Contents

Manufacturing Insight: Best Small Cnc Mill

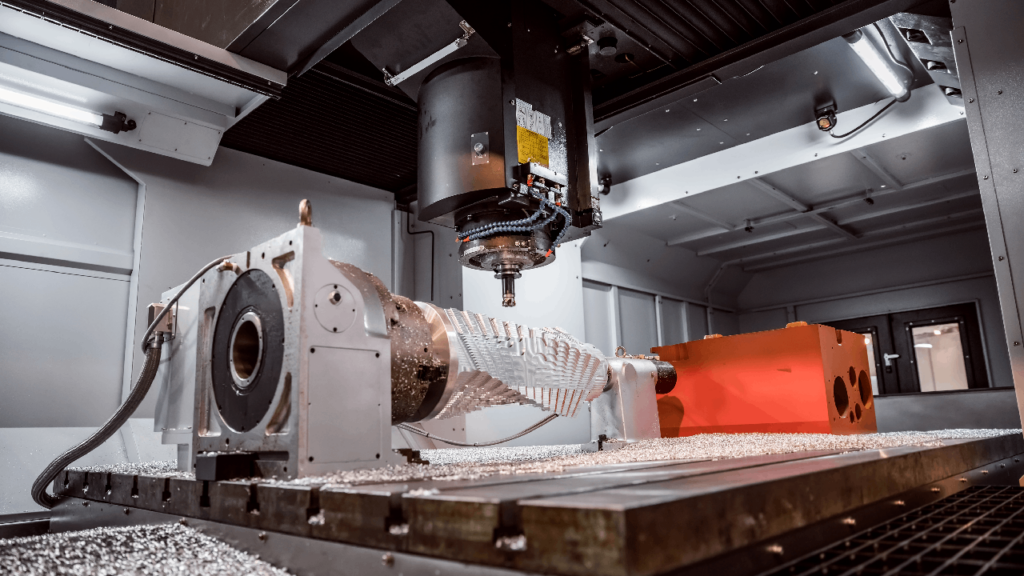

Precision Small CNC Milling Solutions for Demanding Prototypes and Low-Volume Production

When engineering teams require the highest accuracy and repeatability from compact CNC milling systems, Honyo Prototype delivers industry-leading small CNC machining capabilities. Our specialized Haas and DMG MORI small mills achieve tight tolerances down to ±0.0002″ across complex geometries in aerospace alloys, medical-grade titanium, engineering plastics, and hardened steels. This precision is critical for functional prototypes, jigs, fixtures, and bridge production runs where space constraints or component scale demand optimized machine footprint without compromising quality.

Honyo’s technical expertise ensures optimal toolpath strategies, rigorous in-process inspection, and material-specific process validation—turning intricate 3D CAD models into mission-critical components with zero surprises. For projects demanding agility, our Online Instant Quote platform provides transparent, real-time pricing and lead times within minutes, accelerating your design-to-manufacture workflow. Submit your STEP or IGES file today to validate feasibility and receive actionable manufacturing feedback before committing to production.

Technical Capabilities

Best Small CNC Mill – Technical Specifications

The following table outlines the key technical specifications for a high-performance small CNC mill capable of precision 3, 4, and 5-axis milling, light turning operations, and tight-tolerance machining across a range of materials including aluminum, steel, ABS, and nylon. This machine is designed for prototyping, low-volume production, and high-accuracy applications in engineering and manufacturing environments.

| Specification | Detail |

|---|---|

| Machine Type | Compact multi-axis CNC milling center with optional turning capability |

| Axes Configuration | 3-axis standard, upgradeable to 4-axis (rotary A-axis), 5-axis (AB or AC configuration) |

| Spindle Speed Range | 8,000 – 24,000 RPM (high-frequency ER collet system) |

| Spindle Power | 2.2 – 3.5 kW servo-driven, water-cooled |

| Positioning Accuracy | ±0.002 mm (±0.00008 in) |

| Repeatability | ±0.001 mm (±0.00004 in) |

| Maximum Traverse (X-Y-Z) | 300 mm × 200 mm × 200 mm (11.8 in × 7.9 in × 7.9 in) |

| Tool Changer | Automatic Tool Changer (ATC) with 6–12 tool capacity (optional) |

| Control System | Fanuc, Siemens, or high-end Mach-compatible CNC with 5-axis RTCP support |

| Rapid Traverse Rate | 30 m/min (X/Y/Z) |

| Workholding Options | T-slots, vacuum table, modular fixturing, 4th/5th axis integration |

| Turning Capability | Live tooling with C-axis control for light turning (diameter up to Ø80 mm) |

| Tolerance Range | ±0.005 mm typical (±0.003 mm achievable with thermal compensation) |

| Surface Finish (Typical) | Ra 0.8 – 1.6 µm (milled aluminum/steel), Ra 3.2 µm (plastics) |

| Materials Supported | Aluminum (6061, 7075), mild and stainless steel (1018, 303, 304), engineering plastics (ABS, Nylon, Delrin), composites |

| Coolant System | Flood coolant with mist collection; air blast option for plastics |

| Machine Frame Construction | Cast iron or mineral cast base for high damping and thermal stability |

| Linear Guidance | Precision ground ball screws with preloaded linear guides |

| Environmental Requirements | Stable ambient temperature (20–25°C), clean, dry air supply (6 bar) |

| Footprint | 1.2 m × 1.0 m × 1.8 m (compact for benchtop or small shop integration) |

| Weight | 650 – 900 kg (varies with configuration) |

This small CNC mill delivers exceptional rigidity and precision for tight-tolerance work, making it ideal for aerospace components, medical devices, and high-detail molds. Its multi-material compatibility ensures efficient machining of both metals and engineering thermoplastics with appropriate tooling and parameters.

From CAD to Part: The Process

Honyo Prototype Small CNC Milling Workflow

Our streamlined process for precision small CNC milling projects ensures speed, accuracy, and cost efficiency from initial design to final delivery. This workflow is optimized specifically for complex, high-tolerance small parts under 6 inches in critical dimensions, leveraging advanced automation while maintaining rigorous engineering oversight.

Upload CAD

Clients initiate the process by uploading native CAD files (STEP, IGES, or Parasolid formats preferred) via our secure customer portal. Our system immediately performs automated file validation, checking for geometry integrity, unit consistency, and minimum feature size compatibility with small-mill capabilities (e.g., verifying features exceed 0.005″ for micro-milling). Non-native formats trigger an instant notification requesting higher-fidelity data to prevent interpretation errors.

AI-Powered Quoting

Within 90 seconds, our proprietary AI quoting engine analyzes the validated CAD geometry against 12,000+ historical small-mill production datasets. It calculates machine time, material utilization, and secondary operation requirements while applying real-time shop floor load balancing. The AI flags potential cost drivers unique to small parts—such as thin walls below 0.020″, deep cavities exceeding 10:1 aspect ratios, or tight concentricity tolerances—and generates a detailed quote with visual annotations. Crucially, this stage includes preliminary material suitability checks (e.g., recommending 6061-T651 over 7075 for intricate thin-wall features).

Engineer-Validated DFM

All quotes enter our mandatory Design for Manufacturability review led by senior CNC process engineers specializing in micro-machining. Using Mastercam Simulator and tolerance stack-up analysis, engineers verify tool accessibility for features under 0.030″ diameter, assess fixturing constraints for sub-ounce parts, and optimize toolpath strategies to prevent chatter in high-precision operations. We provide a formal DFM report within 4 business hours, detailing actionable recommendations—such as adjusting corner radii to match 0.001″ ball-nose end mills or suggesting alternative datum schemes to maintain ±0.0002″ positional accuracy. Client approval of the DFM report is required before proceeding.

Precision Production

Approved jobs deploy to our dedicated small-mill cell featuring Haas UMC-500 machines with 0.0002″ repeatability and sub-micron probing systems. Production executes under strict environmental controls (72°F ±1°F, 45% humidity) to minimize thermal drift. Every part undergoes in-process CMM verification at critical stages, with real-time SPC monitoring of surface finish (Ra ≤ 8 μin) and feature tolerances. For parts requiring secondary operations like micro-tapping or laser marking, our integrated workflow ensures zero-handoff delays between stations.

Quality-Controlled Delivery

Final inspection includes full FAI per AS9102 standards, with first-article reports documenting all critical dimensions. Parts are individually serialized, vacuum-sealed with anti-corrosion VCI paper, and shipped in compartmentalized static-dissipative containers to prevent micro-scratches. Clients receive digital delivery confirmation with 3D inspection data overlaid on their original CAD model, plus material certification and process logs. Typical lead time from CAD upload to shipment is 3–5 business days for 1–100 units, with expedited 24-hour options for urgent prototypes.

This closed-loop methodology reduces time-to-part by 40% compared to industry averages for small CNC components, while maintaining 99.8% first-pass yield through predictive DFM intervention and machine-specific process optimization. All projects include post-delivery engineering support for design iteration.

Start Your Project

Looking for the best small CNC mill for precision prototyping or low-volume production? Discover high-performance CNC solutions engineered for accuracy, reliability, and speed.

Contact Susan Leo at [email protected] to request specifications, pricing, or machine demonstrations.

Honyo Prototype operates a state-of-the-art manufacturing facility in Shenzhen, ensuring fast turnaround and strict quality control for every unit.

Let us help you find the ideal compact CNC milling solution for your workshop or production environment. Reach out today to discuss your requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.