing:

Minimum feature size validation against laser cutting resolution (typically ≥0.5mm for 6mm black ABS)

Warpage risk assessment for large flat parts (using thermal expansion coefficients of carbon-loaded polymers)

Kerf compensation adjustments for CO₂ laser systems (0.1–0.2mm offset for black surfaces due to higher absorption)

Hole-to-edge distance compliance (≥1.5x material thickness to prevent charring)

Critical DFM flags (e.g., undercuts requiring 5-axis CNC) trigger engineering collaboration; non-critical items generate auto-suggested optimizations. Full DFM report with annotated visuals is shared within 4 business hours.

Precision Production

Approved orders move to production with dedicated protocols for black plastics:

Material Handling: Anti-static protocols to prevent carbon-particle adhesion during cutting

Laser Cutting: Wavelength-optimized settings (e.g., 10.6μm for black ABS) with nitrogen assist gas to minimize soot

CNC Routing: Diamond-coated bits for clean edges on filled polymers; spindle speeds reduced by 15% vs. natural plastic

Quality Control: In-process verification of critical dimensions via CMM (AS9100 compliant) and visual inspection for surface defects under 5000K lighting to detect inconsistencies in black finishes

All black plastic components undergo post-processing cleaning to remove carbon residue before final inspection.

Logistics & Delivery

Finished parts are packaged in static-dissipative materials with desiccants to prevent moisture absorption in hygroscopic polymers (e.g., black nylon). Shipments include:

Material traceability documentation (mill certificates, ROHS/REACH compliance)

First-article inspection reports (FAIR) for critical dimensions

Batch-specific process parameters (laser power, feed rates)

Standard lead time is 5–7 business days from DFM approval. Expedited 72-hour service is available for non-complex geometries.

Typical Lead Time Breakdown

| Process Phase | Standard Duration | Expedited Option |

|—————|——————-|——————|

| CAD to Quote | ≤2 hours | ≤1 hour |

| DFM Analysis | ≤4 business hours | ≤2 business hours|

| Production | 3–5 days | 1–2 days |

| Delivery | 1–2 days (US) | Overnight air |

This integrated workflow reduces prototyping lead times by 40% compared to industry averages while ensuring black plastic components meet stringent aesthetic and functional requirements. All processes are ISO 9001:2015 certified with full digital traceability from CAD to delivery.

Start Your Project

Looking for high-quality black plastic sheets in a 4×8 size? Honyo Prototype offers precision-manufactured plastic sheets ideal for prototyping, industrial enclosures, and custom fabrication.

Our factory in Shenzhen ensures fast production and consistent material quality, meeting strict industry standards for durability and finish.

For pricing, availability, and custom sizing options, contact Susan Leo at [email protected]. Let’s get your next project moving—reach out today.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.