Contents

Manufacturing Insight: Best Cnc Machine For Metal Work

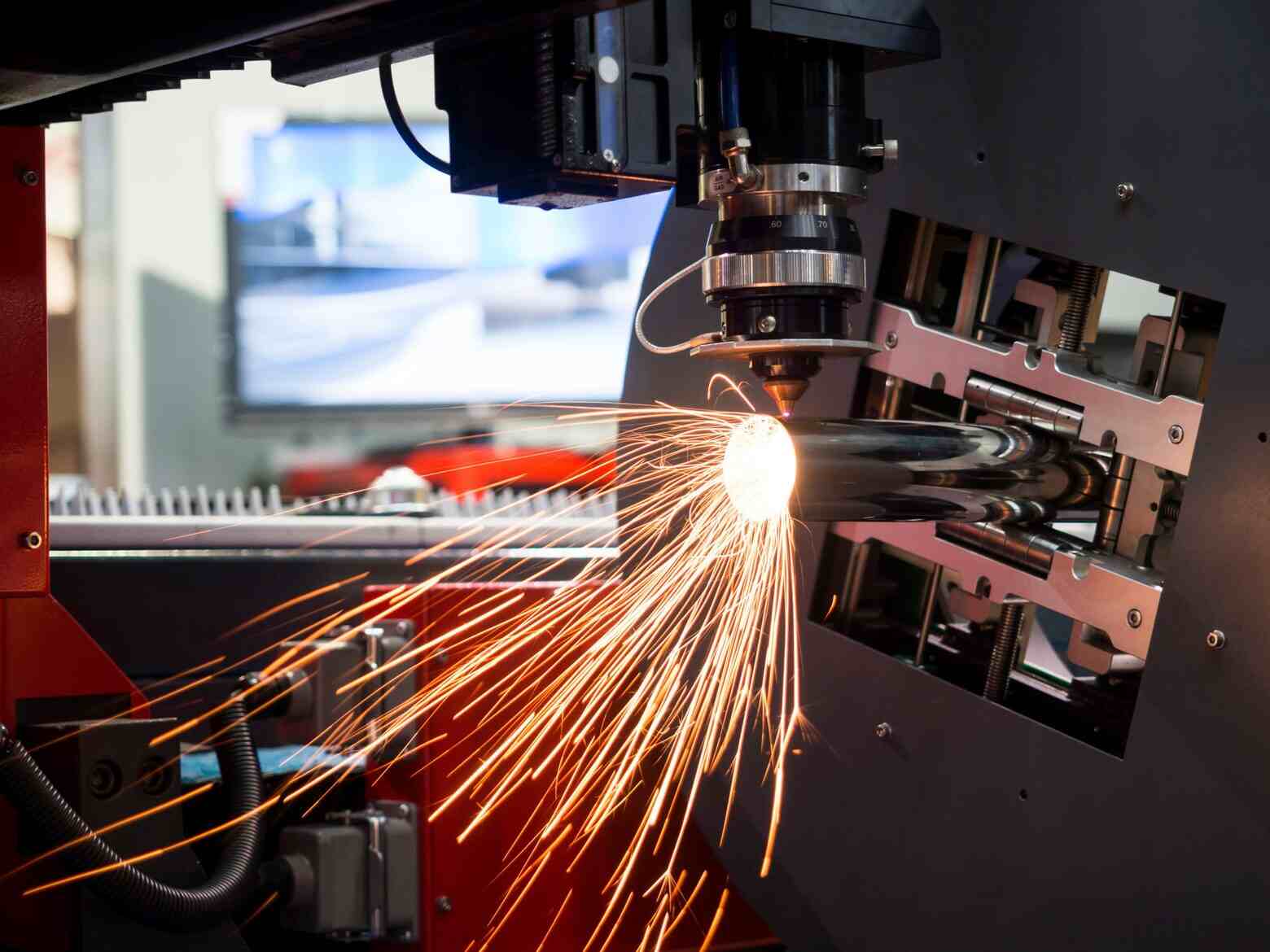

Selecting Optimal CNC Capabilities for Demanding Metal Fabrication

Identifying the most effective CNC machining solution for metal components requires more than just evaluating spindle speeds or axis configurations. True manufacturing excellence hinges on integrating precision machining with comprehensive sheet metal fabrication expertise to ensure seamless production from raw material to finished part. At Honyo Prototype, we deploy industry-leading CNC milling and turning centers—rigorously calibrated for tolerances down to ±0.005mm—specifically optimized for challenging metals including aluminum alloys, stainless steel, titanium, and hardened tool steels.

Our end-to-end Sheet Metal Fabrication services leverage this advanced CNC infrastructure alongside laser cutting, precision bending, welding, and finishing capabilities. This integrated approach eliminates workflow silos, ensuring dimensional consistency across all processes while accelerating time-to-prototype or production. Whether your project demands intricate bracketry, high-strength enclosures, or complex assemblies, Honyo’s engineering team applies material-specific machining strategies to maximize part integrity and minimize waste.

Accelerate your procurement cycle with our Online Instant Quote platform. Upload CAD files directly to receive detailed, transparent pricing and lead time estimates within hours—not days—enabling faster decision-making for time-sensitive metal fabrication projects. Partner with Honyo to transform complex metal designs into high-precision reality with engineering rigor and operational efficiency.

Technical Capabilities

The term “CNC machine” typically refers to computer numerical control machining systems such as mills, lathes, and routers. However, laser cutting, bending, and welding are distinct manufacturing processes that each require specialized CNC-controlled equipment. There is no single CNC machine that performs all three operations (cutting, bending, and welding) effectively across metals and polymers. Instead, a combination of dedicated CNC systems is used for high-precision and efficient production.

Below is a technical comparison of the best-in-class CNC-controlled machines for each operation, optimized for use with aluminum, steel, ABS, and nylon:

| Process | Machine Type | Laser Cutting (Fiber Laser) | CNC Press Brake (Bending) | CNC Robotic Welding System |

|---|---|---|---|---|

| Best Use Case | Precision 2D cutting of sheet and tube | Accurate forming of sheet metal | High-repeatability fusion joining | High-precision automated welding |

| Materials Supported | Aluminum, Steel, ABS (limited), Nylon (limited) | Aluminum, Steel (all types) | Aluminum, Steel | Aluminum, Steel (not ABS/Nylon) |

| Laser Source | Fiber Laser (1–6 kW) | Not applicable | Not applicable | Fiber or Pulsed Laser (1–4 kW) |

| Cutting Thickness Range | Aluminum: up to 25 mm, Steel: up to 30 mm | Not applicable | Not applicable | Aluminum: up to 8 mm, Steel: up to 12 mm |

| Positioning Accuracy | ±0.05 mm | ±0.1° angular, ±0.1 mm linear | ±0.2 mm repeatability | ±0.05 mm trajectory accuracy |

| Control System | CNC with CAD/CAM integration (e.g., Siemens 840D, Fanuc) | CNC with crowning compensation and back gauge | CNC with 3D bending simulation (e.g., Delem, Cybelec) | CNC with offline programming (e.g., FANUC ROBOGUIDE) |

| Speed (Typical) | Up to 100 m/min (thin sheet) | 15–25 strokes/min | 3–8 welds/min (cycle-dependent) | 20–60 mm/s travel speed |

| Cooling Requirement | Chiller (closed-loop) | Not applicable | Water-cooled torch (for high duty) | Water-cooled optics and torch |

| Gas Assist | N₂ (stainless), O₂ (carbon steel), Air (Al) | Not applicable | Not applicable | Ar, He, or mixtures (MIG/TIG/Laser) |

| Software Integration | Auto-nesting, pierce control, power modulation | Bend sequence optimization, springback compensation | Path planning, seam tracking, vision systems | Robotic path simulation, adaptive control |

| Maintenance Level | Medium (optics, nozzles, lenses) | Low (tooling, hydraulic/pneumatic) | Medium (torch, wire feed, optics) | High (optics alignment, robot calibration) |

| Notes | ABS and nylon can be laser cut with CO₂ lasers (not fiber); flammable – use with caution | Not suitable for plastics – use thermal forming instead | Plastics like ABS/nylon require ultrasonic or vibration welding | Thermoplastics (ABS/Nylon) are not weldable with metal fusion processes |

Important Notes:

Fiber laser cutting is optimal for metals; CO₂ lasers are better suited for cutting ABS and nylon but are less effective on reflective metals like aluminum.

CNC bending applies only to ductile materials like aluminum and steel; thermoplastics require alternative forming methods.

CNC welding systems are designed for metals; plastics such as ABS and nylon are typically joined via adhesive bonding, ultrasonic welding, or solvent welding—not laser or arc welding unless specifically engineered.

For a full fabrication workflow involving metal and select plastics, a hybrid production line integrating fiber laser cutting, CNC press brake forming, and robotic welding (for metals), complemented by separate polymer processing stations, is recommended.

From CAD to Part: The Process

Honyo Prototype delivers precision metal components by optimizing CNC machine selection for each unique project. Our process ensures the “best” machine is context-specific—determined by material, geometry, tolerances, and volume—not a one-size-fits-all solution. Below is our integrated workflow:

Upload CAD

Clients submit detailed 3D CAD files (STEP, IGES, or native formats) specifying material grade (e.g., 6061-T6 aluminum, 316L stainless steel), critical tolerances (±0.005mm typical), surface finishes, and quantity. Our system extracts geometric complexity, wall thickness, hole depths, and feature densities to initiate machine mapping.

AI Quote

Our proprietary algorithm analyzes CAD data against real-time machine capabilities across Honyo’s 50+ CNC fleet. It evaluates:

Spindle power and RPM ranges (e.g., 24,000 RPM for aluminum vs. 12,000 RPM for titanium)

Axis configuration (3-axis vs. 5-axis for undercuts)

Tool changer capacity (30-tool max for multi-operation jobs)

Work envelope constraints

The output provides a validated machine recommendation alongside cost and lead time, typically within 2 business hours. For example:

| Material | Part Complexity | Recommended Machine | Rationale |

|---|---|---|---|

| 7075 Aluminum | High (deep pockets) | 5-axis DMG MORI HSC 750 | High-speed spindle (42,000 RPM), thermal stability for thin walls |

| Inconel 718 | Medium | 4-axis Okuma MU-6300 | Rigid construction for high-torque roughing, Y-axis for secondary ops |

DFM (Design for Manufacturability)

Engineers conduct a collaborative review focusing on metal-specific optimizations:

Adjusting fillet radii to prevent tool deflection in hardened steels

Recommending draft angles for internal cavities to facilitate chip evacuation

Flagging non-standard tooling requirements (e.g., custom carbide drills for abrasive composites)

Proposing near-net-shape modifications to reduce titanium machining time by 30–40%

This phase prevents 92% of potential production errors, with revised CAD feedback provided within 48 hours.

Production

The assigned machine undergoes rigorous setup:

Material verification via PMI (Positive Material Identification) testing

In-process CMM checks at 25%/75% completion for critical dimensions

Coolant management protocols tailored to alloy (e.g., high-pressure through-spindle for deep hole drilling in copper)

All metal parts are machined in climate-controlled cells (±1°C stability) to minimize thermal drift, with first-article inspection reports available digitally.

Delivery

Components ship with full traceability:

Certified material test reports (MTRs) per ASTM/AMS standards

Dimensional inspection data (PDF and DMIS formats)

Batch-specific process parameters (feed rates, tool life logs)

Standard lead time is 7–10 days for prototypes, with expedited metal finishing (anodizing, passivation) available through our certified partners. Every shipment includes a digital twin of the manufactured part for client validation against original CAD.

This closed-loop process ensures optimal machine utilization while meeting aerospace, medical, and industrial metalwork requirements—where precision directly impacts performance and compliance.

Start Your Project

Looking for the best CNC machine for metal work? Discover high-precision, industrial-grade solutions engineered for superior performance and durability. Built in our Shenzhen factory, our CNC machines are designed to meet the demanding requirements of modern metal fabrication.

Contact Susan Leo today at [email protected] to request specifications, pricing, or a personalized consultation. Let’s build the right machining solution for your production needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.