Introduction: Navigating the Global Market for best 5 axis cnc

Navigating the complexities of sourcing the best 5-axis CNC machines can be a daunting task for international B2B buyers, particularly in diverse markets such as Africa, South America, the Middle East, and Europe. With an increasing demand for precision manufacturing, businesses are challenged not only by the variety of machine types but also by the specific applications and technologies that can optimize their production processes. This guide aims to demystify the global market for 5-axis CNC machining centers, providing insights into the various types available, their applications across industries, and crucial factors to consider during the supplier vetting process.

From understanding the differences between 3+2 and full simultaneous machining to evaluating cost implications and return on investment, this comprehensive resource equips buyers with the knowledge necessary to make informed purchasing decisions. Additionally, we delve into the latest advancements in technology that can enhance productivity and reduce operational costs. By addressing key challenges and presenting actionable insights, this guide empowers businesses to select the right 5-axis CNC solutions tailored to their unique operational needs, ultimately fostering growth and competitiveness in the global marketplace.

Understanding best 5 axis cnc Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 3+2 Machining Center | Utilizes a three-axis system with a tilting rotary table | Aerospace, automotive components | Pros: Cost-effective, simple setup. Cons: Limited to locked axes during machining. |

| Full Simultaneous 5-Axis | Allows dynamic control of all five axes simultaneously | Complex aerospace parts, molds, and dies | Pros: Greater flexibility, improved surface finish. Cons: Higher initial investment. |

| Gantry-style 5-Axis | Features a large frame, often used for heavy workpieces | Large parts in aerospace and energy sectors | Pros: Handles heavy materials, stable machining. Cons: Requires larger floor space. |

| Horizontal Machining Center | Horizontal spindle orientation for better chip removal | High-volume production, automotive parts | Pros: Efficient for bulk machining, better tool life. Cons: More complex programming needed. |

| Compact 5-Axis Machines | Smaller footprint, ideal for limited space environments | Prototyping, small batch production | Pros: Space-saving, versatile for various tasks. Cons: Limited capabilities for larger parts. |

What are the Characteristics of 3+2 Machining Centers?

3+2 machining centers are characterized by their ability to position a workpiece in multiple orientations using a three-axis system combined with a tilting rotary table. This configuration is particularly suitable for small to medium-sized parts and provides a cost-effective entry point into five-axis machining. B2B buyers should consider the complexity of their parts and the volume of production when evaluating this option, as it is ideal for applications that do not require full simultaneous motion.

How Does Full Simultaneous 5-Axis Machining Differ?

Full simultaneous 5-axis machining centers provide dynamic control over all five axes, enabling intricate designs and complex geometries to be machined in a single setup. This type is best suited for high-precision industries such as aerospace and medical manufacturing. B2B buyers should weigh the benefits of improved surface finishes and reduced cycle times against the higher initial investment and potential complexity in programming and operation.

What Advantages Do Gantry-style 5-Axis Machines Offer?

Gantry-style 5-axis machines are designed with a robust frame that can accommodate large and heavy workpieces, making them ideal for the aerospace and energy sectors. Their stability during machining translates into high precision and reduced vibration. Buyers in industries that require machining of large components should consider the space requirements and the machine’s capability to handle specific weights and dimensions.

Why Choose Horizontal Machining Centers for 5-Axis Machining?

Horizontal machining centers with 5-axis capabilities are distinguished by their horizontal spindle orientation, which facilitates efficient chip removal and is particularly beneficial for high-volume production. These machines are widely used in the automotive industry for producing complex components. B2B buyers should consider their production needs, as while these machines offer excellent efficiency, they may require more complex programming and setup.

What are the Benefits of Compact 5-Axis Machines?

Compact 5-axis machines are designed for environments with limited space, providing versatile machining capabilities for prototyping and small batch production. They are ideal for job shops looking to expand their services without a significant increase in floor space. Buyers should evaluate the machine’s specifications to ensure it meets their production needs while considering the trade-off in capacity and versatility for larger projects.

Key Industrial Applications of best 5 axis cnc

| Industry/Sector | Specific Application of best 5 axis cnc | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Machining complex aircraft components | Reduces setup time and increases precision | Focus on machine accuracy, rigidity, and weight capacity. |

| Medical Devices | Manufacturing orthopedic implants | Enables intricate designs and rapid prototyping | Look for biocompatibility and precision capabilities. |

| Automotive | Production of engine components | Enhances efficiency and reduces material waste | Evaluate machine versatility and tooling options. |

| Mold and Die Making | Creating molds for various industries | Facilitates faster production and improved surface finish | Assess the machine’s ability to handle complex geometries. |

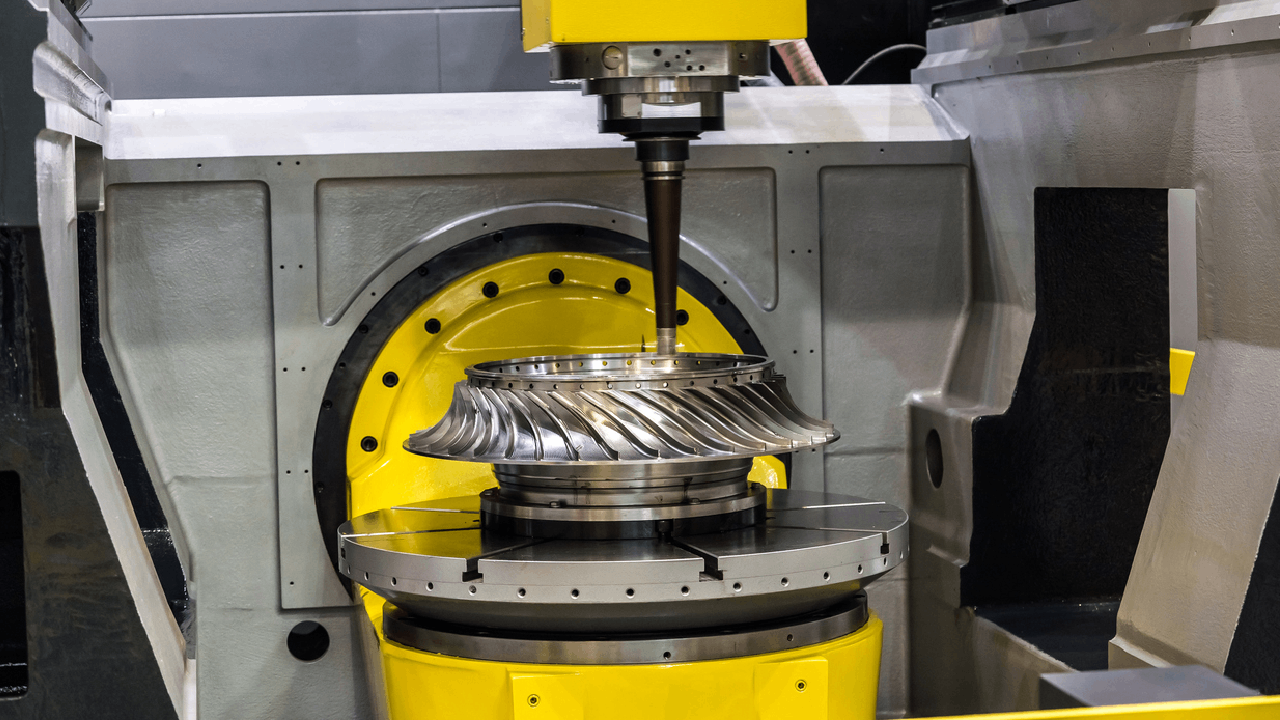

| Energy Sector | Fabrication of turbine components | Supports high precision and reduces lead times | Prioritize machines with robust control systems and high torque. |

How is the Best 5 Axis CNC Used in Aerospace Applications?

In the aerospace sector, best 5 axis CNC machines are essential for machining complex components like turbine blades, brackets, and housings. These machines allow manufacturers to access all five sides of a workpiece in a single setup, significantly reducing setup time and enhancing precision. International buyers, especially from regions like Europe and the Middle East, should prioritize machines with high accuracy and rigidity to meet stringent aerospace standards.

What Role Does 5 Axis CNC Play in Medical Device Manufacturing?

5 axis CNC technology is crucial in producing orthopedic implants, such as hip and knee replacements, that require intricate designs and high precision. This capability allows manufacturers to rapidly prototype and produce complex geometries that are critical for patient-specific solutions. Buyers from Africa and South America should consider sourcing machines that ensure biocompatibility and meet regulatory requirements for medical devices.

How Does 5 Axis CNC Enhance Automotive Component Production?

In the automotive industry, best 5 axis CNC machines are utilized for producing engine components, transmission parts, and intricate assemblies. These machines improve efficiency by allowing manufacturers to reduce material waste and increase machining speed. For international buyers, especially in emerging markets, evaluating the versatility of the machine and the availability of compatible tooling is crucial for optimizing production processes.

Why is 5 Axis CNC Important for Mold and Die Making?

The mold and die making industry benefits significantly from 5 axis CNC technology, which enables the creation of complex molds with superior surface finishes. This technology allows manufacturers to produce intricate shapes that would be challenging with traditional methods, thus accelerating production cycles. Buyers should assess machines based on their ability to handle complex geometries and their overall machining capabilities to ensure they meet industry demands.

What Advantages Does 5 Axis CNC Provide in the Energy Sector?

In the energy sector, particularly in the fabrication of turbine components, best 5 axis CNC machines are vital for achieving the high precision required for efficient energy production. These machines support complex cutting paths and reduce lead times, which is critical in a competitive market. Buyers in this sector should prioritize machines with robust control systems and high torque to handle the demanding requirements of turbine component manufacturing.

3 Common User Pain Points for ‘best 5 axis cnc’ & Their Solutions

Scenario 1: Complex Part Machining Challenges

The Problem: As B2B buyers in the manufacturing sector, many companies find themselves grappling with the increasing complexity of parts they need to produce. This complexity can lead to multiple setups, extended machining times, and higher chances of error, particularly when using traditional three-axis machines. For instance, a buyer from an aerospace component manufacturer may need to create intricate geometries that require access to five sides of a workpiece. This can not only slow down production but also inflate costs due to wasted material and labor hours.

The Solution: To address these challenges, investing in a high-quality five-axis CNC machine is critical. Buyers should look for machines with a “done-in-one” capability, allowing them to machine complex parts in a single setup. When sourcing these machines, it’s essential to evaluate models that offer robust software support, which can simplify programming and setup. For example, consider machines that integrate CAD/CAM systems, enabling seamless transitions from design to production. Additionally, prioritize machines that provide flexibility in tooling and allow for shorter tools to minimize vibration, thus enhancing machining accuracy and surface finish.

Scenario 2: High Initial Investment Concerns

The Problem: Another pain point for B2B buyers, especially in regions like Africa and South America, is the significant initial investment required for a top-tier five-axis CNC machine. Many businesses are cautious about allocating substantial capital to equipment that may not yield immediate returns. This concern is particularly pronounced for smaller shops that might fear being outpaced by larger competitors investing in advanced technologies.

The Solution: To alleviate the concern regarding high initial costs, buyers should consider financing options and leasing arrangements that spread out payments over time. It’s also beneficial to conduct a thorough cost-benefit analysis, taking into account the machine’s potential to reduce setup times and increase output quality. When negotiating with suppliers, inquire about trade-in programs for older machines, which can offset the cost of new equipment. Furthermore, explore brands known for their reliability and low maintenance costs, as investing in machines that require less downtime can lead to better long-term financial outcomes.

Scenario 3: Skills Gap in Operating Advanced Machines

The Problem: Many B2B buyers encounter the issue of a skills gap when integrating five-axis CNC technology into their operations. Workers may be accustomed to operating three-axis machines and lack the necessary training to effectively utilize more complex five-axis systems. This knowledge gap can lead to underutilization of the machine’s capabilities, inefficient operations, and ultimately, a failure to realize the expected ROI.

The Solution: To bridge this skills gap, companies should invest in comprehensive training programs for their workforce. Partnering with machine manufacturers or specialized training organizations can provide hands-on training tailored to the specific five-axis models being employed. Additionally, implementing a mentorship program where experienced operators guide newer employees can foster a culture of continuous learning. Buyers should also consider machines that come equipped with user-friendly interfaces and intuitive controls, which can make the transition smoother for operators. Investing in ongoing training not only enhances machine utilization but also boosts employee morale and retention, as workers feel more competent and valued in their roles.

Strategic Material Selection Guide for best 5 axis cnc

What Are the Key Materials for Best 5 Axis CNC Machining?

When selecting materials for five-axis CNC machining, it’s crucial to consider their properties, advantages, and limitations. The choice of material can significantly impact the performance, durability, and cost-effectiveness of the final product. Below, we analyze three common materials used in five-axis CNC machining: aluminum, titanium, and stainless steel.

How Does Aluminum Perform in 5 Axis CNC Machining?

Aluminum is a popular choice in five-axis CNC machining due to its lightweight nature and excellent machinability. Key properties include a low density, good thermal conductivity, and resistance to corrosion, making it suitable for a variety of applications.

Pros: Aluminum is relatively inexpensive and easy to machine, which allows for faster production times. Its lightweight nature makes it ideal for applications in aerospace and automotive industries, where weight reduction is critical.

Cons: However, aluminum may not be suitable for high-stress applications due to its lower strength compared to other metals. Additionally, it can be prone to scratching and denting, which may affect the aesthetic quality of the final product.

Impact on Application: Aluminum is compatible with various media, including air and water, but may not perform well in high-temperature environments.

International Considerations: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM B221 for aluminum extrusions and DIN 1725 for aluminum alloys.

What Are the Benefits of Titanium in 5 Axis CNC Machining?

Titanium is known for its exceptional strength-to-weight ratio and excellent corrosion resistance. It is often used in specialized applications, such as aerospace, medical implants, and high-performance automotive components.

Pros: The primary advantage of titanium is its strength, which allows it to withstand high stresses and temperatures. Its biocompatibility makes it suitable for medical applications.

Cons: On the downside, titanium is more challenging to machine than aluminum and stainless steel, leading to higher manufacturing costs and longer production times. It also requires specialized tooling and cutting fluids to manage heat generation during machining.

Impact on Application: Titanium is compatible with various media, including aggressive chemicals, making it suitable for harsh environments.

International Considerations: B2B buyers should be aware of compliance with standards like ASTM F136 for titanium alloys used in medical devices and ISO 5832 for surgical implants.

How Does Stainless Steel Compare in 5 Axis CNC Machining?

Stainless steel is renowned for its durability and resistance to corrosion, making it a versatile choice for various applications, including food processing, medical devices, and automotive components.

Pros: Its high strength and toughness make stainless steel suitable for demanding environments. It also offers excellent aesthetic qualities, which can be important for consumer-facing products.

Cons: However, stainless steel is generally more expensive than aluminum and can be more difficult to machine, leading to longer lead times and higher costs.

Impact on Application: Stainless steel is compatible with a wide range of media, including water, steam, and various chemicals, making it a reliable choice for many industries.

International Considerations: Buyers should consider compliance with standards such as ASTM A240 for stainless steel sheets and plates and ISO 9001 for quality management systems.

Summary Table of Material Selection for Best 5 Axis CNC

| Material | Typical Use Case for best 5 axis cnc | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace components, automotive parts | Lightweight and easy to machine | Lower strength, prone to scratches | Low |

| Titanium | Aerospace, medical implants | Exceptional strength and corrosion resistance | Difficult to machine, higher cost | High |

| Stainless Steel | Food processing, medical devices | Durable and corrosion-resistant | More expensive, harder to machine | Med |

This material selection guide provides essential insights for international B2B buyers, enabling informed decisions that align with their specific application requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for best 5 axis cnc

What Are the Main Stages of Manufacturing a High-Quality 5-Axis CNC Machine?

When considering the purchase of a 5-axis CNC machine, understanding the manufacturing process is crucial for B2B buyers. The production of these sophisticated machines involves several key stages: material preparation, forming, assembly, and finishing. Each stage is essential to ensure the machine’s performance, precision, and durability.

How Is Material Prepared for 5-Axis CNC Machines?

Material preparation is the first step in the manufacturing process. High-quality materials, typically aluminum alloys or high-strength steels, are selected based on the machine’s intended application. The chosen materials undergo rigorous quality checks to ensure they meet industry standards.

After selection, the materials are cut to size using precision saws or lasers. This step is vital as it sets the foundation for the machine’s components. Each piece must adhere to exact specifications to maintain the overall integrity of the machine. The prepared materials then move on to the forming stage.

What Techniques Are Used in Forming 5-Axis CNC Machines?

Forming involves shaping the raw materials into the various components of the CNC machine. Techniques such as milling, turning, and grinding are commonly employed. These processes are typically carried out on high-precision CNC machines to ensure accuracy.

During this stage, components such as the base, columns, and gantry are produced. Advanced techniques like additive manufacturing may also be utilized for creating complex geometries that are difficult to achieve with traditional methods. The focus during forming is on achieving tight tolerances, which are critical for the machine’s performance.

How Is the Assembly Process Conducted for 5-Axis CNC Machines?

The assembly process is where all the individual components come together to form the complete machine. This stage requires skilled technicians who follow detailed assembly procedures. Each component must be carefully aligned and secured to ensure optimal performance.

Quality checks are integrated throughout the assembly process. For instance, after the initial assembly, technicians conduct a preliminary alignment check. This ensures that all moving parts are properly calibrated before the machine undergoes further testing.

What Finishing Techniques Are Employed for 5-Axis CNC Machines?

Finishing techniques enhance the machine’s aesthetics and protect it from environmental factors. Common finishing processes include anodizing, powder coating, and painting. These treatments not only improve the machine’s appearance but also increase its resistance to corrosion and wear.

Additionally, final inspections are conducted to ensure that the finishing meets quality standards. This includes checking for surface defects and ensuring that all components function smoothly. Once the finishing is complete, the machine is ready for testing.

What Quality Assurance Practices Are Essential for 5-Axis CNC Machines?

Quality assurance (QA) is a critical aspect of the manufacturing process for 5-axis CNC machines. Implementing rigorous QA practices ensures that the machines meet international standards and perform reliably.

Which International Standards Should B2B Buyers Consider?

International standards such as ISO 9001 are crucial for ensuring quality management systems are in place. This standard focuses on continuous improvement and customer satisfaction, which are vital in a competitive market.

Additionally, industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for oil and gas applications may also be relevant. These certifications demonstrate compliance with safety and quality standards, making them essential considerations for international buyers.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process. These typically include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): During manufacturing, components are regularly checked for accuracy and precision to prevent defects.

- Final Quality Control (FQC): Once the machine is fully assembled, a comprehensive testing phase is conducted, including functionality tests and performance assessments.

Each checkpoint plays a vital role in identifying and rectifying issues before the machine reaches the buyer.

What Common Testing Methods Are Used to Ensure Quality?

Various testing methods are employed to guarantee the quality of 5-axis CNC machines. These include:

- Dimensional Inspection: Utilizes tools like calipers and coordinate measuring machines (CMM) to verify that components meet specified dimensions.

- Functional Testing: Assesses the machine’s operational capabilities, ensuring it performs as intended under various conditions.

- Vibration Analysis: Measures the machine’s stability and can identify potential issues that may affect performance.

These testing methods help in delivering a reliable product to B2B buyers.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying the quality control processes of suppliers is essential. Here are some actionable steps:

What Are the Best Practices for Conducting Supplier Audits?

- On-Site Audits: Conducting on-site audits allows buyers to assess the manufacturing facilities, equipment, and quality control practices firsthand.

- Documentation Review: Requesting access to quality control documentation, including inspection reports and certification records, can provide insights into the supplier’s commitment to quality.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control processes.

What Are the Key QC/CERT Nuances for International Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality certification.

- Regulatory Compliance: Different regions may have unique regulatory requirements. For instance, CE certification is mandatory for products sold in the European Union, while UL certification is vital for the North American market.

- Cultural Considerations: Understanding cultural differences in business practices can influence how quality assurance is perceived and implemented in different regions.

By being informed and diligent, B2B buyers can ensure they select suppliers that adhere to high-quality standards, ultimately leading to better investment returns and product reliability in the long term.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘best 5 axis cnc’

To assist B2B buyers in procuring the best 5-axis CNC machines, this guide provides a practical checklist. By following these steps, you can ensure that your investment aligns with your operational needs and helps drive efficiency in your manufacturing processes.

Step 1: Define Your Technical Specifications

Understanding the specific requirements of your projects is the foundation of your sourcing process. Consider factors such as the size and weight of the parts you will be machining, the complexity of the designs, and the desired accuracy levels. This clarity will help you identify machine features that are crucial for your operations, such as the type of spindle, table size, and software capabilities.

Step 2: Research Different Machine Configurations

Explore the various configurations available in 5-axis CNC machines, such as 3+2 configurations versus full simultaneous machining. Each configuration has its advantages depending on your machining needs. For example, 3+2 machines can be more cost-effective for simpler tasks, while full simultaneous machines offer greater flexibility for complex geometries.

Step 3: Evaluate Potential Suppliers

Before making a purchase, thoroughly vet potential suppliers to ensure they meet your quality and service expectations. Request detailed company profiles, customer references, and case studies that demonstrate their expertise and reliability in delivering 5-axis CNC solutions. This step can help mitigate risks associated with performance and support.

Step 4: Verify Certifications and Compliance

Check that the suppliers possess the necessary certifications and adhere to international standards. Certifications such as ISO 9001 can indicate a commitment to quality management systems, while compliance with safety and environmental regulations is crucial for sustainable operations. This verification process helps ensure that the machines you purchase are of high quality and safe to operate.

Step 5: Request Demonstrations or Trials

Whenever possible, request live demonstrations or trial periods for the machines you are considering. This will allow you to assess the machine’s capabilities firsthand and evaluate its ease of use, programming features, and overall performance. Observing the machine in action can provide valuable insights that specifications alone cannot convey.

Step 6: Analyze Total Cost of Ownership

Look beyond the initial purchase price and consider the total cost of ownership (TCO), which includes maintenance, tooling, software, and training expenses. Understanding the long-term costs associated with a machine can significantly impact your return on investment. Additionally, inquire about warranty terms and after-sales support to factor these into your financial analysis.

Step 7: Negotiate Terms and Conditions

Once you’ve identified a preferred supplier and machine, engage in negotiations to secure the best possible terms. Discuss payment options, delivery timelines, and installation support. Clear communication on these aspects can prevent misunderstandings and ensure a smoother procurement process.

By following these steps, B2B buyers can confidently navigate the sourcing process for 5-axis CNC machines, ensuring they make informed decisions that align with their manufacturing goals.

Comprehensive Cost and Pricing Analysis for best 5 axis cnc Sourcing

What Are the Key Cost Components in Sourcing 5 Axis CNC Machines?

When sourcing 5 axis CNC machines, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include:

-

Materials: The cost of raw materials, such as structural steel and high-performance alloys, can significantly impact the overall price. Higher quality materials typically translate to increased durability and precision, which are essential for complex machining tasks.

-

Labor: Skilled labor is required for both manufacturing and programming CNC machines. Labor costs can vary based on geographical location and the level of expertise needed, with higher wages in regions like Europe compared to emerging markets.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help reduce overhead, thereby lowering the overall price.

-

Tooling: The right tooling is essential for optimizing machining performance. Costs can vary widely based on the complexity and specificity of the tools required, including custom tooling solutions.

-

Quality Control (QC): Implementing robust QC measures is vital to ensure the machines meet specified tolerances and performance standards. This can add to the initial costs but is essential for maintaining quality over the machine’s lifespan.

-

Logistics: Shipping costs can be a significant factor, especially for international buyers. Factors such as shipping distance, mode of transport, and customs duties will affect the total logistics cost.

-

Margin: Suppliers typically build a profit margin into their pricing. Understanding the competitive landscape can help buyers negotiate better terms.

How Do Price Influencers Affect 5 Axis CNC Machine Costs?

Several factors influence the pricing of 5 axis CNC machines:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for volume discounts, making it crucial for buyers to assess their needs carefully. Establishing a long-term relationship with suppliers can also lead to better pricing over time.

-

Specifications and Customization: Customization options can significantly affect the price. Machines tailored to specific applications or featuring advanced technologies will generally cost more. Buyers should evaluate their actual needs to avoid over-specifying.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications (such as ISO or CE) can influence costs. Machines made from high-grade materials with recognized certifications may command higher prices but often provide better performance and reliability.

-

Supplier Factors: Different suppliers have varying pricing strategies based on brand reputation, market position, and service offerings. Researching suppliers and comparing their offerings can yield better pricing options.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) is essential for cost management. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, impacting the total landed cost.

What Are the Best Negotiation and Cost-Efficiency Strategies for International Buyers?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, employing effective strategies can enhance cost-efficiency:

-

Negotiate Terms: Always negotiate payment terms, delivery schedules, and warranty conditions. A flexible approach can lead to significant savings and better cash flow management.

-

Consider Total Cost of Ownership (TCO): Beyond the initial purchase price, buyers should evaluate the TCO, which includes maintenance, operational costs, and potential downtime. A slightly higher upfront cost may be justified by lower long-term operational expenses.

-

Be Aware of Pricing Nuances: Different regions may have unique pricing structures influenced by local market conditions, currency fluctuations, and economic factors. Understanding these nuances can help buyers make informed decisions.

-

Engage Local Distributors: Partnering with local distributors can facilitate smoother transactions and potentially lower costs due to reduced shipping and handling fees.

-

Request Multiple Quotes: Always seek quotes from several suppliers to establish a competitive baseline. This practice not only helps in negotiation but also provides insights into market pricing trends.

Disclaimer on Indicative Prices

Pricing for 5 axis CNC machines can fluctuate based on a multitude of factors, including market demand, technological advancements, and geopolitical influences. Buyers should conduct thorough research and consult with multiple suppliers to obtain the most accurate and current pricing information tailored to their specific needs.

Alternatives Analysis: Comparing best 5 axis cnc With Other Solutions

Introduction to Alternatives in CNC Machining

In the rapidly evolving landscape of CNC machining, the need for efficiency, precision, and versatility has led to the development of various technologies. While the best five-axis CNC machines offer significant advantages for complex part fabrication, alternatives exist that may better suit specific operational needs or budget constraints. This analysis explores how the best five-axis CNC compares with two viable alternatives: three-axis CNC machining and hybrid manufacturing methods.

| Comparison Aspect | Best 5 Axis CNC | Alternative 1: 3-Axis CNC | Alternative 2: Hybrid Manufacturing |

|---|---|---|---|

| Performance | High precision and complex geometries | Good for simple shapes and large volumes | Versatile, combining additive and subtractive processes |

| Cost | Higher initial investment and operational costs | Lower upfront costs and operational efficiency | Variable costs depending on materials and technology used |

| Ease of Implementation | Requires skilled operators and training | Easier to set up and operate, widely understood | Complex integration of technologies may require specialized training |

| Maintenance | Higher maintenance due to advanced technology | Generally lower maintenance needs | Maintenance varies widely based on technology used |

| Best Use Case | Aerospace, medical, and intricate component manufacturing | High-volume production of simple parts | Rapid prototyping and complex assemblies |

Detailed Breakdown of Alternatives

What Are the Pros and Cons of Using 3-Axis CNC Machining?

Three-axis CNC machining is a well-established method that excels in producing simple components with high efficiency. The primary advantage of this method is its cost-effectiveness; it requires a lower initial investment and is easier to operate, making it suitable for businesses just starting with CNC technology. However, its limitations become apparent when dealing with complex geometries or intricate details, as multiple setups are often required to achieve the desired outcomes. This can lead to increased production times and a higher likelihood of errors during part repositioning.

How Does Hybrid Manufacturing Compare?

Hybrid manufacturing combines both additive and subtractive processes, allowing for enhanced versatility in production. This method is particularly advantageous for rapid prototyping and creating complex assemblies that benefit from both 3D printing and CNC machining. One of the key strengths of hybrid systems is their ability to reduce material waste and improve production efficiency. However, the integration of these technologies can be complex and may require specialized training for operators, which could represent a significant barrier for some businesses. Additionally, the cost of hybrid systems can vary widely based on the specific technologies employed.

Conclusion: How Can B2B Buyers Choose the Right Solution?

When selecting the appropriate machining solution, B2B buyers should consider their specific operational needs, production volume, and the complexity of parts they intend to manufacture. The best five-axis CNC machines provide unparalleled precision and efficiency for intricate designs but come with higher costs and maintenance demands. On the other hand, three-axis CNC machining offers simplicity and affordability, making it ideal for straightforward projects. Lastly, hybrid manufacturing represents a cutting-edge option for businesses looking to innovate and streamline their processes. By carefully assessing these factors, buyers can make informed decisions that align with their strategic goals and operational capabilities.

Essential Technical Properties and Trade Terminology for best 5 axis cnc

What Are the Key Technical Properties to Consider When Evaluating the Best 5 Axis CNC Machines?

When selecting a five-axis CNC machine, understanding its technical properties is crucial for ensuring it meets your operational needs. Here are some critical specifications to consider:

-

Material Grade and Construction

The material used in the machine’s construction significantly affects its durability, rigidity, and precision. Common materials include cast iron, steel, and aluminum alloys. A robust construction minimizes vibrations during machining, leading to better surface finishes and extended tool life. For B2B buyers, investing in machines made from high-grade materials can reduce maintenance costs and enhance productivity. -

Tolerance Levels

Tolerance refers to the permissible limit of variation in a physical dimension. In five-axis machining, tighter tolerances enable the production of intricate parts that require high precision, such as aerospace components or medical devices. Understanding the tolerance capabilities of a CNC machine is vital for manufacturers to ensure compliance with industry standards and customer specifications. -

Axis Configuration

Five-axis machines can have different configurations, such as a tilting table or articulating head. The choice of configuration affects the machine’s capability to handle complex geometries. For instance, a tilting-table machine is ideal for small to medium parts, while an articulating-head model is suited for larger components. This distinction is essential for B2B buyers to align their machine choice with the types of parts they manufacture. -

Spindle Speed and Power

The spindle speed (measured in RPM) and power (measured in horsepower) determine how quickly and effectively materials can be cut. High spindle speeds enable faster machining, while powerful spindles can handle tougher materials without stalling. Buyers should consider these factors in relation to their production volume and the materials they typically work with. -

Control Software and User Interface

Modern five-axis CNC machines come equipped with advanced control software that enhances usability and programming efficiency. A user-friendly interface can significantly reduce training time and operational errors. For B2B buyers, investing in machines with intuitive software can lead to faster adoption and improved workflow efficiency. -

Workpiece Capacity

The size and weight capacity of the machine are critical for determining what types of parts can be produced. Specifications such as table size and load capacity must align with the dimensions of the workpieces you intend to manufacture. For buyers, this means ensuring that the chosen machine can accommodate current and future production requirements.

What Are Common Trade Terms Related to Five-Axis CNC Machines?

Familiarity with industry jargon can enhance communication and negotiation with suppliers. Here are some common trade terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help B2B buyers identify reliable suppliers for components or machinery. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. Knowing the MOQ is essential for buyers to assess whether a supplier’s terms align with their purchasing needs, especially for custom parts or machinery. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. Crafting a well-defined RFQ can lead to more accurate quotes and better negotiations, ensuring buyers get the best value for their investment. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps B2B buyers understand their obligations regarding shipping, insurance, and delivery, which is crucial for cost management. -

Lead Time

Lead time is the period between placing an order and receiving the product. Understanding lead times is vital for buyers to plan their production schedules effectively and manage inventory levels. -

CNC (Computer Numerical Control)

CNC refers to the automated control of machining tools by means of a computer. This technology is essential for precision manufacturing, and understanding its capabilities can help buyers evaluate the efficiency and effectiveness of various machines.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when investing in five-axis CNC technology, ensuring they select machines that align with their operational goals and industry requirements.

Navigating Market Dynamics and Sourcing Trends in the best 5 axis cnc Sector

What Are the Key Market Trends Influencing the Best 5 Axis CNC Sector?

The global market for five-axis CNC machines is experiencing a transformative phase driven by technological advancements, increasing demand for precision engineering, and the need for efficiency in manufacturing processes. In regions like Africa, South America, the Middle East, and Europe, international B2B buyers are keenly observing these trends to enhance their operational capabilities. The rise of Industry 4.0 and the Internet of Things (IoT) has made smart manufacturing a reality, with five-axis CNC machines now equipped with advanced sensors and connectivity features that enable real-time monitoring and predictive maintenance.

Moreover, the demand for complex geometries in industries such as aerospace, automotive, and medical devices is pushing manufacturers to invest in sophisticated five-axis technologies. The ability to perform intricate machining tasks in a single setup significantly reduces lead times and improves product quality, making these machines a strategic asset for manufacturers looking to differentiate themselves in competitive markets.

Additionally, there is a growing focus on automation and robotics integration in machining processes, which is enhancing productivity and reducing human error. As international buyers navigate these market dynamics, they are increasingly prioritizing suppliers that offer not just the machinery but also comprehensive support services, training, and scalable solutions that align with their long-term operational goals.

How Is Sustainability Shaping Sourcing Decisions in the Best 5 Axis CNC Market?

Sustainability is becoming an essential criterion for B2B buyers in the five-axis CNC sector, reflecting a broader commitment to environmental stewardship and ethical sourcing. The manufacturing industry is under increasing scrutiny regarding its environmental impact, prompting companies to seek out ‘green’ certifications and materials that minimize ecological footprints. For instance, suppliers that utilize recyclable materials in their machine components or implement energy-efficient technologies are gaining favor among conscious buyers.

Furthermore, ethical supply chains are critical in today’s global marketplace. Buyers are looking for transparency in sourcing practices, ensuring that their suppliers adhere to fair labor standards and responsible sourcing of materials. This trend is particularly pronounced in regions like Europe, where regulations around sustainability are stringent, and consumers are increasingly demanding accountability from businesses.

Investing in sustainable practices not only helps companies comply with regulations but also enhances their brand reputation and attracts environmentally-conscious customers. As such, international buyers are advised to consider suppliers that prioritize sustainability in their production processes and who can demonstrate a commitment to reducing waste and energy consumption.

What Is the Historical Context of Five-Axis CNC Technology in B2B Manufacturing?

The evolution of five-axis CNC technology can be traced back to the early days of CNC machining when manufacturers sought to improve precision and efficiency. Initially, these machines were primarily used in aerospace and defense industries due to their ability to handle complex geometries with high accuracy. Over the decades, advancements in computer technology and software have significantly enhanced the capabilities of five-axis machining centers, allowing for greater flexibility and automation.

By the late 20th century, five-axis machines became more accessible to a broader range of industries, including automotive and medical device manufacturing. The introduction of user-friendly programming interfaces and improved control systems has further democratized this technology, enabling smaller shops to adopt five-axis machining without the need for extensive training or resources. Today, five-axis CNC machines are integral to modern manufacturing, driving innovation and efficiency across various sectors while meeting the growing demands for precision and complexity in part design.

In this context, international B2B buyers must recognize the historical significance of five-axis technology as they evaluate potential investments, ensuring they choose solutions that not only meet current needs but also anticipate future manufacturing trends.

Frequently Asked Questions (FAQs) for B2B Buyers of best 5 axis cnc

-

How do I choose the right 5-axis CNC machine for my business?

Choosing the right 5-axis CNC machine depends on several factors, including the types of parts you manufacture, their size, and the complexity of the features required. Start by assessing the dimensions and weight of your typical workpieces. Consider whether you need a tilting-table configuration for smaller parts or an articulating head for larger, more complex components. Additionally, evaluate your production volume and desired accuracy to ensure the selected machine aligns with your operational goals and budget constraints. -

What are the key benefits of using 5-axis CNC machining?

5-axis CNC machining offers significant advantages over traditional 3-axis machining, such as reduced setup time and increased accuracy. With the ability to access all five sides of a workpiece in a single setup, you can minimize errors associated with repositioning. This technology also allows for shorter tool usage, leading to better surface finishes and longer tool life. Ultimately, it enables the production of more intricate designs efficiently, making it ideal for high-value components in industries like aerospace and automotive. -

What customization options should I consider when sourcing a 5-axis CNC machine?

When sourcing a 5-axis CNC machine, consider customization options that align with your specific manufacturing needs. This includes tool changers, spindle configurations, and control software. Additionally, assess the possibility of integrating automation features to enhance productivity. Engage with suppliers to discuss your requirements, as many manufacturers offer tailored solutions that can improve machine performance and efficiency, ensuring that you get the best fit for your operations. -

What is the typical minimum order quantity (MOQ) for purchasing a 5-axis CNC machine?

The minimum order quantity (MOQ) for purchasing a 5-axis CNC machine can vary significantly depending on the manufacturer and the complexity of the machine. Typically, for standard machines, there may be no MOQ, while custom configurations might require a higher minimum. It’s essential to communicate directly with suppliers to clarify their policies on MOQs and explore financing options if you are looking to invest in multiple machines for larger production runs. -

What payment terms should I expect when sourcing a 5-axis CNC machine internationally?

Payment terms for international purchases of 5-axis CNC machines can differ based on supplier policies and your negotiation. Common terms include upfront deposits ranging from 20% to 50%, with the balance due upon delivery or installation. Some suppliers may offer financing options or extended payment plans for larger orders. Always ensure that payment terms are clearly outlined in the contract and consider using secure payment methods to mitigate risks associated with international transactions. -

How do I vet suppliers for 5-axis CNC machines?

Vetting suppliers for 5-axis CNC machines involves assessing their industry reputation, production capabilities, and customer service. Start by researching online reviews and testimonials from previous buyers. Request references and case studies to understand their experience with similar projects. Additionally, evaluate their after-sales support, warranty policies, and technical assistance to ensure that they can provide ongoing service and maintenance, which is crucial for the longevity of your investment. -

What quality assurance measures should I consider when buying a 5-axis CNC machine?

When purchasing a 5-axis CNC machine, prioritize suppliers that adhere to recognized quality assurance standards, such as ISO certifications. Inquire about their manufacturing processes, inspection protocols, and testing procedures to ensure that the machines meet your specifications and industry standards. It’s also beneficial to request a demonstration of the machine’s capabilities before finalizing the purchase, allowing you to verify the quality and performance firsthand. -

What logistics considerations should I keep in mind for importing a 5-axis CNC machine?

Importing a 5-axis CNC machine involves several logistics considerations, including shipping methods, customs clearance, and transportation to your facility. Evaluate the costs associated with different shipping options, such as air freight versus sea freight, and choose based on your budget and urgency. Ensure that you understand the customs regulations in your country, including tariffs and documentation requirements. Partnering with a reliable logistics provider can streamline the process, reducing delays and ensuring that your machine arrives safely and on time.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Best 5 Axis Cnc Manufacturers & Suppliers List

1. 5-Axis Mill & Lathe – Essential Upgrades for Precision Machining

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 5-axis mill and lathe with a sub spindle are being considered for purchase. The shop currently has 2 Robodrills, a PS65 Makino, a Mazak with Mazatrol, and an SL-20 lathe. The new owners want a 5-axis mill and a lathe with live tooling and a sub-spindle.

2. MMS Online – Five-Axis CNC Machines

Domain: mmsonline.com

Registered: 1997 (28 years)

Introduction: This company, MMS Online – Five-Axis CNC Machines, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Haas – CM-1 with TRT70

Domain: haascnc.com

Registered: 1996 (29 years)

Introduction: This company, Haas – CM-1 with TRT70, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Mori/DMG – HSC 750 Linear

Domain: practicalmachinist.com

Registered: 2000 (25 years)

Introduction: 5 Axis CNC Machines for Mold Making: 1. Current Machines: – Mori/DMG HSC 750 Linear – Mikron HPM 1350U – Fidia K165 (aging, costly maintenance upcoming) 2. Desired Features: – Trunion style machine – Large workspace capacity – HSK 63 tooling – Preferably Heidenhain control 3. Considered Models: – Hermle C52 (18k spindle standard, 24k spindle as custom build) – DMG (layout concerns for loading and …

5. Autodesk – CNC Automation Solutions

Domain: autodesk.com

Registered: 1989 (36 years)

Introduction: Run your CNC machines unsupervised with Autodesk’s advanced software solutions that optimize production efficiency, reduce downtime, and enhance automation capabilities.

6. HEIDENHAIN – CyberMill® Five-Axis Gantry Machine

Domain: heidenhain.us

Registered: 2002 (23 years)

Introduction: The CyberMill® is North America’s largest five-axis gantry machine, located in Detroit. It has an X-axis length of 204 feet (three quarters the length of a football field) and dimensions of 20 feet wide by 204 feet long with 8 feet under the gantry. It operates using two 72 meter HEIDENHAIN LB 382 linear scales, which are the world’s longest, providing positional accuracy of ± 5 microns and except…

7. Penta Machine Co. – Pocket NC 5-Axis CNC Milling Machine

Domain: pentamachine.com

Registered: 2020 (5 years)

Introduction: Penta Machine Co. offers the Pocket NC, the world’s FIRST 5-axis Desktop CNC milling machine. It is designed for startups, educators, and makers, fitting on a desktop and capable of machining materials with hardness up to aluminum. The machine uses standard G-code and features a user-friendly design with a revolutionary software interface. It is manufactured in Montana, USA, and is suitable for ra…

Strategic Sourcing Conclusion and Outlook for best 5 axis cnc

What Are the Key Takeaways for Sourcing the Best 5 Axis CNC Machines?

In conclusion, the strategic sourcing of five-axis CNC machines represents a pivotal investment for manufacturers aiming to enhance operational efficiency and product quality. By understanding the specific requirements of your parts—size, weight, and complexity—you can narrow down the extensive range of available machines to those that provide the best fit for your production needs. The benefits of five-axis technology, such as reduced setup times, improved accuracy, and the ability to produce intricate features, can substantially elevate your competitive edge in the global market.

How Can International Buyers Leverage 5 Axis CNC Technology?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, the opportunity to adopt advanced five-axis machining technology is significant. As industries evolve and demand for precision increases, investing in these machines can lead to greater efficiency and profitability. Engaging with reputable suppliers who understand local market dynamics will ensure you make informed decisions that align with your business goals.

What’s Next for Your Manufacturing Operations?

As you consider your options, take the time to evaluate different manufacturers and their offerings. Engage with experts, attend trade shows, and request demonstrations to see firsthand how these machines can transform your operations. The future of manufacturing is increasingly reliant on advanced technology—now is the time to position your business for success by embracing the benefits of five-axis CNC machining.