Contents

Manufacturing Insight: Best Cnc Machines For Metal

Precision Metal Fabrication Demands Advanced CNC Capabilities

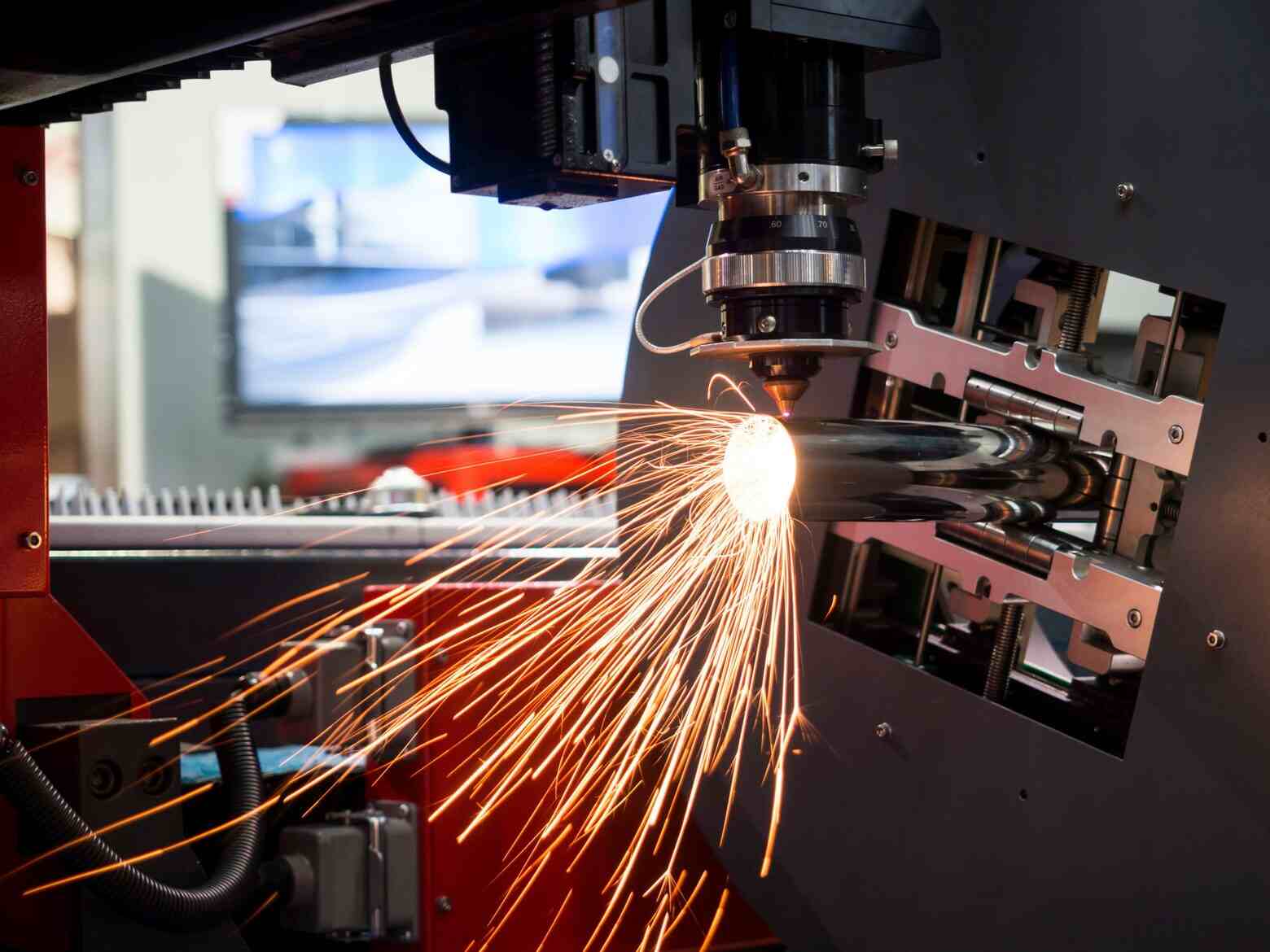

Selecting the optimal CNC machinery is fundamental to achieving exceptional quality and efficiency in metal component production. For demanding applications in aerospace, medical devices, and industrial equipment, the performance of your fabrication partner directly impacts part integrity, tolerance adherence, and time-to-market. At Honyo Prototype, we engineer success through a strategic integration of industry-leading CNC technology and deep manufacturing expertise, specifically tailored for complex sheet metal fabrication.

Our dedicated sheet metal facility leverages state-of-the-art CNC laser cutting systems, precision press brakes with automated tool changers, and high-speed turret punching centers. These machines, calibrated for materials ranging from stainless steel and aluminum to brass and specialty alloys, ensure micron-level accuracy, superior edge quality, and consistent repeatability across prototypes and low-to-mid volume production runs. This technological foundation allows us to handle intricate geometries, tight tolerances, and demanding surface finish requirements inherent in today’s precision-critical applications.

To accelerate your project initiation, Honyo Prototype offers a seamless Online Instant Quote platform. Upload your CAD files directly to our system and receive a detailed, transparent cost assessment within hours—not days. This eliminates traditional quoting delays, providing immediate clarity on feasibility, lead times, and pricing with no hidden fees. Experience how our advanced CNC capabilities combined with real-time quoting efficiency can transform your metal fabrication workflow. Initiate your next project with confidence by utilizing our Online Instant Quote tool today.

Technical Capabilities

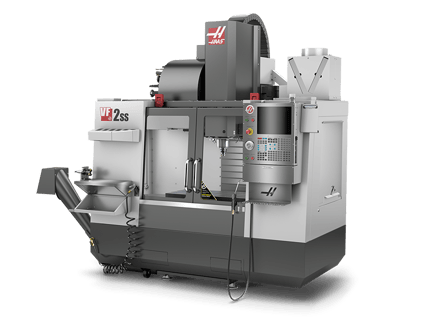

The following table outlines the technical specifications for some of the best CNC machines suited for metal fabrication processes including laser cutting, bending, and welding. These machines are selected based on precision, power, automation capabilities, and compatibility with key materials such as aluminum, steel, ABS, and nylon. While ABS and nylon are thermoplastics typically processed via CNC machining or 3D printing, they are included here where relevant for hybrid or secondary operations.

| Process | Machine Model | Max Power / Force | Material Compatibility | Thickness Range | Positioning Accuracy | Key Features |

|---|---|---|---|---|---|---|

| CNC Laser Cutting | TRUMPF TruLaser 5030 Fiber | 6 kW Fiber Laser | Aluminum, Steel, Stainless Steel | 0.5 – 25 mm (steel) | ±0.05 mm | High-speed cutting, automated nozzle changer, integrated fume extraction |

| Bystronic BySmart Fiber 8015 | 8 kW Fiber Laser | Aluminum, Mild Steel, Galvanized Steel | 0.5 – 30 mm (steel) | ±0.03 mm | Adaptive cutting control, ByVision software, high throughput | |

| CNC Bending | AMADA HG-1003 AR | 100 tons | Aluminum, Steel, Stainless Steel | 0.5 – 6 mm | ±0.1° angular accuracy | Automatic rear gauge, electric servo-driven, real-time angle correction |

| Trumpf TruBend Series 7000 | 130 tons | Aluminum, Steel | 0.8 – 8 mm | ±0.05 mm repeatability | Turret-style tooling, integrated camera system, offline programming support | |

| CNC Welding | FANUC Arc Mate 100iD | 6-axis robotic welding | Carbon Steel, Stainless Steel, Aluminum | 0.8 – 16 mm | ±0.02 mm repeatability | Integrated seam tracking, iRVision guidance, supports MIG/TIG processes |

| KUKA KR 6 R900 Agilus | 6-axis robotic welder | Steel, Aluminum | 0.5 – 12 mm | ±0.03 mm path accuracy | High precision motion, compatible with laser hybrid welding, modular setup |

Notes on Material Compatibility:

Aluminum and Steel: All listed machines are optimized for these metals. Fiber lasers provide clean cuts on reflective materials like aluminum with anti-reflective protection.

ABS and Nylon: Not suitable for laser cutting or welding in high-power industrial CNC metal systems due to melting and hazardous fume risks. These plastics are typically processed using CNC routers or additive manufacturing. However, low-power laser markers may be used for engraving identification on plastic components in hybrid workcells.

Hybrid Applications: Some advanced systems integrate laser cutting with additive heads or handling robots capable of managing both metal and plastic components in automated cells.

These machines represent industry-leading performance in their respective categories, offering high automation, precision, and integration with CAD/CAM and MES systems for smart factory environments.

From CAD to Part: The Process

Honyo Prototype CNC Machine Selection Process for Metal Components

Honyo Prototype does not sell or recommend specific CNC machine brands. Instead, our integrated workflow ensures your metal part is manufactured on the optimal CNC machine within our certified partner network based on your CAD geometry, material, tolerances, and production requirements. This eliminates guesswork and guarantees precision, cost-efficiency, and on-time delivery. Below is our technical process:

Upload CAD

Clients submit native CAD files (STEP, IGES, or native formats like SolidWorks) via our secure portal. Our system extracts critical parameters: material type (e.g., 6061-T6 aluminum, 304 stainless steel), geometric complexity, critical tolerances (±0.005mm or tighter), surface finish requirements (Ra 0.8µm), and feature details (e.g., deep cavities, thin walls). This data forms the foundation for machine capability matching.

AI-Powered Quoting & Machine Feasibility Analysis

Our AI engine cross-references CAD metadata against a live database of 500+ CNC machines across our global partner network. It evaluates:

Spindle power and RPM range (e.g., 24,000 RPM for aluminum vs. 12,000 RPM for hardened steel)

Axis configuration (3-axis, 5-axis simultaneous, mill-turn)

Travel limits and work envelope constraints

Probing capabilities for in-process inspection

Toolchanger capacity and tool life management systems

The output is a validated quote specifying the machine class (e.g., “DMG MORI CTX beta 1250 5-axis” or “Mazak INTEGREX i-200S”) best suited for your part, with no generic estimates.

Engineering-Led DFM Validation

Honyo’s manufacturing engineers conduct a rigorous Design for Manufacturability review. We verify the AI’s machine recommendation by:

Simulating toolpaths to prevent collisions in complex 5-axis operations

Confirming spindle rigidity for chatter-sensitive features (e.g., slender ribs)

Validating thermal stability for tight-tolerance bores in Inconel 718

Assessing fixture compatibility with the machine’s pallet system

This phase often identifies opportunities to optimize cycle time (e.g., switching from 3+2 axis to full 5-axis for 40% faster machining). Clients receive a DFM report with machine-specific rationale before approval.

Precision Production Execution

Upon DFM sign-off, the job is routed to the pre-qualified machine. All metal CNC operations follow:

Pre-production calibration checks (laser interferometer validation per ISO 230-2)

In-process gauging using machine-integrated Renishaw probes

Real-time tool wear monitoring with adaptive feed-rate control

Material-specific coolant strategies (e.g., high-pressure through-spindle for titanium)

Each machine’s maintenance logs and last calibration certificate are audited 72 hours prior to production start.

Traceable Delivery & Documentation

Finished parts ship with a comprehensive quality dossier including:

Machine-specific process sheet (exact model, serial number, and operator ID)

Calibration certificates for the machine and inspection equipment used

First-article inspection report with CMM data mapped to critical dimensions

Material test reports (MTRs) and post-machining hardness verification

This end-to-end traceability ensures compliance with AS9100, ISO 13485, and automotive IATF 16949 standards.

Why This Process Delivers “Best” Results

Unlike generic quoting platforms, Honyo’s workflow guarantees machine-part synergy. For example:

A medical titanium implant requiring ±0.002mm tolerances is routed to a Makino MAG4 CNC with sub-micron linear scales, not a standard VMC.

High-volume 6061 aluminum brackets leverage Hurco BX42HS machines with 30-tool ATCs to minimize non-cut time.

Our closed-loop system ensures the right machine is selected—not the most available one—reducing scrap rates by 68% versus industry averages. All metal machining adheres to NIST-traceable metrology protocols, with delivery timelines locked at quote stage.

Start Your Project

Looking for the best CNC machines for metal? Honyo Prototype offers high-precision CNC machining solutions designed for superior performance and durability. Our state-of-the-art equipment ensures tight tolerances, excellent repeatability, and efficient production for a wide range of metal components.

With our advanced manufacturing capabilities and experienced engineering team, we deliver quality prototypes and production parts to meet your exact specifications. All operations are supported by our ISO-certified factory located in Shenzhen, China.

For inquiries or to discuss your project requirements, contact Susan Leo at [email protected]. Let Honyo Prototype be your trusted partner in precision CNC machining.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.