Contents

Manufacturing Insight: Black Oxidized Steel

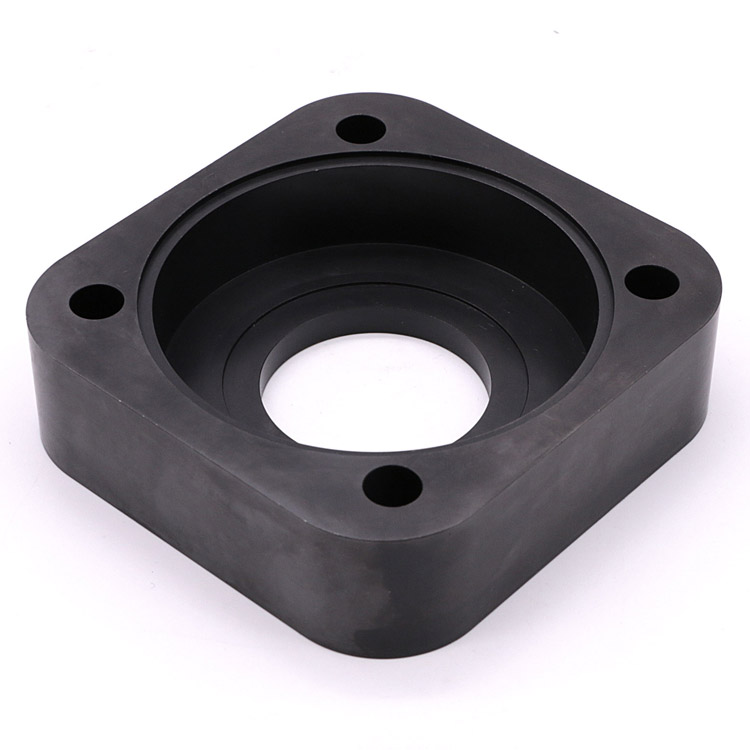

Precision Engineering with Black Oxidized Steel: Enhance Your Prototypes and Production Parts

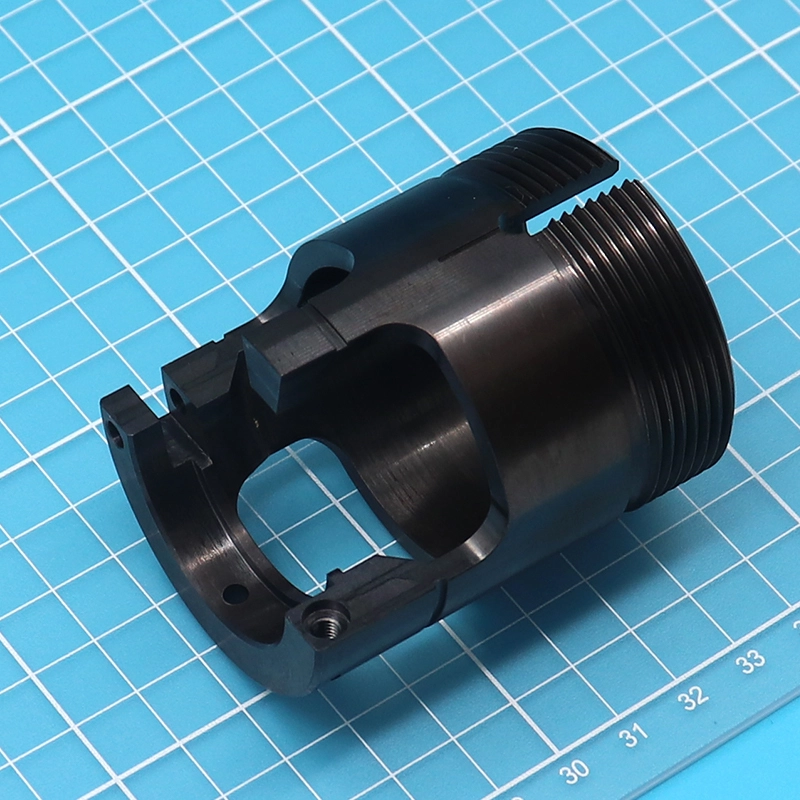

Black oxidized steel represents a critical surface treatment solution for demanding industrial applications, providing a functional matte-black finish through a chemical conversion process that forms magnetite (Fe₃O₄) on the substrate. Unlike paint or plating, this process penetrates the steel’s surface without altering critical dimensions, delivering uniform corrosion resistance, reduced light reflection, and enhanced wear properties while maintaining substrate integrity. For engineers requiring both aesthetic refinement and operational durability in components—from hydraulic fittings to aerospace brackets—black oxide delivers subsurface protection without compromising tight tolerances.

At Honyo Prototype, we integrate black oxidation seamlessly into our end-to-end CNC machining workflow, ensuring dimensional stability from raw material to finished part. Our precision milling, turning, and multi-axis capabilities maintain tolerances as tight as ±0.0002″ prior to finishing, eliminating post-treatment rework. By controlling bath chemistry, temperature, and immersion time in-house, we prevent hydrogen embrittlement in high-strength steels and guarantee consistent adhesion across complex geometries. This synergy between CNC accuracy and controlled oxidation ensures your components meet ASTM D6679 or MIL-DTL-13924 standards without sacrificing mechanical performance.

Leverage Honyo’s expertise to optimize your black oxidized steel projects from concept to shipment. Our Online Instant Quote platform accelerates prototyping and production planning, providing real-time cost and lead-time estimates for CNC-machined parts with black oxide finishing—all within 60 seconds. Upload your STEP or IGES file today to validate manufacturability, receive actionable DFM feedback, and move from design to delivery faster. Partner with Honyo Prototype where precision machining meets uncompromised surface engineering.

Technical Capabilities

Black oxidized steel refers to a surface finish applied to carbon and alloy steels through a chemical conversion coating process known as hot black oxide. The process involves immersing the steel component in a hot alkaline solution (typically sodium hydroxide and nitrates at ~140–150°C), forming a magnetite (Fe₃O₄) layer on the surface. This results in a uniform, matte black appearance with mild corrosion resistance and improved aesthetic and light-absorbing properties. It does not significantly alter dimensional tolerances, making it suitable for tight-tolerance machined components.

While black oxide is a post-machining surface treatment, the base material must be compatible with precision 3-, 4-, and 5-axis milling and turning processes. Below is a comparison of typical materials used in such high-precision manufacturing, including steel that can be black oxidized, alongside Aluminum, ABS, and Nylon.

| Material | Typical Use in Milling/Turning | Machinability Rating | Tight Tolerance Capability (±) | Notes on Black Oxidation | Thermal & Dimensional Stability |

|---|---|---|---|---|---|

| Carbon Steel (e.g., 1018, 1045) | High – commonly used for structural and mechanical parts | Moderate to Good | ±0.0005″ (12.7 µm) achievable | Ideal candidate for black oxide; enhances corrosion resistance slightly and reduces glare | Good stability; minimal creep; holds tight tolerances well |

| Alloy Steel (e.g., 4140, 4340) | High – used in high-stress applications | Moderate | ±0.001″ (25.4 µm) typical; tighter with finishing passes | Excellent for black oxide; often used in aerospace and tooling after hardening and stress relieving | High stability; low thermal expansion; suitable for precision components |

| Stainless Steel (e.g., 303, 304, 17-4 PH) | Moderate – more abrasive, requires carbide tooling | Fair to Moderate | ±0.0005″–±0.001″ achievable with precision CNC | Not typically black oxidized due to passive chromium layer; specialized blackening processes exist but are less common | High corrosion resistance; moderate thermal expansion |

| Aluminum (e.g., 6061, 7075) | Very High – excellent for high-speed 3–5-axis milling | Excellent | ±0.0005″ (12.7 µm) routinely achieved | Cannot be black oxidized; uses anodizing (Type II or III) for black finish | Low thermal mass; high expansion; requires careful fixturing for tight tolerances |

| ABS (Acrylonitrile Butadiene Styrene) | High – easily machined on CNC mills and lathes | Excellent | ±0.002″ (50 µm) typical; sensitive to tool heat | Not applicable – thermoplastic; no metal conversion coating | Poor thermal stability; prone to warping; not for high-temp environments |

| Nylon (e.g., PA6, PA66) | Moderate – tough but tends to gum up tools | Fair | ±0.002″–±0.005″ (50–127 µm); hygroscopic swelling affects precision | Not applicable – polymer; cannot undergo black oxide treatment | Absorbs moisture; dimensional changes post-machining possible; limited to low-stress, non-critical environments |

Key Notes:

Black oxide adds approximately 0.00005″ to 0.0001″ per surface, but since it’s a conversion coating (half penetrates, half grows), net dimensional change is negligible. This makes it ideal for components requiring tight tolerances after finishing.

For high-precision steel parts produced via 3-, 4-, or 5-axis CNC milling or turning, black oxide is often the final step after stress relieving, precision grinding, or lapping.

Aluminum, ABS, and Nylon require alternative surface treatments for black finishes: anodizing, painting, or dyeing, respectively.

Tool wear, coolant selection, and fixturing are critical when holding tight tolerances across all materials, especially in multi-axis setups where tool access and rigidity vary.

From CAD to Part: The Process

Honyo Prototype Black Oxidized Steel Process Overview

Honyo Prototype executes black oxidized steel finishing through a rigorously controlled five-stage workflow designed for precision, material integrity, and dimensional stability. This chemical conversion coating process transforms surface iron into magnetite (Fe₃O₄), providing mild corrosion resistance, light absorption, and a matte black aesthetic without altering part tolerances. Below is the technical workflow.

CAD File Upload and Initial Processing

Clients initiate the process by uploading native CAD files (STEP, IGES, or native SOLIDWORKS formats preferred) via our secure portal. Our system immediately validates file integrity and extracts critical geometry data. Material specification is mandatory at this stage; black oxide is exclusively compatible with low-carbon steels (e.g., 1008, 1010, 1018, 1020) and select alloy steels. Incompatible materials (e.g., stainless steel, high-sulfur steels like 12L14) are flagged prior to quoting.

AI-Powered Quoting and Feasibility Analysis

Our AI engine performs a multi-parameter analysis within 90 seconds of CAD upload:

Material compatibility verification against ASTM D769 standards

Surface area calculation for chemical bath immersion time

Detection of design features risking incomplete coverage (e.g., blind holes >3x diameter depth, sharp internal corners)

Preliminary cost modeling based on part volume, surface area, and rack density

The AI generates a binding quote with explicit process limitations. For instance, parts with blind holes exceeding aspect ratio 3:1 receive automatic DFM notes recommending vent holes. Human engineering review follows for complex geometries.

Engineering-Driven DFM Optimization

All quotes undergo mandatory DFM review by our manufacturing engineering team. Key focus areas for black oxide include:

Specifying racking points to prevent contact marks on critical surfaces

Adjusting tolerances for minimal dimensional impact (black oxide adds 0.00001″–0.00002″ per surface)

Recommending pre-plate surface finishing (e.g., 125–250 μin Ra) for uniform appearance

Flagging high-residual-stress areas prone to smut formation

Material compatibility is re-verified against this internal matrix:

| Steel Grade | Black Oxide Suitability | Critical Constraints |

|---|---|---|

| 1008/1010 | Excellent | None beyond standard process limits |

| 1018/1020 | Excellent | Avoid cold-working >20% reduction |

| 4140 | Conditional | Requires stress relief @ 300°F+ pre-treatment |

| 12L14 | Poor | Sulfur causes streaking; not recommended |

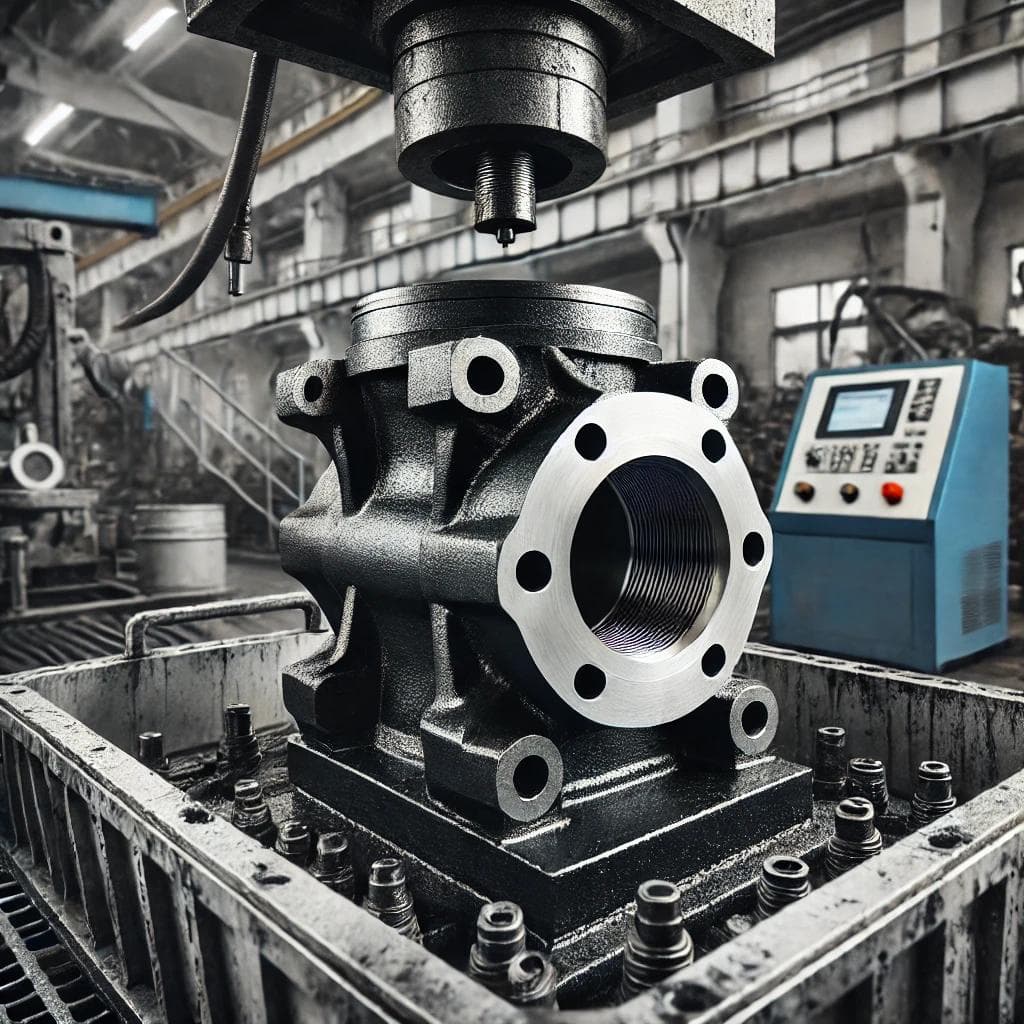

Controlled Production Execution

Approved orders enter a sequential 12-stage production line:

1. Vapor degreasing (60°C, 10 min) to remove hydrocarbons

2. Alkaline soak cleaning (85°C, pH 11.5)

3. Electrolytic cleaning (6V DC, 60 sec)

4. Triple-stage DI water rinsing (conductivity <5 μS/cm)

5. Black oxide immersion (285–295°F, sodium nitrite/nitrate bath, 15–25 min)

6. Hot DI water seal rinse (190°F)

7. Post-treatment immersion (Type II oil or Type III wax sealant)

8. Final DI rinse and forced-air drying (120°F)

Throughout production, in-line monitoring maintains bath chemistry within ±0.5% of specification and temperature within ±2°F. Every batch undergoes salt spray testing per ASTM B117 (minimum 48-hour rating).

Quality-Controlled Delivery

Final inspection validates:

Color uniformity (measured via spectrophotometer; ΔE < 2.0 from master sample)

Coating weight (150–250 mg/ft² per MIL-DTL-13924)

Dimensional conformance to pre-oxide blueprint

Absence of smut or uncoated areas

Parts ship in anti-tarnish VCI paper with desiccant packs inside rigid containers. Lead time is typically 7–10 business days from DFM approval, with full traceability via our digital lot-tracking system. This process ensures black oxide finishes meet aerospace and medical device requirements where dimensional stability and chemical resistance are critical.

Start Your Project

Looking for high-quality black oxidized steel components? Honyo Prototype offers precision manufacturing with fast turnaround times. Our Shenzhen-based factory ensures strict quality control and efficient production for your prototyping and low-volume needs.

Contact Susan Leo today at [email protected] to request a quote or discuss your project specifications.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.