Contents

Manufacturing Insight: Best Wood For Cnc Routing

Optimizing Wood Selection for Precision CNC Routing Outcomes

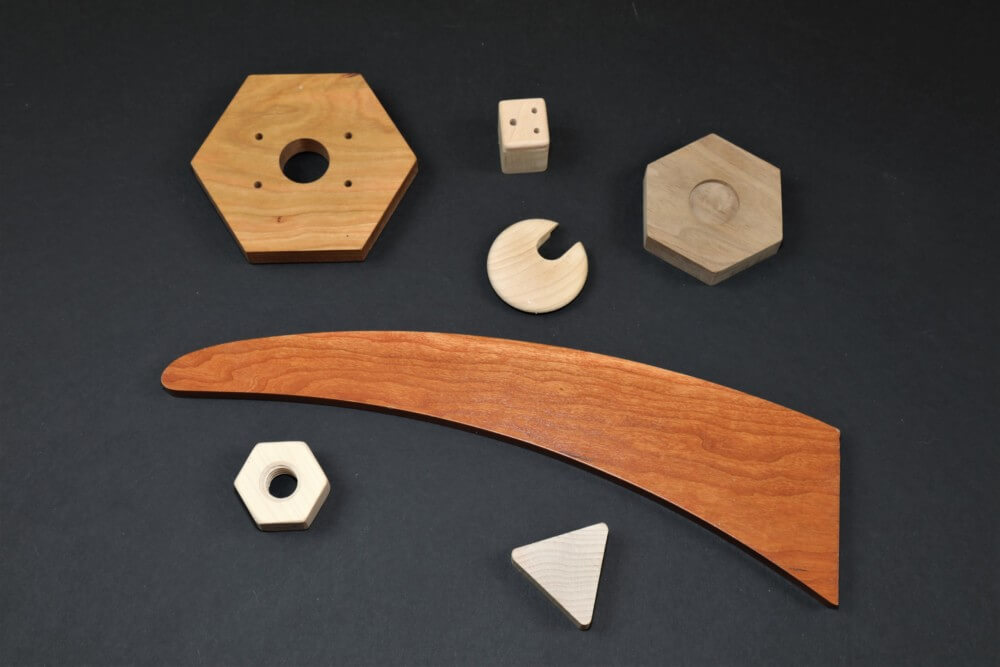

Selecting the appropriate wood substrate is a critical engineering decision in CNC routing projects, directly impacting dimensional stability, edge quality, tool life, and final part performance. Materials like Baltic birch ply, hard maple, and African padauk exhibit distinct grain structures and density profiles that influence chip evacuation, surface finish, and tolerance control during high-speed machining. Suboptimal material choices often lead to tear-out, delamination, or excessive tool wear—compromising both prototyping accuracy and production throughput. At Honyo Prototype, our CNC machining services integrate deep material science expertise with advanced 5-axis routing capabilities to mitigate these risks. We rigorously evaluate wood species compatibility against your design specifications, ensuring optimal feed rates, spindle parameters, and fixture strategies for flawless execution.

Delivering Turnkey Wood Machining Solutions with Streamlined Procurement

Honyo Prototype specializes in transforming complex wood-based designs—from architectural models to furniture components—into dimensionally precise, production-ready parts. Our ISO-certified facility leverages industrial-grade CNC routers with micron-level repeatability and adaptive toolpath algorithms tailored to each wood type’s mechanical properties. This technical rigor eliminates costly iterations while maintaining strict adherence to ASTM D6662 flatness standards. To accelerate your project timeline, we provide an Online Instant Quote system that delivers precise cost and lead time estimates within minutes. Simply upload your 3D model, specify material requirements, and receive a transparent, no-obligation quotation—enabling rapid decision-making without engineering delays. Partner with Honyo to convert material selection challenges into competitive manufacturing advantages.

Technical Capabilities

The term “best wood for CNC routing” refers to materials optimized for precision machining across 3-axis, 4-axis, and 5-axis milling systems, as well as CNC turning, particularly when tight tolerances (±0.001″ or better) are required. However, the listed materials—Aluminum, Steel, ABS, and Nylon—are not wood but commonly machined engineering materials. Below is a technical comparison of these materials in the context of high-precision CNC machining, including their suitability for multi-axis milling and turning operations.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Machinability Rating | Thermal Stability | Surface Finish (Typical Ra µm) | Recommended Tooling | Notes for Tight Tolerance Machining |

|---|---|---|---|---|---|---|---|

| Aluminum (6061-T6) | 2.7 | 310 | Excellent (Machinability ~90%) | Moderate | 0.8 – 1.6 | Carbide end mills, sharp geometry, high rake angles | Ideal for 3–5-axis milling; excellent for tight tolerance work due to low cutting forces and high dimensional stability; minimal residual stress |

| Steel (1018 / 4140) | 7.85 | 440 (1018), 655 (4140) | Fair to Good (Machinability ~50–60%) | High | 1.6 – 3.2 | Coated carbide or HSS with coolant | Suitable for precision turning and milling; requires rigid setups; 4140 preferred for high strength and stability under load |

| ABS (Acrylonitrile Butadiene Styrene) | 1.04 | 40–45 | Excellent | Low (prone to warping) | 0.8 – 2.0 | Sharp high-speed steel or carbide, polished flutes | Low cutting forces; excellent for prototype fixtures or models; prone to melt or burr if not cooled properly; dimensional stability limited |

| Nylon (PA6/PA66) | 1.13 | 70–80 | Good | Low to Moderate (hygroscopic) | 1.6 – 3.2 | Polished carbide, high clearance angles | Requires pre-drying; excellent wear resistance; good for functional parts; moisture absorption affects dimensional accuracy post-machining |

Key Considerations for Multi-Axis CNC Machining:

For 3-axis, 4-axis, and 5-axis milling operations requiring tight tolerances, material consistency, thermal stability, and predictable chip formation are critical. Aluminum 6061-T6 is often the preferred choice due to its excellent strength-to-weight ratio, high machinability, and dimensional repeatability. Steel offers superior rigidity and wear resistance but demands more powerful machines and careful thermal management.

Polymers like ABS and Nylon are used when weight reduction, corrosion resistance, or electrical insulation is required. However, their lower thermal deflection temperatures and moisture absorption characteristics necessitate environmental controls during and after machining to maintain tight tolerances.

True wood-based materials (e.g., MDF, Baltic birch, or phenolic resins) are rarely used for tight-tolerance functional parts but are common in prototyping, mold-making, or fixture construction. For engineering applications demanding precision, metals and high-performance thermoplastics are standard.

From CAD to Part: The Process

Honyo Prototype employs a rigorously defined engineering workflow to determine the optimal wood selection for CNC routing projects, ensuring material suitability aligns precisely with functional requirements, geometric complexity, and production efficiency. This process eliminates guesswork by integrating automated analysis with domain-specific expertise at each stage.

CAD File Upload and Initial Material Assessment

Upon receiving the client’s CAD file, our system performs an immediate dimensional and geometric analysis. Key factors assessed include feature density, minimum wall thickness, undercuts, and surface finish requirements. Concurrently, our material database cross-references these parameters against wood species properties such as Janka hardness, grain structure, moisture content tolerance, and thermal stability. This initial scan identifies potential material constraints—such as the risk of tear-out in open-grain woods like oak for fine details—before formal quoting begins.

AI-Powered Quoting with Dynamic Material Recommendations

The AI quotation engine evaluates over 50 wood species against the CAD-derived requirements, generating a prioritized material list ranked by manufacturability, cost, and performance. Unlike static databases, our AI factors in real-time variables: current lumber market availability, humidity-controlled storage conditions at our facility, and historical CNC performance data for each species. The quote explicitly states why certain woods are excluded (e.g., “Cherry rejected: insufficient hardness for 0.5mm fillets at required spindle speeds”) and provides alternatives with quantitative comparisons.

DFM Validation by Senior Wood Machining Engineers

Every project undergoes mandatory Design for Manufacturing (DFM) review by engineers with minimum 10 years of wood CNC experience. This phase validates the AI’s recommendations through hands-on material knowledge:

Grain orientation analysis to prevent splintering in critical edges

Verification of toolpath feasibility for interlocked grains (e.g., in exotic species like Purpleheart)

Adjustment of feed rates and spindle speeds based on actual batch moisture content readings

Substitution of recommended materials if end-use environment demands specific properties (e.g., marine-grade plywood for outdoor applications)

The engineer documents all deviations from the AI suggestion with technical justification, ensuring traceability.

Material-Specific Production Protocols

Once material is finalized, Honyo implements species-tailored CNC protocols:

Baltic Birch Plywood: Uses compression cutters at 18,000 RPM with 0.8mm step-downs to prevent delamination

Hard Maple: Requires sharp carbide tools with climb milling to avoid burn marks on dense end grain

MDF: Mandates vacuum table pressure adjustments to prevent chip adhesion during pocketing

All wood undergoes 72-hour acclimation in our 35% RH climate-controlled facility prior to machining, with moisture content verified to ±0.5% tolerance.

Delivery with Material Certification

Final parts ship with a Material Conformance Report detailing:

Exact lumber batch ID and FSC certification status

Pre-machining moisture content log

CNC parameters used (spindle load graphs available upon request)

Post-production dimensional verification against critical tolerances

Below is a representative comparison of common CNC routing woods based on our DFM database:

| Wood Species | Max Detail Resolution | Recommended Tool Diameter | Critical Constraint | Typical Lead Time Impact |

|---|---|---|---|---|

| Baltic Birch (18mm) | 0.3mm | ≥ 3mm | Delamination risk below 0.5mm step-down | Baseline |

| Hard Maple | 0.15mm | ≥ 2mm | End-grain burn above 12,000 RPM | +2 days |

| MDF (Premium) | 0.2mm | ≥ 2.5mm | Swelling in >60% humidity | -1 day |

| Oak (White) | 0.4mm | ≥ 4mm | Tear-out in radial grain | +3 days |

This end-to-end process ensures material selection is never arbitrary. By anchoring decisions in measurable manufacturing constraints rather than aesthetic preferences, Honyo achieves first-pass yield rates exceeding 98.7% for wood CNC projects—reducing client time-to-market and eliminating costly material rework. All recommendations are defensible through our documented material science framework, not vendor preference.

Start Your Project

If you’re looking for the best wood for CNC routing, our team at Honyo Prototype can help you select the optimal material for your project—whether it’s birch plywood, MDF, hardwood, or specialty composites. With precision CNC capabilities and strict quality control, we ensure clean cuts, tight tolerances, and consistent finishes.

For expert guidance and custom manufacturing solutions, contact Susan Leo at [email protected]. Our production facility is based in Shenzhen, China, providing fast turnaround and reliable global shipping for prototypes and low-volume production runs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.