Contents

Manufacturing Insight: Best Aluminum For Machining

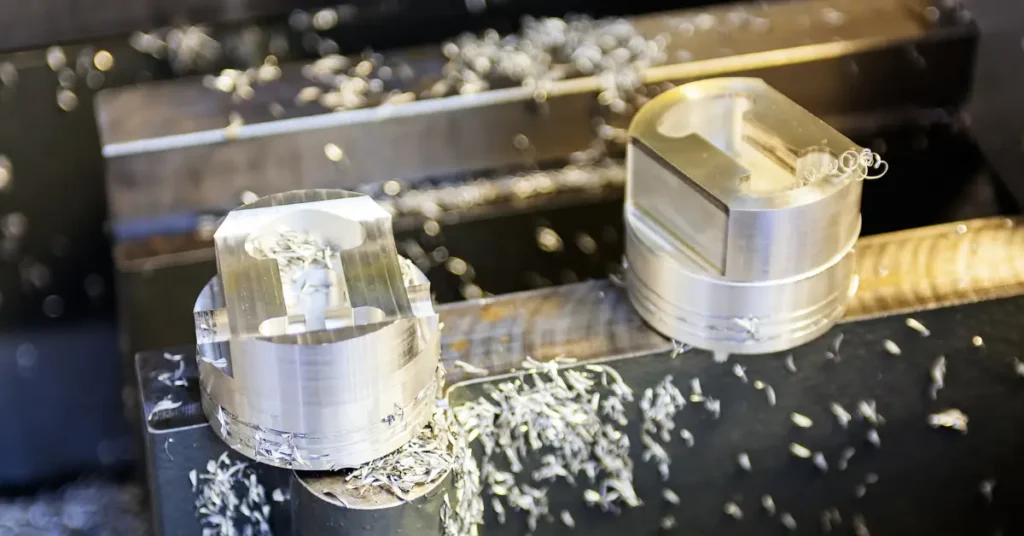

Optimizing Aluminum Selection for Precision CNC Machining

Aluminum remains the premier material choice for prototyping and low-volume production due to its exceptional strength-to-weight ratio, thermal conductivity, and machinability. However, selecting the optimal aluminum alloy significantly impacts part performance, tool life, and production efficiency. Common grades like 6061-T6 offer balanced mechanical properties for structural components, while 7075-T6 delivers superior strength for aerospace applications, and 2024-T3 excels in high-stress environments. The wrong alloy selection can lead to excessive tool wear, dimensional inaccuracies, or compromised part integrity—costing time and resources.

At Honyo Prototype, our CNC machining services integrate deep material science expertise with advanced 3-, 4-, and 5-axis capabilities to maximize yield and precision for every aluminum project. Our process engineers tailor cutting parameters, coolant strategies, and fixturing to each alloy’s unique properties, ensuring tight tolerances down to ±0.0002″ and superior surface finishes. This material-centric approach minimizes scrap rates and accelerates time-to-part without sacrificing quality.

Accelerate your prototyping workflow with Honyo’s Online Instant Quote system. Upload your CAD file, specify your aluminum grade and requirements, and receive a detailed manufacturing assessment and competitive pricing within hours—not days. Eliminate procurement delays and leverage our decades of CNC machining experience to transform your design into a high-performance aluminum component efficiently. Start your project today at honyoprototype.com/quote.

Technical Capabilities

When selecting the best aluminum alloy for high-precision machining applications such as 3-axis, 4-axis, and 5-axis milling or CNC turning with tight tolerances (±0.0005″ or better), several factors must be considered: machinability, dimensional stability, strength-to-weight ratio, thermal conductivity, and surface finish quality. While other materials like steel, ABS, and nylon are commonly machined, aluminum—particularly specific wrought alloys—offers the optimal balance for precision components in aerospace, medical, and robotics industries.

Among aluminum alloys, 6061-T6 and 7075-T6 are most frequently specified, with 2024-T3 and 5052-H32 used in specialized cases. For the highest precision and ease of machining, 6061-T6 is often preferred due to its excellent dimensional stability and good machinability. 7075-T6 offers higher strength but is slightly more challenging to machine consistently at micron-level tolerances.

Below is a comparative table of key materials used in precision CNC machining:

| Material | Alloy/Form | Tensile Strength (psi) | Hardness (Brinell) | Machinability Rating | Thermal Conductivity (BTU/hr·ft·°F) | Typical Applications | Notes for Precision Machining |

|---|---|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 45,000 | 95 | 85% | 120 | Enclosures, brackets, aerospace components | Excellent balance of strength, machinability, and stability; ideal for tight-tolerance 3–5 axis work |

| Aluminum | 7075-T6 | 83,000 | 150 | 60% | 110 | High-stress aerospace parts, molds | High strength but prone to tool wear; requires rigid setups for tight tolerances |

| Aluminum | 2024-T3 | 68,000 | 120 | 65% | 95 | Aircraft structures, military | Good strength; lower corrosion resistance; moderate precision performance |

| Aluminum | 5052-H32 | 30,000 | 60 | 75% | 88 | Marine, chemical tanks | Excellent corrosion resistance; softer, may challenge dimensional control |

| Steel | 4140 Annealed | 100,000 | 210 | 65% | 27 | Tooling, shafts, fixtures | High rigidity but slower machining; significant tool wear; not ideal for high-speed 5-axis |

| Steel | 303 Stainless | 75,000 | 180 | 70% | 9 | Fasteners, instrument parts | Free-machining due to sulfur; lower corrosion resistance than 304 |

| ABS | Thermoplastic | 6,000 | 80 (Rockwell R) | 90% | 1.1 | Prototypes, enclosures | Low melting point; chips can gum; excellent for low-load prototypes |

| Nylon (PA6/PA66) | Reinforced or GF | 10,000–14,000 | 85 (Rockwell R) | 80% | 0.8 | Gears, bushings, insulators | Hygroscopic; requires drying; excellent wear resistance; moderate precision |

For tight tolerance machining (±0.0005” or better) in multi-axis environments, 6061-T6 aluminum is typically the best overall choice due to its predictable behavior, minimal residual stress, and compatibility with high-speed machining strategies. It maintains dimensional accuracy across complex geometries and supports excellent surface finishes (Ra < 32 μin) with proper toolpaths and tooling.

While steel offers higher rigidity and wear resistance, its lower thermal conductivity and higher tool wear make it less ideal for intricate 5-axis contours. Plastics like ABS and nylon are suitable for non-structural prototypes but lack the thermal and dimensional stability required for micron-level tolerances.

Material selection should also consider post-machining requirements such as anodizing (Aluminum), heat treatment (Steel), or stress-relieving cycles—especially in high-precision applications.

From CAD to Part: The Process

Honyo Prototype employs a structured, data-driven methodology to determine the optimal aluminum alloy for each machining project within our end-to-end workflow. The term “best aluminum” is context-dependent, defined by balancing mechanical requirements, geometric complexity, cost targets, and delivery timelines. Material selection is not a standalone step but an integrated outcome of our Design for Manufacturability (DFM) analysis, ensuring the chosen alloy aligns precisely with the part’s functional intent and manufacturability. Below is the detailed process flow:

Upload CAD

Clients submit 3D CAD models via our secure portal. Our system performs initial geometry validation, extracting critical features such as thin walls, tight tolerances, internal cavities, and surface finish requirements. Basic material constraints (e.g., “must be aluminum”) are noted, but no alloy specification occurs at this stage. The CAD data feeds directly into our AI-driven quoting engine.

AI Quote Generation

Our proprietary AI analyzes the CAD geometry alongside historical production data, live material market pricing, and machine capacity. While generating a preliminary cost and lead time estimate, the AI flags potential material-related risks: for instance, high-aspect-ratio features may trigger alerts for alloys prone to chatter (e.g., advising against 7075 for thin-walled components). The quote includes a preliminary alloy suggestion based on common applications but explicitly states this is provisional pending DFM validation.

Design for Manufacturability (DFM) Analysis

This is the critical phase where the “best aluminum” is technically validated. Honyo’s engineering team conducts a multi-parameter review:

Functional Requirements: Cross-referencing client specifications (e.g., tensile strength >300 MPa, weldability needed) against alloy property databases.

Geometric Suitability: Assessing if features like deep pockets or fine threads are compatible with the alloy’s chip formation characteristics and thermal stability.

Cost-Performance Tradeoffs: Evaluating whether premium alloys (e.g., 2024 for high strength) justify costs versus standard options (e.g., 6061-T6) when requirements permit.

Secondary Process Integration: Confirming compatibility with planned post-machining steps (anodizing, welding, etc.).

The DFM report provides a definitive alloy recommendation with technical justification, shared with the client for approval. No production proceeds without this sign-off.

Production

Once the alloy is confirmed, Honyo sources material from certified suppliers with full mill test reports. CNC programming optimizes toolpaths specifically for the selected alloy’s machinability index (e.g., higher feed rates for free-machining 2011 versus 6061). In-process inspections verify dimensional stability, as thermal expansion differences between alloys (e.g., 7075 vs 5052) can affect precision.

Delivery

Final parts undergo alloy verification via portable XRF spectrometry to confirm material composition. Documentation includes the approved DFM report, material certifications, and traceability records linking the specific heat number to the delivered components.

Alloy Selection Decision Framework

The following table illustrates how Honyo evaluates common aluminum alloys against critical project parameters during DFM:

| Critical Factor | Application Example | Honyo’s Selection Logic |

|---|---|---|

| Strength-to-weight ratio | Aerospace bracket under cyclic load | Recommends 7075-T6 over 6061 if yield strength >500 MPa required; otherwise 6061-T6 for cost efficiency |

| Machinability | Complex manifold with fine threads | Prefers 6061-T6 or 2011 over 7075 due to reduced tool wear and smoother surface finish |

| Corrosion resistance | Marine component exposed to saltwater | Specifies 5052-H32 over 2024; verifies with salt-spray test data from material certs |

| Weldability | Assembly requiring post-machining welds | Excludes 2024/7075; defaults to 6061-T6 with MIG weld validation in DFM report |

| Anodizing quality | Cosmetic part requiring Type II anodize | Selects 6061 over 2014 for uniform oxide layer; checks silicon content in material certs |

This process ensures the “best aluminum” is objectively defined by engineering merit rather than default assumptions. Honyo’s DFM phase transforms material selection from a procurement decision into a value-engineering opportunity, consistently achieving optimal part performance while minimizing total project cost and risk. Client collaboration during DFM is mandatory, as final alloy approval rests with the customer based on our technical rationale.

Start Your Project

Looking for the best aluminum for machining? Our expert team at Honyo Prototype can help you select the optimal grade for your precision components. With our state-of-the-art machining facility in Shenzhen, we deliver high-quality aluminum prototypes and production parts with tight tolerances and fast turnaround.

Contact Susan Leo at [email protected] to discuss your project and get technical support tailored to your manufacturing needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.