Introduction: Navigating the Global Market for black fiberglass sheet

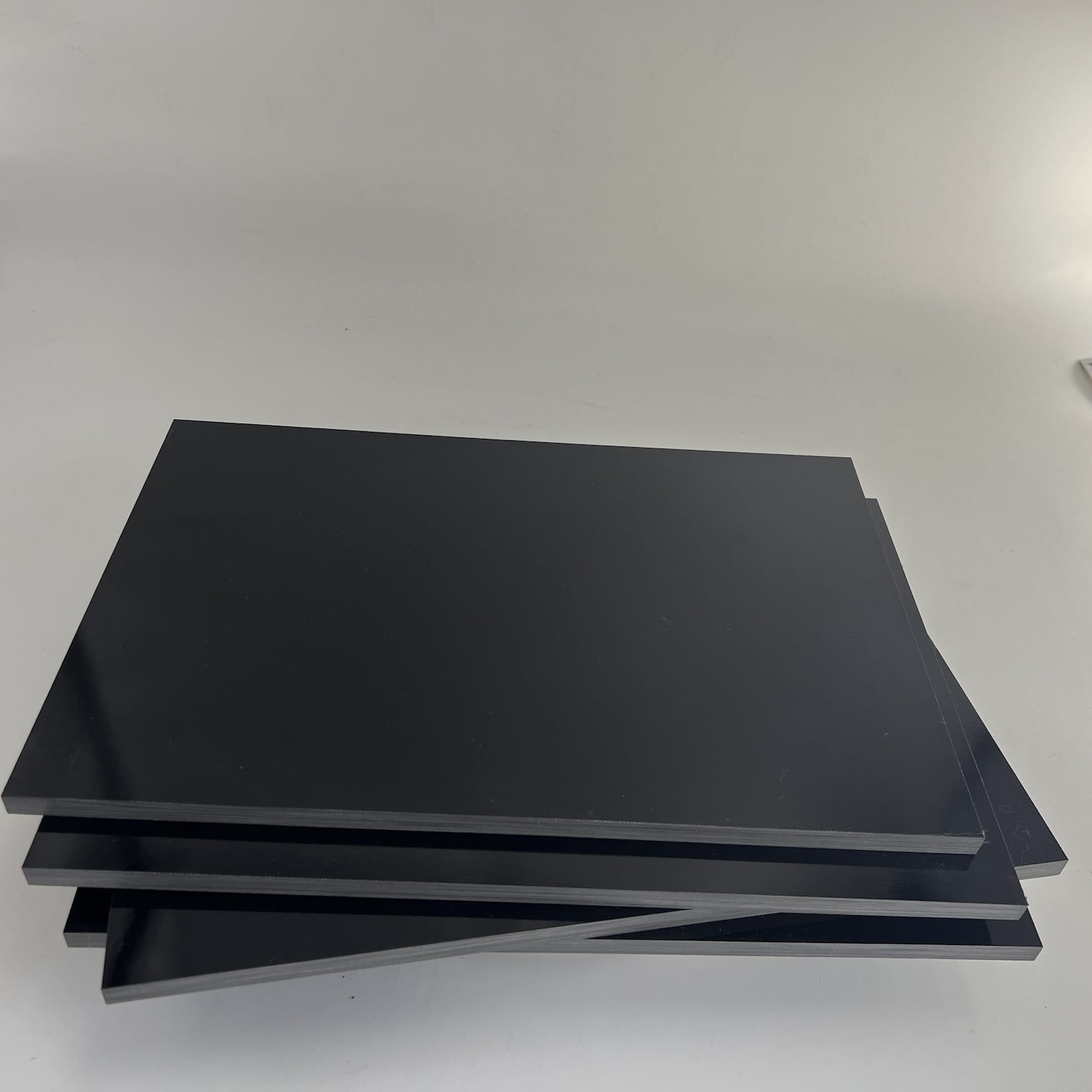

The global market for black fiberglass sheet is growing rapidly, presenting a unique challenge for international B2B buyers: how to effectively source high-quality materials that meet specific operational needs while ensuring cost-efficiency. Black fiberglass sheets, made from woven fiberglass fabric and epoxy resin, are renowned for their durability, electrical insulation properties, and versatility across various applications, including electronics, automotive, and construction. However, navigating the complexities of suppliers, quality standards, and pricing structures can be daunting, particularly for buyers in regions like Africa, South America, the Middle East, and Europe, including markets such as Saudi Arabia and Vietnam.

This comprehensive guide is designed to empower B2B buyers by providing in-depth insights into the different types of black fiberglass sheets available, their myriad applications, and essential criteria for supplier vetting. We will explore cost factors and market trends, enabling you to make informed purchasing decisions that align with your business objectives. Whether you are looking to enhance your product offerings or seeking reliable materials for manufacturing processes, understanding the nuances of black fiberglass sheets will be crucial to your success. By leveraging the information in this guide, you can confidently navigate the global market, ensuring that your sourcing strategies yield the best quality materials at competitive prices.

Understanding black fiberglass sheet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Norplex-Micarta NP510A | High strength, brominated epoxy resin, engineered to NEMA FR-4 | Electrical insulation, terminal boards | Pros: Excellent mechanical and electrical properties. Cons: Higher cost compared to standard fiberglass sheets. |

| Smooth Fiberglass FRP Sheet | Smooth surface finish, lightweight, customizable thickness options | Automotive, construction, signage | Pros: Aesthetic appeal, ease of machining. Cons: May not provide the same strength as thicker variants. |

| G10 Black Fiberglass Sheet | Glass epoxy laminate, good dimensional stability | Electronics, military applications | Pros: Cost-effective, good electrical insulation. Cons: Limited chemical resistance compared to other types. |

| Phenolic Black Fiberglass Sheet | Phenolic resin matrix, flame-resistant properties | Aerospace, industrial machinery | Pros: High heat resistance, excellent durability. Cons: Heavier and more expensive than standard fiberglass sheets. |

| FR-4 Black Fiberglass Sheet | Standardized electrical insulation properties, versatile thicknesses | PCB substrates, electronic enclosures | Pros: Widely used, readily available. Cons: May not meet specific high-performance requirements. |

What Are the Characteristics of Norplex-Micarta NP510A Black Fiberglass Sheets?

Norplex-Micarta NP510A is a high-performance black fiberglass sheet made from woven fiberglass fabric and brominated epoxy resin. It meets NEMA grade FR-4 standards, making it suitable for applications requiring excellent mechanical strength and electrical insulation, such as terminal boards and lapping carriers. When considering procurement, buyers should assess the sheet’s temperature resistance, moisture absorption, and tensile strength, as these properties are crucial for various operational environments.

How Do Smooth Fiberglass FRP Sheets Stand Out?

Smooth Fiberglass FRP Sheets are characterized by their lightweight and customizable thickness options, making them ideal for applications in automotive, construction, and signage. Their smooth surface finish not only provides aesthetic appeal but also facilitates easier machining. Buyers should consider the specific thickness and finish required for their application, as well as the potential trade-offs between weight and strength.

Why Choose G10 Black Fiberglass Sheets?

G10 Black Fiberglass Sheets are glass epoxy laminates known for their good dimensional stability and electrical insulation properties. Commonly used in electronics and military applications, these sheets are cost-effective solutions for projects needing reliable performance. B2B buyers should evaluate the chemical resistance and overall durability of G10 sheets, especially if they are used in harsh environments.

What Are the Benefits of Phenolic Black Fiberglass Sheets?

Phenolic Black Fiberglass Sheets utilize a phenolic resin matrix, providing flame-resistant properties ideal for aerospace and industrial machinery applications. These sheets are known for their high heat resistance and durability, making them suitable for demanding environments. When purchasing, buyers should weigh the benefits of enhanced durability against the potential for increased weight and cost.

How Do FR-4 Black Fiberglass Sheets Fit into the Market?

FR-4 Black Fiberglass Sheets are standardized for electrical insulation and are available in various thicknesses, making them versatile for PCB substrates and electronic enclosures. Their widespread use in the industry ensures availability and ease of procurement. Buyers should consider whether FR-4 meets their specific performance requirements, as it may not suffice for specialized applications needing advanced properties.

Key Industrial Applications of black fiberglass sheet

| Industry/Sector | Specific Application of black fiberglass sheet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electrical & Electronics | Insulating components in circuit boards | Provides high dielectric strength and thermal stability | Ensure compliance with international standards (e.g., NEMA, MIL) |

| Automotive | Structural components and panels in vehicles | Lightweight yet strong, improving fuel efficiency and safety | Consider weight specifications and environmental regulations |

| Construction | Wall panels and flooring in commercial buildings | Offers durability and moisture resistance, enhancing lifespan | Assess local building codes and fire safety regulations |

| Aerospace & Defense | Structural parts in aircraft and military equipment | High strength-to-weight ratio, essential for performance | Verify material certifications and performance under extreme conditions |

| Medical Equipment | Components in diagnostic and therapeutic devices | Biocompatibility and ease of sterilization are crucial | Ensure compliance with health and safety regulations |

How is Black Fiberglass Sheet Used in the Electrical & Electronics Sector?

In the electrical and electronics industry, black fiberglass sheets are primarily utilized as insulating components in circuit boards. Their high dielectric strength and thermal stability make them ideal for applications where electrical insulation is critical. International B2B buyers must ensure that the sheets meet specific standards such as NEMA and MIL certifications, particularly when sourcing for projects in regions with stringent electrical regulations.

What Role Does Black Fiberglass Sheet Play in the Automotive Industry?

In the automotive sector, black fiberglass sheets are employed as structural components and panels within vehicles. Their lightweight nature contributes to improved fuel efficiency while maintaining high strength, which is essential for safety. Buyers should consider sourcing options that comply with environmental regulations, as automotive manufacturers increasingly focus on sustainable materials to meet global emissions standards.

Why Are Black Fiberglass Sheets Important in Construction?

Black fiberglass sheets find significant applications in the construction industry, particularly as wall panels and flooring in commercial buildings. Their durability and resistance to moisture make them an excellent choice for enhancing the lifespan of structures. B2B buyers should assess local building codes and fire safety regulations when sourcing these materials to ensure compliance and safety in construction projects.

How Is Black Fiberglass Sheet Used in Aerospace & Defense?

In the aerospace and defense industries, black fiberglass sheets are crucial for manufacturing structural parts in aircraft and military equipment. Their high strength-to-weight ratio is essential for performance, particularly in applications where weight savings are critical. Buyers must verify material certifications and ensure that products can withstand extreme conditions, which is often a requirement for aerospace components.

What Are the Applications of Black Fiberglass Sheet in Medical Equipment?

Black fiberglass sheets are widely used in the medical equipment sector, particularly in diagnostic and therapeutic devices. Their biocompatibility and ease of sterilization make them suitable for various applications, ensuring patient safety and compliance with health regulations. When sourcing for this sector, international buyers should ensure that materials meet health and safety standards to avoid regulatory issues in different markets.

3 Common User Pain Points for ‘black fiberglass sheet’ & Their Solutions

Scenario 1: Sourcing Quality Black Fiberglass Sheets for Industrial Applications

The Problem: B2B buyers often struggle with sourcing high-quality black fiberglass sheets that meet specific industrial requirements. In regions like Africa and South America, where local suppliers may lack the necessary certifications or technical expertise, finding a reliable source can be daunting. Buyers may face issues with material consistency, dimensional accuracy, and compliance with international standards, leading to delays in production and increased costs.

The Solution: To effectively source black fiberglass sheets, buyers should start by identifying reputable manufacturers that provide detailed product specifications and certifications, such as NEMA FR-4 or MIL-I-24768/27. Engaging with suppliers that offer custom solutions can also ensure that the sheets meet specific project needs, including thickness and mechanical properties. It is advisable to request samples for testing prior to placing bulk orders, as this allows buyers to evaluate the material’s performance in real-world applications. Establishing a long-term partnership with a trusted supplier can also enhance supply chain reliability and quality assurance.

Scenario 2: Managing Temperature and Humidity Effects on Performance

The Problem: Many B2B buyers in diverse climates are concerned about how temperature and humidity affect the performance of black fiberglass sheets. In regions with high moisture or temperature fluctuations, such as the Middle East and Southeast Asia, the risk of delamination or reduced mechanical strength can significantly impact product lifespan and reliability. Buyers may be hesitant to use fiberglass sheets that are not tested under varying environmental conditions, leading to uncertainty in material selection.

The Solution: To mitigate concerns about environmental effects, buyers should look for black fiberglass sheets specifically designed to withstand extreme conditions, such as those with enhanced moisture resistance and thermal stability. When discussing options with suppliers, inquire about the material’s performance metrics, including flexural strength and dielectric properties under humid conditions. Implementing a robust testing protocol, including accelerated aging tests, can provide insights into how the material will perform over time. Additionally, maintaining proper storage conditions for the sheets before use can help preserve their integrity.

Scenario 3: Difficulty in Customizing Black Fiberglass Sheets for Unique Projects

The Problem: Customization is often a key requirement for B2B buyers who need black fiberglass sheets tailored to specific dimensions or applications. However, navigating the customization process can be complicated, especially when suppliers do not offer flexible options or have long lead times. Buyers may face challenges in achieving the desired specifications, leading to project delays and increased costs.

The Solution: To streamline the customization process, buyers should select suppliers that provide comprehensive customization capabilities, including CNC machining, cutting, and surface finishing. Before placing an order, it is crucial to have a clear understanding of the project requirements, including thickness, size, and any specific performance characteristics. Engaging with suppliers early in the design phase allows for better collaboration and faster turnaround times. Buyers should also consider leveraging digital tools, such as CAD software, to provide precise specifications that can help suppliers understand their needs more effectively. This proactive approach can lead to successful outcomes and reduced time to market.

Strategic Material Selection Guide for black fiberglass sheet

What Are the Key Properties of Black Fiberglass Sheets?

Black fiberglass sheets are primarily composed of woven fiberglass fabric combined with a resin matrix, typically epoxy. The most common grades include FR-4 and G10, which are recognized for their excellent electrical insulation properties. These materials exhibit high flexural and tensile strength, with typical flexural strengths reaching up to 65,000 psi. They also demonstrate superior chemical resistance and dimensional stability, making them suitable for various applications, including electrical insulation, structural components, and industrial applications.

What Are the Pros and Cons of Using Black Fiberglass Sheets?

-

FR-4 Epoxy Resin Composite

– Key Properties: High dielectric strength (up to 66 kV), excellent moisture resistance, and a temperature index of 130°C.

– Pros: Offers strong mechanical properties and electrical insulation, making it ideal for electronics and electrical applications. It is also lightweight and can be easily machined.

– Cons: Higher manufacturing complexity can lead to increased costs. The material may not perform well in extreme temperatures beyond its rated limits.

– Impact on Application: Suitable for environments where electrical insulation is critical, such as circuit boards and terminal boards.

– Considerations for International Buyers: Compliance with standards like ASTM D709 and IEC 60893 is essential, especially in regulated markets in Europe and the Middle East. -

Brominated Epoxy Resin Composite

– Key Properties: Enhanced flame resistance with a V-0 flammability rating.

– Pros: Provides excellent fire safety, making it suitable for applications in aerospace and military sectors. The black pigment gives an aesthetic appeal similar to carbon fiber at a lower cost.

– Cons: The addition of brominated compounds can complicate recycling processes and may face regulatory scrutiny in certain regions.

– Impact on Application: Ideal for applications requiring stringent fire safety standards, such as in transportation and construction.

– Considerations for International Buyers: Buyers should be aware of local regulations regarding brominated compounds, particularly in the EU where REACH compliance is mandatory. -

Smooth Fiberglass (FRP) Sheets

– Key Properties: Excellent chemical resistance and low moisture absorption.

– Pros: Highly durable and resistant to corrosion, making it suitable for harsh environments such as chemical processing and marine applications.

– Cons: Generally more expensive than standard fiberglass sheets due to the enhanced properties and manufacturing processes.

– Impact on Application: Particularly well-suited for environments exposed to aggressive chemicals and moisture, such as in the oil and gas industry.

– Considerations for International Buyers: Understanding local chemical compatibility standards is crucial, especially in industries heavily regulated for safety and environmental impact. -

Custom Laminated Fiberglass Sheets

– Key Properties: Tailored thickness and surface finishes can be achieved based on specific requirements.

– Pros: Flexibility in design allows for optimized performance for niche applications. Customization can lead to better fit-for-purpose solutions.

– Cons: Custom manufacturing can lead to longer lead times and increased costs compared to off-the-shelf products.

– Impact on Application: Ideal for specialized applications where standard sizes and properties do not meet performance requirements.

– Considerations for International Buyers: Buyers should ensure that custom solutions meet international standards and certifications relevant to their specific industry.

Summary Table of Material Selection for Black Fiberglass Sheets

| Material | Typical Use Case for black fiberglass sheet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| FR-4 Epoxy Resin Composite | Circuit boards, electrical insulation | Strong mechanical and electrical properties | Higher manufacturing complexity | Medium |

| Brominated Epoxy Resin Composite | Aerospace, military applications | Excellent flame resistance | Complicated recycling processes | High |

| Smooth Fiberglass (FRP) Sheets | Chemical processing, marine applications | Highly durable and corrosion resistant | Generally more expensive | High |

| Custom Laminated Fiberglass Sheets | Specialized industrial applications | Flexibility in design and performance | Longer lead times and increased costs | Medium to High |

This guide provides a comprehensive overview of the strategic material selection for black fiberglass sheets, emphasizing the critical properties, advantages, disadvantages, and considerations for international B2B buyers. Understanding these factors will facilitate informed decision-making and optimize material selection for specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for black fiberglass sheet

What Are the Key Stages in the Manufacturing Process of Black Fiberglass Sheets?

The manufacturing process for black fiberglass sheets involves several critical stages that ensure the production of high-quality, durable products suited for various applications. Understanding these stages can help B2B buyers evaluate potential suppliers effectively.

Material Preparation: How Is the Raw Material Selected and Processed?

The first step in manufacturing black fiberglass sheets is the selection and preparation of raw materials. The primary materials include woven fiberglass fabric and epoxy resin, often with a black pigment added for aesthetic and functional purposes.

- Fiberglass Fabric: The quality and type of fiberglass fabric used can significantly influence the mechanical properties of the final product. Manufacturers typically opt for E-glass or S-glass, depending on the required strength and thermal resistance.

- Resin Preparation: The epoxy resin is carefully formulated to ensure optimal curing properties. It’s essential to maintain a consistent ratio of resin to hardener to achieve the desired strength and durability.

Once the materials are selected, they undergo a thorough inspection to ensure they meet industry standards before moving to the forming stage.

How Are Black Fiberglass Sheets Formed?

The forming stage is where the raw materials are combined and molded into sheets. This process involves several techniques, including:

- Lay-Up Process: Layers of fiberglass fabric are placed in a mold, and resin is applied to saturate the fabric. This method allows for controlled thickness and can enhance the structural integrity of the sheet.

- Compression Molding: In this method, the resin and fiberglass are placed in a heated mold, where pressure is applied to form the sheet. This technique is beneficial for achieving uniform thickness and density.

- Curing: The formed sheets are then cured under controlled temperature and humidity conditions to facilitate proper hardening of the resin. This step is crucial for achieving the desired physical and chemical properties.

What Finishing Techniques Are Commonly Used for Black Fiberglass Sheets?

After the sheets are cured, they undergo various finishing processes to enhance their performance and appearance:

- Trimming and Cutting: Sheets are trimmed to specified dimensions using precision cutting techniques, ensuring that they meet exact specifications.

- Surface Treatment: Depending on the application, additional treatments may be applied to improve surface properties, such as enhancing adhesion for coatings or improving UV resistance.

- Quality Inspection: Each sheet is subjected to rigorous quality checks to ensure it meets the required specifications before packaging.

What Quality Assurance Practices Are Essential for Black Fiberglass Sheets?

Quality assurance is a vital aspect of the manufacturing process, ensuring that the black fiberglass sheets meet international and industry-specific standards.

What International Standards Are Relevant for Quality Assurance?

Manufacturers of black fiberglass sheets typically adhere to several international standards, including:

- ISO 9001: This quality management standard ensures that manufacturers maintain consistent quality and continuous improvement in their processes.

- NEMA Standards: The National Electrical Manufacturers Association (NEMA) provides guidelines for materials used in electrical applications, with FR-4 being a common designation for fiberglass sheets.

- CE Marking: In Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

How Are Quality Control Checkpoints Integrated into the Manufacturing Process?

Quality control (QC) is integrated into various stages of the manufacturing process through systematic checkpoints:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specifications before being used in production.

- In-Process Quality Control (IPQC): During manufacturing, samples are regularly taken for testing to ensure that processes are being followed correctly and that the product meets quality standards.

- Final Quality Control (FQC): Before packaging, final inspections are conducted to check for defects and ensure that the finished products meet the required specifications.

What Testing Methods Are Commonly Used to Ensure Quality?

Several testing methods are employed to verify the quality and performance of black fiberglass sheets:

- Mechanical Testing: This includes tensile strength, flexural strength, and impact resistance tests to ensure the sheets can withstand the required loads.

- Electrical Testing: Given the insulating properties of fiberglass, dielectric strength and breakdown voltage tests are crucial for applications in electrical environments.

- Chemical Resistance Testing: Sheets are exposed to various chemicals to assess their durability and performance in potentially harsh environments.

How Can B2B Buyers Verify Supplier Quality Control Practices?

When sourcing black fiberglass sheets, B2B buyers should take proactive steps to verify the quality control practices of their suppliers:

- Supplier Audits: Conducting on-site audits can provide insights into the supplier’s manufacturing processes and adherence to quality standards.

- Requesting Quality Reports: Buyers should ask for documentation that outlines the supplier’s quality control processes, including test results and compliance with international standards.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality assurance practices.

What Nuances Should International Buyers Consider Regarding Quality Certification?

For international buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality certification is essential:

- Regulatory Compliance: Different regions may have specific regulatory requirements for materials, which can affect the certification process. Buyers should be aware of local standards and ensure that their suppliers comply with them.

- Cultural and Market Differences: Different markets may prioritize various attributes of quality. Understanding these differences can help buyers communicate their requirements more effectively.

By familiarizing themselves with these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing black fiberglass sheets, ensuring they select reliable suppliers that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘black fiberglass sheet’

In the competitive landscape of B2B procurement, sourcing black fiberglass sheets requires careful consideration and strategic planning. This guide provides a step-by-step checklist to help international buyers navigate the complexities of selecting the right materials for their needs.

Step 1: Define Your Technical Specifications

Start by clearly outlining the technical requirements of the black fiberglass sheet you need. This includes specifications such as thickness, size, and material properties like flexural strength and electrical insulation capabilities. Defining these parameters upfront ensures you source materials that meet your project’s needs and comply with industry standards.

- Important properties to consider:

- Thickness variations: Common thicknesses range from .010″ to .094″.

- Mechanical and thermal properties: Look for specifications on flexural strength, thermal expansion, and moisture absorption.

Step 2: Identify Your Application Needs

Understanding the specific applications for the black fiberglass sheets is crucial. Different industries, such as automotive, electronics, and construction, may require distinct properties. Knowing your application helps in selecting materials that offer the necessary durability and performance.

- Key questions to ask:

- Will the sheets be used in humid environments?

- Do they need to meet specific fire retardancy ratings?

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, vet potential suppliers thoroughly. Look for companies that have a proven track record in supplying black fiberglass sheets. Request company profiles, case studies, and references from buyers in similar industries or regions. This helps ensure that the supplier can meet your quality and service expectations.

- Supplier evaluation criteria:

- Certifications (e.g., ISO, NEMA).

- Reviews and testimonials from other businesses.

Step 4: Request Samples for Testing

Always request samples before making a bulk purchase. Testing the samples in your specific application can help assess their performance under real-world conditions. This step is essential to validate the supplier’s claims regarding the material properties.

- What to check in samples:

- Mechanical strength and flexibility.

- Compatibility with adhesives or other materials used in your application.

Step 5: Negotiate Pricing and Terms

Once you have selected a supplier and tested samples, it’s time to negotiate pricing and terms. Discuss bulk discounts, shipping costs, and delivery timelines to ensure that you secure the best deal. Establishing clear terms upfront can prevent misunderstandings later.

- Negotiation tips:

- Leverage your volume requirements to negotiate better prices.

- Clarify payment terms to align with your cash flow needs.

Step 6: Verify Compliance with Standards

Ensure that the black fiberglass sheets meet all relevant regulatory and industry standards. Compliance with standards like MIL-I-24768 and ANSI/NEMA IM 60000-2021 is critical for applications in sectors such as electronics and defense. This verification protects your company from potential legal issues and ensures product quality.

- Standards to confirm:

- Electrical and mechanical properties.

- Environmental impact and sustainability practices.

Step 7: Establish a Long-Term Relationship

Building a long-term relationship with your supplier can lead to better service, pricing, and product availability. Consider discussing future needs and potential collaborations that could enhance both parties’ business opportunities. A reliable supplier can become a valuable partner in your sourcing strategy.

- Benefits of a long-term relationship:

- Priority access to new products or technologies.

- More favorable terms based on loyalty and volume.

By following this checklist, B2B buyers can ensure a comprehensive and strategic approach to sourcing black fiberglass sheets, ultimately leading to successful procurement and enhanced project outcomes.

Comprehensive Cost and Pricing Analysis for black fiberglass sheet Sourcing

What Are the Key Cost Components in Black Fiberglass Sheet Sourcing?

When sourcing black fiberglass sheets, understanding the cost structure is critical for B2B buyers. The primary cost components include:

-

Materials: The cost of raw materials, primarily woven fiberglass fabric and brominated epoxy resin, significantly influences the overall price. Quality variations in these materials can lead to substantial price differences.

-

Labor: Labor costs encompass the wages of workers involved in the manufacturing process, including cutting, machining, and finishing. Skilled labor is often required for customizations, which can increase costs.

-

Manufacturing Overhead: This includes expenses related to utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help reduce these overhead costs.

-

Tooling: For custom orders, tooling costs can be significant. This includes the creation of molds or specialized equipment needed for specific configurations or dimensions.

-

Quality Control (QC): Rigorous QC processes ensure that products meet industry standards. This involves testing for electrical properties, mechanical strength, and compliance with certifications, all of which contribute to the overall cost.

-

Logistics: Shipping and handling costs are vital, especially for international buyers. These expenses can vary widely based on distance, shipping methods, and the terms agreed upon (Incoterms).

-

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can vary based on market demand, supplier reputation, and the complexity of the order.

How Do Pricing Influencers Affect Black Fiberglass Sheet Costs?

Several factors can influence the pricing of black fiberglass sheets, particularly in a B2B context:

-

Volume/MOQ: Bulk purchases often lead to lower per-unit costs. Many suppliers offer discounts for larger orders, so it’s beneficial to negotiate Minimum Order Quantities (MOQs) that align with your needs.

-

Specifications and Customization: Customized products often incur higher costs due to the additional labor and material requirements. Standardized sheets are generally cheaper, but buyers should weigh the benefits of customization against the costs.

-

Material Quality and Certifications: Higher quality materials that meet specific certifications (e.g., MIL-I-24768, NEMA FR-4) tend to be more expensive. Buyers should assess whether these certifications are necessary for their applications.

-

Supplier Factors: Supplier reliability, reputation, and location can all affect pricing. Established suppliers may command higher prices but offer better quality assurance and service.

-

Incoterms: The agreed-upon shipping terms (e.g., FOB, CIF) impact the total landed cost of the product. Understanding these terms is crucial for budgeting and financial planning.

What Tips Can Help Buyers Optimize Costs in Black Fiberglass Sheet Sourcing?

To effectively navigate the sourcing process for black fiberglass sheets, consider these buyer tips:

-

Negotiate Wisely: Engage in open discussions with suppliers about pricing, especially if you are ordering in bulk. Leverage your buying power to negotiate favorable terms.

-

Assess Total Cost of Ownership (TCO): Beyond the initial purchase price, consider factors such as durability, maintenance, and potential downtime. A higher upfront cost may lead to lower long-term expenses.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, import duties, and taxes that could affect final pricing. Establishing a clear understanding of these factors can prevent unexpected costs.

-

Research and Compare Suppliers: Don’t settle for the first supplier. Compare multiple options to find the best balance between cost, quality, and service. Look for suppliers with good reviews and a solid track record in your region.

-

Utilize Local Networks: Engage with local industry associations or trade groups in your region (e.g., Africa, South America, the Middle East, and Europe) to gain insights and recommendations for reliable suppliers.

In conclusion, while indicative prices for black fiberglass sheets can range from approximately $74.55 to $190.91, various factors will influence the actual costs. By understanding the cost components, pricing influencers, and strategic sourcing tips, international B2B buyers can make informed decisions that align with their budget and project needs.

Alternatives Analysis: Comparing black fiberglass sheet With Other Solutions

Introduction

When considering material solutions for industrial applications, B2B buyers often explore various alternatives to ensure they select the best product for their needs. Black fiberglass sheets, known for their high strength, electrical insulation properties, and chemical resistance, are a popular choice. However, alternatives such as carbon fiber sheets and phenolic laminate panels offer distinct advantages and disadvantages that may align better with specific project requirements. This analysis will provide a comprehensive comparison to help buyers make informed decisions.

| Comparison Aspect | Black Fiberglass Sheet | Carbon Fiber Sheet | Phenolic Laminate Panel |

|---|---|---|---|

| Performance | High flexural and tensile strength, good dielectric properties | Superior strength-to-weight ratio, excellent tensile strength | Good mechanical properties, fire resistance |

| Cost | Moderate ($74.55 – $190.91) | High ($200 – $700 per sheet) | Low to moderate ($50 – $150) |

| Ease of Implementation | Easy to machine and fabricate | Requires specialized cutting tools | Easy to handle and install |

| Maintenance | Low maintenance, durable in various conditions | Low maintenance, but susceptible to UV damage | Low maintenance, resistant to moisture |

| Best Use Case | Electrical insulation, structural components | Aerospace, automotive, high-performance applications | Industrial applications, electrical enclosures |

Detailed Breakdown of Alternatives

How Do Carbon Fiber Sheets Compare to Black Fiberglass Sheets?

Carbon fiber sheets are renowned for their exceptional strength-to-weight ratio, making them ideal for applications in aerospace and automotive industries where weight savings are critical. They provide superior tensile strength and stiffness compared to black fiberglass sheets. However, the cost of carbon fiber can be significantly higher, ranging from $200 to $700 per sheet, which may not be justifiable for all applications. Furthermore, machining carbon fiber requires specialized tools and techniques, which can complicate implementation. While they are low maintenance, they can be prone to UV damage if not properly coated.

What Advantages Do Phenolic Laminate Panels Offer Over Black Fiberglass Sheets?

Phenolic laminate panels are a cost-effective alternative, typically priced between $50 and $150. They exhibit good mechanical properties and fire resistance, making them suitable for industrial applications and electrical enclosures. Their ease of handling and installation also makes them appealing for large-scale projects. However, they generally do not match the tensile strength or electrical insulation properties of black fiberglass sheets. While they are low maintenance, their performance in humid conditions can be inferior to fiberglass, which may affect their longevity in certain environments.

Conclusion

Choosing the right material solution involves a careful evaluation of performance, cost, ease of implementation, maintenance, and suitability for specific applications. Black fiberglass sheets stand out for their strength and electrical insulating capabilities, making them a reliable choice for many industries. However, in scenarios where weight is a critical factor, carbon fiber sheets may offer advantages, albeit at a higher price. On the other hand, phenolic laminate panels provide a budget-friendly alternative with decent mechanical properties but may fall short in demanding conditions. B2B buyers should assess their specific needs and project requirements against these factors to select the most appropriate solution.

Essential Technical Properties and Trade Terminology for black fiberglass sheet

What Are the Key Technical Properties of Black Fiberglass Sheets?

Black fiberglass sheets are engineered materials known for their exceptional strength and versatility. Understanding their critical specifications can help B2B buyers make informed decisions. Here are some essential technical properties:

-

Material Grade (FR-4)

The standard grade for black fiberglass sheets is FR-4, a grade that signifies its suitability for electrical insulation applications. FR-4 is a composite made from woven fiberglass fabric and epoxy resin, ensuring high mechanical strength and excellent electrical insulating properties. For buyers, selecting FR-4 grade materials guarantees compliance with industry standards and reliability in applications like circuit boards and electrical enclosures. -

Thickness Tolerance

Thickness variations in black fiberglass sheets can significantly affect their performance. Common thicknesses range from 0.010″ to 0.094″, with specific tolerances such as +/- 0.002″ for thinner sheets and +/- 0.009″ for thicker ones. Precise thickness is crucial for applications requiring exact specifications, such as in aerospace or automotive industries. Buyers should prioritize suppliers that provide accurate thickness tolerances to avoid issues in machining and assembly. -

Flexural and Tensile Strength

Flexural strength indicates how much load the material can withstand before bending, while tensile strength measures its ability to resist being pulled apart. Typical flexural strength values for black fiberglass sheets are around 65,000 psi, with tensile strength reaching up to 40,000 psi. High values in these areas are vital for applications exposed to mechanical stress, ensuring durability and longevity. B2B buyers in sectors like construction and manufacturing should evaluate these strengths to ensure suitability for their projects. -

Moisture Absorption Rate

The moisture absorption rate for black fiberglass sheets is typically around 0.10%. Low moisture absorption is important for maintaining dimensional stability and preventing warping, especially in humid environments. Buyers in tropical or humid regions should consider this property to avoid material failure in their applications. -

Chemical Resistance

Black fiberglass sheets are known for their excellent chemical resistance, making them suitable for use in environments where exposure to harsh chemicals is a concern. This property is essential for industries such as chemical processing and oil and gas. Buyers should confirm the chemical compatibility of the sheets with specific substances in their applications to prevent degradation and extend service life. -

Flammability Rating (V-0 Class)

The flammability rating indicates how quickly a material ignites and burns. Black fiberglass sheets often carry a V-0 classification, meaning they will not support combustion. This property is crucial for applications in building materials and electronics, where fire safety is paramount. Understanding the flammability rating helps buyers meet regulatory requirements and ensure safety in their operations.

What Are Common Trade Terms Related to Black Fiberglass Sheets?

Familiarity with industry jargon can streamline communication and negotiations in the B2B space. Here are some key terms to know:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of black fiberglass sheets, buyers may engage with OEMs for custom solutions that meet specific requirements for their products. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for B2B buyers to manage inventory and cash flow effectively. Suppliers of black fiberglass sheets may have varying MOQs based on production capabilities and material availability. -

RFQ (Request for Quotation)

An RFQ is a document sent by buyers to suppliers requesting pricing and terms for specific products. For black fiberglass sheets, issuing an RFQ helps buyers compare offers from different suppliers, ensuring they secure the best deal. -

Incoterms (International Commercial Terms)

Incoterms are a set of standardized trade terms used internationally to define the responsibilities of buyers and sellers. Familiarity with these terms is essential for B2B transactions involving black fiberglass sheets, as they dictate shipping costs, risks, and delivery points. -

Lead Time

Lead time refers to the time taken from placing an order to its delivery. Understanding lead times for black fiberglass sheets is crucial for project planning, especially in industries where timing is critical. -

Custom Fabrication

This term refers to the process of tailoring a product to meet specific requirements, including cutting, machining, or finishing black fiberglass sheets to fit unique applications. Buyers should inquire about custom fabrication options to ensure that their specific needs are met.

By grasping these technical properties and trade terms, international B2B buyers can navigate their procurement processes with greater confidence and precision.

Navigating Market Dynamics and Sourcing Trends in the black fiberglass sheet Sector

What Are the Current Market Dynamics and Sourcing Trends for Black Fiberglass Sheets?

The black fiberglass sheet market is experiencing significant growth driven by the increasing demand for lightweight, durable materials in various industries such as automotive, construction, electronics, and aerospace. Global trends indicate a shift towards composite materials that offer superior mechanical properties and corrosion resistance. In emerging markets like Africa and South America, there is a burgeoning need for advanced materials in infrastructure projects, which is propelling the demand for black fiberglass sheets. Furthermore, the Middle East and Europe are seeing a rise in the adoption of these materials for electrical insulation applications, particularly in sectors that require high-performance solutions under extreme conditions.

Technological advancements in manufacturing processes are also shaping the market landscape. The integration of CNC machining and custom fabrication techniques allows manufacturers to cater to specific requirements, enhancing the appeal of black fiberglass sheets to B2B buyers looking for tailored solutions. Additionally, e-commerce platforms are streamlining the sourcing process, enabling international buyers to access a broader range of suppliers and products with ease. As companies increasingly prioritize efficiency and cost-effectiveness, the ability to source high-quality materials online is becoming a critical advantage.

How Is Sustainability Influencing Sourcing Decisions in the Black Fiberglass Sheet Sector?

Sustainability is becoming a core consideration in the sourcing of black fiberglass sheets. The environmental impact of raw materials and production processes is under scrutiny, leading buyers to seek out suppliers who prioritize eco-friendly practices. Companies are increasingly recognizing the importance of ethical supply chains that minimize waste and reduce carbon footprints. This shift is prompting suppliers to invest in sustainable production methods and materials, including the use of recycled fibers and resins.

Moreover, certifications for sustainable practices are gaining importance. B2B buyers are now more inclined to partner with manufacturers who hold ‘green’ certifications, such as ISO 14001, which indicates a commitment to environmental management. As awareness of climate change and sustainability grows, buyers from regions like Europe and North America are particularly proactive in demanding transparency in sourcing practices. This trend not only enhances brand reputation but also aligns with global sustainability goals, creating a competitive advantage for companies that prioritize ethical sourcing.

What Is the Historical Context Behind the Development of Black Fiberglass Sheets?

The evolution of black fiberglass sheets can be traced back to the mid-20th century when fiberglass composites began to gain traction in various industrial applications due to their superior strength-to-weight ratio and resistance to environmental degradation. Initially, these materials were predominantly used in aerospace and military applications where durability was paramount. Over time, advancements in resin technology and manufacturing processes led to the development of more versatile and cost-effective solutions, making black fiberglass sheets accessible to a broader range of industries.

As industries have evolved, so too have the applications for black fiberglass sheets. Today, they are integral to sectors such as electronics, where their electrical insulating properties are crucial, and construction, where they provide a robust solution for building materials. The ongoing refinement of these materials continues to open new avenues for innovation, catering to the dynamic needs of international B2B buyers seeking high-performance solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of black fiberglass sheet

-

How do I choose the right black fiberglass sheet for my application?

Selecting the appropriate black fiberglass sheet involves evaluating specific properties required for your application. Consider mechanical strength, thermal stability, and electrical insulation properties. For instance, sheets with NEMA grade FR-4 are ideal for electrical applications due to their excellent dielectric strength. Additionally, assess the sheet’s thickness and size based on your project requirements. Collaborating with suppliers to understand customization options can also help ensure the product meets your precise needs. -

What are the key benefits of using black fiberglass sheets in industrial applications?

Black fiberglass sheets offer numerous advantages, including high mechanical strength, excellent chemical resistance, and superior dimensional stability. They are particularly valued for their electrical insulating properties, making them suitable for various applications such as terminal boards and structural components. The aesthetic appeal of the black finish can also enhance the visual aspect of products. Moreover, their lightweight nature can lead to cost savings in shipping and installation. -

What is the minimum order quantity (MOQ) for black fiberglass sheets?

MOQs for black fiberglass sheets can vary significantly based on the supplier and the specific product. Generally, MOQs may range from a few sheets to several hundred, depending on the customization and manufacturing processes involved. It’s advisable to discuss your project needs with potential suppliers to negotiate MOQs that align with your budget and production timeline. Some suppliers may offer flexibility in MOQs for first-time buyers or bulk orders. -

How can I verify the quality of black fiberglass sheets before purchasing?

To ensure the quality of black fiberglass sheets, request certifications such as MIL-I-24768/27 or compliance with NEMA standards. Suppliers should provide detailed technical data sheets that outline physical and electrical properties. Additionally, consider requesting samples for testing before committing to a larger order. Engaging with suppliers who have a robust quality assurance process and positive customer reviews can further enhance your confidence in product quality. -

What payment terms are typically available for international orders of black fiberglass sheets?

Payment terms for international orders can vary based on the supplier and the buyer’s relationship. Common options include upfront payments, partial payments with the balance due upon delivery, or letters of credit. It’s essential to discuss payment terms during negotiations to find a mutually agreeable solution. Always ensure that the payment method chosen offers sufficient protection against fraud or non-delivery, especially in cross-border transactions. -

How do I handle customs and logistics when importing black fiberglass sheets?

When importing black fiberglass sheets, it’s crucial to understand the customs regulations in your country. Engage a freight forwarder or logistics provider familiar with international shipping to navigate documentation, tariffs, and import duties. Ensure that your supplier provides all necessary shipping documents, including invoices and certificates of origin. Planning logistics well in advance can help mitigate delays and additional costs associated with customs clearance. -

Can I customize the specifications of black fiberglass sheets?

Yes, many manufacturers offer customization options for black fiberglass sheets, including variations in thickness, size, and surface finish. Depending on your application, you may also be able to specify different resin types or fiber materials. It’s advisable to communicate your specific requirements early in the procurement process to ensure that the supplier can accommodate your needs. Customization can enhance the performance and functionality of the sheets for your particular application. -

What are the common applications for black fiberglass sheets in various industries?

Black fiberglass sheets are utilized across multiple industries, including electronics, automotive, and construction. They are commonly used for electrical insulation, structural components, and decorative finishes. In the electronics sector, they serve as substrates for circuit boards due to their excellent dielectric properties. In construction, they can be employed in flooring, wall panels, and other architectural elements, benefiting from their durability and aesthetic appeal. Understanding these applications can help you identify potential uses within your own industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Black Fiberglass Sheet Manufacturers & Suppliers List

1. TCH – Smooth Fiberglass Sheet

Domain: us.tchweb.com

Registered: 1998 (27 years)

Introduction: {“Product Name”: “Smooth Fiberglass (FRP) Sheet – Black”, “MFG Item No”: “510-3700900”, “Price”: “$90.10 USD”, “Sheet Size”: “47-1/2″ x 95-1/2″”, “Total Thickness”: “1 mm / 0.040″”, “Color”: “Black”, “Width”: “47.50 in [1206.5 mm]”, “Height”: “0.06 in [1.5 mm]”, “Depth”: “95.50 in [2425.7 mm]”, “Weight”: “9.50 lb [4.3 kg]”, “Country of Origin”: “United States”, “Shipping Information”: “Free shippi…

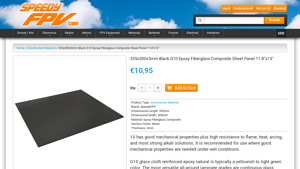

2. SpeedyFPV – Epoxy Fiberglass Composite Sheet

Domain: speedyfpv.com

Registered: 2017 (8 years)

Introduction: {“Product Type”:”Construction Material”,”Brand”:”SpeedyFPV”,”Dimensional Length”:”335mm”,”Dimensional Width”:”300mm”,”Thickness”:”3mm”,”Material”:”Epoxy Fiberglass Composite”,”Surface Finish”:”Matte”,”Color”:”Black”,”Size”:”300x335x3mm (11.8″ x 13″)”,”Specifications”:”G10 has good mechanical properties plus high resistance to flame, heat, arcing, and most strong alkali solutions. Recommended for u…

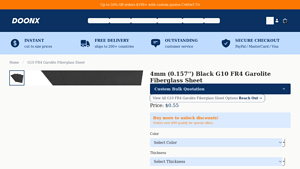

3. DoonX – 4mm Black G10 FR4 Garolite Fiberglass Sheet

Domain: doonx.com

Registered: 2021 (4 years)

Introduction: {“Product Name”: “4mm (0.157”) Black G10 FR4 Garolite Fiberglass Sheet”, “Price”: “$0.55”, “Discounts”: “Buy more to unlock discounts! Orders over $99 qualify for special offers.”, “Color”: “Black”, “Thickness”: “4mm (0.157”)”, “Material”: “FR-4”, “Opacity”: “Opaque”, “Machining Precision”: “High (±0.2mm)”, “Density”: “2.3”, “Features”: [“Electrical insulators and components”, “Knife handles and…

4. Bee Plastic – Black FR4 G10 Fiberglass Sheet for 3D Printing

Domain: beeplastic.com

Registered: 2023 (2 years)

Introduction: Black FR4 G10 Fiberglass Sheet for 3D Printing

– Thickness options: 1mm, 1.5mm, 2mm, 3mm, 4mm, 5mm

– Size options: 100x100mm, 100x150mm, 150x150mm, 200x200mm, 235x235mm, 250x250mm, 300x300mm, 330x330mm, 350x350mm, 400x400mm, 500x300mm

– Regular price: $25.02 USD

– Bulk savings: Buy 3 or more items and enjoy >15% off

– Free standard shipping by default

– Instant discount: Get >5% off your entire or…

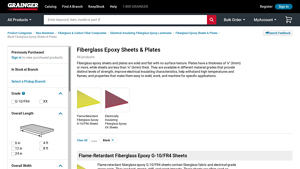

5. Grainger – Black Fiberglass Epoxy Sheets

Domain: grainger.com

Registered: 1994 (31 years)

Introduction: This company, Grainger – Black Fiberglass Epoxy Sheets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. AliExpress – Durable FR4 Fiberglass Sheets

Domain: aliexpress.com

Registered: 2006 (19 years)

Introduction: This company, AliExpress – Durable FR4 Fiberglass Sheets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Interstate Plastics – G-10/FR4 Glass Epoxy Sheet

Domain: interstateplastics.com

Registered: 1997 (28 years)

Introduction: {“product_name”: “G-10/FR4 Glass Epoxy Sheet”, “color”: “Black”, “dimensions”: {“width”: 12, “length”: 12, “thickness”: 0.125}, “price_per_sheet”: 35.43, “total_price”: 35.43, “warning”: “This product may have sharp edges and points. Contact may result in injury. Handle with care.”, “disclaimer”: “Interstate Plastics makes no representations about any of its products that are modified in any way a…

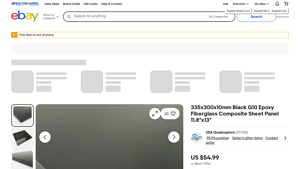

8. USA Quadcopters – Black G10 Epoxy Fiberglass Composite

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“dimensions”:”335x300x10mm (11.8\”x13\”)”,”material”:”Black G10 Epoxy Fiberglass Composite”,”condition”:”New”,”price”:”$54.99″,”shipping”:”Free USPS Ground Advantage”,”returns”:”30 days returns, buyer pays for return shipping”,”seller”:”USA Quadcopters”,”seller_feedback”:”99.3% positive”,”item_number”:”255299366815″,”brand”:”SpeedyFPV”,”UPC”:”615764398487″}

Strategic Sourcing Conclusion and Outlook for black fiberglass sheet

How Can Strategic Sourcing Enhance Your Procurement of Black Fiberglass Sheets?

In conclusion, the strategic sourcing of black fiberglass sheets presents a unique opportunity for international B2B buyers to optimize their procurement processes. This versatile material, characterized by its exceptional mechanical strength, chemical resistance, and electrical insulating properties, is ideal for various applications across multiple industries, including electronics, automotive, and construction. By understanding the specifications and potential uses of black fiberglass sheets, buyers can make informed decisions that align with their operational needs and budget constraints.

Moreover, fostering strong relationships with reliable suppliers can lead to better pricing, enhanced customization options, and improved supply chain resilience. As markets in Africa, South America, the Middle East, and Europe continue to evolve, staying ahead of industry trends and material innovations will be crucial for maintaining competitive advantage.

As you explore sourcing options, consider engaging with manufacturers who offer customization and technical support, ensuring that your specific requirements are met with precision. Take proactive steps today to enhance your procurement strategy and capitalize on the advantages that black fiberglass sheets can provide for your business. Let’s build a sustainable and efficient supply chain together.