Contents

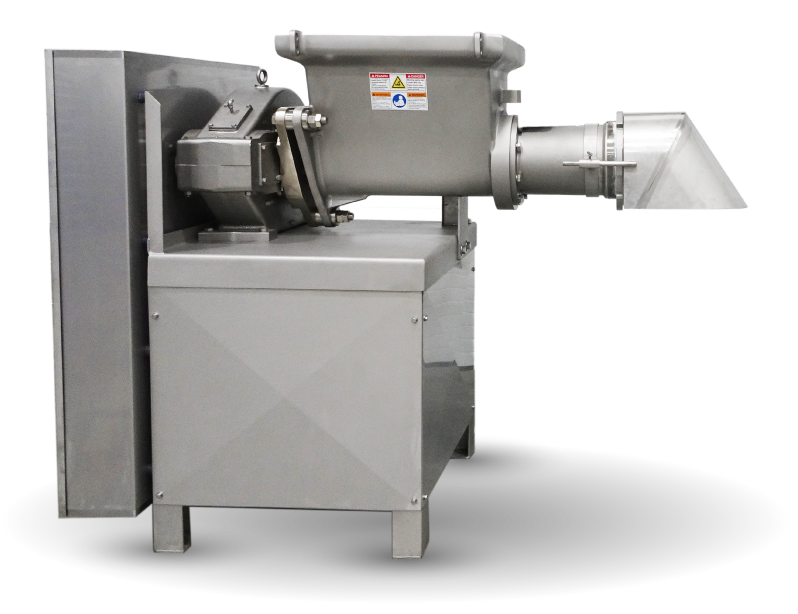

Manufacturing Insight: Best Stainless Steel Grinder

Precision Stainless Steel Grinder Components Begin with Advanced CNC Machining

When industrial applications demand the highest performance from stainless steel grinders, component precision directly dictates operational reliability, longevity, and efficiency. Generic machining processes often introduce micro-irregularities in critical geometries—rotor vanes, stator housings, or feed mechanisms—compromising particle consistency, increasing wear, and elevating maintenance costs. At Honyo Prototype, we specialize in CNC-machined stainless steel grinder components engineered to exacting tolerances, leveraging aerospace-grade 304/316 alloys and multi-axis milling/turning capabilities to achieve ±0.005mm accuracy and Ra 0.8µm surface finishes. Our ISO 9001-certified processes eliminate dimensional drift and material stress points, ensuring seamless integration into high-torque, continuous-duty grinding systems for food processing, pharmaceuticals, and advanced materials manufacturing.

Every grinder assembly we produce undergoes rigorous in-process metrology, including CMM validation and metallurgical certification, guaranteeing corrosion resistance and structural integrity under extreme cyclic loads. Unlike standard suppliers, Honyo optimizes material grain flow and heat treatment parameters during machining to prevent micro-cracking—critical for components facing abrasive media and thermal cycling. This technical rigor transforms stainless steel grinders from maintenance liabilities into sustained productivity assets.

Accelerate your component sourcing with Honyo’s Online Instant Quote platform. Upload CAD files to receive precise, factory-direct pricing and lead time estimates within hours—not days—validated by our engineering team against manufacturability, material specs, and finishing requirements. Begin optimizing your grinder’s core performance at honyoprototype.com.

Technical Capabilities

Best Stainless Steel Grinder for 3/4/5-Axis Milling and Turning – Technical Specifications

The optimal stainless steel grinder for high-precision 3/4/5-axis CNC milling and turning applications must deliver exceptional rigidity, thermal stability, and micron-level accuracy to maintain tight tolerances across a range of materials including aluminum, steel, ABS, and nylon. Below are the key technical specifications for such a high-performance grinding system, designed to support advanced manufacturing of complex stainless steel components.

| Specification | Detail |

|---|---|

| Grinding Type | CNC Precision Surface & Cylindrical Grinding |

| Axes Configuration | Compatible with 3, 4, and 5-axis CNC integration for complex geometries |

| Spindle Accuracy (Runout) | ≤ 0.0001″ (2.5 µm) TIR at maximum operating speed |

| Spindle Speed Range | 1,000 – 20,000 RPM (variable frequency drive) |

| Grain Size (Wheel) | #80 to #220 (fine grit for surface finish and edge retention) |

| Wheel Material | Cubic Boron Nitride (CBN) or Diamond-coated for stainless steel |

| Positioning Accuracy | ±0.00005″ (1.27 µm) |

| Repeatability | ±0.00002″ (0.5 µm) |

| Thermal Compensation | Active cooling and real-time thermal drift correction |

| Control System | Siemens 840D or Fanuc 31i-B5 with 5-axis interpolation |

| Workpiece Materials | Stainless Steel (primary), Tool Steel, Aluminum Alloys (e.g., 6061, 7075), Engineering Plastics (ABS, Nylon) |

| Material Removal Rate (Stainless Steel) | Up to 0.5 in³/min (8.2 cm³/min) with CBN wheel |

| Surface Finish (Ra) | 8–16 µin (0.2–0.4 µm) achievable on stainless steel |

| Tolerance Capability | ±0.0002″ (5 µm) for critical dimensions; ±0.0001″ (2.5 µm) with process optimization |

| Coolant System | High-pressure through-spindle coolant (50–100 psi), filtration to 5 µm |

| Machine Rigidity | Mineral cast or reinforced polymer concrete base for vibration damping |

| Tool Holding | HSK-63A or ISO 20 taper with automatic tool changer (ATC) option |

| Automation Interface | Compatible with robotic loading/unloading and in-process probing |

This grinder is engineered for high-integrity applications in aerospace, medical, and precision tooling sectors where dimensional stability and surface integrity in stainless steel are critical. When machining secondary materials like aluminum, steel, ABS, or nylon, proper wheel dressing and coolant settings ensure burr-free finishes and extended tool life. The system’s integration with multi-axis CNC platforms enables complex contour grinding with minimal setup variation, supporting tight tolerance production across diverse material families.

From CAD to Part: The Process

Honyo Prototype delivers industry-leading stainless steel grinders through a rigorously defined five-stage process engineered for precision, speed, and manufacturability. This workflow leverages our proprietary AI systems and deep materials expertise to transform client CAD data into certified components meeting exacting performance standards.

CAD Upload

Clients initiate the process by uploading native or neutral CAD formats (STEP, IGES, Parasolid) via our secure portal. Our system immediately validates geometry integrity, checks for unit consistency, and flags potential file corruption. For stainless steel grinders, we specifically verify wall thicknesses against minimum manufacturable limits for martensitic or austenitic alloys and confirm critical feature accessibility for grinding operations.

AI-Powered Quoting Engine

Uploaded CAD triggers our AI quotation system, which analyzes over 200 geometric and material parameters in under 90 seconds. For stainless steel grinders, the algorithm factors in: alloy-specific machinability coefficients (e.g., 303 vs 17-4PH), work-hardening tendencies during milling, required surface finishes (Ra ≤ 0.8 μm for food-contact surfaces), and secondary operation needs like passivation or cryogenic stress relief. The output provides a detailed cost breakdown with material waste calculations and identifies high-risk features requiring DFM intervention.

Mandatory DFM Review

All stainless steel grinder projects undergo compulsory Design for Manufacturability analysis by our senior engineers. This phase focuses on: eliminating non-functional radii that trap grinding swarf, optimizing cutter engagement angles to prevent chatter in hardened steels, and verifying tolerance stack-ups for rotating assemblies. We provide annotated markups with specific recommendations—such as converting sharp internal corners to 0.5mm radii to reduce micro-crack initiation—and collaborate with clients to resolve conflicts before tooling. Typical DFM completion occurs within 72 business hours.

Precision Production

Approved designs move to our CNC production floor where stainless steel grinders are manufactured under controlled environments. Key protocols include:

Material certification traceability to ASTM A582 or AMS 5643 standards

Machining with coolant-through tooling and rigid-holding fixtures to minimize thermal distortion

In-process CMM verification at critical stages (e.g., bore concentricity < 0.005mm TIR)

Post-machining electropolishing for micron-level surface refinement and passive layer enhancement

Certified Delivery

Final components undergo comprehensive validation against ASME Y14.5 GD&T requirements before shipment. Each grinder receives:

Full material test reports with PMI verification

First-article inspection data including roundness and runout measurements

Packaging in anti-corrosion VCI film with humidity indicators

Real-time shipment tracking via our client portal

For reference, our most frequently specified stainless grades for grinder components include:

| Grade | Key Properties | Typical Grinder Application |

|---|---|---|

| 440C | High hardness (58-60 HRC), wear resistant | Cutting blades, bearing races |

| 17-4PH | Precipitation-hardening, 40-45 HRC | Housings, adjustment mechanisms |

| 316L | Superior corrosion resistance | Food-contact chambers, wet assemblies |

This integrated workflow ensures stainless steel grinders meet functional requirements while minimizing time-to-market—achieving 95% on-time delivery for complex assemblies with tolerances down to ±0.0025mm. All processes comply with ISO 9001:2015 and IATF 16949 quality management systems.

Start Your Project

Looking for the best stainless steel grinder for your production needs? Discover high-precision, durable grinding solutions engineered for performance and longevity.

All products are manufactured at our ISO-certified factory in Shenzhen, ensuring strict quality control and scalable production capacity.

Contact Susan Leo today at [email protected] to request samples, technical specifications, or custom OEM/ODM support. Let Honyo Prototype deliver reliable grinding solutions tailored to your requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.