Guide Contents

Project Insight: Best Aluminum For Machining

Manufacturing Insight: Best Aluminum for Precision Machining

Why Aluminum Dominates Prototyping & End-Use Parts

6061-T6 is the industry gold standard: Exceptional machinability, corrosion resistance, and strength-to-weight ratio make it ideal for functional prototypes and end-use parts.

Cost efficiency: Aluminum reduces material costs by up to 40% vs. steel or titanium while maintaining performance—critical for startups optimizing R&D budgets.

Versatile applications: From aerospace (2024) to high-stress components (7075-T6), we tailor alloy selection to your exact needs—without sacrificing speed or precision.

Surface finish excellence: Achieves mirror-like finishes and tight tolerances with minimal post-processing, accelerating time-to-market.

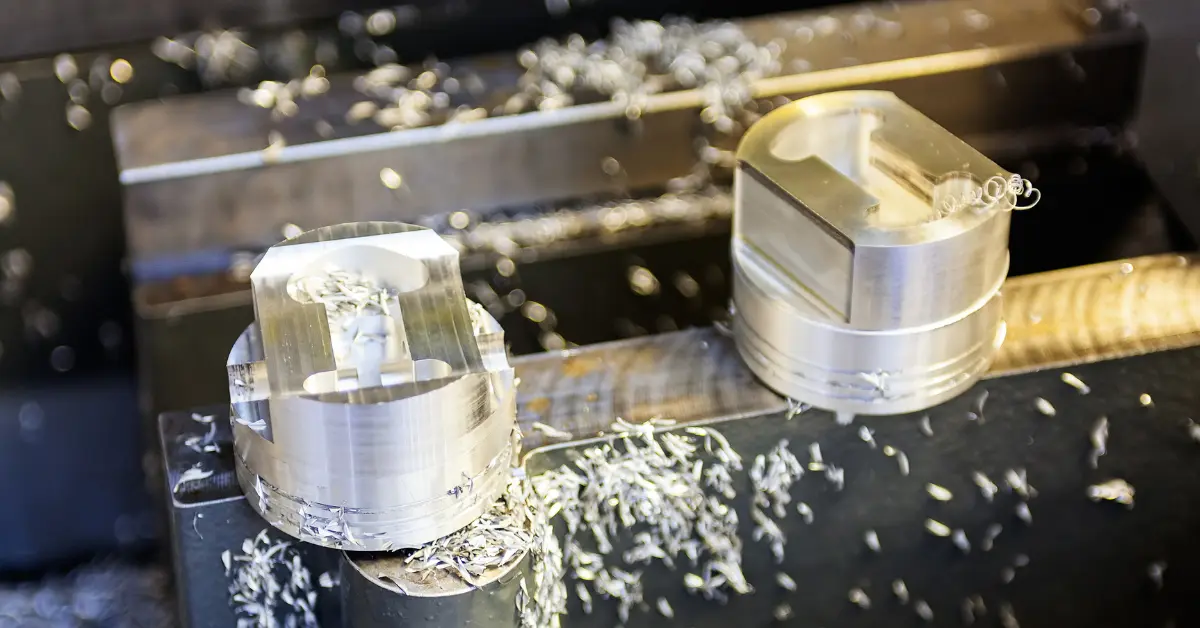

Speed & Precision: The Core of Agile Product Development

Rapid iteration: Aluminum’s fast machining speeds enable design validation in days, not weeks—critical for hardware startups racing to secure funding or market validation.

Tight tolerance mastery: ±0.01mm precision ensures parts function flawlessly from the first prototype, eliminating costly rework and certification delays.

Complex geometries, simplified: Our 5-axis CNC capabilities handle intricate designs in a single setup, slashing lead times by 30% vs. traditional multi-step processes.

Honyo Prototype: Precision Engineered for Your Success

✅ Online Instant Quote: Our AI-powered platform analyzes your CAD file in seconds, delivering accurate pricing and DFMA feedback instantly—no waiting, no guesswork.

✅ 3-Day Prototyping Turnaround: Leverage Shenzhen’s agile supply chain to receive precision-machined parts in as little as 72 hours, keeping your product development cycle on track.

✅ End-to-End Digital Workflow: From CAD upload to delivery, our integrated system ensures seamless collaboration with real-time updates and zero communication gaps.

✅ Founder-Led Quality Commitment: Under Susan Leo’s vision, every part undergoes aerospace-grade QC checks—because your innovation deserves perfection.

“At Honyo, we don’t just machine aluminum—we engineer speed, precision, and confidence into every prototype. Let’s turn your vision into reality, faster.”

— Susan Leo, Founder

Honyo Capabilities & Technology

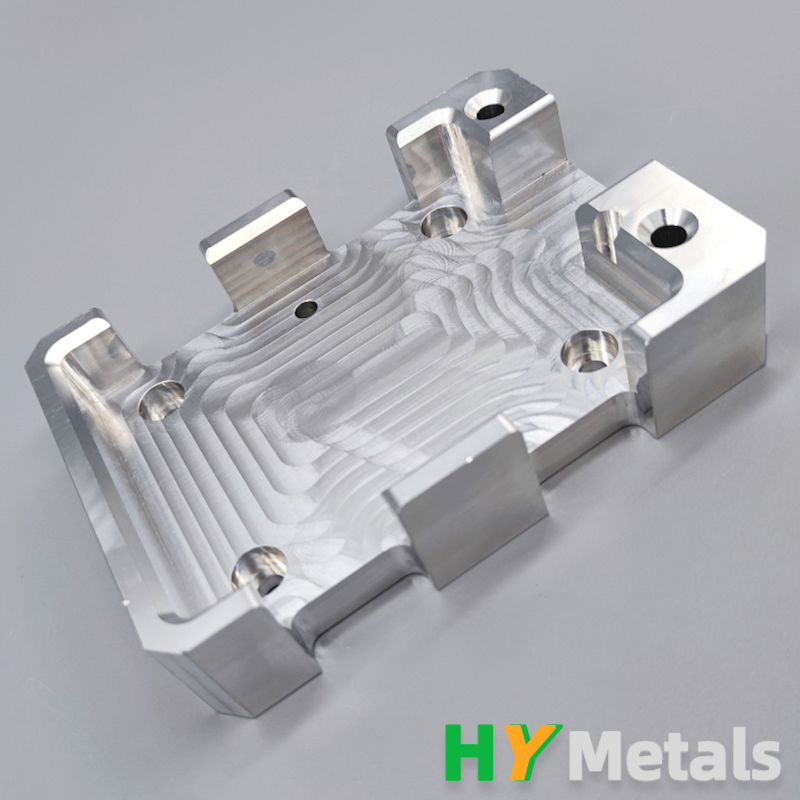

Precision Aluminum Machining Capabilities

At Honyo Prototype, we specialize in machining the finest aluminum alloys to deliver functional prototypes and end-use parts with unmatched precision and efficiency. Our capabilities are engineered to solve complex manufacturing challenges for hardware startups, product engineers, and procurement teams—combining cutting-edge technology, scalable production, and digital innovation.

Optimized for High-Performance Aluminum Alloys

Industry-leading expertise in 6061-T6 (versatile, corrosion-resistant), 7075 (aerospace-grade strength), and 2024 (structural applications)

Tailored machining parameters for each alloy to maximize efficiency, surface finish, and dimensional stability

Seamless handling of both solid billet and extruded profiles for cost-effective solutions—reducing lead times by up to 30% compared to standalone CNC machining

Advanced Multi-Axis CNC Technology

3/4/5-axis machining for complex geometries without re-fixturing, eliminating setup errors and reducing cycle times

Tight tolerances of ±0.01mm for critical functional components, validated through ISO 9001-certified metrology

Proprietary toolpath optimization to minimize thermal deformation in aluminum, ensuring consistent results for aerospace, medical, and automotive applications

Scalable Production Capacity

From single prototypes to 10,000+ production parts with zero compromise on quality or consistency

No minimum order quantities—ideal for hardware startups validating designs or iterating rapidly

Flexible scheduling with 48-hour expedited turnaround options for urgent projects, without sacrificing precision

ISO-Certified Quality Assurance

Rigorous in-process inspections and final QA reports with GD&T compliance for functional accuracy

Full material traceability and certifications (e.g., ASTM, ISO) for aerospace, medical, and automotive sectors

First-article inspection (FAI) documentation provided upon request—ensuring every part meets your exact specifications

Digital Innovation for Speed & Transparency

AI-powered instant quote platform delivering real-time pricing in seconds—no hidden fees or manual estimates

Cloud-based project tracking with live updates and milestone notifications, keeping you informed at every stage

Industry-leading 3–5 day prototype lead times (vs. 7–10 days industry average)—accelerating time-to-market for your innovations

Partner with Honyo Prototype to transform aluminum into precision-engineered solutions. From concept to delivery, we engineer efficiency.

Materials & Surface Finishes

Material Options & Finishes

Choosing the Right Aluminum Alloy for Precision Machining

Aluminum 6061: The industry-standard choice for most applications. Exceptional machinability, corrosion resistance, and cost efficiency. Ideal for structural components, aerospace parts, and consumer products.

Billet vs. Extruded Stock: For complex geometries requiring tight tolerances (+/-0.01mm), billet 6061-T6 ensures uniform material properties. For high-volume, simpler shapes, extruded profiles + post-machining reduce costs by up to 40% vs. solid billet machining.

Aluminum 7075: Highest-strength aluminum alloy (comparable to mild steel). Best for aerospace, defense, and high-stress applications where weight savings are critical. Requires advanced machining expertise due to hardness.

Other Material Options for Specialized Applications

Stainless Steel 304/316: Corrosion-resistant options for medical, marine, and food-grade applications.

Brass: Excellent electrical conductivity and aesthetic appeal for decorative or electrical components.

PEEK: High-performance polymer for extreme temperature and chemical resistance in medical/engineering parts.

Surface Finishes to Enhance Performance & Aesthetics

Anodizing (Type II/III): Type II for decorative color options; Type III (hard coat) for wear-resistant surfaces.

Powder Coating: Durable, scratch-resistant finishes in any color—ideal for consumer products.

Precision Polishing: Mirror-like finishes for optical or aesthetic-critical applications.

Bead Blasting: Uniform matte texture for professional, non-reflective surfaces.

Why Honyo Prototype Delivers Unmatched Value

🚀 AI-Powered Instant Quotes: Upload your CAD file and receive real-time pricing in seconds—no manual estimates, no hidden fees.

⏱️ Rapid Turnaround: Prototypes delivered in 3 days; production runs in 1-2 weeks—accelerate your time-to-market.

💡 Cost Optimization: Reduce machining costs by up to 30% through smart material selection and process efficiency.

🔍 Precision Engineering: Tight tolerances (+/-0.01mm) across 3/4/5-axis CNC machining for functional prototypes and end-use parts.

🌍 Global Material Sourcing: Premium aluminum (6061 starting at $2.00/lb) and other materials with volume discounts—no supply chain delays.

Pro Tip: For hardware startups, 6061 aluminum + extrusion + post-machining is the smartest balance of cost and precision for most projects. Our AI platform instantly calculates savings vs. full-billet machining—get your quote now.

From Quote to Part: Our Process

How It Works: From CAD to Part

Step 1: Upload CAD File

Seamless, secure upload—no technical expertise needed. Supported formats: STEP, STP, STL, IGES, and more.

Auto-validation ensures your file is manufacturable-ready, eliminating back-and-forth delays.

Step 2: Get Instant AI-Powered Quote

Real-time pricing generated by our AI engine: Analyze geometry, material (e.g., 6061-T6 aluminum at ~$2.10/lb), tolerances (±0.01mm), and complexity in seconds.

Transparent cost breakdown—no hidden fees. See exactly what you pay for machining time, setup, and materials.

Compare alloys & quantities instantly (6061, 7075, etc.) to optimize cost efficiency without manual quotes.

Step 3: DFM Analysis & Optimization

Proactive AI-driven feedback identifies manufacturability risks (e.g., thin walls, sharp corners) and suggests design tweaks to reduce costs by up to 30%.

Collaborative refinement—iterate on your design via our platform with engineering experts, ensuring optimal functionality and cost savings.

Step 4: Precision Production & Delivery

Shenzhen-based manufacturing with 3/4/5-axis CNC capabilities and strict quality control for ±0.01mm tolerances—perfect for functional prototypes and end-use parts.

Fast-track turnaround: Prototypes in 3–5 days, bulk orders in weeks. Real-time order tracking and proactive updates keep you informed every step of the way.

Why Honyo? Our AI-powered platform transforms complex machining into a streamlined, transparent process—so you get precision parts faster, with zero guesswork. From upload to delivery, we engineer efficiency into every step.

Start Your Project with Honyo

Start Your Project with Honyo: Precision Aluminum Machining, Simplified

From concept to completion, Honyo Prototype delivers unmatched precision and speed for aluminum parts—whether you need functional prototypes or end-use components. Our streamlined process ensures you get the best aluminum alloy for your application, optimized for cost, performance, and scalability.

Instant, AI-Powered Pricing in Seconds

Real-time quotes via our AI-driven platform—no hidden fees, no delays

Intelligent material recommendations (e.g., 6061-T6 for versatility, 7075 for high strength) and process optimization

Hybrid solutions like extrusion + precision machining reduce costs by up to 30% for high-volume projects

Fastest Turnaround for Prototypes & Production

24-hour quote turnaround, prototypes delivered in 3–5 days

3/4/5-axis CNC machining with ±0.01mm tolerances for complex geometries

Scalable production from single prototypes to 10,000+ units—no compromise on quality

Your Trusted Partner from Concept to Completion

Founder Susan Leo and our Shenzhen/Dongguan engineering team ready to collaborate

Contact us: [email protected] | +86 139 2843 8620

Visit our facilities for hands-on support and rapid prototyping

Ready to transform your design into reality?

Get Your Instant Quote Now →

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.