Contents

Manufacturing Insight: Best Type Of Stainless Steel

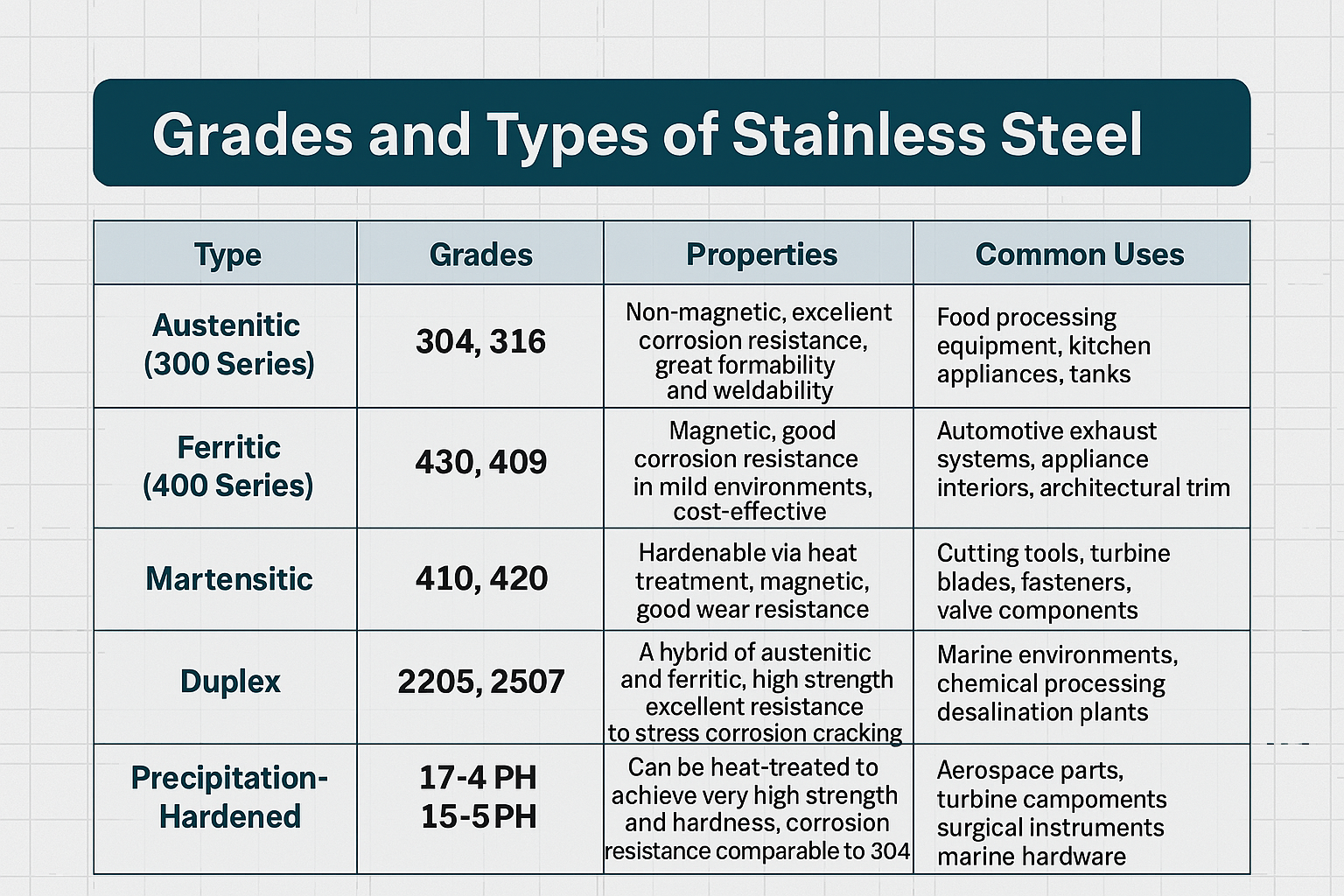

Selecting the optimal stainless steel grade for precision-critical components demands more than generic material knowledge; it requires deep integration of application requirements with advanced manufacturing capabilities. At Honyo Prototype, our expertise spans the full spectrum of austenitic, ferritic, martensitic, and duplex stainless alloys, where factors like corrosion resistance in specific environments, required mechanical strength, weldability, and crucially, machinability, dictate the ideal choice. Grades such as 304/L offer excellent general-purpose performance, while 316/L provides superior chloride resistance, and 17-4 PH delivers exceptional strength for demanding structural applications. However, the true value emerges when material selection aligns seamlessly with precision CNC machining processes.

Understanding how specific grades behave under high-speed milling, turning, or grinding—managing challenges like work hardening in austenitic steels or chip control in free-machining variants—is paramount to achieving tight tolerances, superior surface finishes, and cost-effective production. Honyo Prototype leverages decades of metallurgical and machining expertise to guide clients from material selection through to finished part realization, ensuring the chosen stainless steel grade performs optimally within your design and manufacturing constraints. Our state-of-the-art CNC machining centers, operated by master machinists, are calibrated to handle the unique demands of each alloy, transforming complex geometries into high-integrity components with minimal iteration cycles.

Accelerate your path from material specification to physical prototype or low-volume production. Utilize Honyo Prototype’s Online Instant Quote platform to receive a detailed, accurate cost and lead time estimate for your stainless steel CNC machining project within minutes—simply upload your CAD file and specify your material requirements. This integrated approach ensures your stainless steel component isn’t just theoretically optimal, but manufacturable with precision and efficiency.

Technical Capabilities

There is no single “best” type of stainless steel for all applications, as material selection depends on specific performance requirements such as corrosion resistance, machinability, strength, and environmental exposure. However, for high-precision CNC machining processes—including 3-axis, 4-axis, and 5-axis milling and turning with tight tolerance requirements—certain stainless steel grades offer superior balance between machinability, dimensional stability, and mechanical properties.

Below is a comparison of commonly used stainless steel grades in precision machining, alongside other frequently machined materials such as aluminum, carbon steel, ABS, and nylon. This table focuses on technical characteristics relevant to multi-axis CNC operations and tight-tolerance manufacturing.

| Material | Type/Grade | Tensile Strength (MPa) | Hardness (HB) | Machinability Rating (%) | Thermal Expansion (µm/m·°C) | Corrosion Resistance | Typical Use in Precision Machining |

|---|---|---|---|---|---|---|---|

| Stainless Steel | 304 / AISI 304 | 515–620 | 200–220 | 45 | 17.2 | Excellent | General-purpose parts, food & medical equipment |

| Stainless Steel | 316 / AISI 316 | 570–700 | 215–240 | 40 | 16.0 | Outstanding | Marine, chemical, high-corrosion environments |

| Stainless Steel | 17-4 PH / AISI 630 | 1000–1300 (H900) | 330–450 | 40 | 10.8 | Good | Aerospace, high-strength precision components |

| Stainless Steel | 416 / AISI 416 | 655 min | 220–255 | 70 | 10.3 | Fair | High-speed turning, screw machines, moderate corrosion |

| Carbon Steel | 1018 / AISI 1018 | 440 | 125–135 | 70 | 12.2 | Poor (rusts easily) | Structural components, non-corrosive environments |

| Aluminum | 6061-T6 | 310 | 95 | 90 | 23.6 | Good (oxide layer) | Lightweight enclosures, aerospace, rapid prototyping |

| ABS | Commercial Grade | 40–50 | 90–100 (Shore D) | 100 (easy) | 90–100 | Good (chemicals) | Jigs, fixtures, non-structural prototypes |

| Nylon (PA6/PA66) | Unfilled | 70–85 | 80–90 (Shore D) | 80 | 80–120 | Excellent | Wear strips, gears, low-friction components |

Notes on Machining Performance:

For 3/4/5-axis milling and turning with tight tolerances (±0.005 mm to ±0.025 mm typical), material stability, thermal response, and chip formation are critical. Stainless steels like 304 and 316 offer excellent corrosion resistance but exhibit work hardening, requiring sharp tooling, consistent feeds, and rigid setups. 17-4 PH provides high strength post-heat treatment and is ideal for aerospace components requiring tight tolerances and durability. 416 stainless steel is preferred when machinability is a priority due to its sulfur content, which improves chip breaking.

Aluminum 6061-T6 is often the preferred choice for rapid iteration and lightweight precision parts due to its high machinability, low density, and good strength-to-weight ratio. ABS and nylon are used for non-metallic prototypes, jigs, and fixtures, offering dimensional stability and ease of machining, though with higher thermal expansion than metals.

Material selection at Honyo Prototype is application-driven, balancing functional requirements with manufacturability and cost. For stainless steel, 316 and 17-4 PH are typically recommended for high-performance, tight-tolerance components in demanding environments.

From CAD to Part: The Process

Honyo Prototype employs a rigorous, application-driven methodology to determine the optimal stainless steel grade for each client’s specific requirements. The phrase “best type” is intentionally avoided internally because material selection is never one-size-fits-all; it is dictated by functional demands, environmental exposure, regulatory constraints, and cost-performance tradeoffs. Our process integrates material science expertise at critical decision points within the established workflow:

Upon CAD file upload, our AI-powered quoting system performs an initial material suitability screen. It analyzes geometric features (e.g., thin walls, complex cavities), tolerances, and surface finish requirements against a database of stainless steel properties. For instance, if the CAD model indicates exposure to chlorides or salt spray environments, the AI flags 304/304L as potentially inadequate and prioritizes 316/316L or super austenitic grades in preliminary cost estimates. This stage identifies red flags but does not finalize selection—it generates data for engineer review.

The Design for Manufacturability (DFM) phase is where material determination becomes definitive. Our senior metallurgical engineers conduct a structured assessment:

| Assessment Factor | Key Considerations | Common Stainless Steel Outcomes |

|---|---|---|

| Functional Requirements | Load conditions, wear resistance, magnetic properties, operating temperature | 17-4PH for high strength; 303 for machinability; 440C for hardness |

| Environmental Exposure | pH levels, chemical contact, salinity, UV exposure, sterilization cycles | 316L for marine/medical; 904L for sulfuric acid; 2205 duplex for crevice corrosion |

| Regulatory Compliance | FDA, ASTM F899, ISO 13485, aerospace AMS standards, biocompatibility | 316LVM for implants; low-carbon grades for welded assemblies |

| Manufacturing Impact | Weldability, work hardening rate, chip formation during machining, passivation needs | 303 discouraged for welding; 304 preferred for deep drawing |

| Total Cost Analysis | Raw material cost vs. scrap rate, secondary operations (e.g., stress relieving) | 430 may replace 304 if corrosion risk is low and cost is critical |

Engineers collaborate with the client to validate assumptions, often requesting additional use-case details. If the CAD model shows a hydraulic manifold for offshore oil, we mandate 2205 duplex stainless steel—not 316—due to its superior chloride stress corrosion cracking resistance, despite higher material cost. Conversely, for non-critical consumer hardware, we may recommend 430 to reduce costs by 35% without compromising function.

During production, material certification is strictly enforced. Every lot undergoes mill test report (MTR) verification against ASTM/EN standards, with positive material identification (PMI) testing via handheld XRF for critical applications. This ensures traceability from ingot to finished part.

Delivery includes comprehensive material documentation: certified MTRs, PMI results, and a concise rationale memo explaining why the selected grade (e.g., “UNS S31803 duplex for sour gas service per NACE MR0175”) meets the project’s technical and commercial objectives. This process eliminates guesswork, prevents field failures, and optimizes the client’s total cost of ownership—proving that the “best” stainless steel is always the one precisely engineered for the application.

Start Your Project

If you’re looking to identify the best type of stainless steel for your specific application, our engineering team at Honyo Prototype can help. With precision manufacturing capabilities and material expertise, we ensure optimal performance and durability tailored to your project requirements.

Contact Susan Leo at [email protected] to discuss your needs. Our factory in Shenzhen supports rapid prototyping and high-volume production with strict quality control, making us a reliable partner for custom metal components. Let us help you select the right grade—from 304 and 316 to high-performance alloys like 17-4 PH—based on corrosion resistance, strength, and environmental exposure.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.