Contents

Manufacturing Insight: Best Spray Paint For Cnc Aluminum

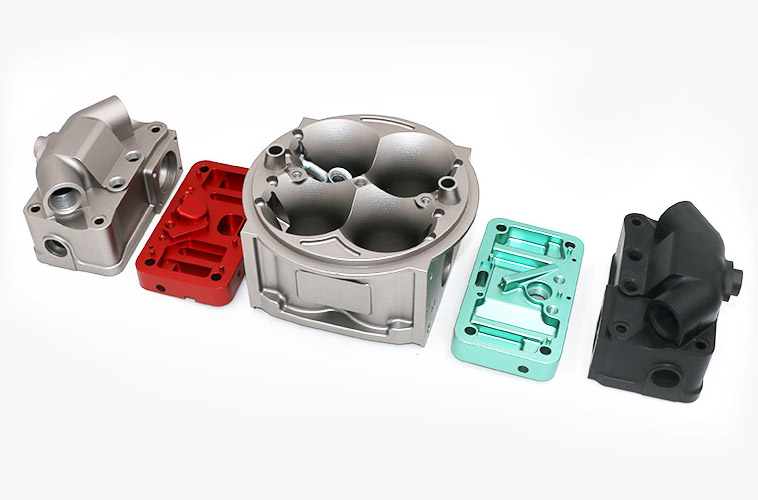

Optimizing Surface Finish for CNC Aluminum: Selecting the Right Spray Paint Solution

Achieving a durable, high-performance finish on CNC-machined aluminum components requires more than just selecting a premium spray paint. The inherent challenges of aluminum—its reactive oxide layer, surface porosity from machining, and thermal expansion characteristics—demand a holistic approach where precision manufacturing directly influences paint adhesion and longevity. At Honyo Prototype, our CNC machining services are engineered to deliver optimal substrate preparation, ensuring surfaces meet stringent industry standards for cleanliness, micro-roughness, and dimensional stability before any finishing process begins.

Surface Preparation Critical for Paint Adhesion

Aluminum’s natural oxide layer and residual machining oils can compromise paint bonding if not addressed during fabrication. Our CNC processes integrate controlled deburring, precision cleaning protocols, and tailored surface profiling to eliminate contaminants and create an ideal anchor pattern. This foundational step is non-negotiable for preventing peeling, blistering, or corrosion under film—common failures when machining and finishing are treated as disconnected operations.

Honyo’s Integrated Approach to Aluminum Finishing

We recognize that the “best” spray paint for your CNC aluminum part depends on application-specific factors: environmental exposure, mechanical stress, regulatory requirements (e.g., MIL-PRF, ASTM D3359), and aesthetic needs. While epoxy-polyurethane hybrids often excel in industrial durability or acrylic lacquers in rapid turnaround scenarios, success hinges on substrate readiness. Our engineering team collaborates with clients to align material selection, machining parameters, and post-processing—ensuring your chosen coating performs as intended in-field.

Streamline Your Prototyping Workflow

Eliminate guesswork in your next aluminum enclosure, aerospace bracket, or medical device component. Leverage Honyo’s end-to-end CNC machining expertise to build finish-ready parts from the first cut. Validate your design-to-finish strategy efficiently with our Online Instant Quote platform, providing transparent lead times and pricing within minutes—so you can focus on performance, not procurement delays.

Material Compatibility Reference

| Coating Type | Adhesion to Machined Aluminum | Key Applications | Pre-Treatment Requirement |

|————————|——————————-|——————————–|—————————-|

| Epoxy-Polyurethane | Excellent (with proper prep) | Automotive, Marine, Industrial | Alodine/Chromate Conversion |

| Acrylic Lacquer | Good | Consumer Electronics, Displays | Light Abrasion + Degrease |

| Powder Coat (Liquid) | Superior | Heavy Machinery, Architecture | Phosphating or Grit Blast |

| Two-Part Urethane | Excellent | Aerospace, Defense | Anodizing or Chemical Etch |

Technical Capabilities

When selecting the best spray paint for use on CNC-machined aluminum parts—particularly those produced on 3/4/5-axis milling machines and turning centers with tight tolerance requirements—the coating must meet stringent performance criteria. These include excellent adhesion to machined metals and engineering plastics, minimal overspray for precision applications, fast drying without warping, and compatibility with secondary operations such as anodizing masking, inspection, or metrology.

The ideal spray paint should be non-reactive, low-outgassing, and thermally stable to avoid dimensional changes in tight-tolerance components (±0.0005″ or better). It must also adhere uniformly across diverse materials commonly machined at Honyo Prototype, including aluminum (6061, 7075), stainless steel, ABS, and nylon.

Below is a comparison of top-performing technical spray paints suitable for precision CNC environments:

| Feature | Krylon Fusion for Plastic | VHT SP229 Chassis Black | MG Chemicals 422B High-Temp Coating | SEM Normal Spherical Spray Paint |

|---|---|---|---|---|

| Primary Use | Plastic and metal marking, layout | High-durability chassis coating | High-temperature masking and identification | Precision layout and scribing |

| Adhesion to Aluminum | Excellent | Excellent | Excellent | Excellent |

| Adhesion to Steel | Very Good | Excellent | Excellent | Very Good |

| Adhesion to ABS | Excellent | Good | Poor | Excellent |

| Adhesion to Nylon | Good | Fair | Poor | Good |

| Film Thickness (dry) | 1.5–2.0 mils | 2.0–3.0 mils | 1.0–1.5 mils | 1.0–1.8 mils |

| Drying Time (tack-free) | 15–20 minutes | 20–30 minutes | 10–15 minutes | 10–20 minutes |

| Thermal Stability | Up to 120°C continuous | Up to 150°C | Up to 600°C (intermittent) | Up to 150°C |

| Color Contrast (for scribing) | High (white, yellow options) | Medium (typically black) | Medium (silver) | High (white, dyed variants) |

| Overspray Control | Moderate | Low | Moderate | High (fine mist control) |

| Chemical Resistance | Good | Excellent | Excellent | Good |

| Recommended for Tight Tolerance Work | Yes (for layout only) | No (too thick) | No (brittle at micron levels) | Yes (precision marking) |

Recommendation for 3/4/5-Axis & Turning Applications:

For precision layout marking on aluminum and steel components with tight tolerances, SEM Normal Spherical Spray Paint or Krylon Fusion for Plastic (White or Yellow) are preferred due to fine atomization, high visibility, and minimal build-up. These support accurate scribing and inspection without interfering with geometric tolerances.

Avoid heavy-bodied coatings like VHT chassis paint in precision contexts due to excessive film thickness. For high-temp fixturing or thermal cycling environments, consider MG Chemicals 422B, though it is less suitable for fine feature marking.

All coatings should be applied in controlled environments with clean, degreased surfaces. Use isopropyl alcohol or acetone-based cleaners pre-application. For metrology-grade parts, verify coating does not interfere with CMM probing or optical scanning.

From CAD to Part: The Process

Honyo Prototype delivers precision CNC aluminum prototypes and production parts with surface finishing as a value-added service. We do not select or specify the “best spray paint” for your application. Coating selection is a critical engineering decision based on your specific functional requirements, environmental exposure, regulatory standards, and aesthetic goals. Our process ensures your client-defined coating specification is accurately manufactured. Below is our structured workflow for CNC aluminum parts requiring spray painting:

Upload CAD

You submit your 3D model and detailed technical package. This must include explicit coating requirements: paint type (e.g., epoxy, polyurethane, powder coat), brand/part number if specified, color code (e.g., RAL, Pantone), thickness range, adhesion standards (e.g., ASTM D3359), and any pre-treatment mandates (e.g., chromate conversion, anodizing undercoat). We verify CAD geometry for manufacturability but do not assess coating suitability at this stage.

AI Quote

Our AI-driven quoting engine analyzes the CAD file for material, machining complexity, and labor. If your technical package includes coating specifications, the quote will factor in secondary operations: media blasting for adhesion, chemical pre-treatment, masking requirements, paint application method (automated spray booth vs. manual), and curing cycles. Quotes exclude coating material costs unless explicitly provided in your RFQ; we require your approved paint spec or vendor data sheet for accurate costing.

DFM (Design for Manufacturing) Review

Our engineering team conducts a rigorous DFM analysis focused on coating feasibility. We identify potential issues such as inadequate draft angles for uniform coverage, sharp edges causing paint thinning, internal cavities requiring specialized spraying, or geometric features prone to masking errors. We provide actionable feedback like recommending minimum radii for edge coverage or suggesting design modifications to avoid shadowing. Crucially, we validate that your specified coating process aligns with aluminum metallurgy (e.g., avoiding alkaline paints on untreated 2024-T3) but do not recommend alternative paints.

Production

Machining occurs per your dimensional tolerances. For coated parts, we perform sequential steps: precision cleaning, specified pre-treatment (e.g., Alodine 1200), automated spray application in climate-controlled booths (ensuring ±5μm thickness per your spec), and oven curing at documented time/temperature profiles. All coating parameters are recorded for traceability. We strictly adhere to your provided coating standard—deviations require your written engineering change order.

Delivery

Finished parts undergo dimensional validation and coating inspection per your requirements: thickness checks (micrometer or eddy current), visual defect review, and adhesion testing if specified. We provide a full inspection report including coating process parameters. The coating’s performance in your end-use environment remains your validation responsibility; our role ends with delivering parts meeting your contractual finish specification.

Client and Honyo Prototype Responsibilities Regarding Coatings

| Responsibility Area | Client Ownership | Honyo Prototype Execution |

|---|---|---|

| Coating Specification | Define paint chemistry, color, thickness, standards, pre-treatment | Apply only to your written specification |

| Material Sourcing | Provide approved paint supplier data sheets or purchase coating | Procure coating per your PO; verify lot traceability |

| Process Validation | Confirm coating suitability for end-use environment | Execute documented process; provide SPC data |

| Quality Acceptance | Define test methods (e.g., salt spray hours) | Perform tests only if explicitly contracted |

IMPORTANT: Honyo Prototype is a contract manufacturer, not a coatings consultant. We implement your engineering decisions with precision. Engage a coatings specialist or paint supplier to determine the optimal formulation for your application. Provide us with a complete, unambiguous finish specification to ensure flawless execution within our CNC and finishing workflow.

Start Your Project

Looking for the best spray paint for CNC aluminum parts? Achieve a durable, high-quality finish with our premium coating solutions, optimized for precision-machined aluminum components. Ideal for prototypes and low-volume production runs.

All services are supported by our in-house team at the Honyo Prototype factory in Shenzhen, ensuring tight control over quality and turnaround times.

For technical specifications or bulk ordering, contact Susan Leo at [email protected].

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.