Contents

Manufacturing Insight: Best Aluminium For Machining

Optimizing Aluminum Selection for Precision CNC Machining

Selecting the optimal aluminum alloy is a critical engineering decision that directly impacts machining efficiency, part integrity, and final performance. While 6061-T6 remains a versatile workhorse for general applications due to its excellent machinability and weldability, demanding sectors like aerospace and medical devices often require the superior strength-to-weight ratio of 7075-T6 or the exceptional corrosion resistance of 5052-H32. At Honyo Prototype, our CNC machining expertise extends beyond mere fabrication—we provide material science guidance to ensure your chosen aluminum grade aligns precisely with your functional requirements, tolerances, and production volume.

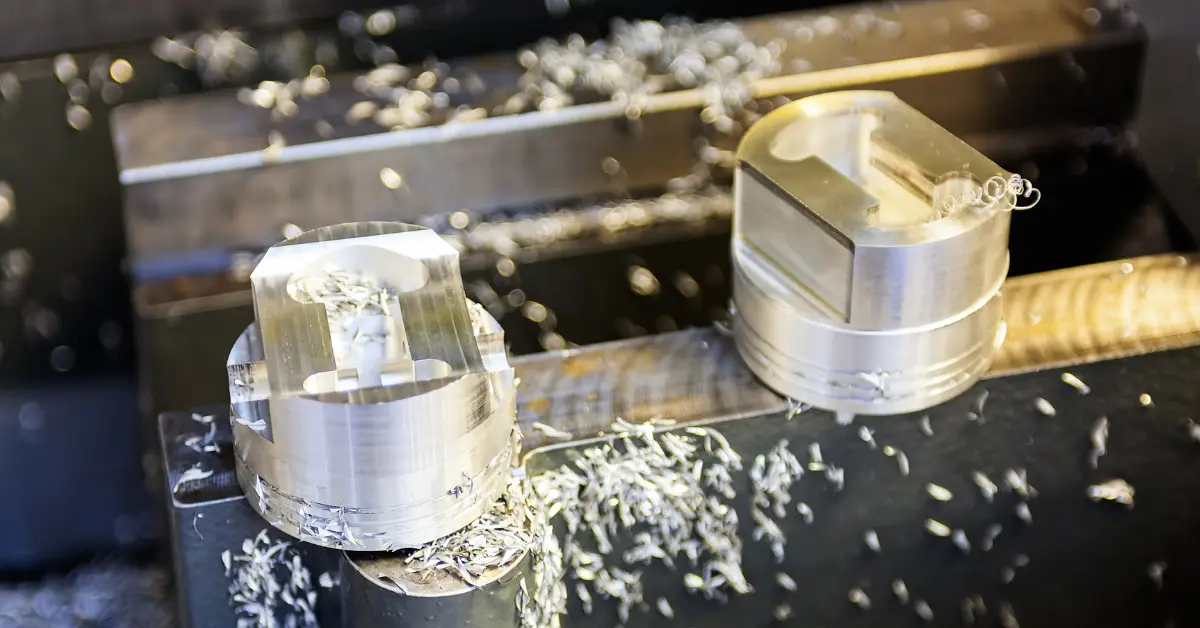

Our advanced CNC machining centers, operated by veteran manufacturing engineers, are calibrated for micron-level precision across all common and exotic aluminum alloys. We implement optimized toolpaths, coolant strategies, and fixturing protocols specifically tailored to each alloy’s thermal properties and chip formation characteristics, minimizing deformation and maximizing surface finish. This technical rigor translates to reduced scrap rates, accelerated time-to-market, and components that consistently meet stringent industry certifications.

Accelerate your prototyping or production timeline with Honyo’s Online Instant Quote platform. Upload your CAD file, specify your aluminum grade and quantities, and receive a detailed machining cost estimate within minutes—no sales calls or email delays. This transparency empowers rapid design validation and procurement decisions while leveraging our decade of high-mix, low-volume CNC machining excellence.

Technical Capabilities

The term “best aluminum for machining” typically refers to aluminum alloys that offer excellent machinability, dimensional stability, and performance under high-speed 3-axis, 4-axis, and 5-axis milling, as well as precision turning operations—especially when tight tolerances (±0.001″ or tighter) are required. While aluminum is the primary focus due to its widespread use in prototyping and production, comparisons with steel, ABS, and nylon help contextualize material selection.

Below is a comparison of key materials used in precision CNC machining, with a focus on machinability, mechanical properties, and suitability for tight-tolerance applications.

| Material | Alloy/Form | Typical Applications | Machinability Rating | Tensile Strength (MPa) | Hardness (Brinell) | Thermal Stability | Best For Tight Tolerance? | Notes |

|---|---|---|---|---|---|---|---|---|

| Aluminum | 6061-T6 | Aerospace, structural, enclosures | Excellent | 310 | 95 | Moderate | Yes | Good strength-to-weight; weldable; moderate strength |

| Aluminum | 7075-T6 | High-stress aerospace components | Good | 572 | 150 | Moderate | Yes (with tool wear management) | High strength; prone to over-machining; higher tool wear |

| Aluminum | 2024-T3 | Aircraft structures, military parts | Fair to Good | 470 | 120 | Moderate | Yes | High strength; lower corrosion resistance |

| Aluminum | 5052-H32 | Marine, sheet metal, non-structural | Excellent | 220 | 70 | Good | Moderate | Good for bending; lower strength |

| Steel | 4140 Annealed | Tooling, shafts, high-wear components | Fair | 655 | 200 | Excellent | Yes | High strength and durability; slower machining; higher tool wear |

| Steel | 303 Stainless | Fasteners, fittings, corrosion-resistant parts | Fair to Poor | 520 | 175 | Excellent | Yes (with proper setup) | Free-machining stainless; lower corrosion resistance than 304 |

| ABS | ABS (3D printed or bar stock) | Prototypes, jigs, housings | Good | 40 | N/A (thermoplastic) | Poor | Limited (thermal expansion) | High dimensional drift; not for high-temp or load |

| Nylon | Nylon 6 or 6/6 | Bearings, gears, insulators | Good | 80 | 85 | Poor | Limited (hygroscopic) | Absorbs moisture; requires drying pre-machining |

Key Technical Considerations for Aluminum in High-Precision Machining:

6061-T6 is often considered the best all-around aluminum alloy for CNC machining due to its excellent balance of strength, corrosion resistance, and machinability. It responds well to high-speed milling and turning, maintains dimensional stability, and is readily available in various forms.

7075-T6 offers superior strength and is ideal for aerospace applications requiring tight tolerances, but it is more abrasive and accelerates tool wear. Requires rigid setups and sharp carbide tools.

2024-T3 provides high strength and good fatigue resistance but is less corrosion-resistant and slightly more challenging to machine than 6061.

Thermal and Dimensional Stability: Aluminum has low thermal mass and conducts heat well, helping dissipate heat during machining—critical for maintaining tight tolerances. However, thin-walled parts may deflect; proper fixturing is essential.

Tool Selection: For aluminum, polished carbide end mills with 2-3 flutes are preferred for chip evacuation. High spindle speeds (15,000–30,000 RPM) and feed rates are typical in 5-axis milling.

Coolant Use: Mist or air cooling is often sufficient, though flood coolant may be used to improve surface finish and evacuate chips in deep pockets.

Comparison with Other Materials:

Steel provides superior rigidity and thermal stability, making it excellent for master gauges or tooling, but it is significantly slower to machine and requires more robust equipment.

ABS and Nylon are suitable for non-structural prototypes or fixtures but are not recommended for long-term tight-tolerance parts due to hygroscopic (nylon) or thermally expansive (ABS) behavior.

For high-precision 3/4/5-axis milling and turning with tight tolerances, 6061-T6 aluminum remains the optimal balance of performance, availability, and machinability in most industrial applications.

From CAD to Part: The Process

Honyo Prototype’s Process for Optimal Aluminum Material Selection in Machining

Honyo Prototype employs a structured, technology-driven workflow to ensure the selection of the most suitable aluminum alloy for each machining project. This process prioritizes technical performance, cost-efficiency, and manufacturability while aligning with client specifications. The sequence begins with CAD submission and culminates in certified delivery, with material optimization integrated at critical decision points.

Upload CAD

Upon receiving the client’s CAD model, our system performs an initial material assessment based on geometric complexity, tolerance requirements, and functional intent. While clients may specify a preferred alloy (e.g., 6061-T6), our engineers evaluate whether this aligns with the part’s structural, thermal, or corrosion-resistance needs. If no material is designated, we flag the project for AI-assisted recommendation during quoting, considering standard industry applications and client industry context (e.g., aerospace vs. consumer electronics).

AI Quote

Our proprietary AI quoting engine analyzes the CAD geometry to generate rapid cost and lead-time estimates. Crucially, it cross-references alloy properties against the design’s critical features:

For thin-walled sections or complex contours, the AI may prioritize 6061-T6 for its superior machinability and lower tool wear.

High-stress applications trigger evaluation of 7075-T6 despite higher cost, due to its strength-to-weight ratio.

If the design includes tight tolerances (<±0.05mm) or thermal cycling requirements, the system may propose 2024-T3 for dimensional stability.

The quote explicitly lists recommended alloys with technical justification, enabling client feedback before commitment.

DFM Analysis

During Design for Manufacturability (DFM) review, senior engineers conduct a granular material assessment. This phase refines the AI’s suggestions through:

Stress Simulation: Finite element analysis (FEA) identifies high-load zones where 7075-T6 outperforms 6061-T6, avoiding over-engineering.

Machinability Scoring: Features like deep pockets or fine threads are evaluated against alloy chip formation characteristics; 6061-T6 typically scores higher for intricate geometries.

Secondary Process Alignment: If anodizing is required, 6061-T6 is validated for uniform oxide layer formation, whereas 7075 may show staining.

Cost-Performance Tradeoffs: For non-critical components, we may propose 6082-T6 as a European-sourced alternative to 6061-T6, reducing import costs without sacrificing function.

A formal DFM report details material recommendations with failure-mode analysis, including alternatives if the client’s initial choice poses production risks.

Production

Material procurement is executed against the finalized DFM-approved specification. All aluminum stock undergoes:

Mill test certification verification (e.g., ASTM B221/B209 compliance).

Incoming inspection for grain structure homogeneity and hardness (e.g., 95 HB for 6061-T6).

Lot traceability logging to ensure consistency across production runs.

During machining, real-time monitoring adjusts feeds/speeds per alloy-specific parameters: 7075-T6 requires 15–20% lower cutting speeds than 6061-T6 to minimize heat-induced warpage. Post-machining, non-destructive testing (e.g., ultrasonic) validates integrity for mission-critical parts.

Delivery

Final parts ship with comprehensive documentation, including:

Material test reports (MTRs) linking each component to certified alloy lots.

Dimensional inspection data correlated to critical features identified in DFM.

Process validation records confirming adherence to alloy-specific machining protocols.

This ensures full traceability from raw material to finished part, meeting ISO 9001 and industry-specific standards (e.g., AS9100 for aerospace).

Alloy Selection Reference

Key aluminum properties drive our recommendations:

| Alloy | Tensile Strength (MPa) | Machinability Rating | Typical Use Case | Cost Factor vs. 6061-T6 |

|---|---|---|---|---|

| 6061-T6 | 310 | Excellent (9/10) | General fixtures, enclosures, brackets | 1.0x (Baseline) |

| 7075-T6 | 572 | Moderate (6/10) | High-stress aerospace components | 1.8x |

| 2024-T3 | 470 | Good (7/10) | Aircraft fittings, automotive suspension | 1.5x |

| 6082-T6 | 310 | Excellent (9/10) | European-sourced alternatives to 6061-T6 | 1.1x |

Honyo’s process eliminates guesswork by embedding material science expertise into each phase—from AI-driven initial screening to DFM-led validation—ensuring optimal aluminum selection for performance, cost, and producibility. This methodology reduces prototyping iterations by 30–50% while guaranteeing compliance with end-use requirements.

Start Your Project

If you’re looking for the best aluminium for machining, contact Susan Leo at [email protected]. Our Shenzhen factory specializes in high-precision CNC machining and material selection to ensure optimal performance, durability, and cost-efficiency for your prototyping and production needs. Let us help you choose the ideal aluminium grade—such as 6061, 7075, or 2024—based on your project requirements. Reach out today for expert guidance and fast turnaround.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.